A fan blade with wave-shaped vortex generator and design method thereof

A vortex generator and fan blade technology, which is applied to wind turbines, engines, mechanical equipment and other directions that are consistent with the wind direction, can solve the problems of less research on the aerodynamic characteristics of vortex generators, and reduce the design workload, Improve blade lift, delay effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

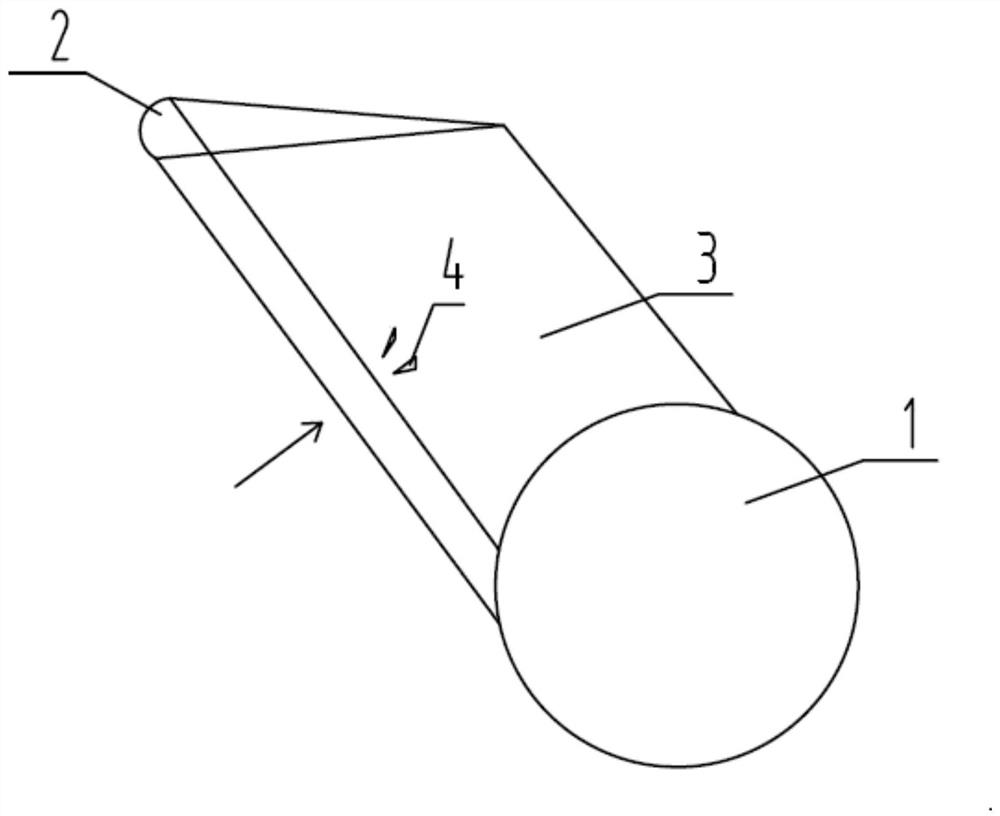

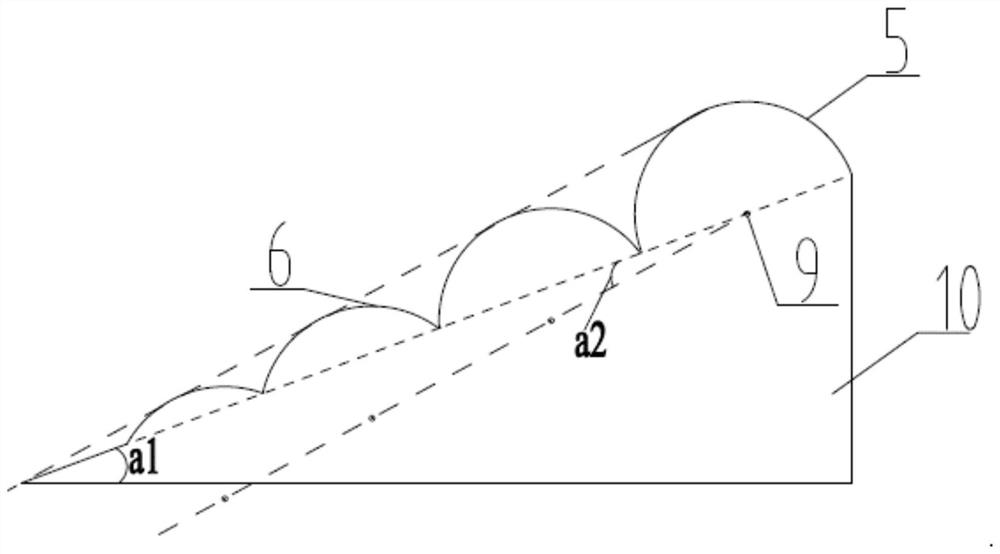

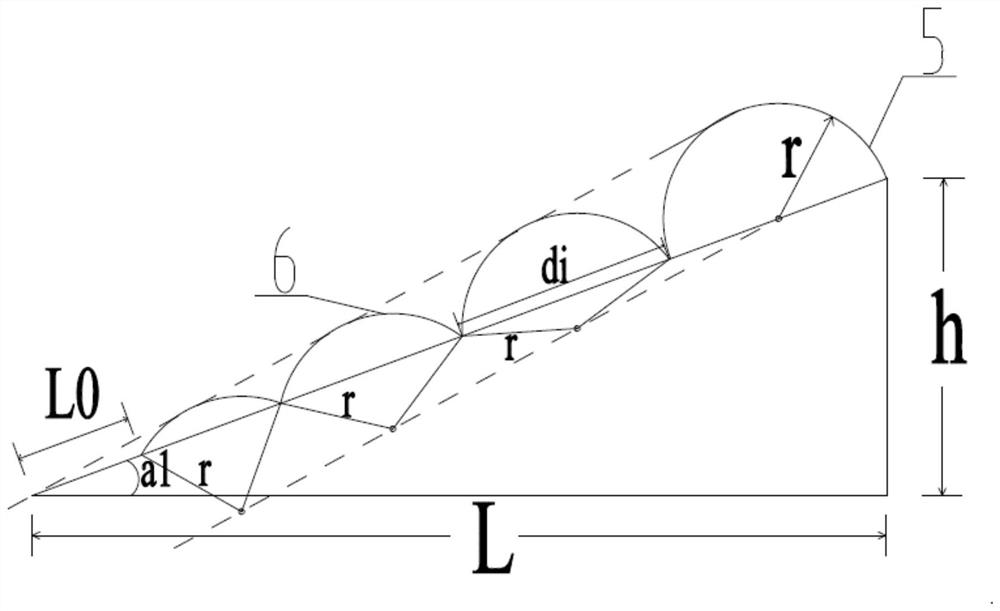

[0051] A fan blade with a wave-shaped vortex generator of the present invention, such as figure 1As shown, between the blade root 1 and the blade tip, a number of wave-shaped vortex generators 4 arranged symmetrically in pairs are installed at a suitable position near the blade suction surface 3 near the blade leading edge 2, and the cross-sectional shape of a single wave-shaped vortex generator 4 See figure 2 , due to the small thickness of the vortex generator, generally no more than 1cm, figure 2 Only list the sectional view on the chord direction of the blade, and the specific layout of the paired wave-shaped vortex generators 4 is shown in Figure 4 .

[0052] Such as figure 2 As shown, the wave-shaped vortex generator 4 can be considered to be compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com