Blowing-type drying machine based on chemical fertilizer production

A technology of drying machine and drying fan, which is applied in the direction of non-progressive drying machine, manure drying, drying machine, etc., can solve the problems of poor adaptability, poor practicability, and different drying degrees of fertilizer particles, and achieve uniform drying treatment and improve Flexibility, good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purposes, solutions and advantages of the technical solutions of the present invention clearer, the technical solutions of the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings of specific embodiments of the present invention. Unless otherwise specified, terms used herein have their ordinary meanings in the art. The same reference numbers in the figures represent the same parts.

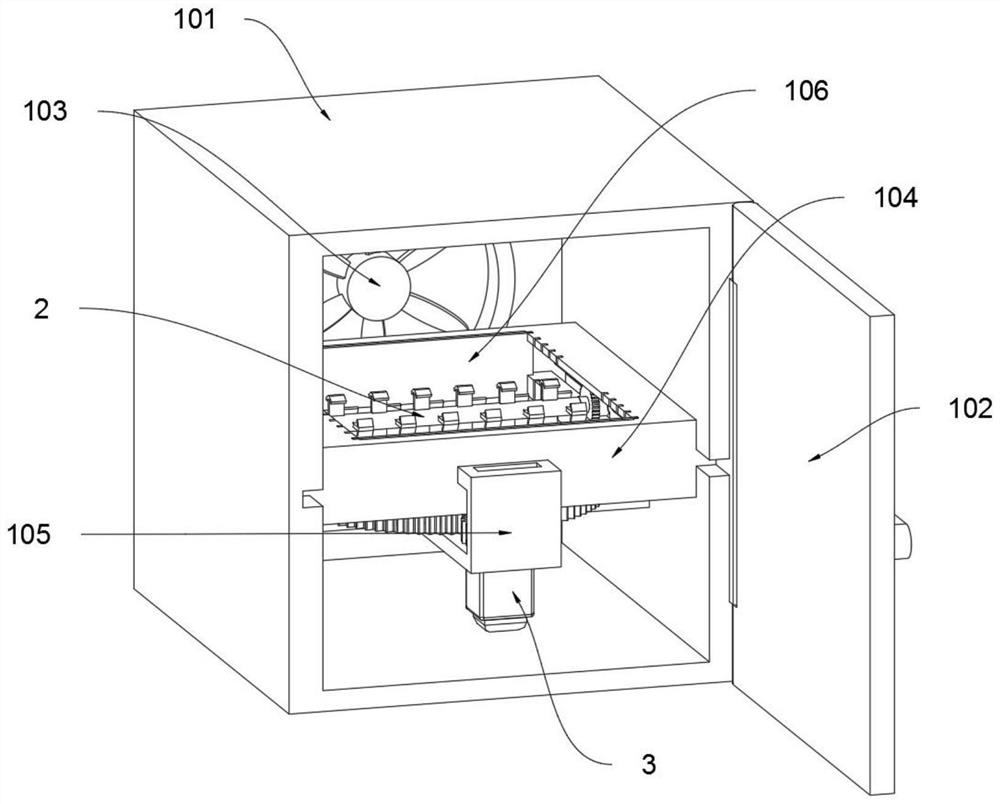

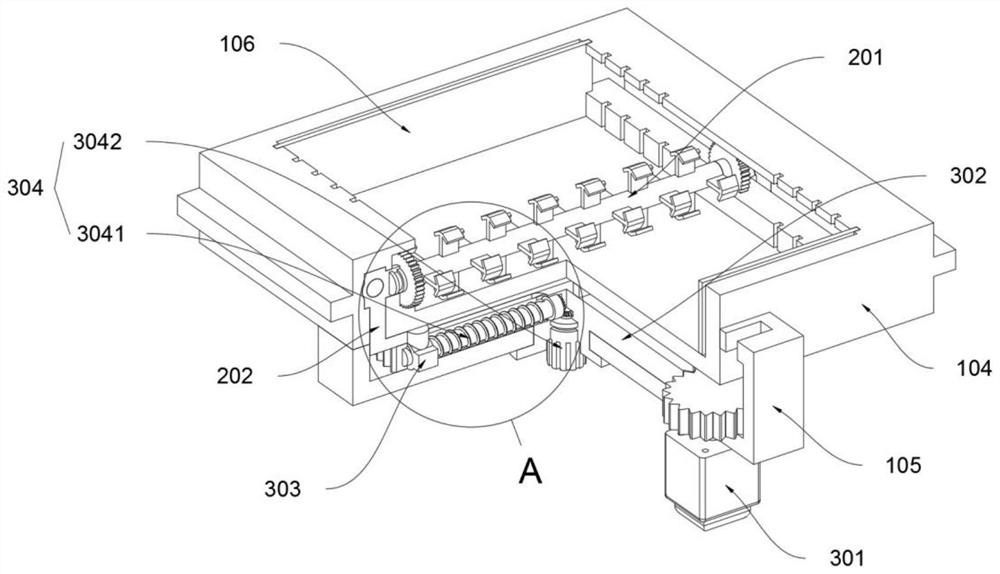

[0036] Please refer to Figure 1 to Figure 10 , The blast dryer based on chemical fertilizer production of the present invention includes: a drying assembly 1, the drying assembly 1 includes a drying box 101, a sealing door 102, a drying fan 103, a drying tray 104 and a holder 105, and the sealing door 102 is rotatably connected to the The front side of the drying box 101, and the drying fan 103 is fixedly installed on the rear side of the drying box 101, the drying tray 104 is inserted into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com