Bolt drying device with uniform heating function

A drying device and bolt technology, applied in drying, drying machine, drying gas arrangement and other directions, can solve the problems of long drying time, unsatisfactory drying effect, uneven addition, etc., to achieve uniform heating and improve drying. Dry effect, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

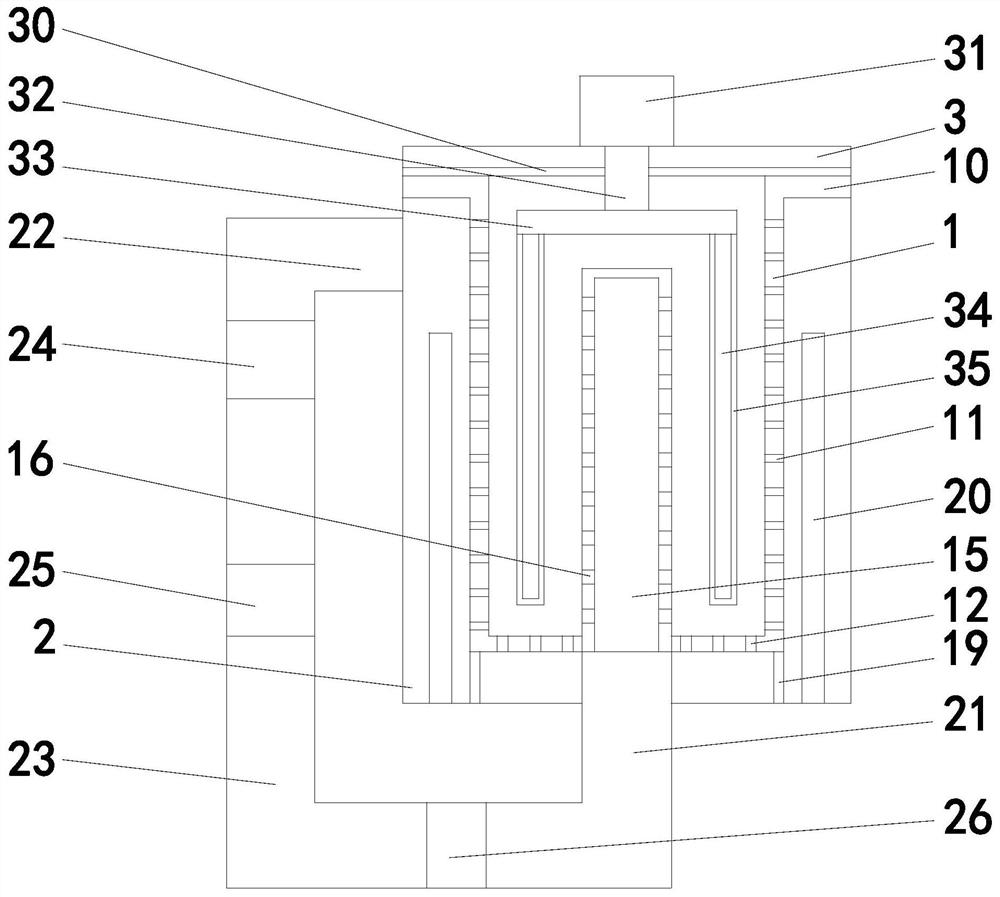

[0016] refer to figure 1 , a uniformly heated bolt drying device of the present invention, comprising a drying box 2, a material storage cylinder 1, a gas outlet cylinder 15, an air inlet pipe 21, and an air outlet pipe 22, and the top of the material storage cylinder 1 is covered with a sealing cover 3. A flange 19 is provided on the top edge of the material storage cylinder 1, and a drying box 2 is fixed on the bottom of the flange 19, and the drying box 2 surrounds the material storage cylinder 1, and a venting cylinder 15 is arranged inside the material storage cylinder 1 , the top of the outlet bag 15 is sealed, the bottom of the outlet bag 15 is open and runs through the bottom wall of the material container 1, the side wall of the outlet bag 15 is provided with some first through holes 16, the bottom of the outlet bag 15 is connected with an air inlet pipe, and the air inlet pipe Penetrate into the drying box 2 from the outside of the drying box 2, the drying box 2 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com