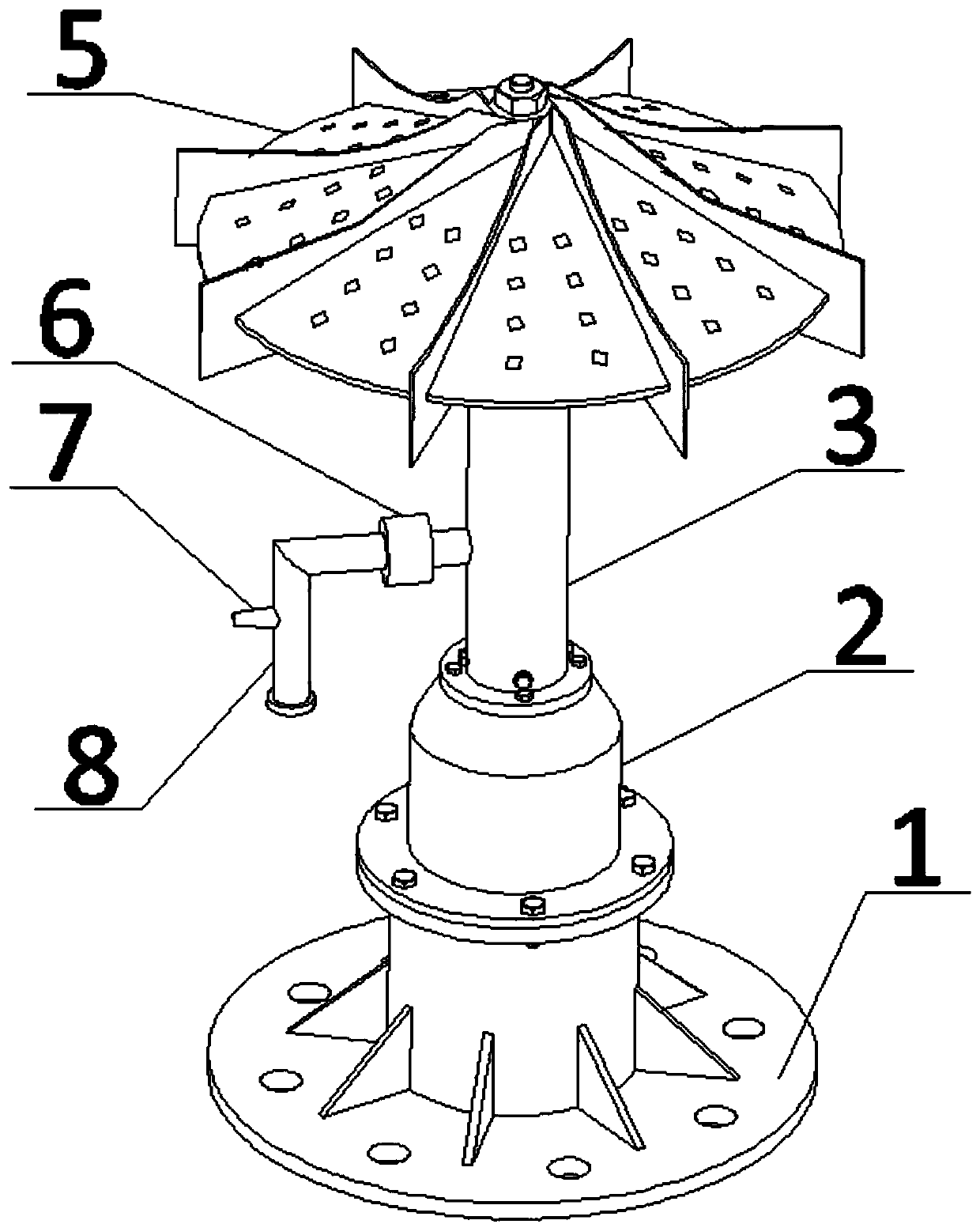

Biomass fuel boiler device and working method thereof

A technology of biomass fuel and boiler equipment, which is applied in the direction of combustion methods, safety devices of combustion chambers, combustion chambers, etc., and can solve problems such as low flow, elevated temperature, and reduced heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

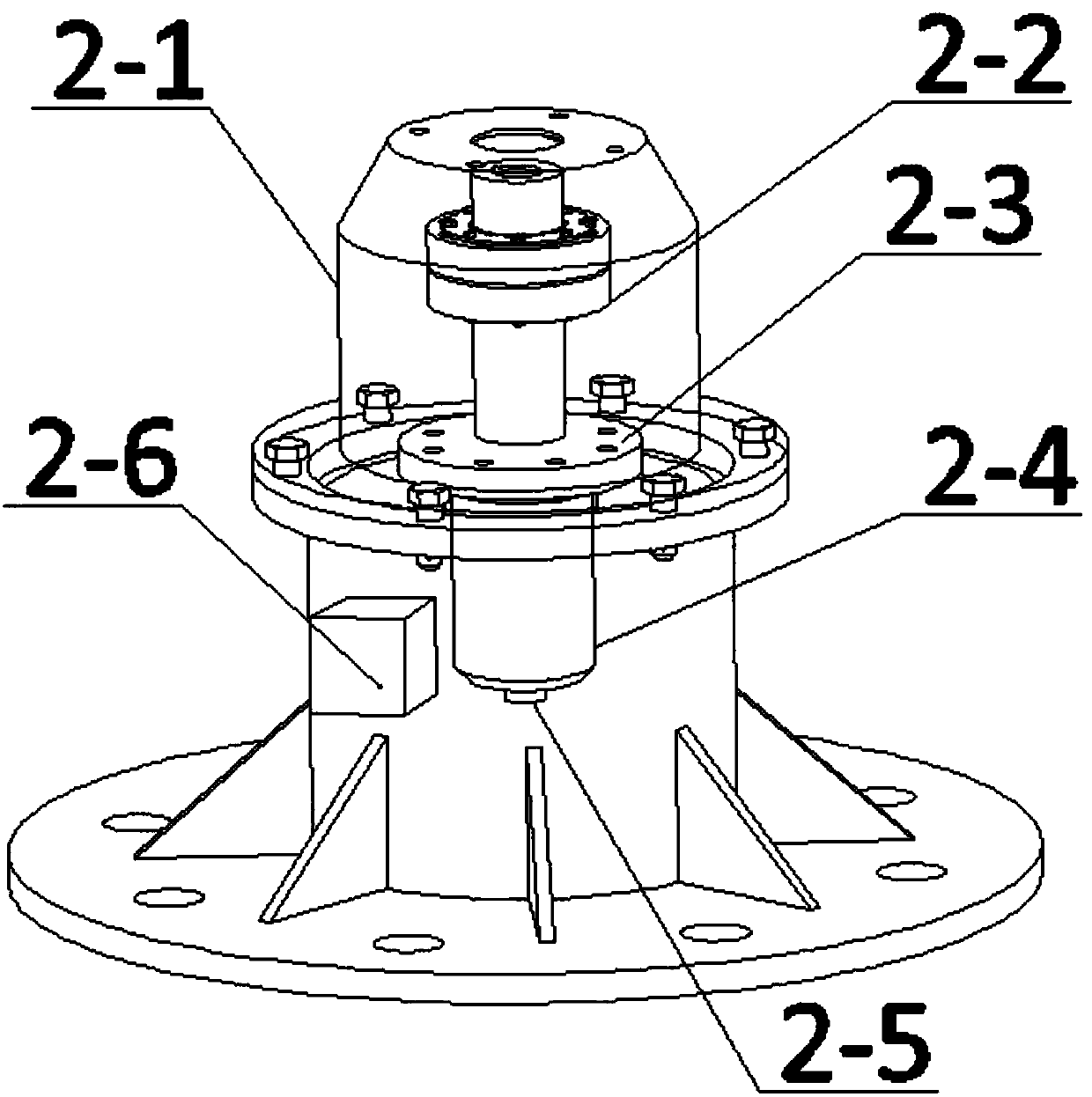

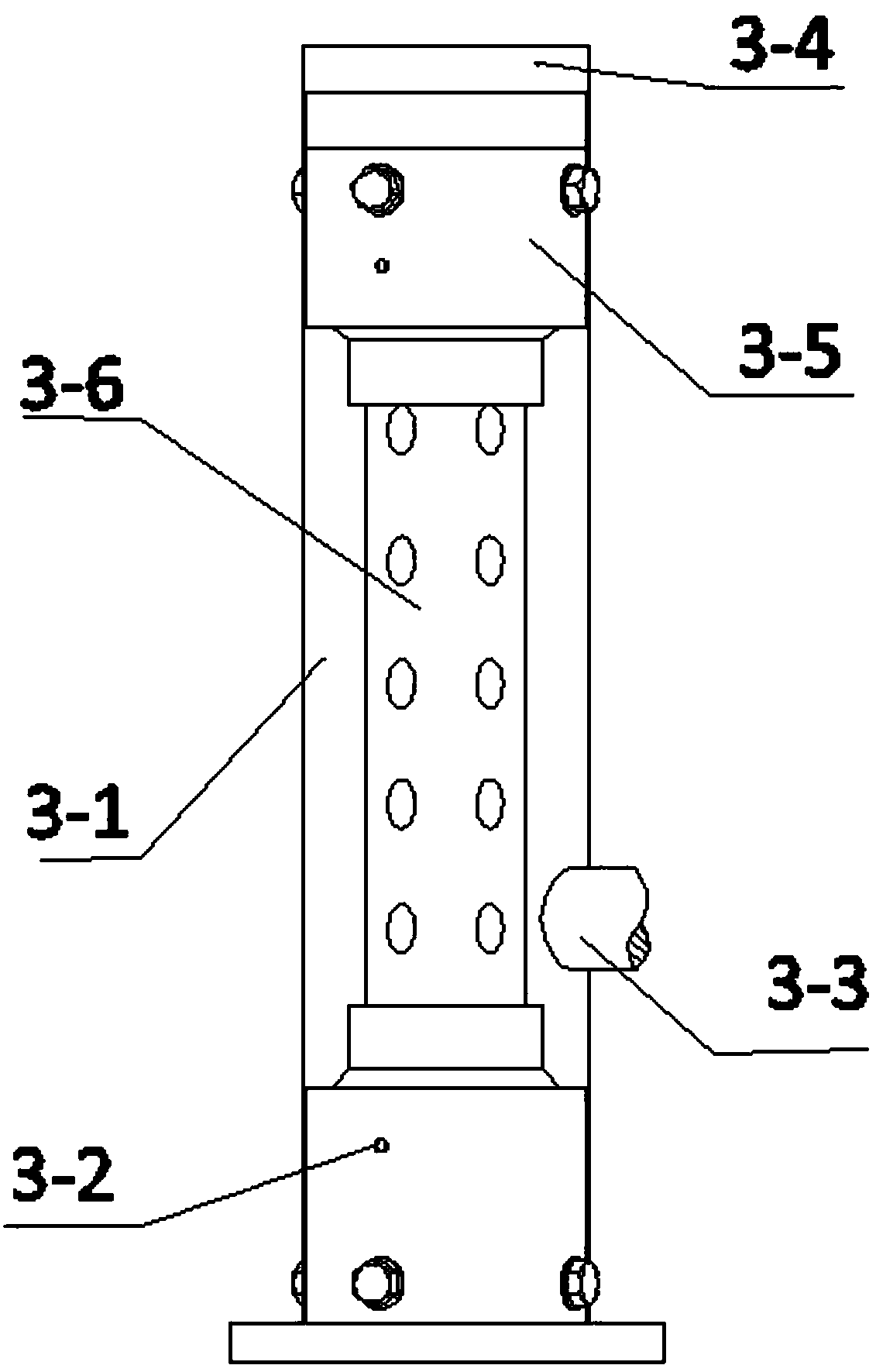

Method used

Image

Examples

preparation example Construction

[0062] In order to obtain a gas disturbance impeller with high tensile strength, small thermal deformation effect, good corrosion resistance and long service life, the preparation method of the gas disturbance impeller 3-4-4 includes the following steps:

[0063] Step 1: Add 2501 to 4801 parts of ultrapure water with a conductivity of 4.65 μS / cm to 7.75 μS / cm into the reactor, start the stirrer in the reactor at a speed of 86 rpm to 131 rpm, and start the heating pump to make The temperature in the reaction kettle rose to 66 ℃ ~ 96 ℃; 3,4-dimethyl-5-oxopiperazine-1-carboxylate benzyl ester, 4-(3-nitrobenzylidene)piperidine- tert-butyl 1-carboxylate, 1,1-dimethylethyl 4-[2-[(acetylamino)methyl]-4-aminophenyl]-1-piperazinecarboxylate, stirred until completely dissolved , adjust the pH value to 4.6 to 9.6, adjust the agitator speed to 131 rpm to 241 rpm, the temperature to 121 °C to 166 °C, and the esterification reaction for 16 to 31 hours;

[0064] Step 2: Take ethyl 3-((1-met...

Embodiment 1

[0076] Manufacture the gas disturbance impeller 3-4-4 of the present invention according to the following steps, and in parts by weight:

[0077] Step 1: Add 2501 parts of ultrapure water with a conductivity of 4.65 μS / cm into the reactor, start the stirrer in the reactor at a speed of 86 rpm, and start the heating pump to raise the temperature in the reactor to 66°C; Add 31 parts of benzyl 3,4-dimethyl-5-oxopiperazine-1-carboxylate, 89 parts of tert-butyl 4-(3-nitrobenzylidene)piperidine-1-carboxylate, 4 -55 parts of 1,1-dimethylethyl [2-[(acetylamino)methyl]-4-aminophenyl]-1-piperazinecarboxylate, stirred until completely dissolved, and adjusted to pH 4.6, Adjust the rotation speed of the agitator to 131 rpm, the temperature is 121°C, and the esterification reaction is carried out for 16 hours;

[0078] Step 2: Take 29 parts of ethyl 3-((1-methyl-1H-pyrazol-4-yl)methylamino)propionate, 1-benzyl-2,4-dioxopiperidine-3 - 69 parts of methyl carboxylate are pulverized, the powd...

Embodiment 2

[0083] Manufacture the gas disturbance impeller 3-4-4 of the present invention according to the following steps, and in parts by weight:

[0084] Step 1: Add 3651 parts of ultra-pure water with a conductivity of 6.25 μS / cm into the reactor, start the stirrer in the reactor at a speed of 108 rpm, and start the heating pump to raise the temperature in the reactor to 81°C; Add 48 parts of benzyl 3,4-dimethyl-5-oxopiperazine-1-carboxylate, 114 parts of tert-butyl piperidine-1-carboxylate, 4 -75 parts of 1,1-dimethylethyl [2-[(acetylamino)methyl]-4-aminophenyl]-1-piperazinecarboxylate, stirred until completely dissolved, and adjusted to pH 7.3, Adjust the rotation speed of the agitator to 186 rpm, the temperature is 146°C, and the esterification reaction takes 23 hours;

[0085] Step 2: Take 52 parts of ethyl 3-((1-methyl-1H-pyrazol-4-yl)methylamino)propionate, 1-benzyl-2,4-dioxopiperidine-3 - 116 parts of methyl carboxylate are pulverized, and the particle size of the powder is 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com