New-energy power battery relay ceramic material and preparation method thereof

A technology of ceramic materials and relays, applied in the field of inorganic ceramic materials, can solve problems such as splashing, contact deformation failure, contact material melting, etc., and achieve the effects of temperature rise, low electrical and thermal conductivity, and low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

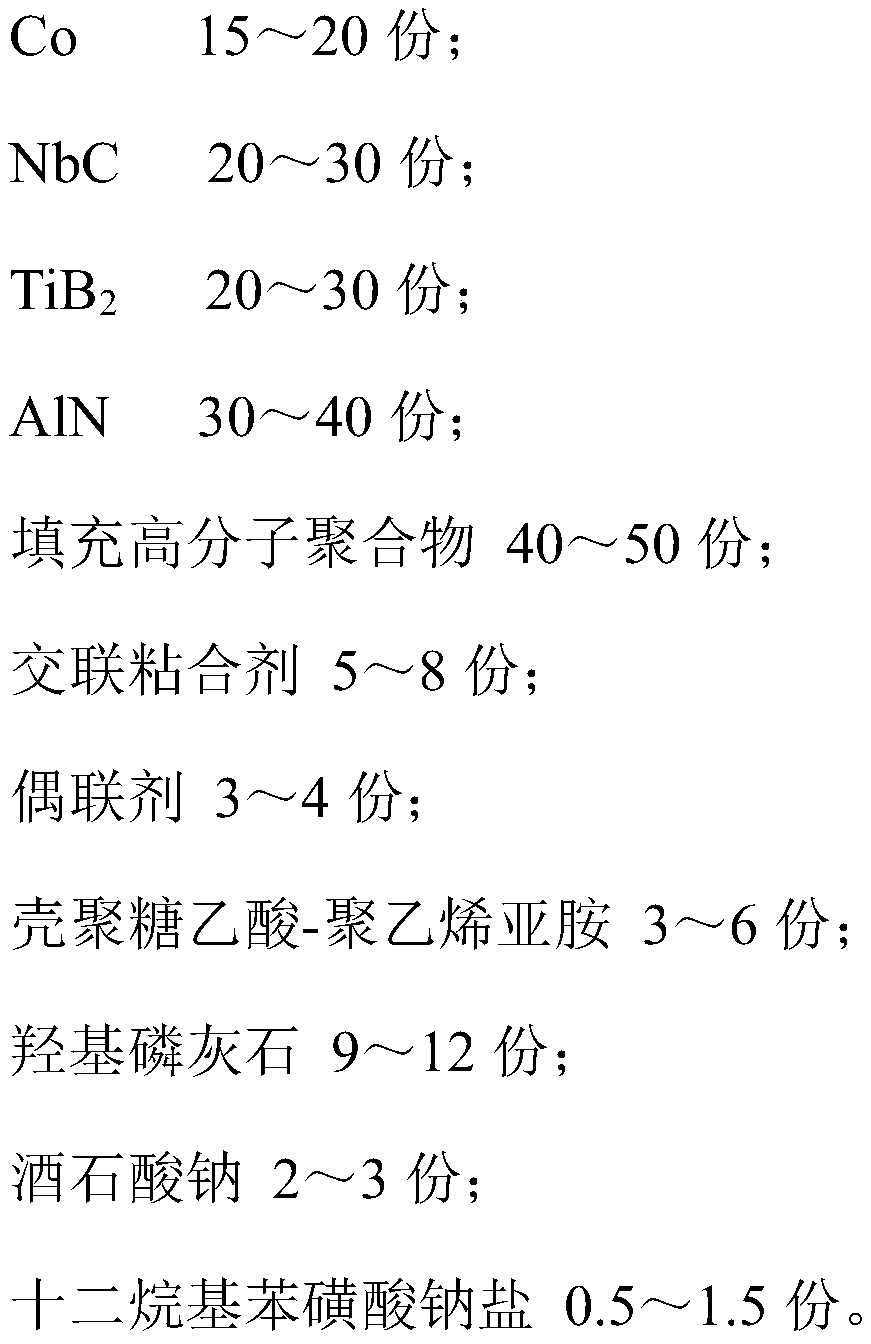

[0038] A metal-based composite nano-vacuum relay ceramic material provided by the invention comprises the following components by weight:

[0039]

[0040] Among them, the tricalcium phosphate-polysiloxane polymer is an inorganic salt filler-tricalcium phosphate uniformly filled in the network matrix structure formed by the polymer-polysiloxane, and the tricalcium phosphate-polysiloxane The preparation method of alkane macromolecular polymer comprises the following steps:

[0041] S1: Dissolve 50mg of polyoxyethylene grafted polyoxypropylene copolymer in 5ml of distilled water at 4°C, stir the 4M polymer for 50min, then add 0.3M of N,N'-methylene-bis Acrylamide, 0.8M potassium persulfate and 0.4M N,N,N',N'-tetramethylethylenediamine form polysiloxane polymer network matrix structure colloid;

[0042] S2: dissolving the polysiloxane polymer network matrix structure colloid obtained in step S1 in distilled water to form a colloid solution with a concentration of 50%;

[0043]...

Embodiment 2

[0053] A metal-based composite nano-vacuum relay ceramic material provided by the invention comprises the following components by weight:

[0054]

[0055] Wherein, the Ni-polyamide polymer is a metal filler-Ni is uniformly filled in the network matrix structure formed by the polymer-polyamide, and the preparation method of the Ni-polyamide polymer comprises the following steps:

[0056] S1: Dissolve 50mg of polyoxyethylene grafted polyoxypropylene copolymer in 7.5ml of distilled water at 4°C, stir 4.5M polyamide polymer for 60min, then add 0.35M N,N'- Methyl-bisacrylamide, 0.9M potassium persulfate and 0.45M N,N,N',N'-tetramethylethylenediamine form polyamide polymer network matrix structure colloid;

[0057] S2: dissolving the polyamide polymer network matrix structure colloid obtained in step S1 in distilled water to form a colloid solution with a concentration of 53%;

[0058] S3: Add pentylene glycol to the colloidal solution obtained in step S2, stir for 1-2 minutes,...

Embodiment 3

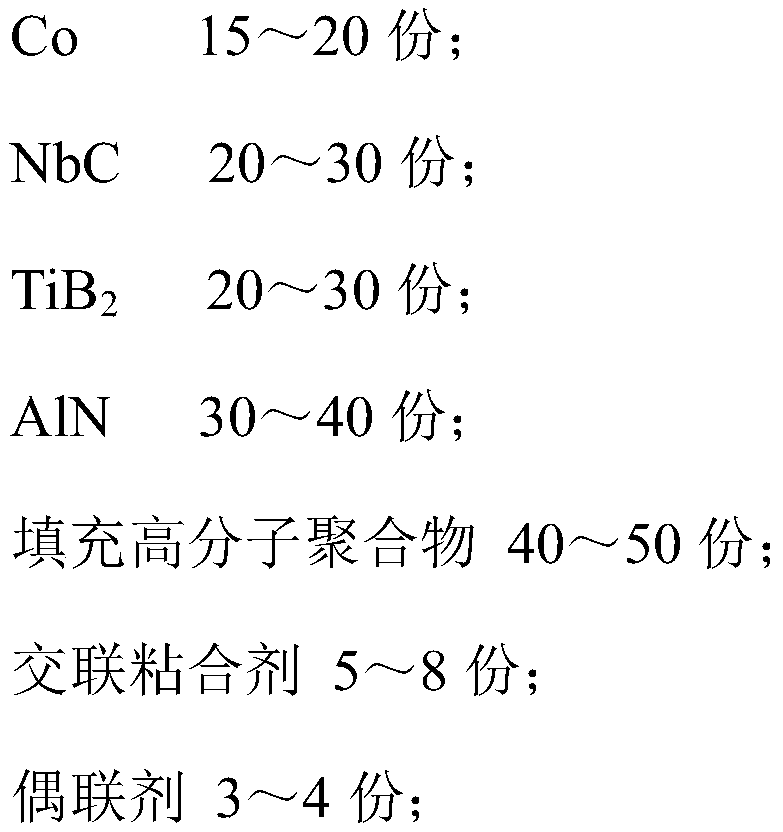

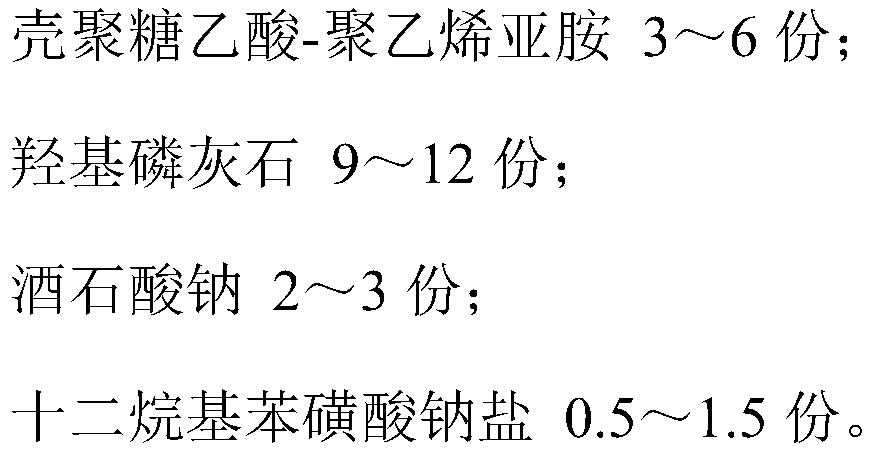

[0068] A metal-based composite nano-vacuum relay ceramic material provided by the invention comprises the following components by weight:

[0069]

[0070] Wherein, the filled high molecular polymer is that the filler-diyttrium trioxide is uniformly filled in the network matrix structure formed by the styrene / acrylamide copolymer polymer, and the described diyttrium trioxide-styrene / acrylamide The preparation method of polymer comprises the following steps:

[0071] S1: Dissolve 50mg of polyoxyethylene grafted polyoxypropylene copolymer in 10ml of distilled water at 4°C, stir 5M styrene / acrylamide polymer for 70min, then add 0.4M N,N'- Methylene-bisacrylamide, 1.0M potassium persulfate and 0.5M N,N,N',N'-tetramethylethylenediamine form a styrene / acrylamide polymer network matrix structure colloid;

[0072] S2: dissolving the styrene / acrylamide polymer network matrix structure colloid obtained in step S1 in distilled water to form a colloid solution with a concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com