A Laser Additive Manufacturing Method for High Stability Particle Dispersion Strengthened Titanium Alloy

A technology of dispersion strengthening and high stability, which is applied in the field of titanium alloy materials, can solve problems such as poor fluidity of molten pool, and achieve excellent effects of creep and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

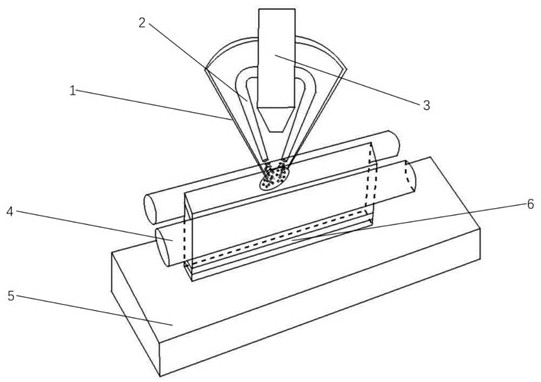

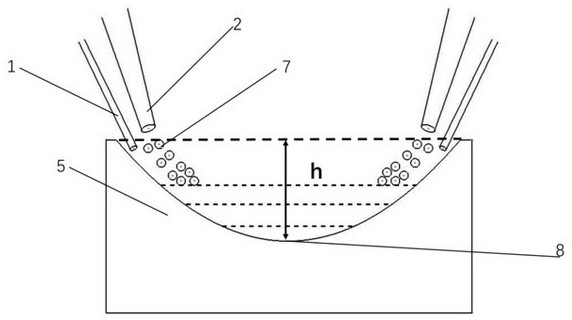

Method used

Image

Examples

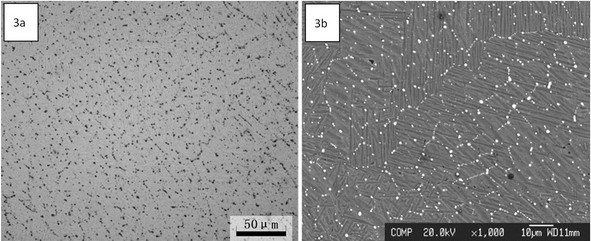

Embodiment 1

[0035] (1) First, TC11 (its nominal composition is shown in Table 1 below, wt.%) is selected as the titanium alloy main body in the present invention, and Y, CaAl, and Th alloy powders of 150-300 μm are added to the TC11 alloy powder to obtain 500 g Mix the alloy powder and put it into a ball mill jar. In order to make Y, CaAl, and Th play a stable and strengthening role and avoid segregation that may be caused by their addition, the addition amount of Y, CaAl, and Th is respectively according to the TC11 alloy powder The mass ratio is 0.6wt.%-8wt.%. Add 500 g of 440C wear-resistant steel balls with a diameter of 20-130 mm, fill the tank with argon gas and seal the tank, so that the entire ball milling process can be carried out in an oxygen-free environment to avoid rapid oxidation of the fresh surface produced during ball milling; make the high-energy ball mill, First use 250 rpm premixing for 30 minutes to ensure that the alloy powder is evenly mixed, then use 600 rpm for h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com