Formula and preparation of train wheel tread friction control agent based on inorganic adhesive

A technology of wheel tread and adhesive, applied in the direction of coating, etc., to achieve good adhesion performance, improve physical and mechanical properties, and adjust the effect of reducing friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

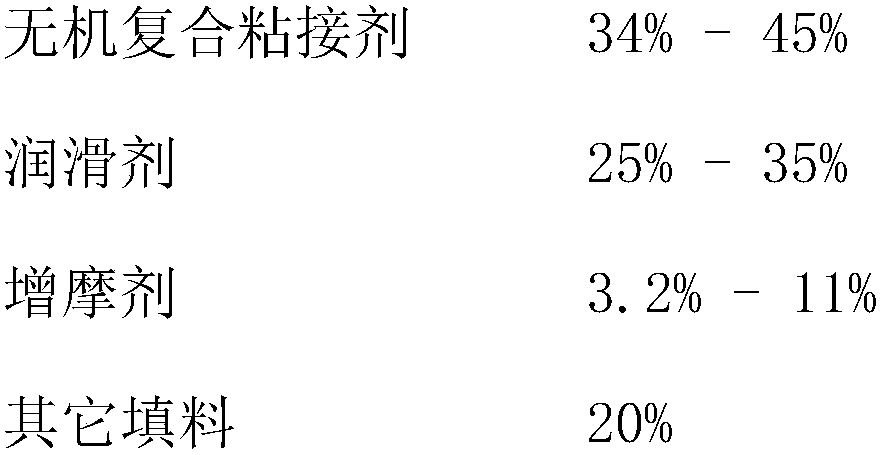

Method used

Image

Examples

Embodiment 1

[0027] A wheel tread friction control agent based on an inorganic composite adhesive, prepared from the following components in mass percentage: 27.5% aluminum dihydrogen phosphate, 16.5% sulfur, 4.2% graphite, 21.4% molybdenum disulfide, silicic acid Zirconium 10.4%, calcium carbonate 20%.

[0028] Its preparation method comprises the following steps:

[0029] 1) Weigh calcium carbonate, zirconium silicate, sulfur, molybdenum disulfide, and graphite into a beaker according to the formula, and after stirring evenly, add aluminum dihydrogen phosphate dropwise;

[0030] 2) Preliminary mixing of raw materials, manual stirring for 20 minutes, through the rolling action of the stirring rod and the wall of the beaker to make the liquid and solid powder into one;

[0031] 3) Transfer the raw materials after preliminary mixing treatment to the pulverizer, turn on the power supply, and pulverize at high speed for 3-5 times to obtain uniform blended powder;

[0032] 4) Weigh a certain...

Embodiment 2

[0036] A wheel tread friction control agent based on an inorganic composite adhesive, prepared from the following components in mass percentage: 27% aluminum dihydrogen phosphate, 16.2% sulfur, 4.2% graphite, 25.4% molybdenum disulfide, potassium long Stone 7.2%, calcium carbonate 20%.

[0037] Its preparation method comprises the following steps:

[0038] 1) Weigh zirconium silicate, calcium carbonate, sulfur, molybdenum disulfide, and graphite into a beaker according to the formula, and after stirring evenly, add aluminum dihydrogen phosphate dropwise;

[0039] 2) After the raw materials are initially mixed, manually stir for 20 minutes, and the liquid and solid powder are mixed together through the rolling action of the stirring rod and the wall of the beaker;

[0040] 3) Transfer the primary processed raw materials to the pulverizer, turn on the power, and pulverize at high speed for 3-5 times to obtain uniform blended powder;

[0041] 4) Weigh a certain amount of blende...

Embodiment 3

[0045] A wheel tread friction control agent based on an inorganic composite adhesive, prepared from the following components in mass percentages: 23% aluminum dihydrogen phosphate, 13.2% sulfur, 29.5% graphite, 4.9% molybdenum disulfide, silicic acid Zirconium 9.4%, talcum powder 20%.

[0046] Its preparation method comprises the following steps:

[0047] 1) Weigh zirconium silicate, talcum powder, sulfur, molybdenum disulfide, and graphite into a beaker according to the formula, and after stirring evenly, add aluminum dihydrogen phosphate dropwise;

[0048] 2) After the raw materials are initially mixed, manually stir for 20 minutes, and the liquid and solid powder are mixed together through the rolling action of the stirring rod and the wall of the beaker;

[0049] 3) Transfer the raw materials after preliminary mixing treatment to the pulverizer, turn on the power supply, and pulverize at high speed for 3-5 times to obtain uniform blended powder;

[0050] 4) Weigh a certain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com