Wear prevention reaction kettle

A technology for preventing wear and reaction kettles, which is applied in the field of wear prevention reaction kettles, can solve problems such as poor radial fluidity, poor mixing effect of material and liquid, and influence on heat transfer, so as to reduce the generation of air bubbles, improve the mixing effect, and improve agitation degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

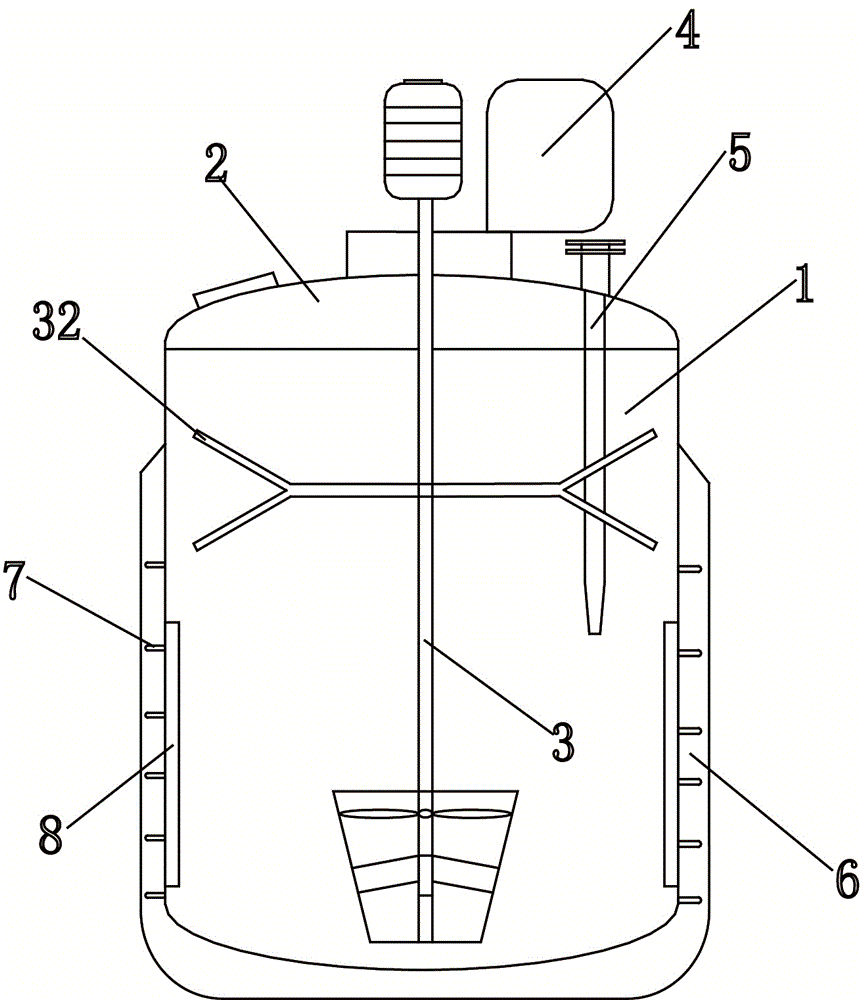

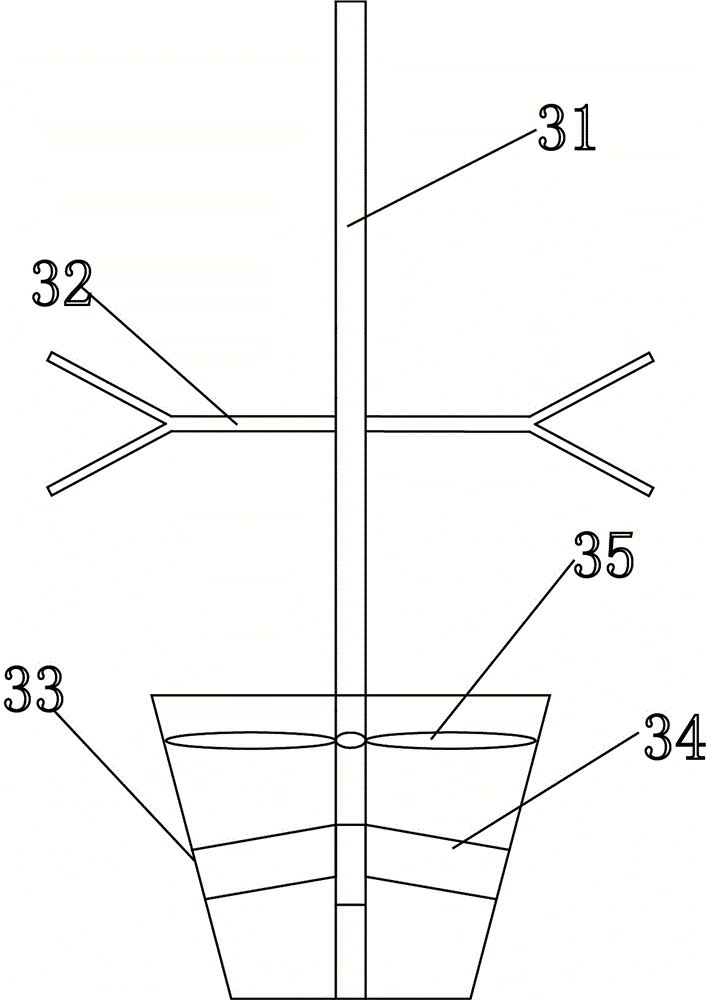

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 , figure 2 , a reaction kettle for preventing abrasion, comprising a kettle body 1, a kettle cover 2 and a stirring device, characterized in that: the upper end of the kettle body 1 is provided with a feed inlet, and the lower end of the kettle body 1 is provided with a discharge outlet, so The stirring device includes a stirrer 3, a transmission device, an air pump 4, a shaft seal and a support seat, the stirrer 3 is located inside the kettle body 1, and the air pump 4, the shaft seal and the support seat are located in the On the kettle cover 2, it is connected with the agitator 3 through the transmission device, the thermometer sleeve 5 extends into the kettle body 1 and the upper end is fixed on the kettle cover 2, and the thermometer sleeve 5 is equipped with a thermometer , the agitator 3 includes a stirring shaft 31, a Y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com