Patents

Literature

32results about How to "Reduce the generation of air bubbles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

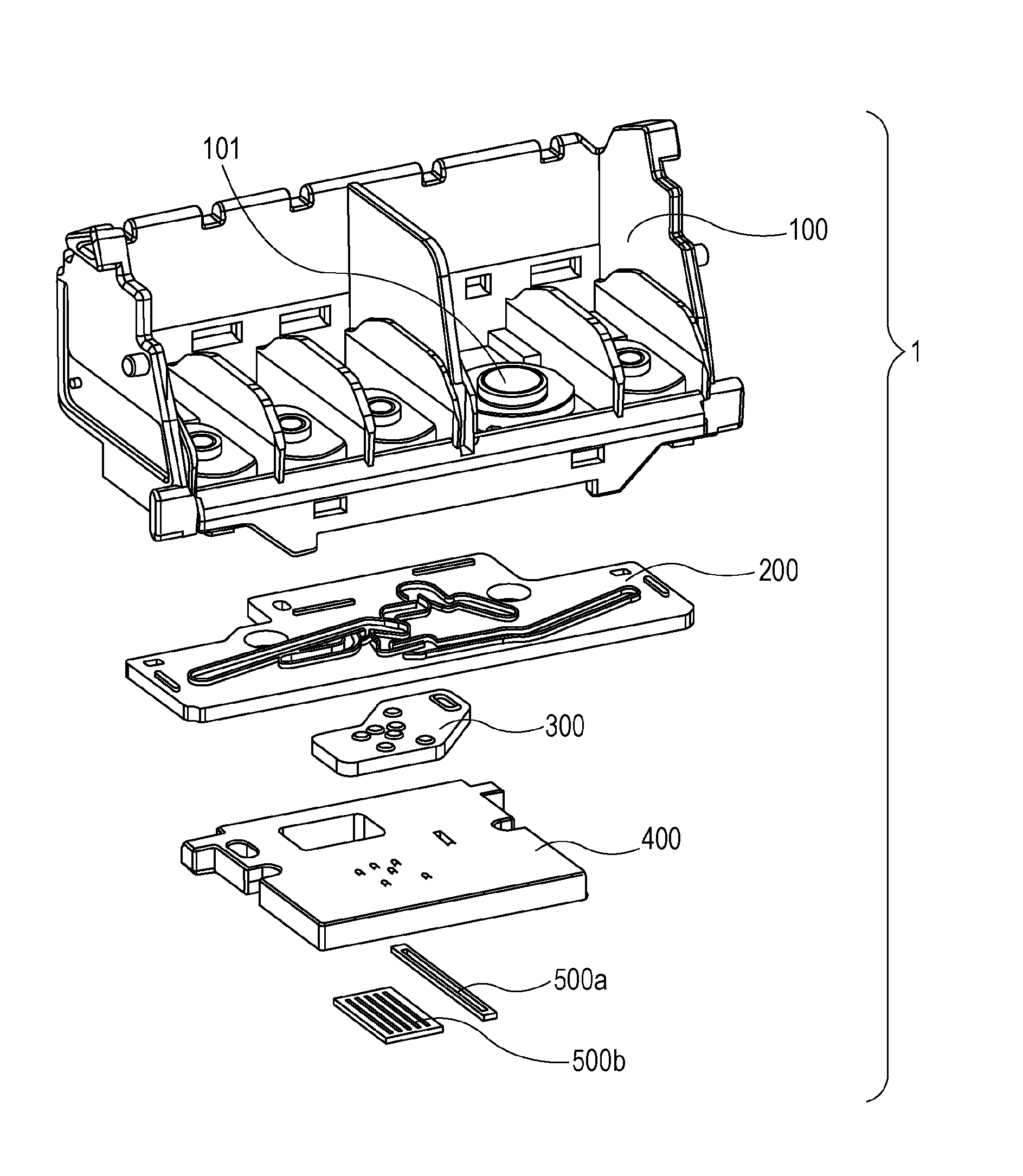

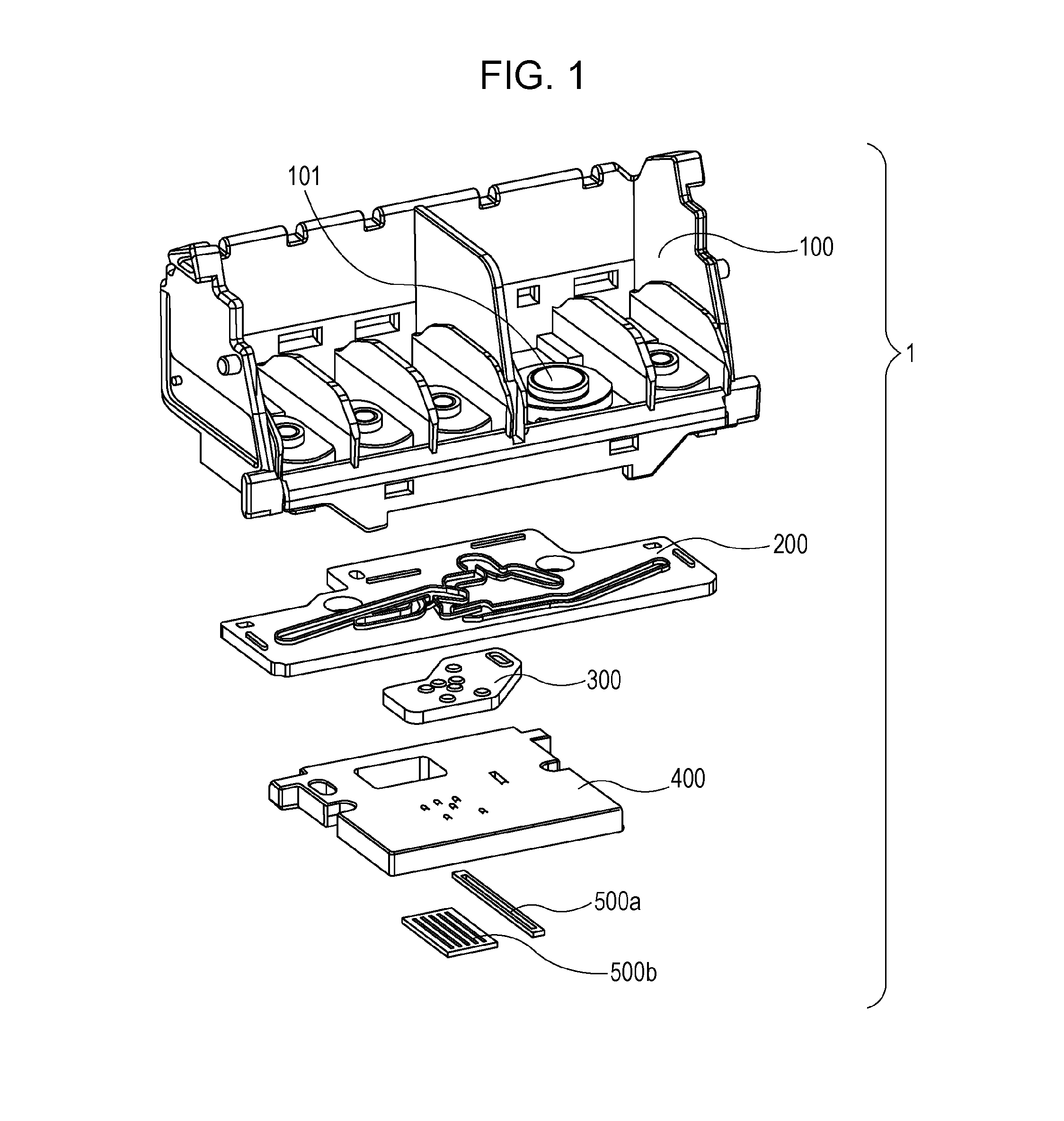

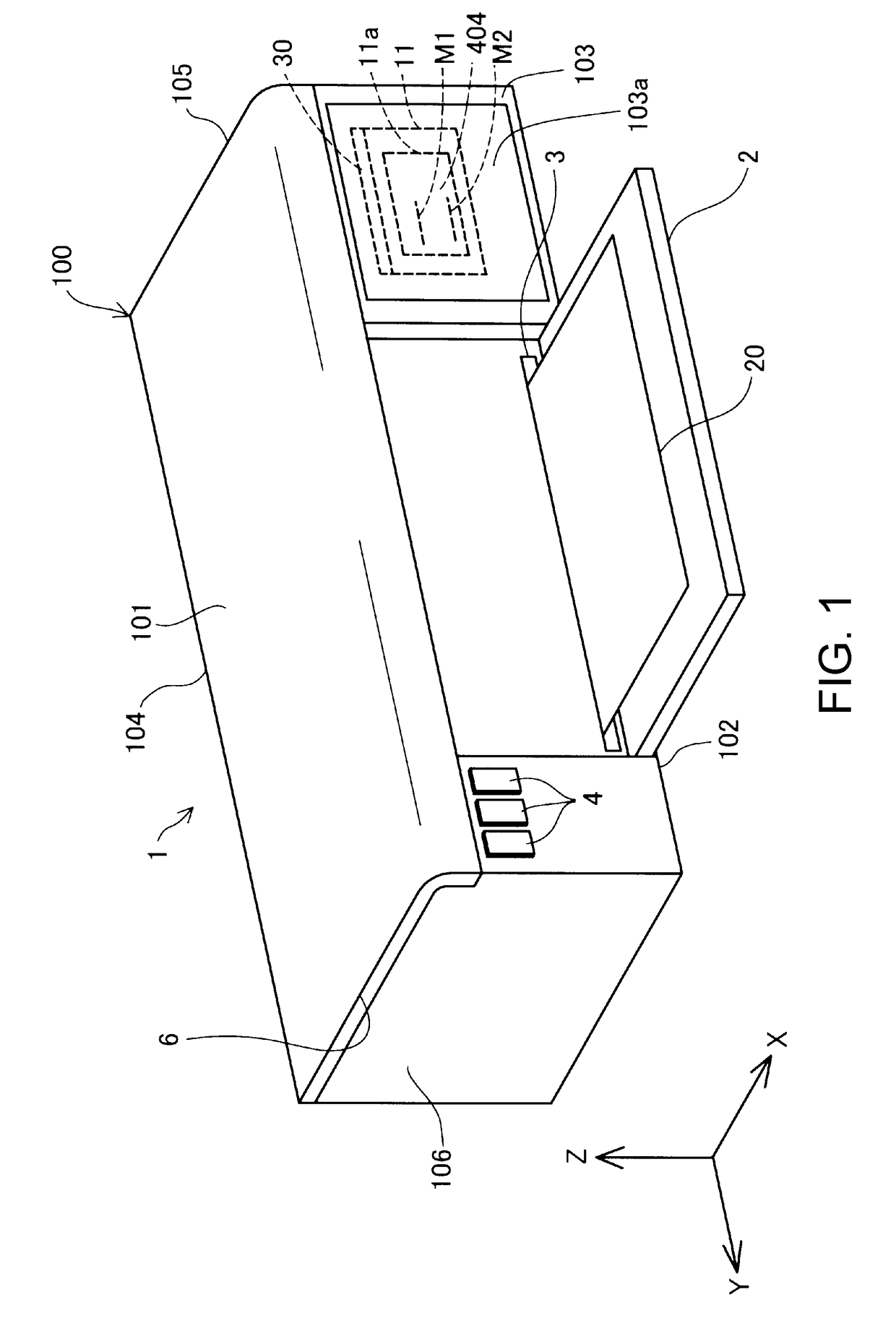

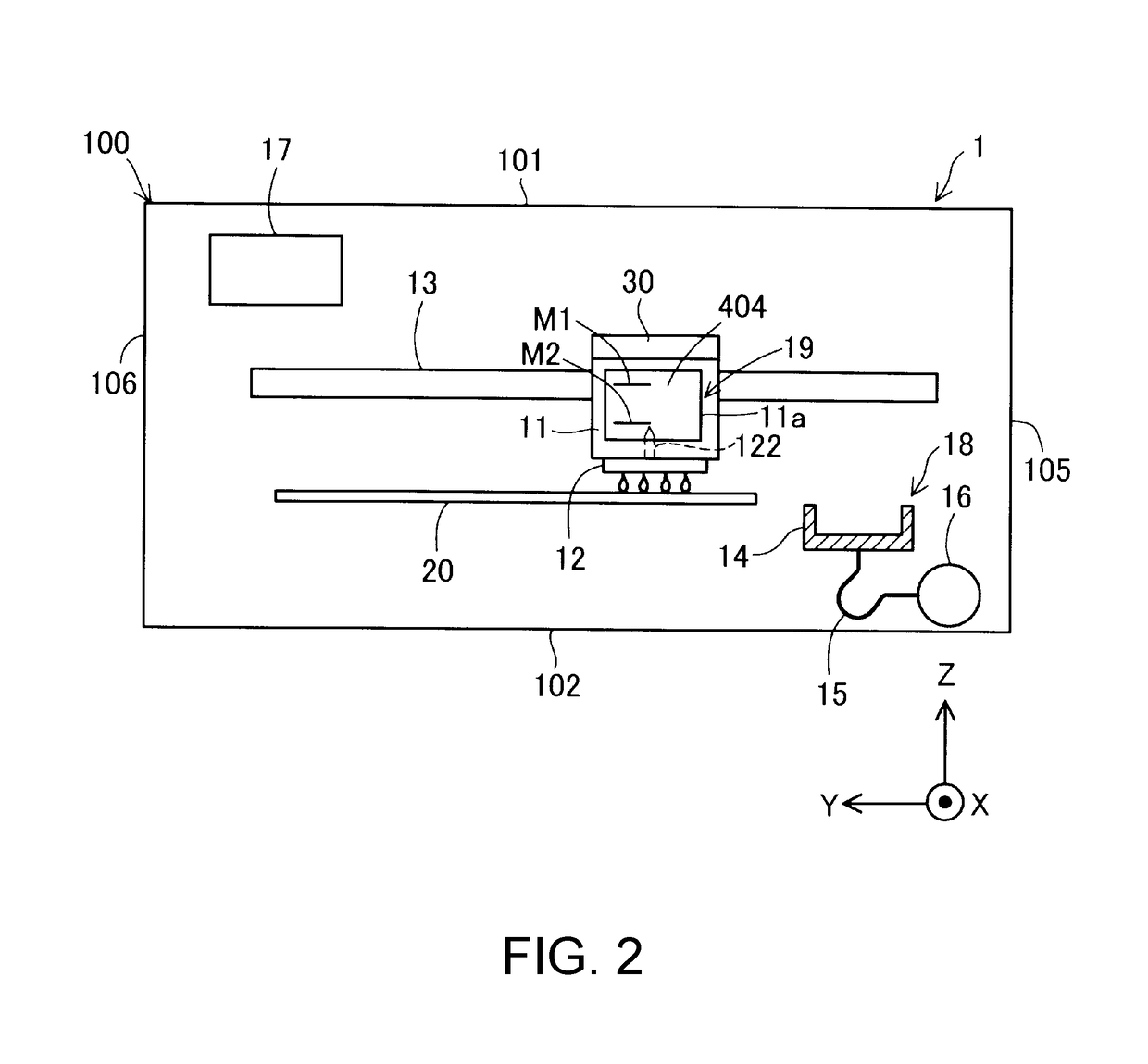

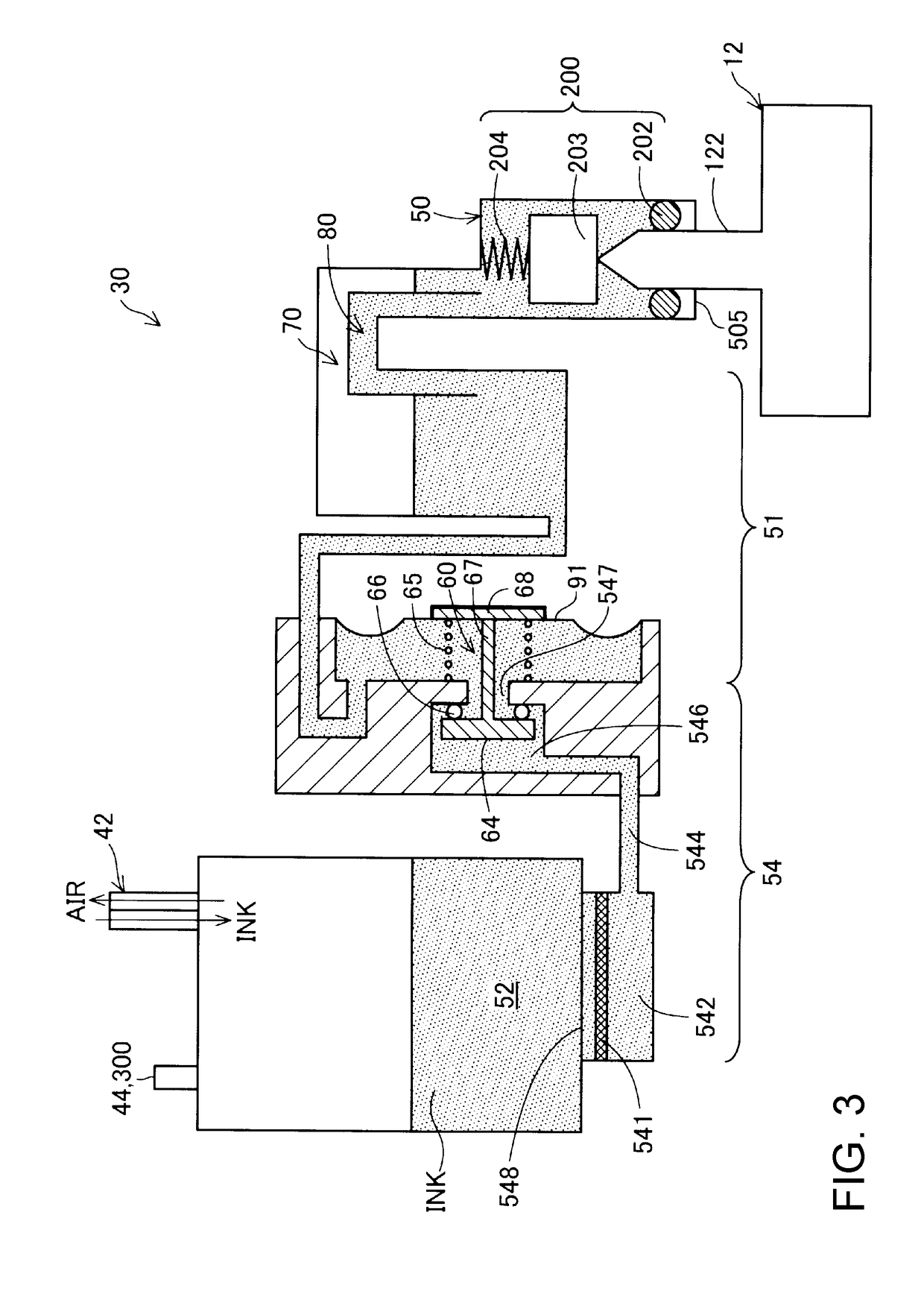

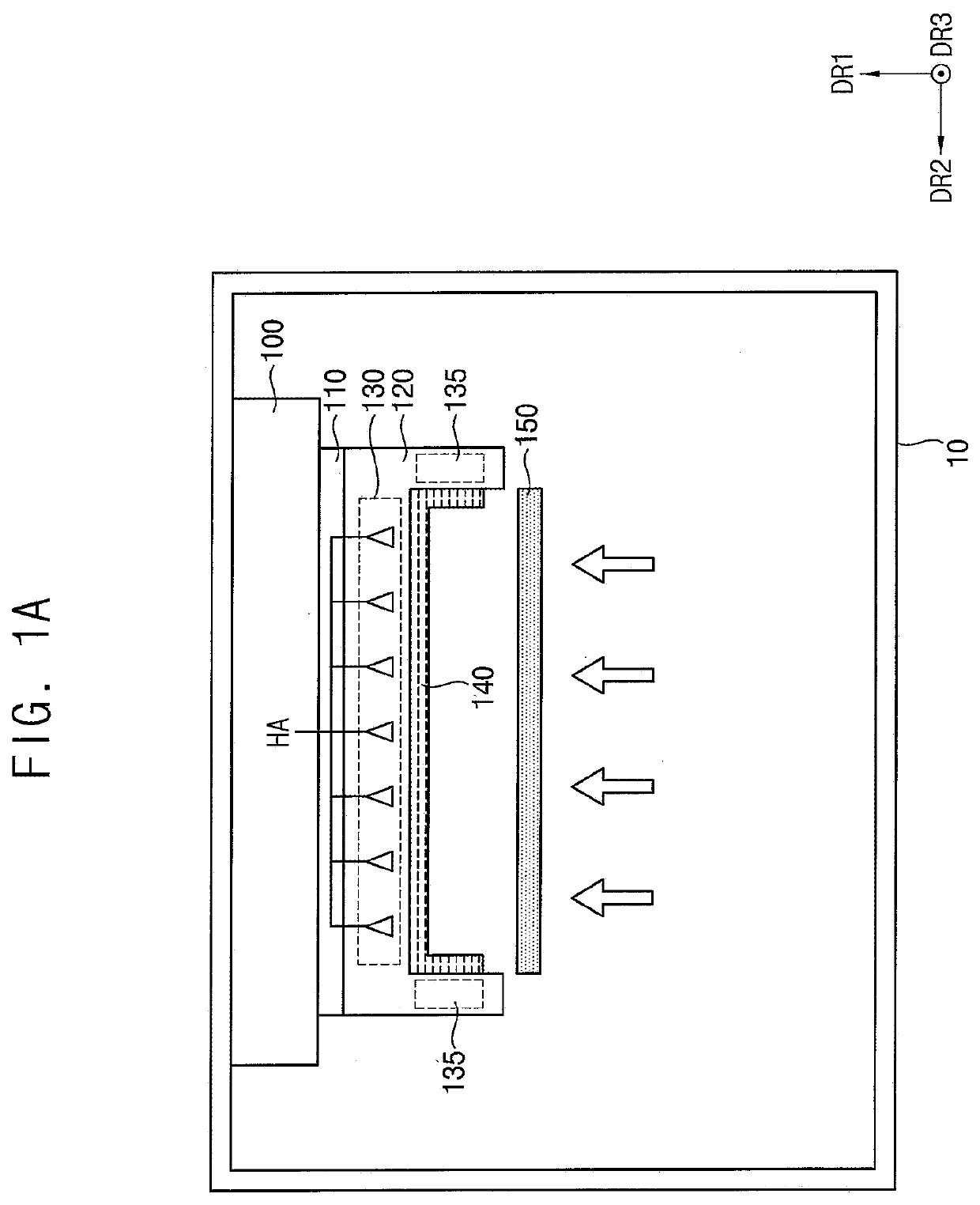

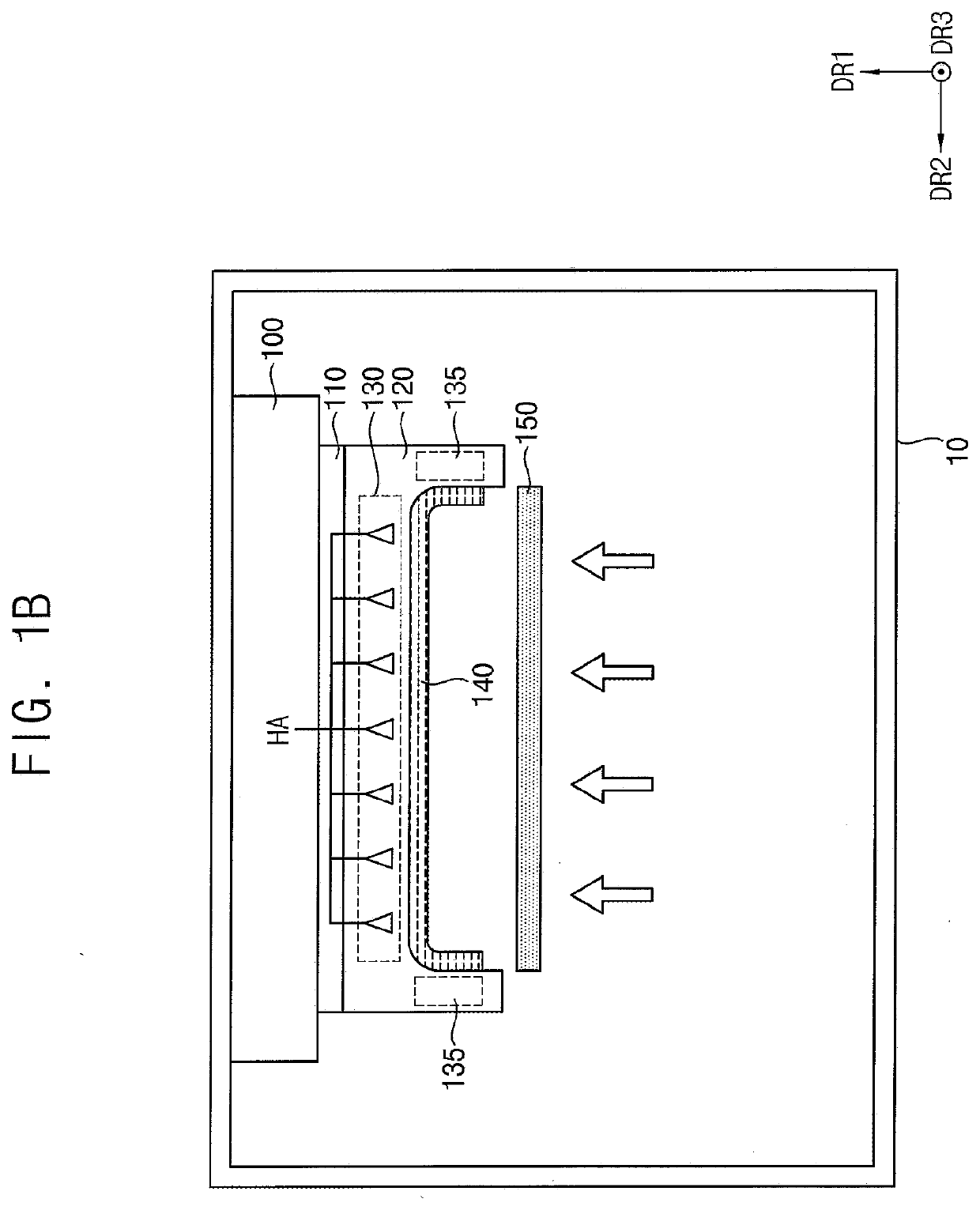

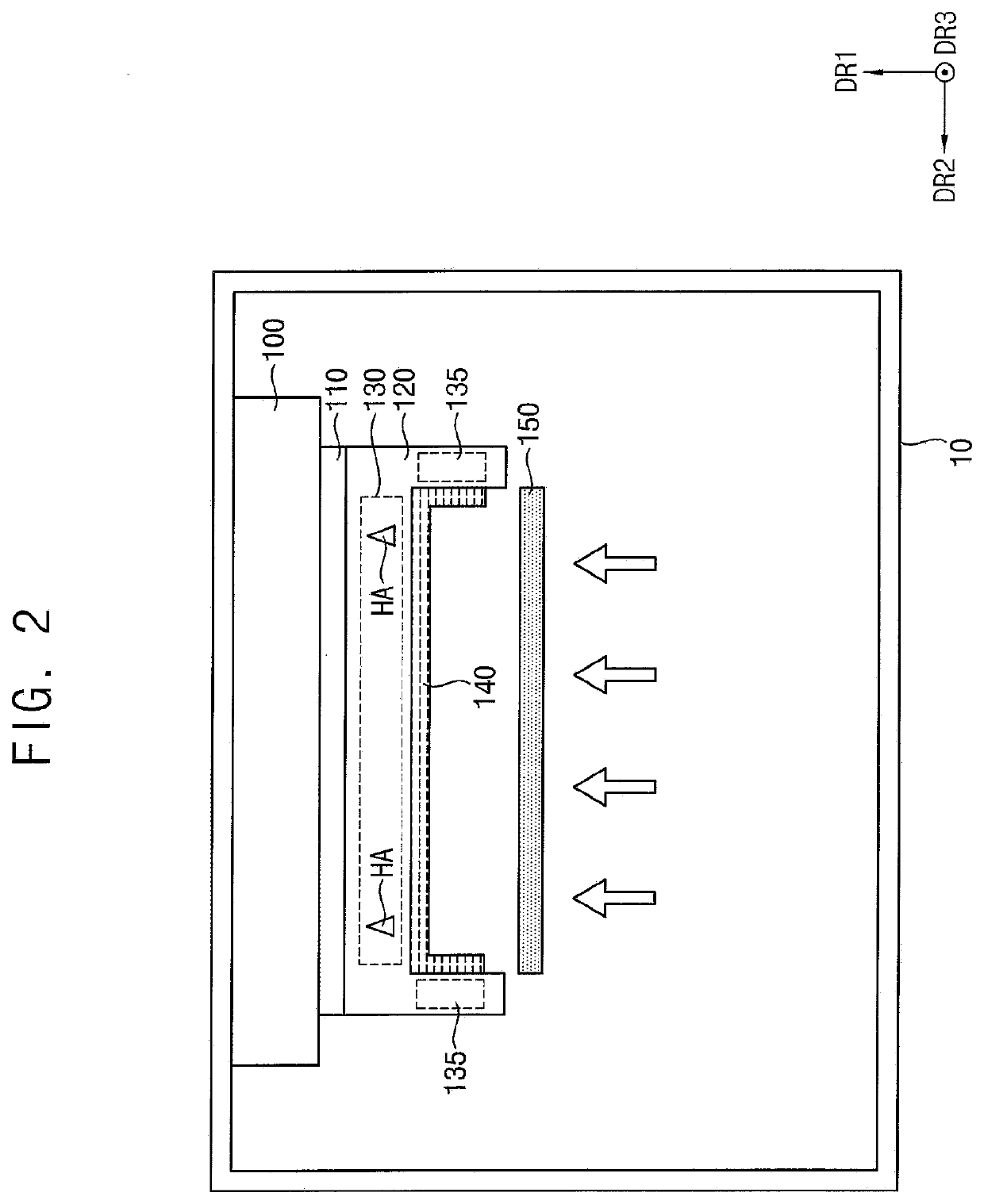

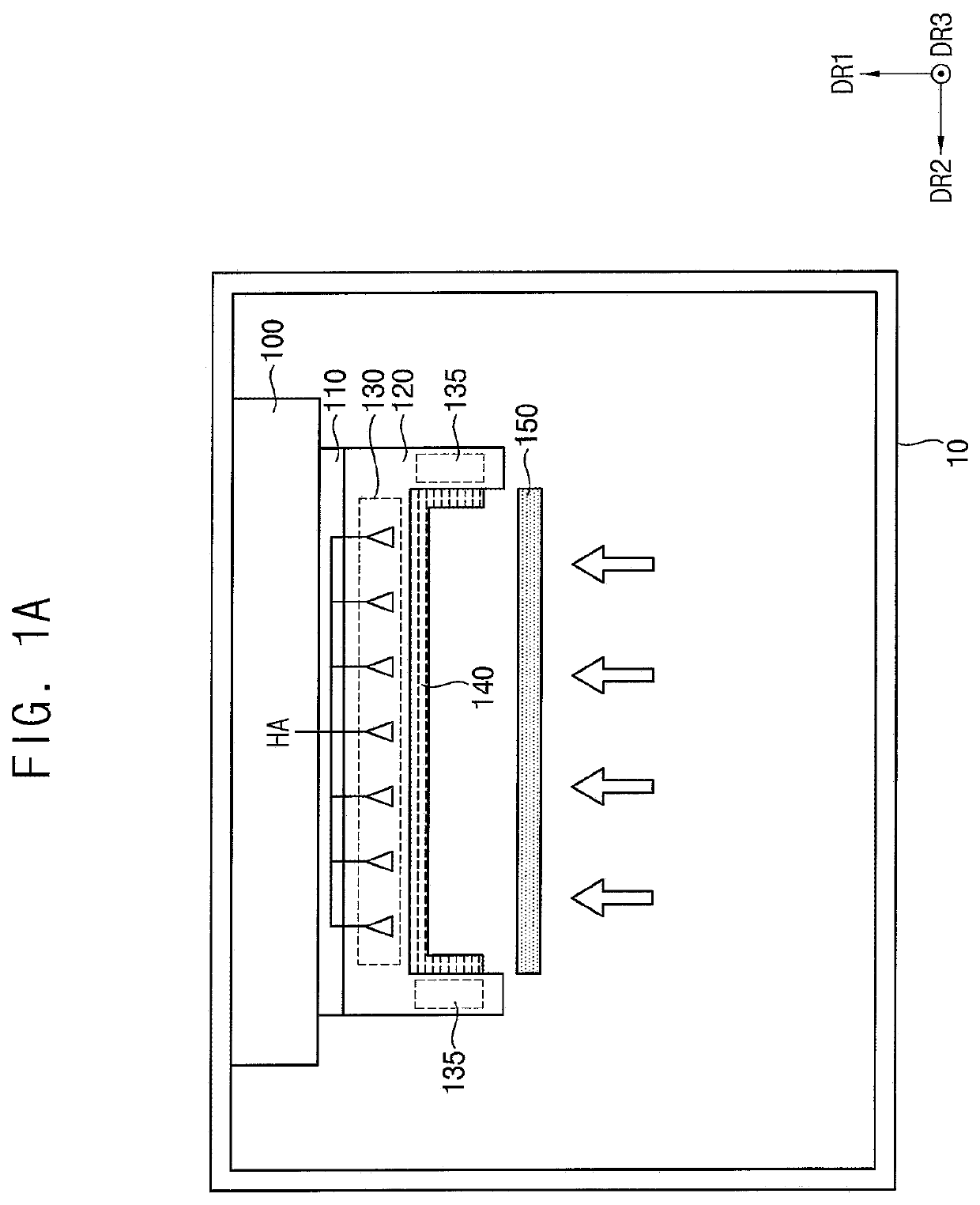

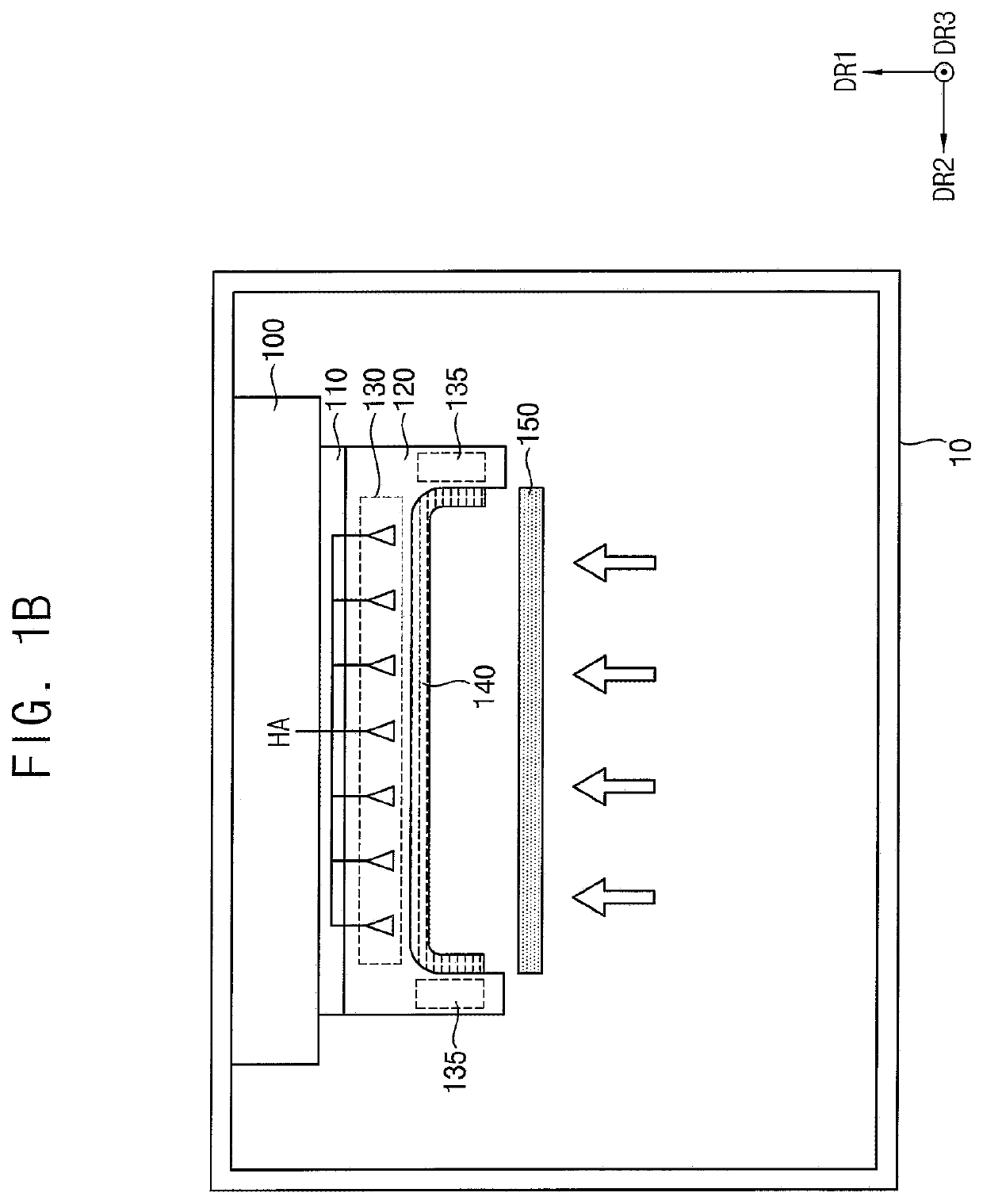

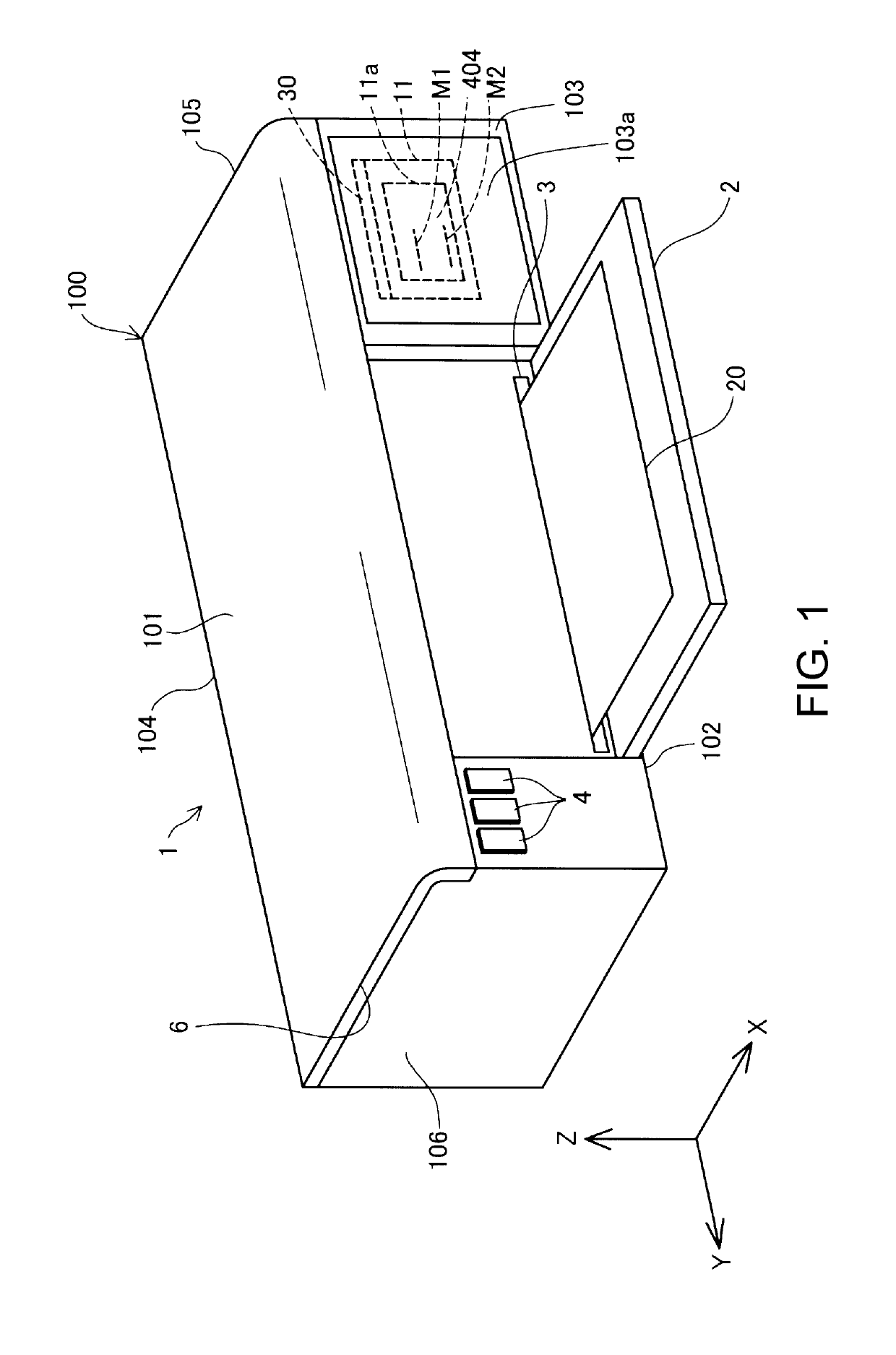

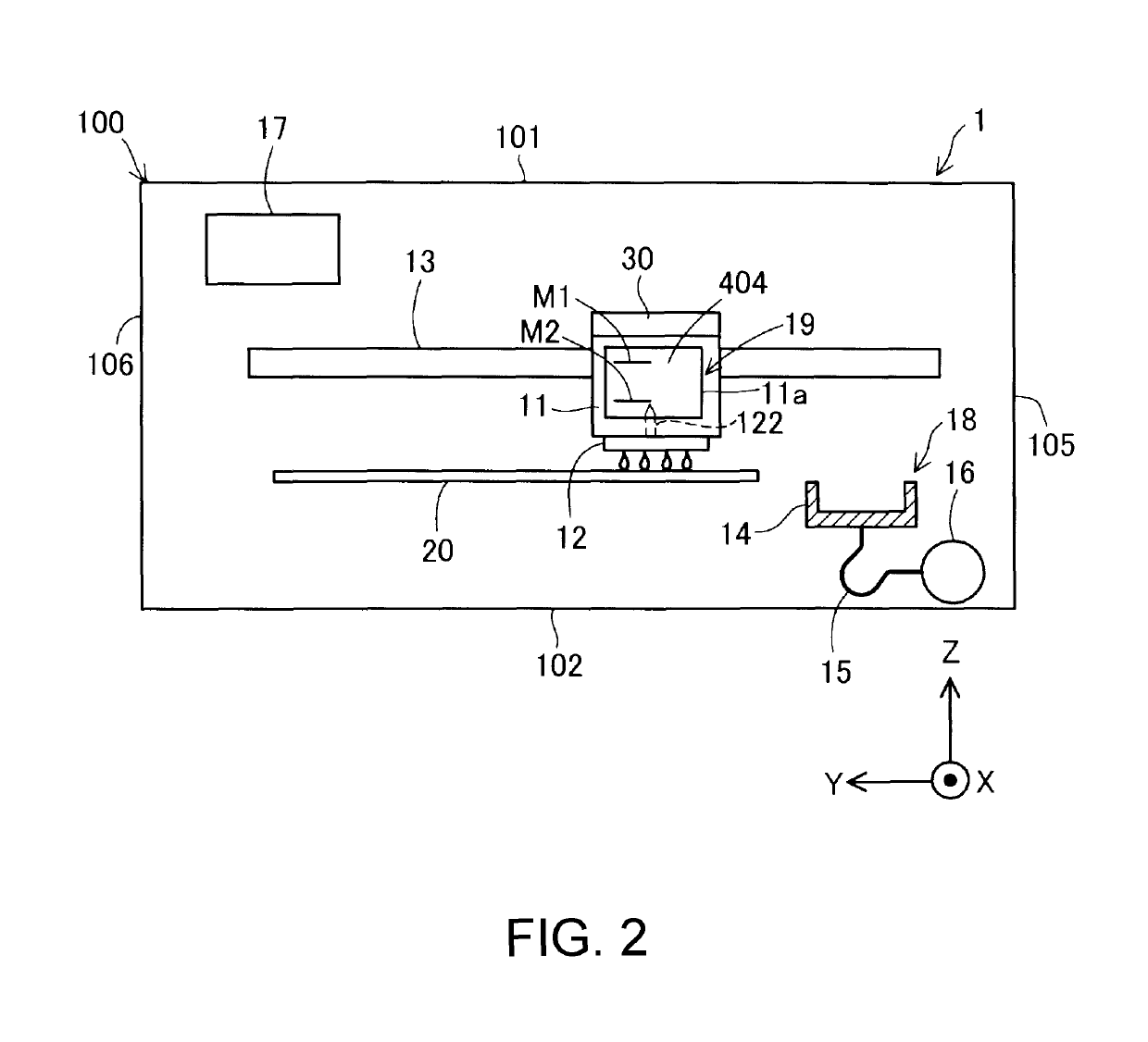

Liquid discharge head and liquid discharge apparatus

ActiveUS20140043395A1Suppress the generation of air bubblesSuppress generationPrintingEngineeringHead parts

A liquid discharge head includes a liquid discharge substrate configured to discharge liquid; a flow channel configured to supply the liquid to the liquid discharge substrate and including a first flow channel portion, a second flow channel portion communicating with the first flow channel portion and extending in a direction intersecting a predetermined direction in which the first flow channel portion extends, and a third flow channel portion provided on a downstream side of a position of communication between the first and second flow channel portion with respect to a flow of liquid flowing in the first flow channel portion and communicating with the first flow and second flow channel portion, the third flow channel portion including a first wall defining an end portion of a flow channel and a second wall having an inclined surface inclining toward a wall which defines the second flow channel portion.

Owner:CANON KK

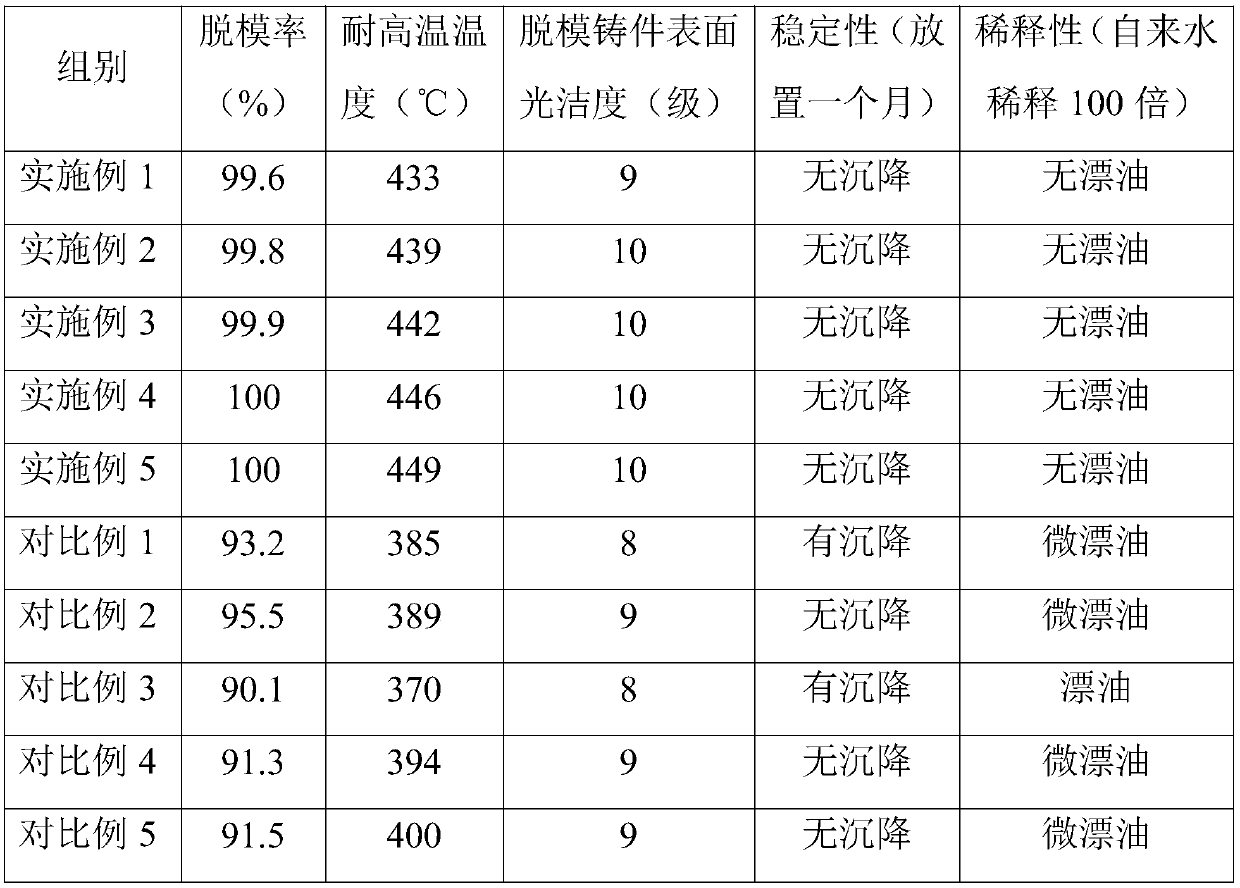

Die-casting mold releasing agent and preparation method thereof

InactiveCN107335777AImprove high temperature resistanceSpray lessFoundry mouldsFoundry coresWaxEmulsion

The invention provides a die-casting mold releasing agent and a preparation method thereof. The die-casting mold releasing agent is prepared from, by weight, 15%-18% of modified organic silicone oil, 3.2%-4% of oxidized polyethlene wax emulsion, 10%-12% of oleate emulsion, 1%-2% of Turkey red oil, 3%-5% of emulsifier and the balance water. The preparation method comprises the steps that (1), the modified organic silicone oil, the oxidized polyethlene wax emulsion, the oleate emulsion, the Turkey red oil, the emulsifier and the water are weighed according to the proportion for use; and (2), the modified organic silicone oil and the emulsifier are mixed firstly and then put into a high-speed shearing disperser, the silicone oil is emulsified through a reverse emulsifying method at normal temperature to obtain a silicone oil emulsion, then the oxidized polyethlene wax emulsion, the oleate emulsion and the Turkey red oil are added into the silicone oil emulsion, all the materials are mixed to be uniform to obtain a mixed emulsion, and then the mixed emulsion is subjected to homogenization treatment through a high pressure homogenizer, and therefore the die-casting mold releasing agent can be obtained. The die-casting mold releasing agent is good in high temperature resistance, the spray quantity of the mold releasing agent is small, the die-casting circulating period is shortened, and the production efficiency is improved.

Owner:佛山市高质压铸材料有限公司

Metal pressure casting releasing agent and preparing method thereof

The invention discloses a metal pressure casting releasing agent. The releasing agent comprises, by mass percent, 8 to 15% of epoxy soybean oil modified amino silicone oil, 20 to 30% of Tween 80-ricinoleic acid n-hexadecyl ester-oxprenolol glucosiduronide copolymer, 2 to 5% of 1-hexadecanaminium,2-hydroxy-N-(2-hydroxyethyl)-N,N-dimethyl-,chloride, 1 to 4% of aminopropanol ascorbic acid phosphate,2 to 4% of an emulsifying agent, 0.5 to 1.2% of a defoaming agent and the balance water. The invention further discloses a preparing method of the metal pressure casting releasing agent. The metal pressure casting releasing agent has the good lubricating and mold releasing performance under the high temperature environment, stability is good, when a casting after pressure casting is separated froma mold, mold releasing is easy, smoothness on the surface of the casting after mold releasing is high, and the mold protection effect is good.

Owner:HUNAN QIWEI TECH CO LTD

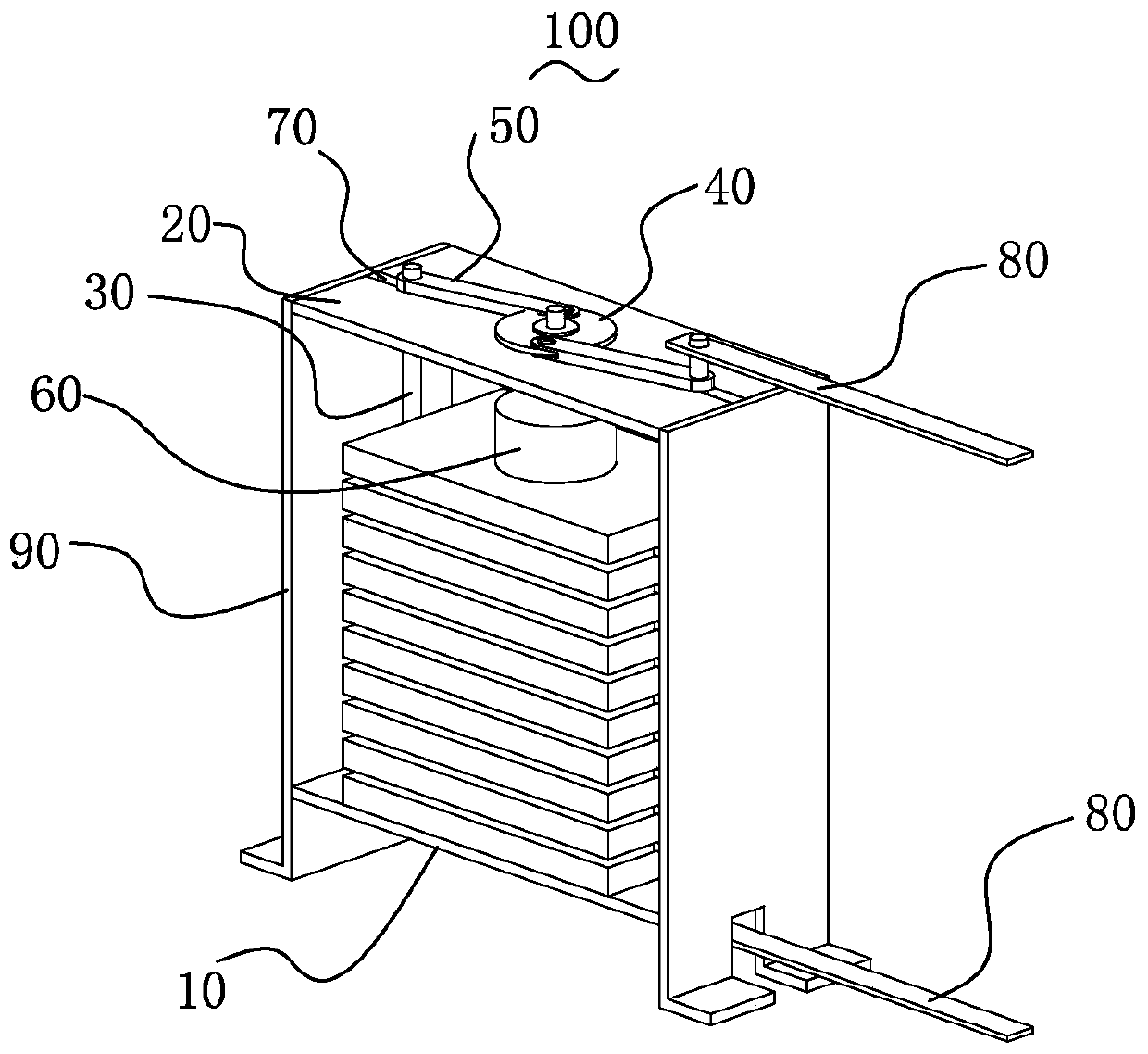

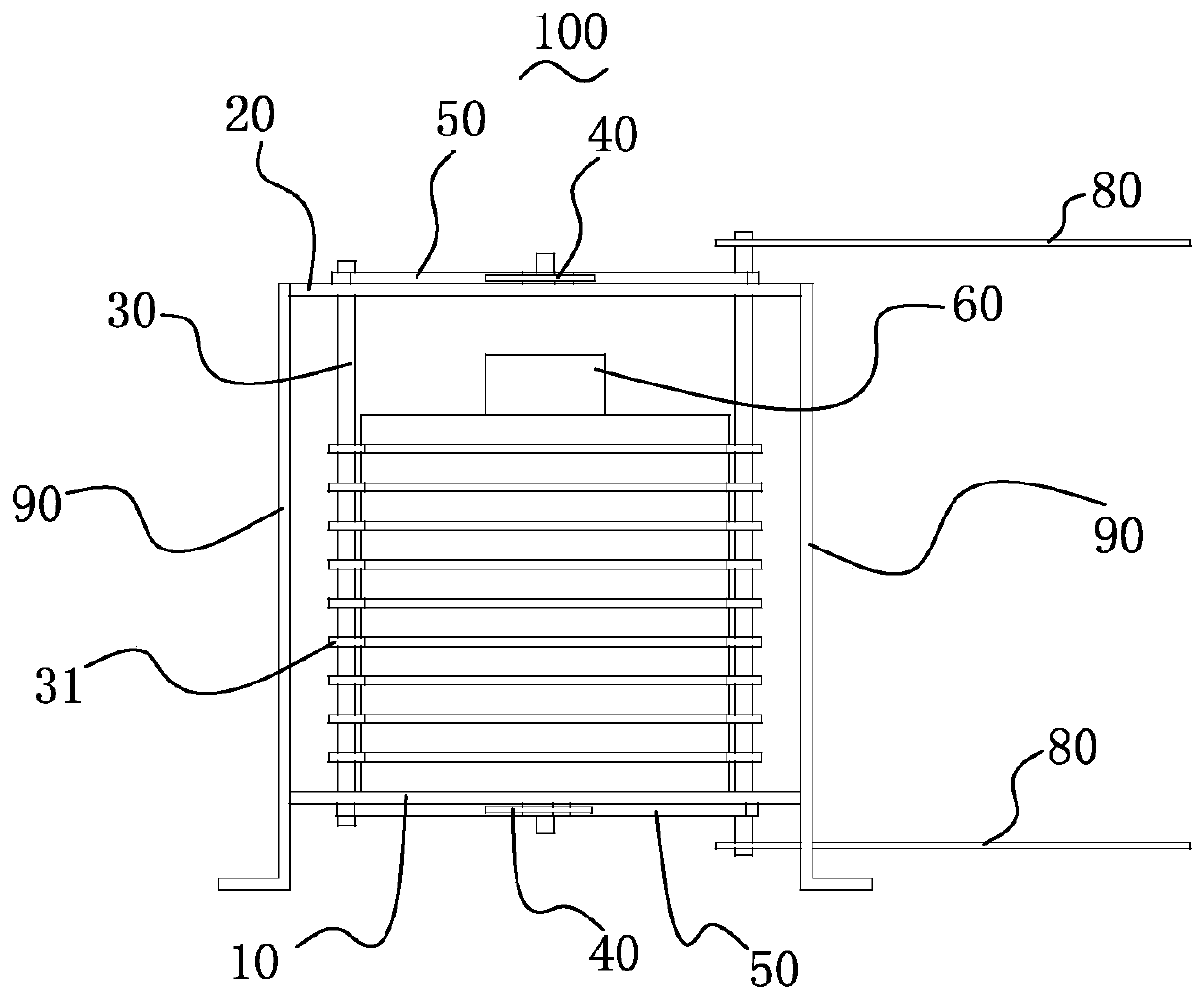

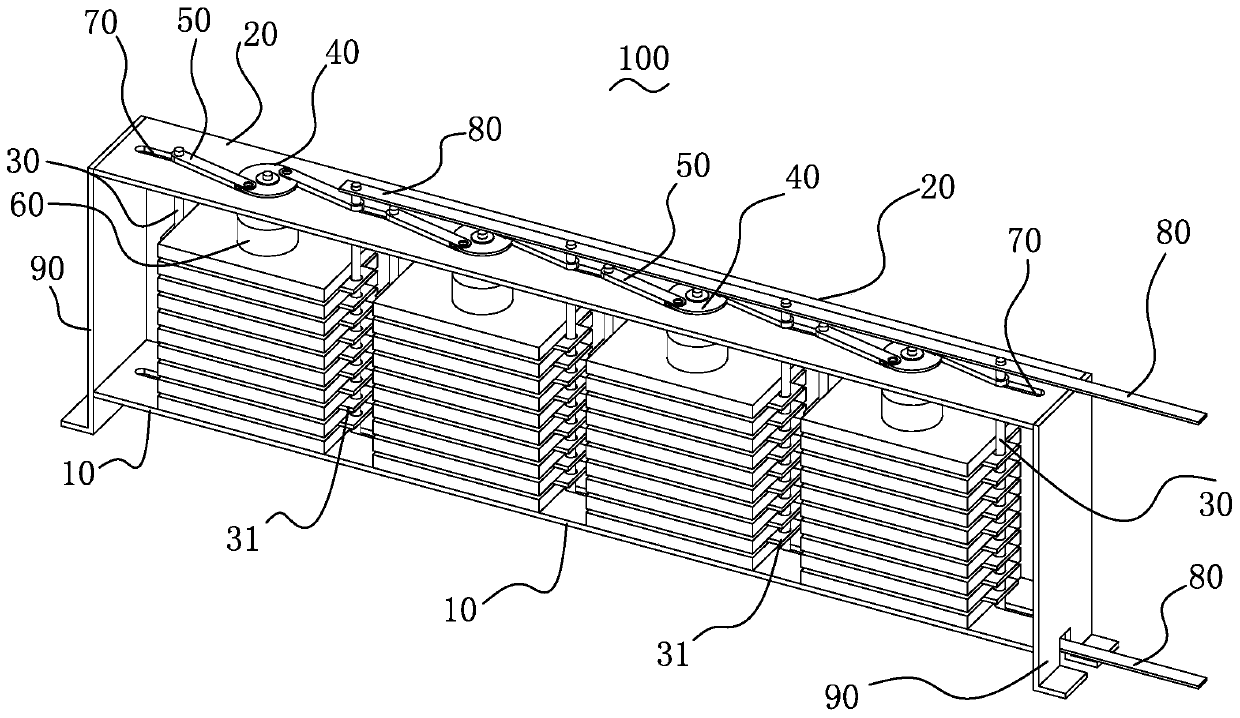

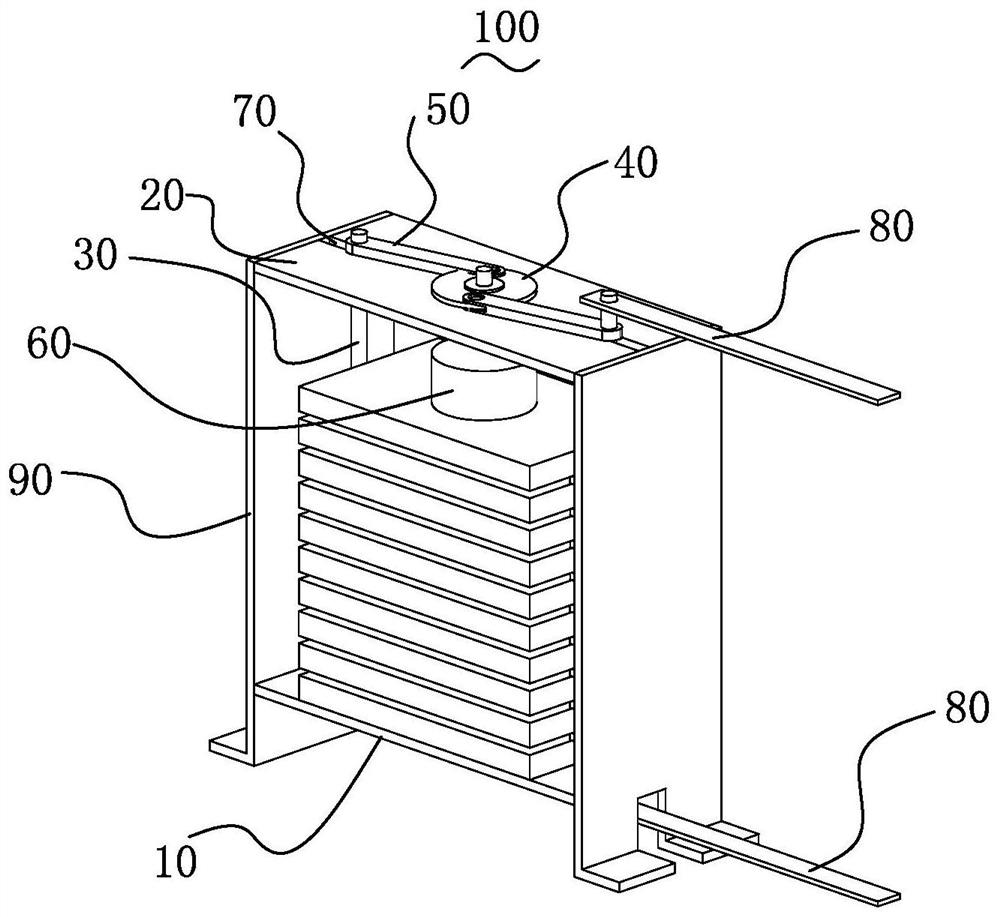

Manufacturing method of low-eddy-current heating combined magnet and clamping tool

ActiveCN110942908APlay a binding roleImprove bindingInductances/transformers/magnets manufactureLaboratory ovenMagnet

The invention discloses a manufacturing method of a low-eddy-current heating combined magnet and a clamping tool. The method comprises the following steps of preheating a magnet assembly; forming a thermosetting resin layer which is not completely cured on at least one surface of the pretreated magnet assembly; stacking the magnet assembly by adopting a clamping tool, forming the thermosetting resin layer which are not completely cured on the stacked surfaces of the magnet assembly and extruding the stacked magnet assembly under the extrusion force of 0.01 MPa to 2.5 MPa; baking and curing thestacked magnet assembly and the clamping tool in an oven atthe baking temperature of 150-200 DEG C for 10-24 h; cooking the above to acquire a combined manget. The invention further discloses a clamping tool for preparing the low-eddy-current heating combined magnet. According to the invention, the resin layer is formed on the surface of the magnet assembly and is heated and cured after being stacked, and extra treatment of redundant viscose is not needed.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

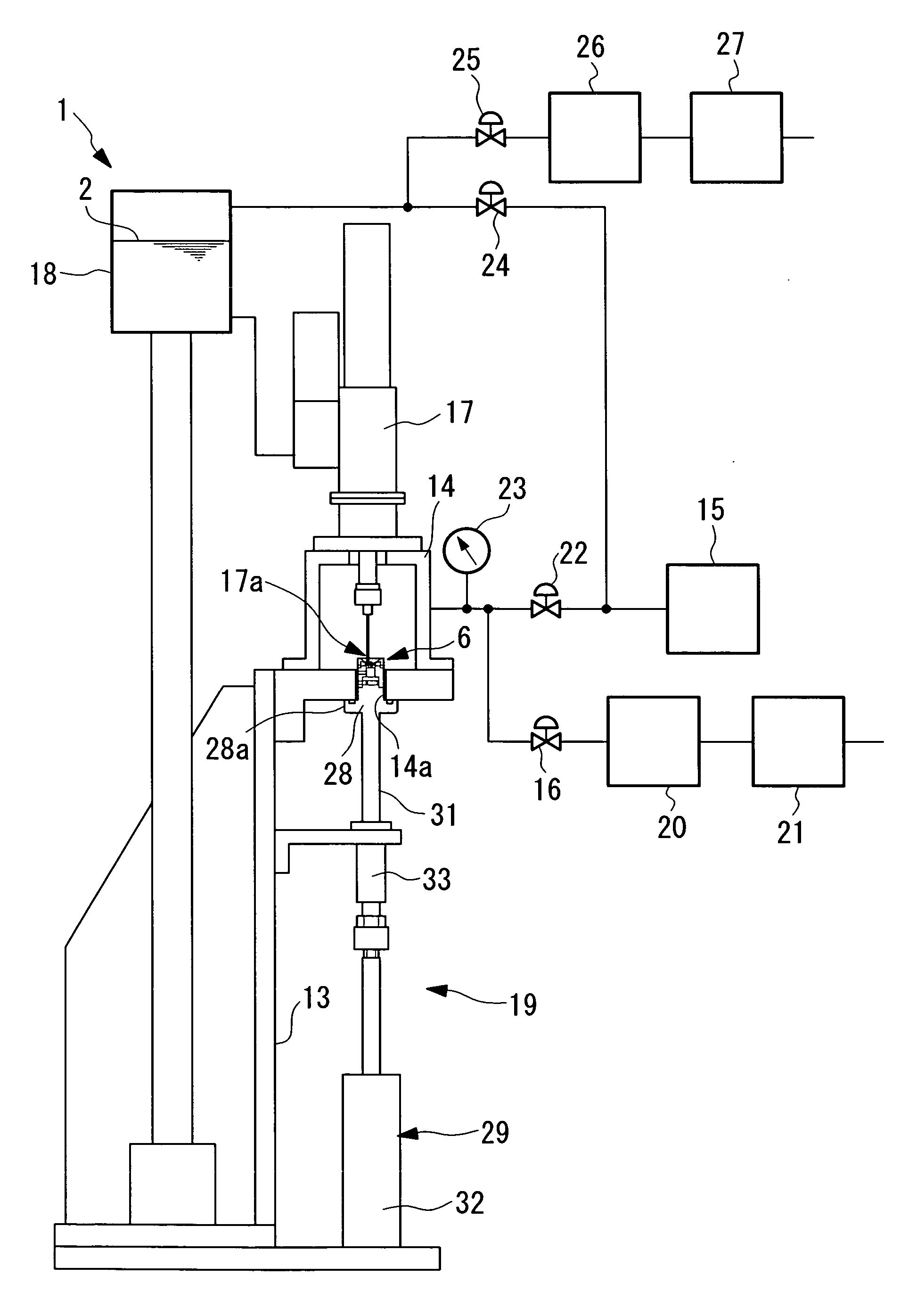

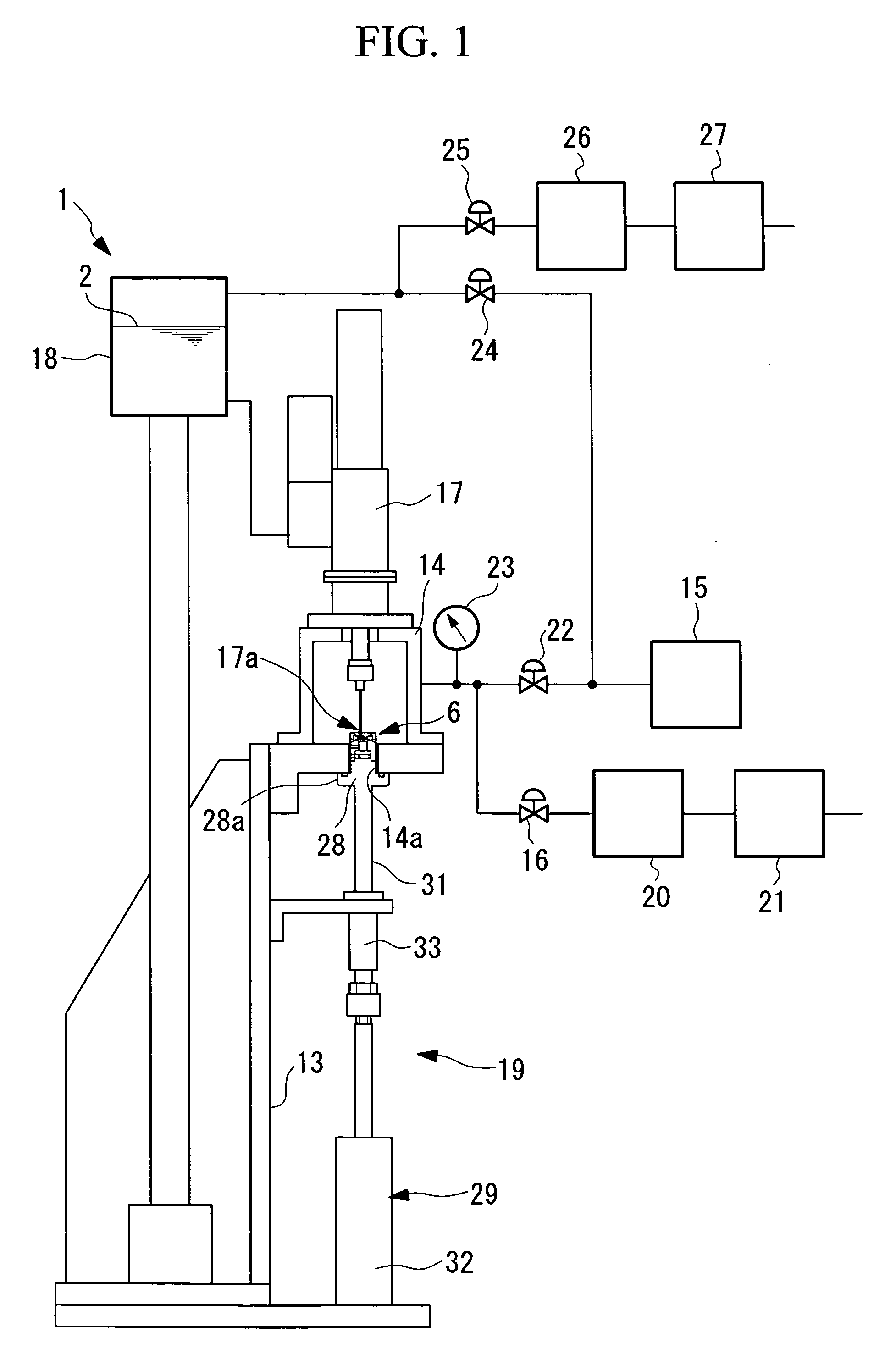

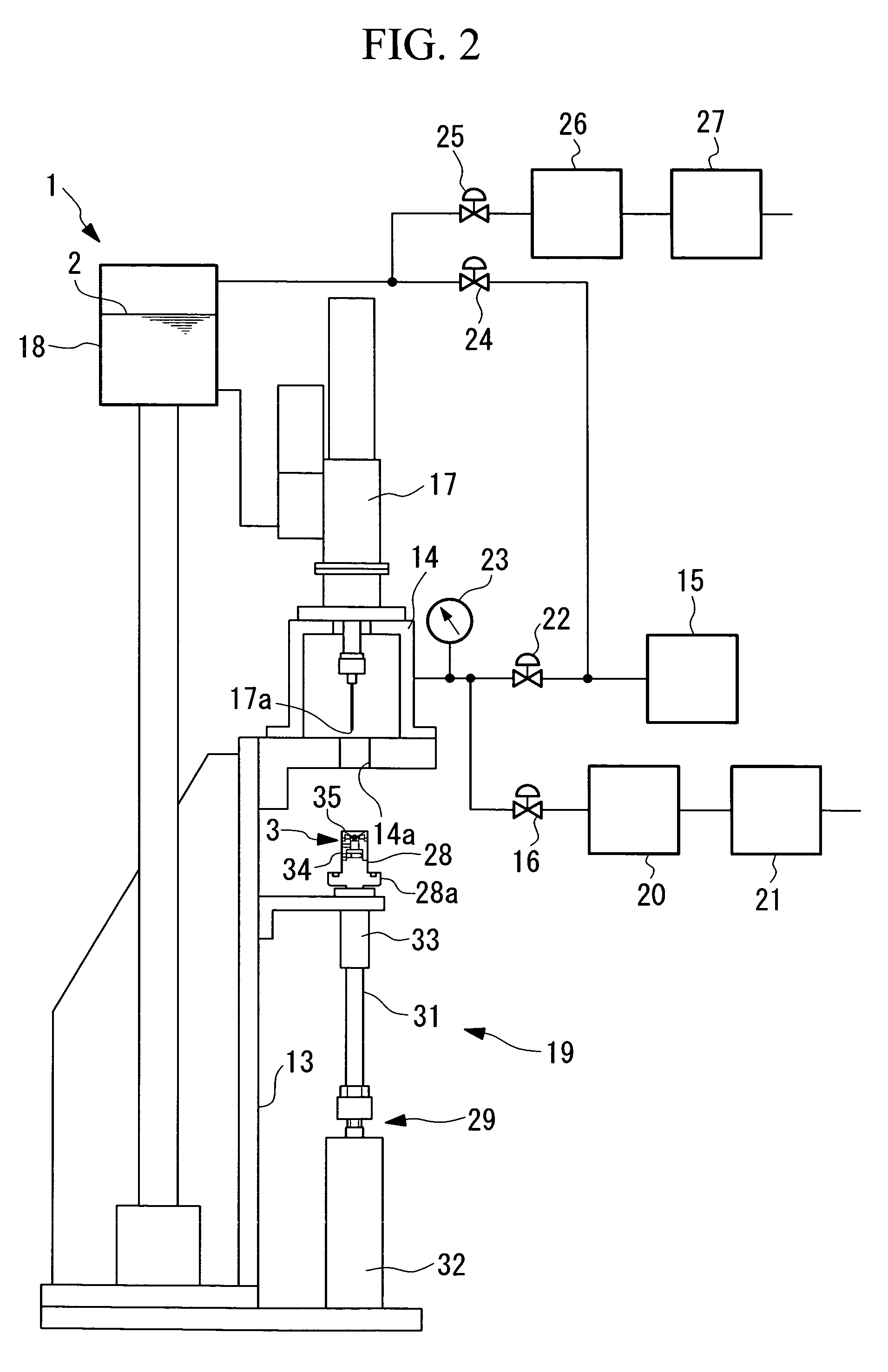

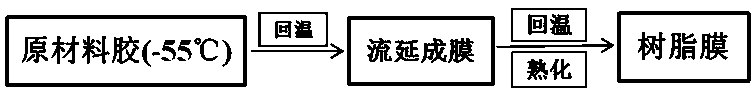

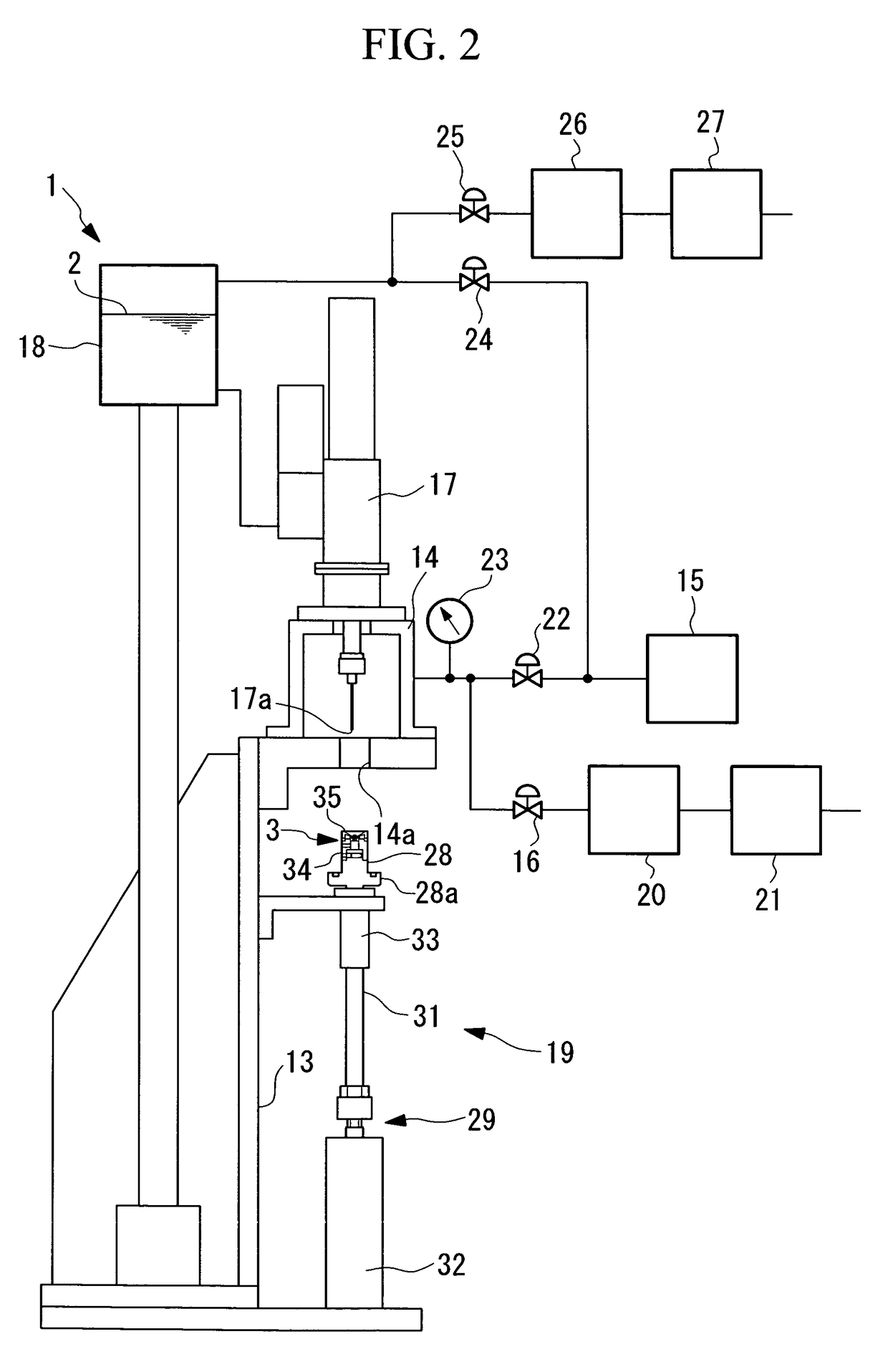

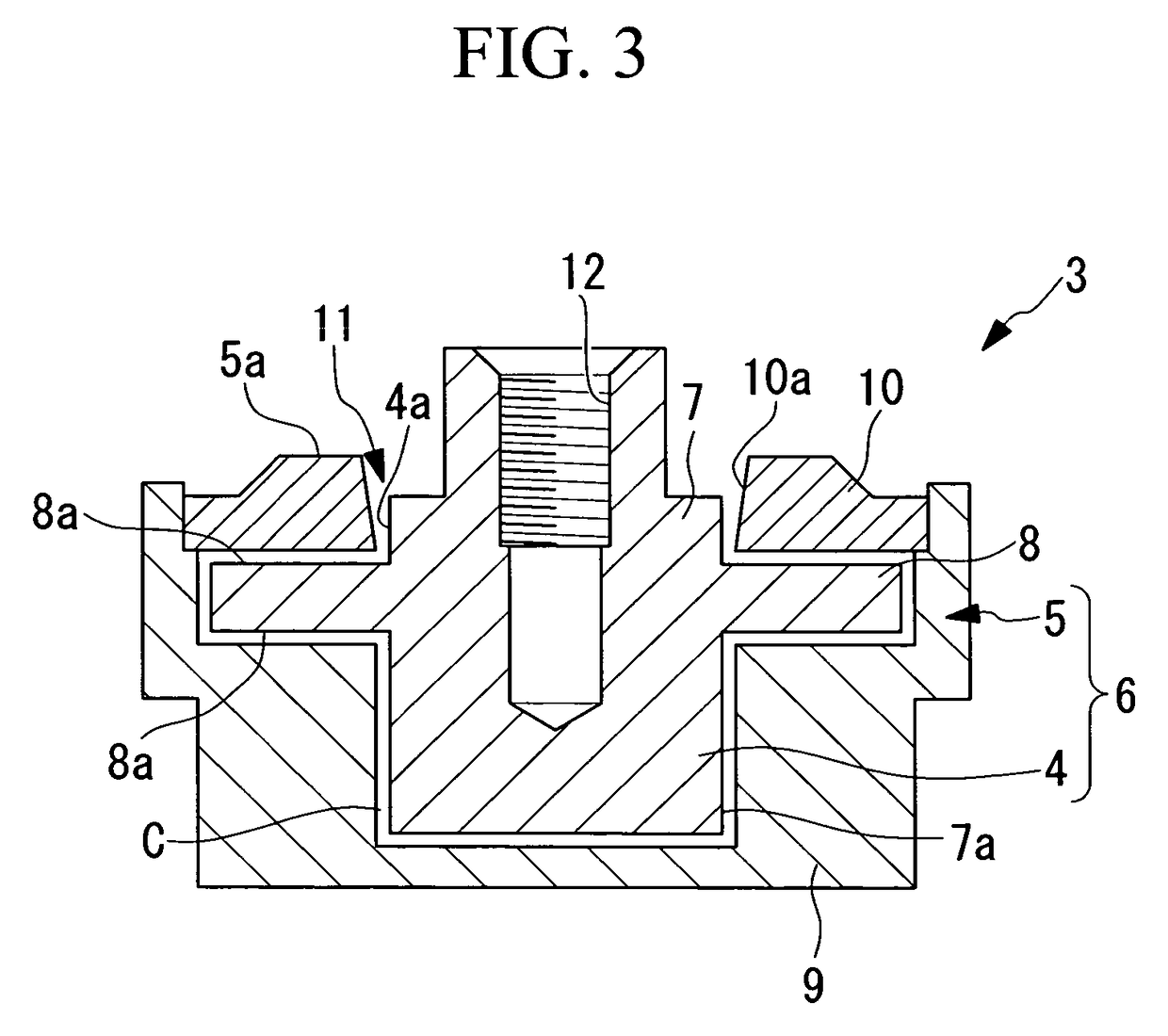

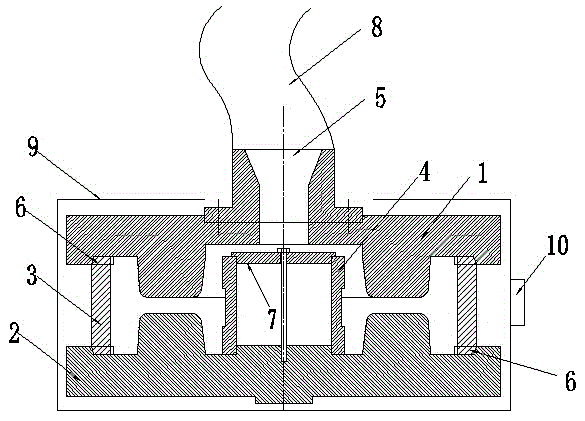

Working fluid injection apparatus for a fluid dynamic pressure bearing, method thereof, and method of manufacturing a fluid dynamic pressure bearing

InactiveUS20070175704A1Reliable manufacturingReduction in vibration and noiseProportioning devicesBearing componentsInterior spaceWorking fluid

A working fluid is filled into a fine gap in a bearing unit while the working fluid is not mixed with air bubbles and droplets of the working fluid are not dispersed to the periphery through simple and easy steps. There is provided a working fluid injection apparatus for a fluid dynamic pressure bearing including: a cover member 35, which is mounted, in a contact state, on an upper surface 5a of a housing 5, in which a ring-shape open portion 11 is arranged upward which is formed in an opening portion 10a thereof and which forms, above the open portion 11, a reservoir portion 39 capable of storing a working fluid 2; a chamber 14 that sealably holds a bearing unit 6 onto which the cover member 35 is mounted; a valve device which opens / closes an internal space of the chamber 14 with respect to an external space thereof; an exhaust device which exhausts air in the internal space of the chamber 14 to obtain a decompressed state; and a dispenser which drops the working fluid 2 to the reservoir portion 39 in the chamber 14 in the decompressed state.

Owner:SEIKO INSTR INC

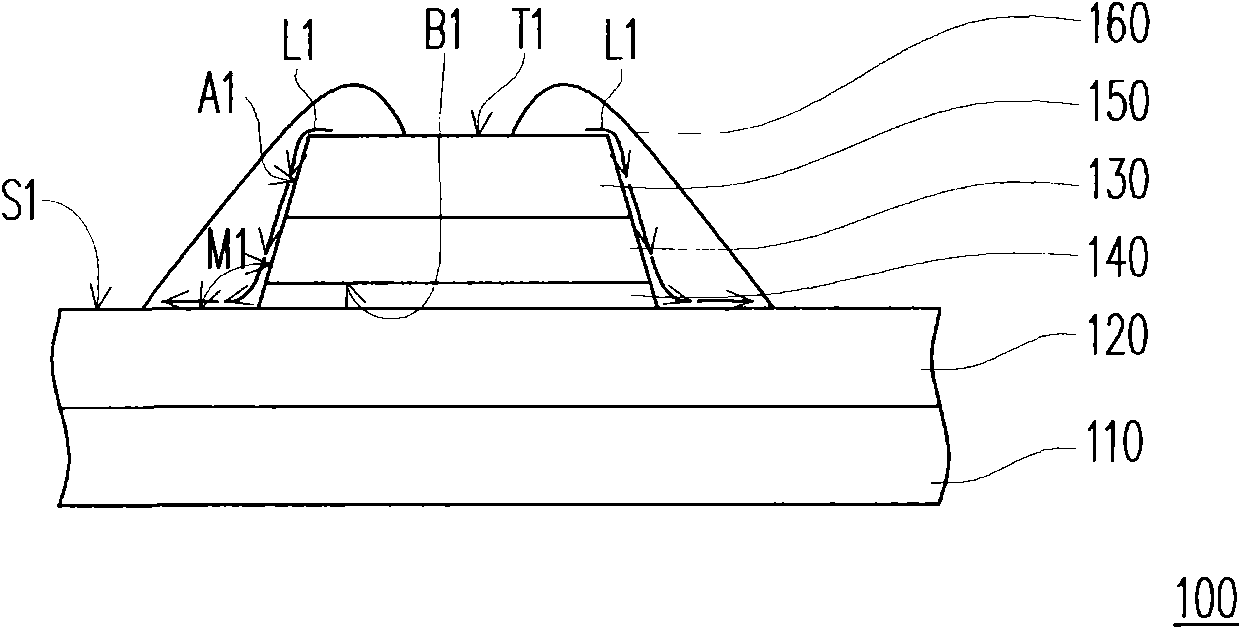

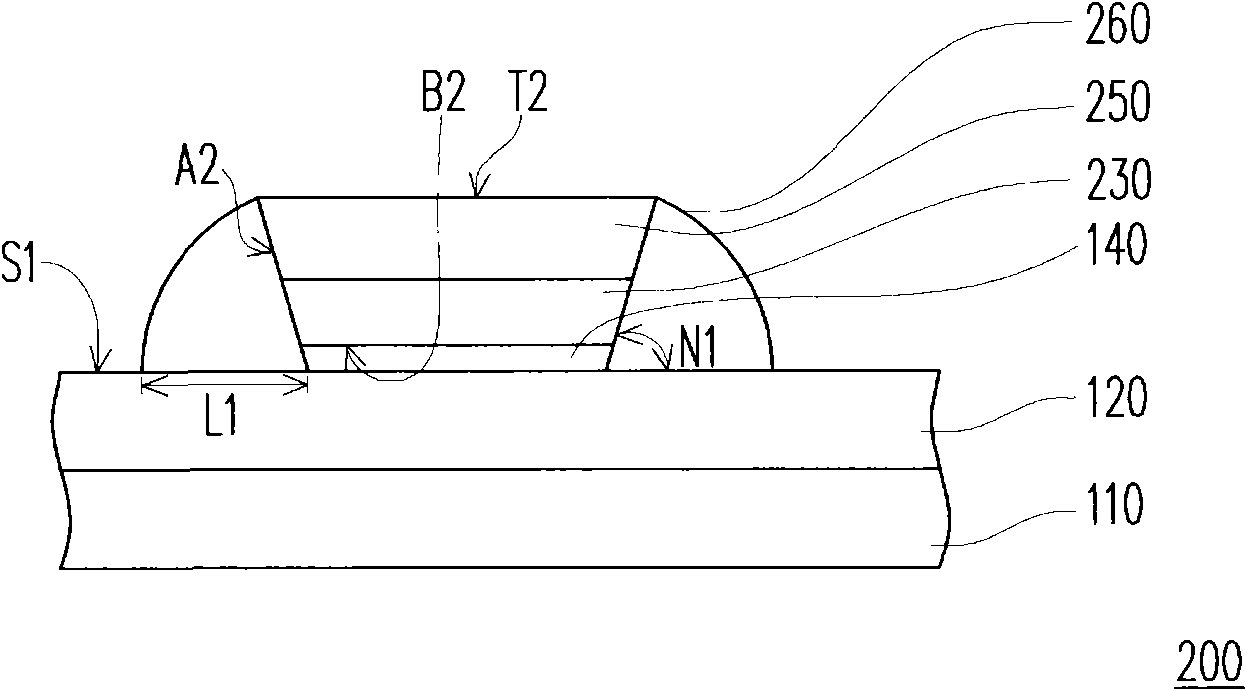

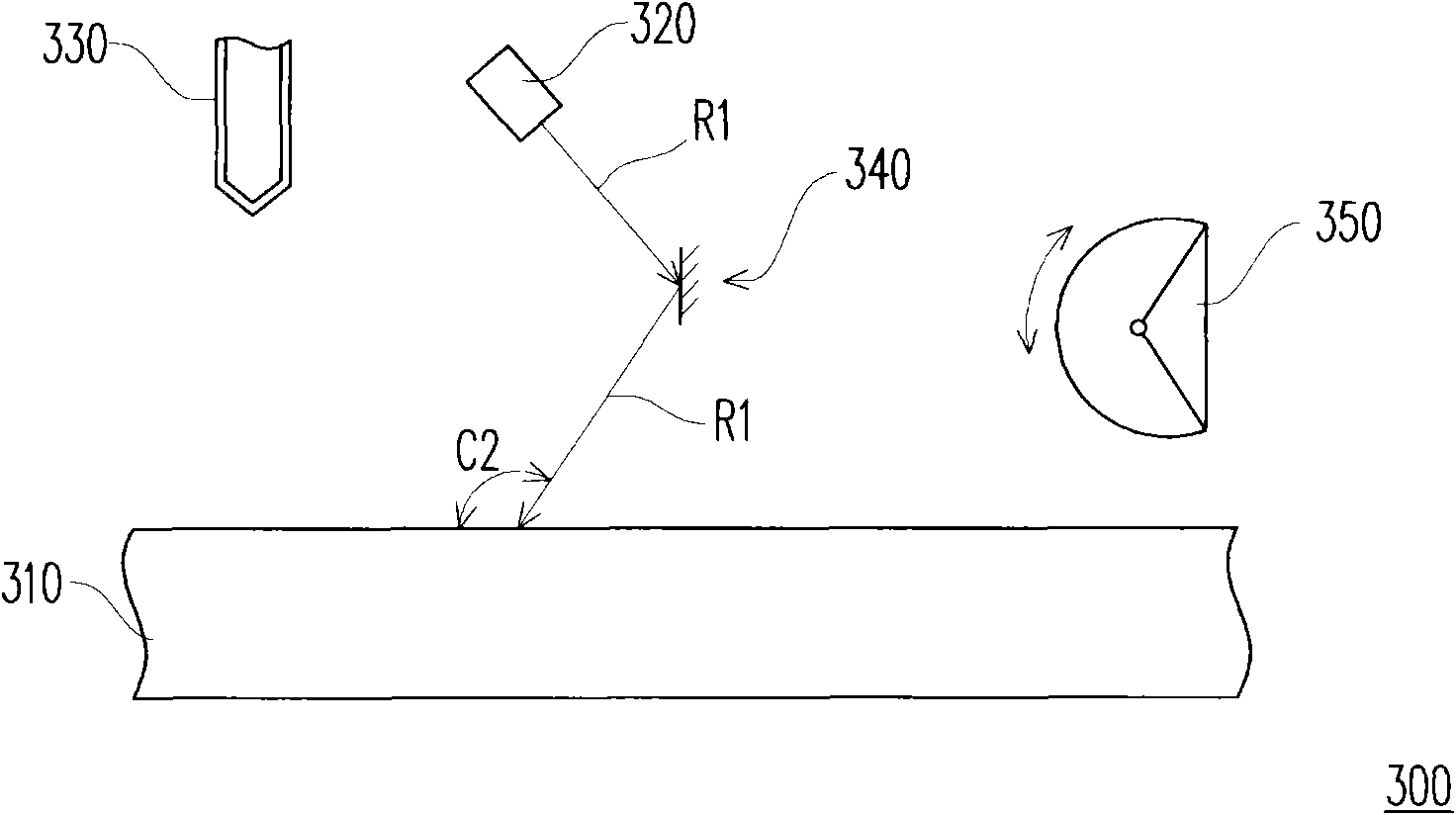

Electronic paper unit, cutting device and manufacture method for electronic paper unit

InactiveCN102109728ALess intrusiveIncrease production capacityMetal working apparatusNon-linear opticsAdhesiveAcute angle

The invention provides an electronic paper unit, a cutting device and a manufacture method for the electronic paper unit.The electronic paper unit comprises a flexible substrate, a thin film transistor layer, an electronic ink layer, a waterproof layer and a frame adhesive.The c is arranged on the flexible substrate.The electronic ink layer is arranged on the surface of the thin film transistor layer.The waterproof layer is arranged on the electronic ink layer.A sidewall is formed by the end face of the waterproof layer together with the end face of the electronic ink layer.A first acute angle or a first obtuse angle is formed between the sidewall and the surface.The frame adhesive is coated on the sidewall and the surface.Meanwhile, a cutting device and a manufacture method for the electronic paper unit are also provided.

Owner:AU OPTRONICS CORP

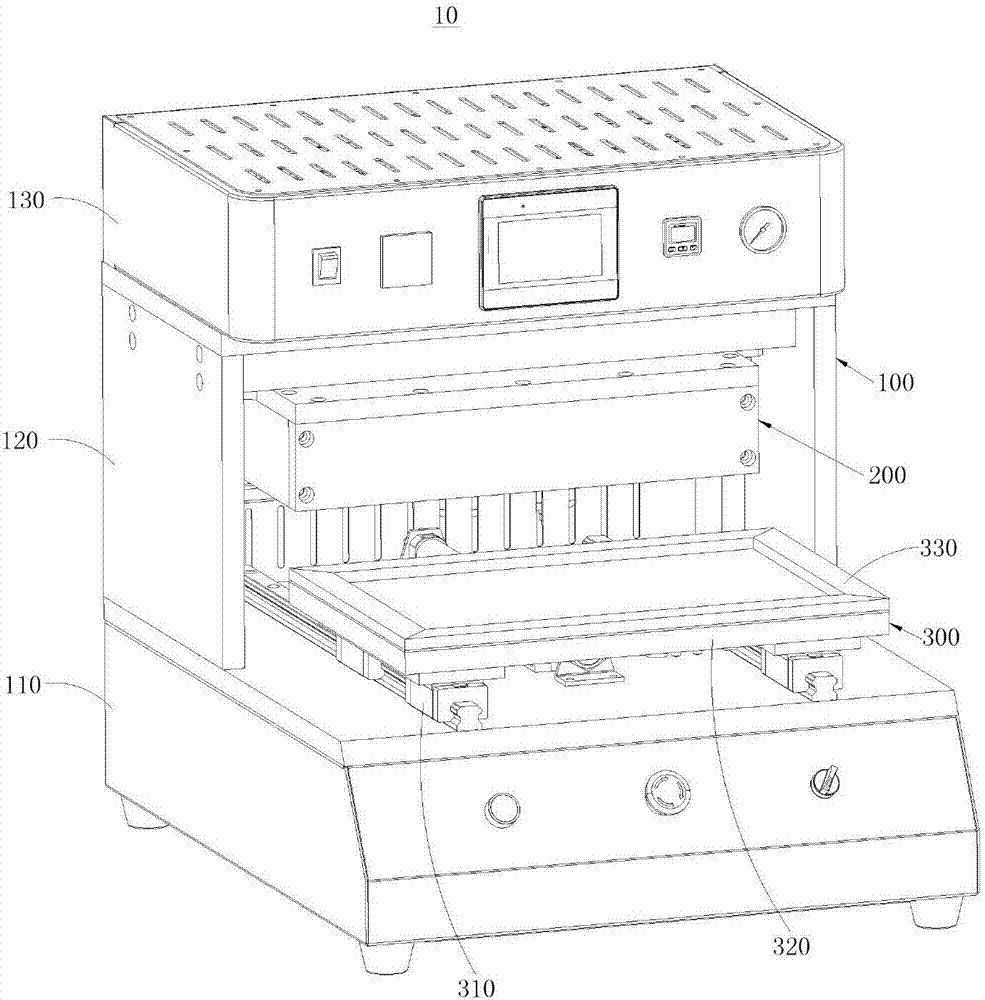

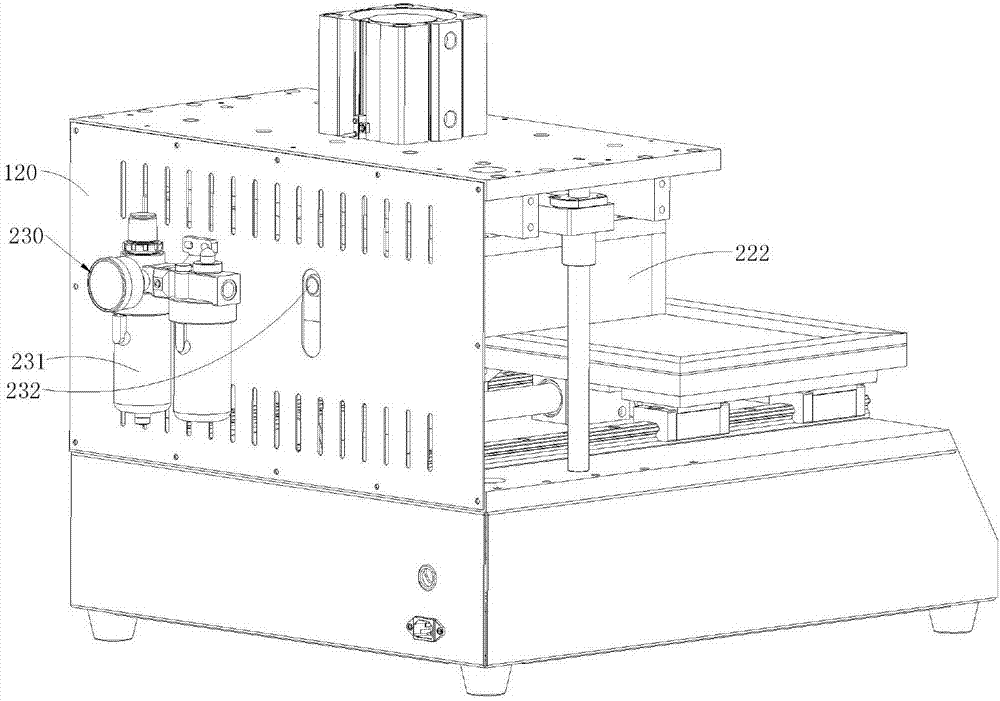

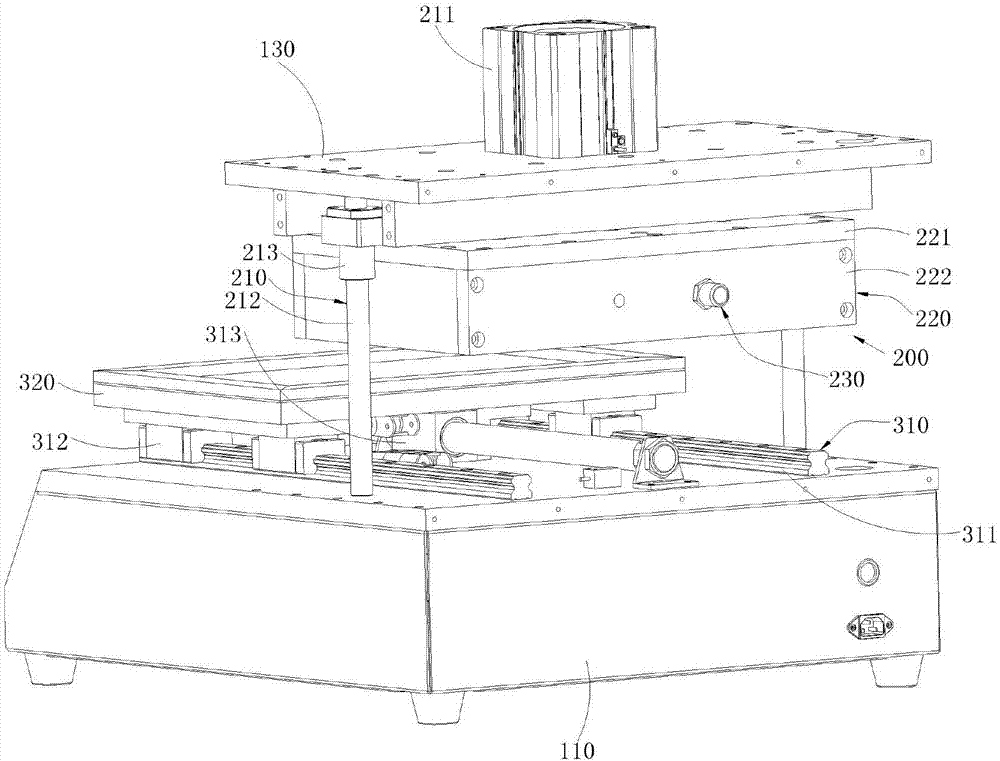

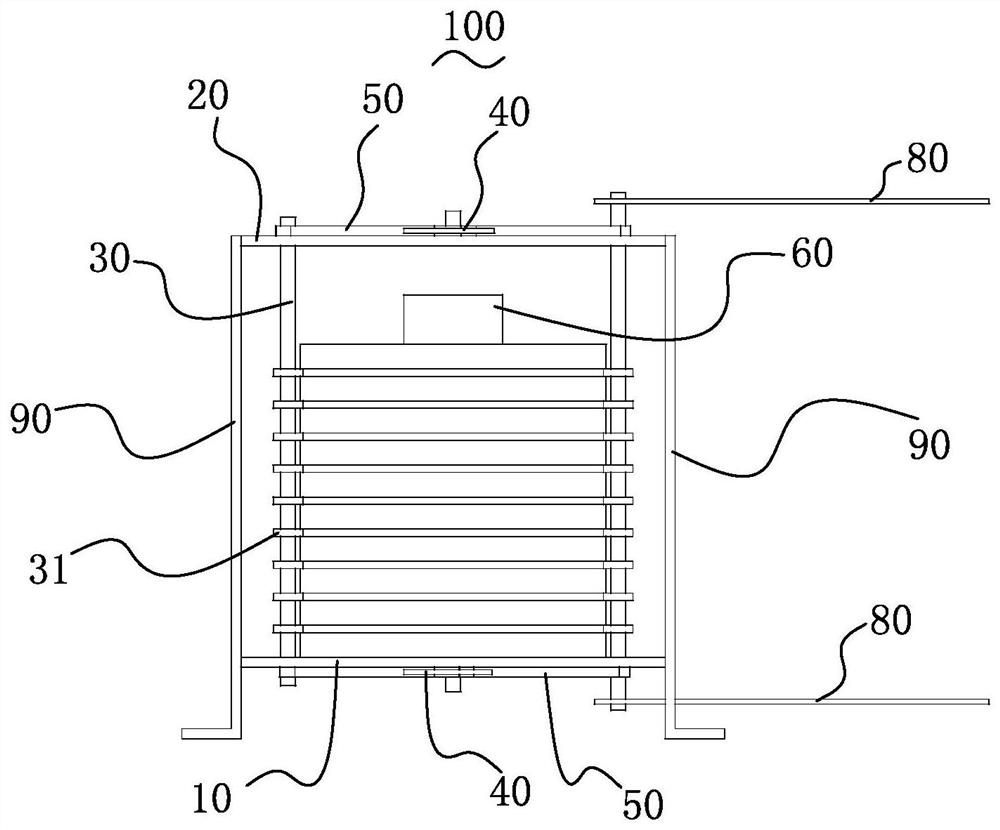

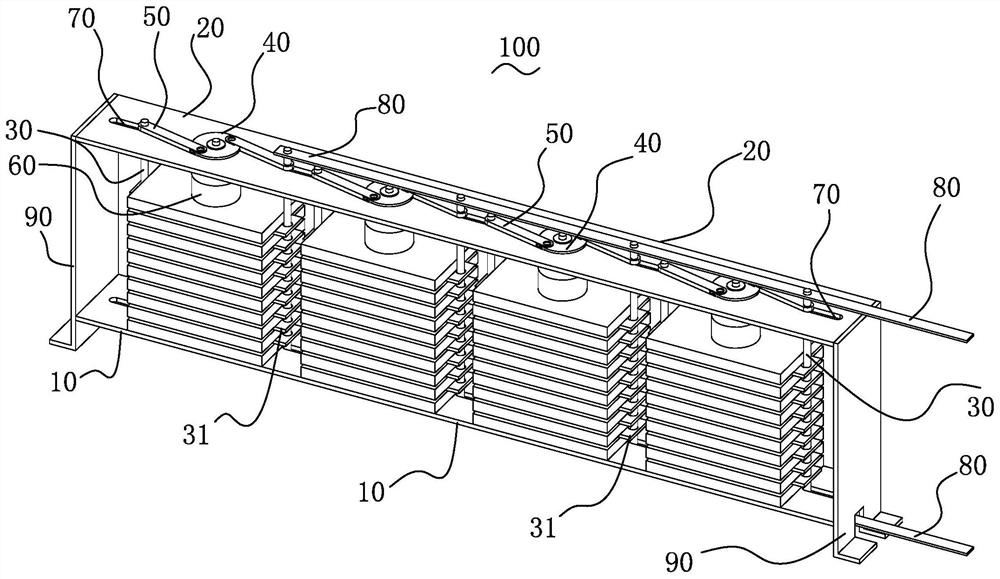

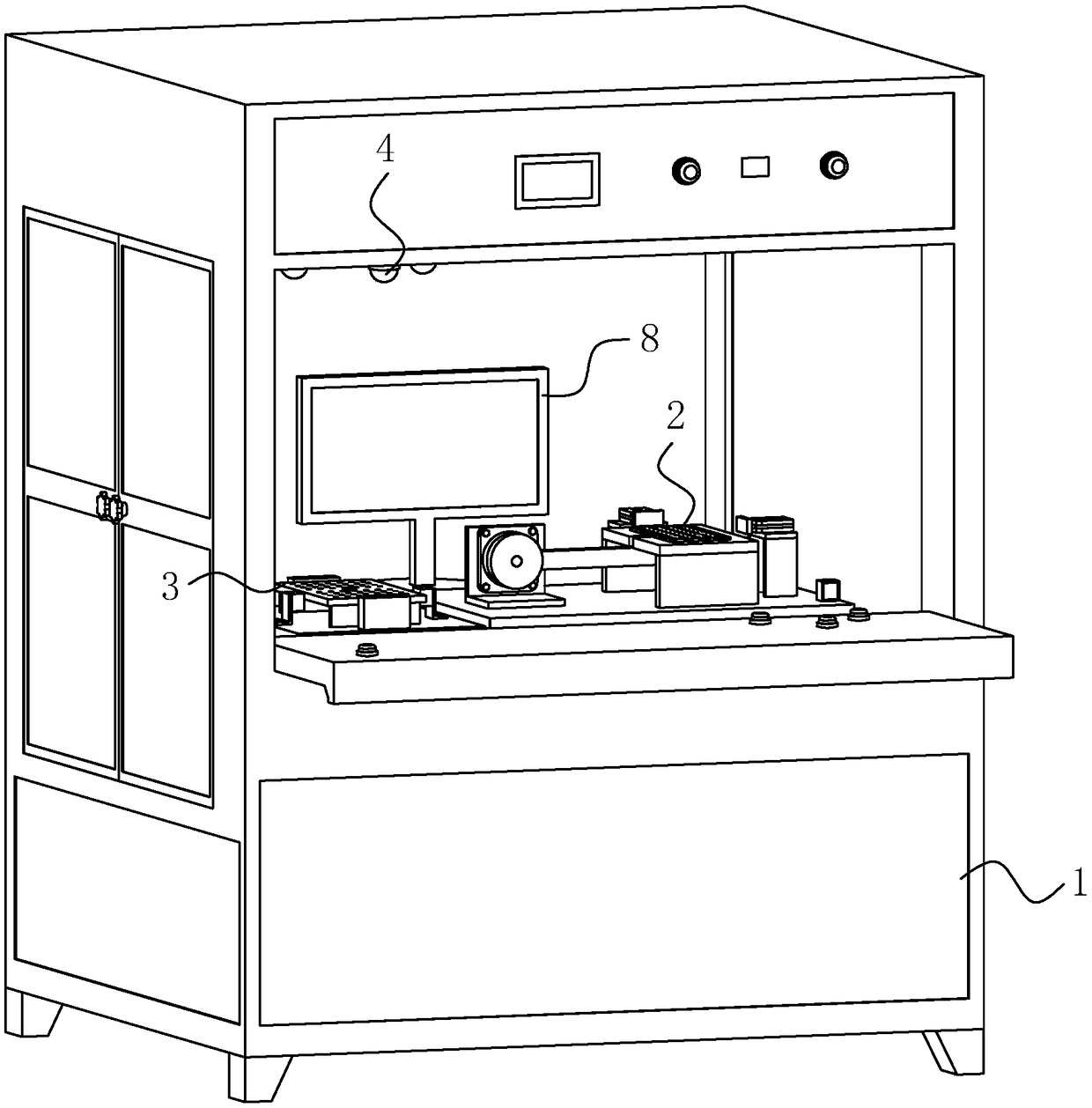

Laminating machine and laminating method

PendingCN107877990AReduce the generation of air bubblesReduce generationLaminationLamination apparatusPhysicsVacuum chamber

The invention relates to a laminating machine and a laminating method. The laminating machine comprises a mounting and supporting mechanism, a vacuum heating mechanism and a sliding sealing mechanism,wherein the mounting and supporting mechanism comprises a base, a support frame and a top box; the vacuum heating mechanism comprises a lifting device, a vacuum box, a vacuum device and a heating pressing assembly; the lifting device comprises a lifting cylinder, a guide rod and a sliding sleeve; the vacuum box comprises a mounting substrate and a mounting frame; the vacuum device comprises a mounting hose and a vacuum generation assembly; the heating pressing assembly comprises a mounting seat, a thermal baffle, a heating lower pressing plate and a heating pipe; the sliding sealing mechanismcomprises a sliding track device, a supporting device and a sealing device; the sliding track device is arranged on the base; the supporting device is arranged on the sliding track device; and the sealing device is arranged on the supporting device and is used for sealing a vacuum chamber together with the second end of the mounting frame. Therefore, bubbles in the product can be reduced in the product laminating process.

Owner:惠州保均新材科技有限公司

Production method of PETG heat shrinkable film

InactiveCN104589675AIncrease productivityImprove product qualityFlat articlesFiltrationMaterials science

The invention discloses a production method of a PETG heat shrinkable film, and relates to the field of packing material. The production method comprises the following steps: batching, raw material conveying, raw material drying, feeding, extruding, metering, filtering, static mixing, die head, sheet casting, thickness measurement, longitudinal stretching, transverse stretching, side shearing, secondary thickness measurement, corona treatment, rolling, aging treatment, and cutting and package. The PETG heat shrinkable film produced according to the production method has ordered and reasonable production process, the production efficiency is high, and the product quality is good.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

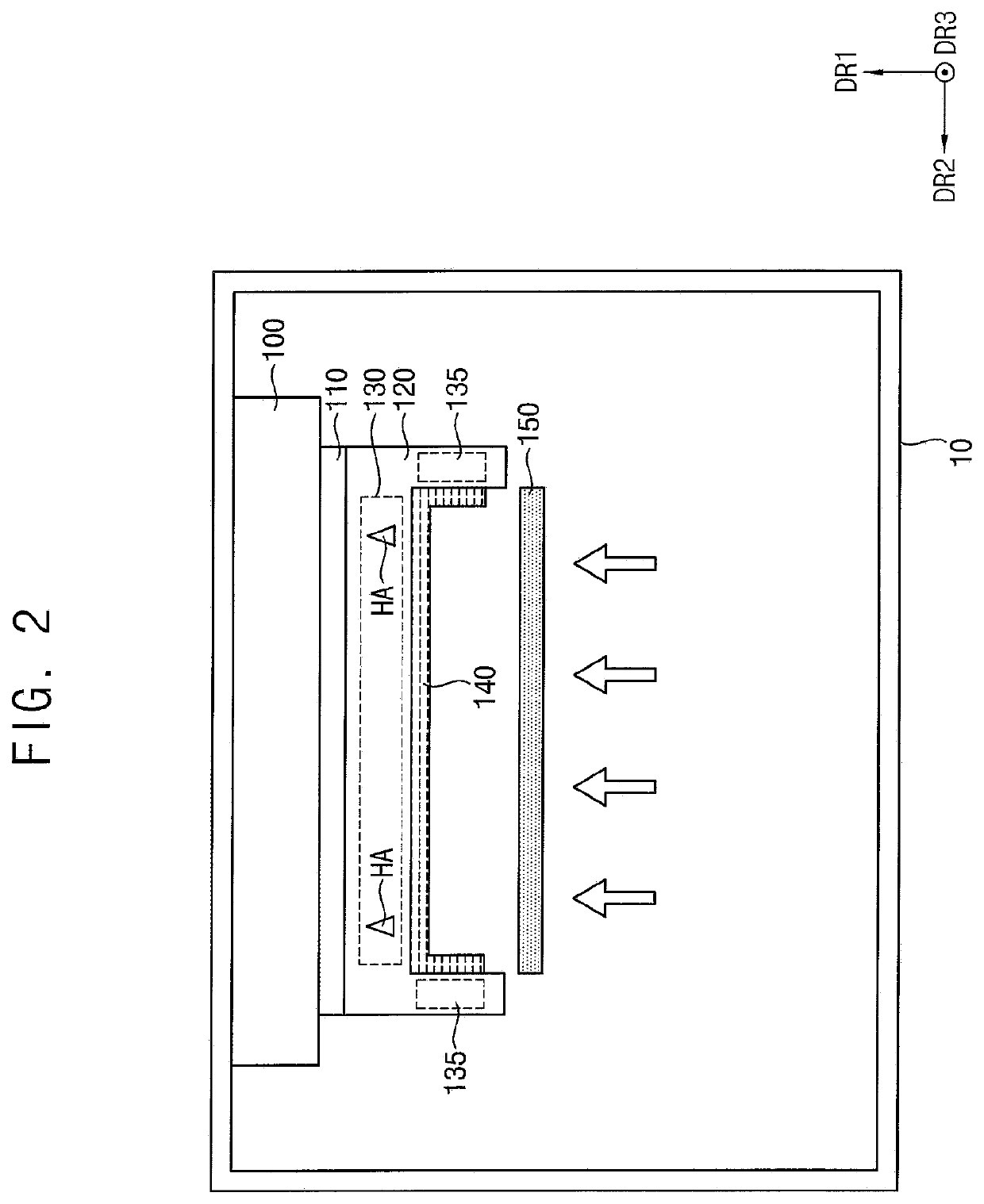

Liquid tank

ActiveUS20190061363A1Inhibition heightReduce the possibilityOther printing apparatusEngineeringAir bubble

Provided is a technique for reducing the likelihood of air bubbles flowing to a liquid ejection head, in a liquid tank mounted on a carriage. The liquid tank mounted on the carriage movable in a Y direction includes a liquid chamber, a liquid inlet port, an atmospheric air introduction portion, a liquid outlet, and a division wall arranged in the liquid chamber. The division wall has first division walls perpendicular to the Y direction in a mounted state on the carriage, and the liquid chamber includes a plurality of small liquid chambers partitioned by the first division walls, an upper communication portion allowing the small liquid chambers to be in communication with each other, and a lower communication portion positioned below the upper communication, and allowing the small liquid chambers to be in communication with each other.

Owner:SEIKO EPSON CORP

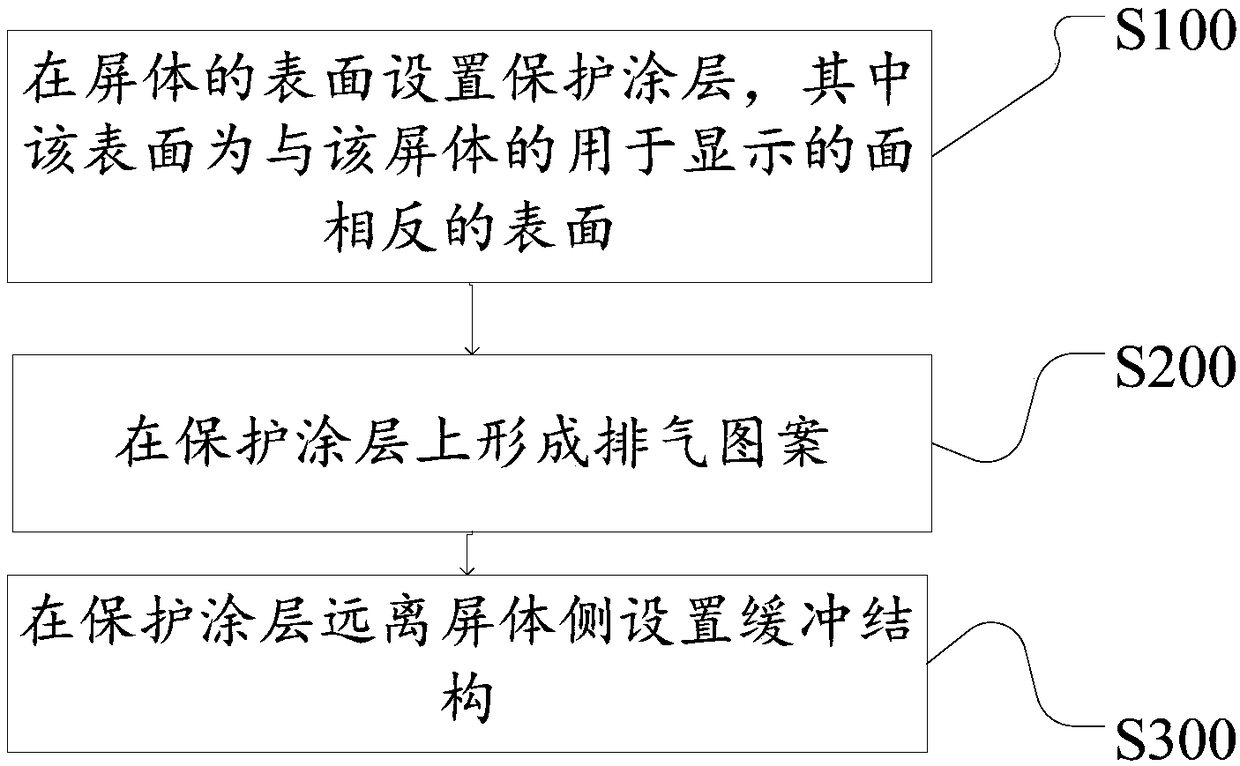

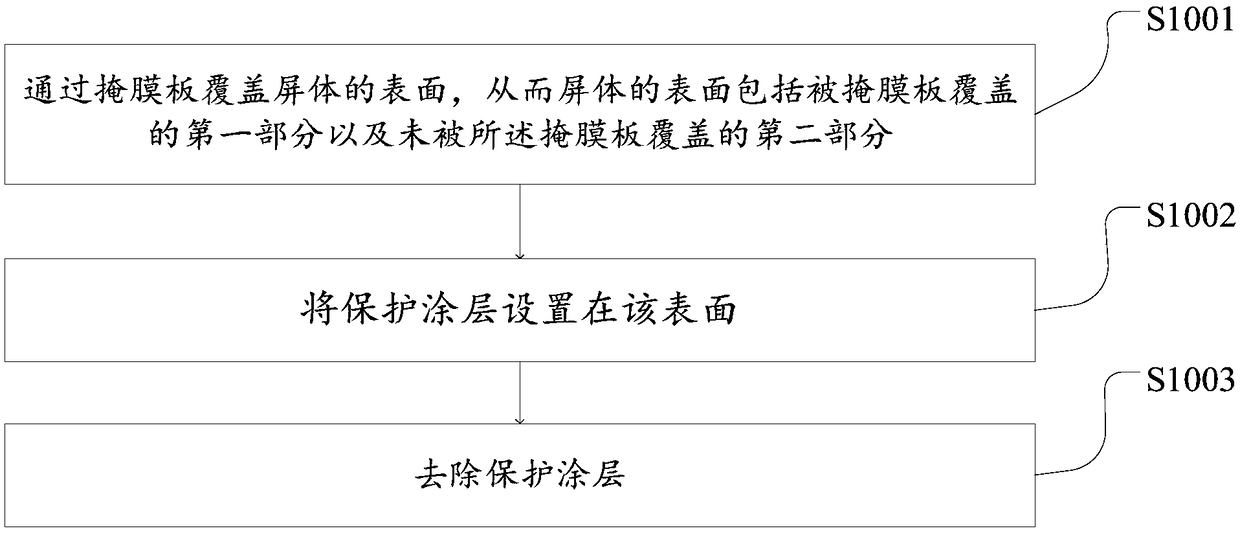

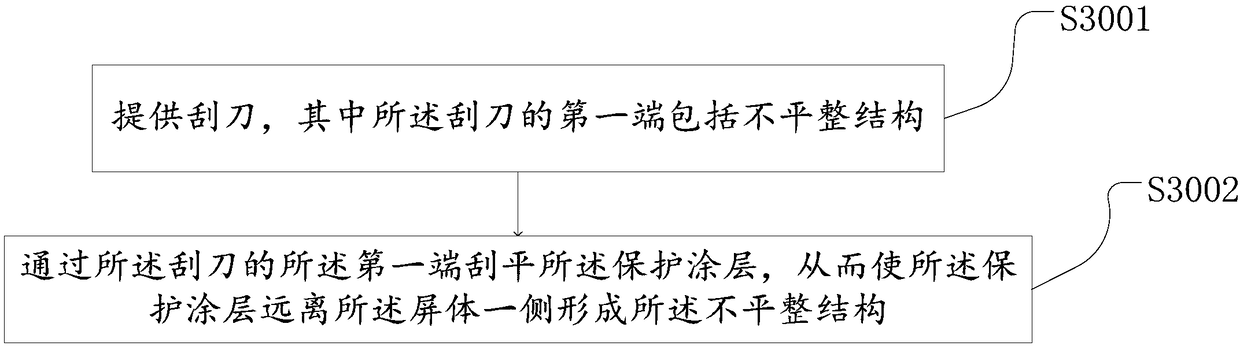

Screen body structure, display screen preparation method, display device and leveling device

ActiveCN108320673AReduce the generation of air bubblesImprove product performanceIdentification meansDisplay deviceCoating

The invention provides a screen body structure, a display screen preparation method, a display device and a leveling device. The screen body preparation method includes the steps of arranging a protection coating on the surface of a screen body, wherein the surface is opposite to the surface, used for display, of the screen body; forming an exhaust pattern on the protection coating; arranging a buffer structure on the side, away from the screen body, of the protection coating. According to the method, by forming the exhaust pattern on the protection coating, the exhaust effect of the screen body can be improved, and the display screen quality can be improved.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

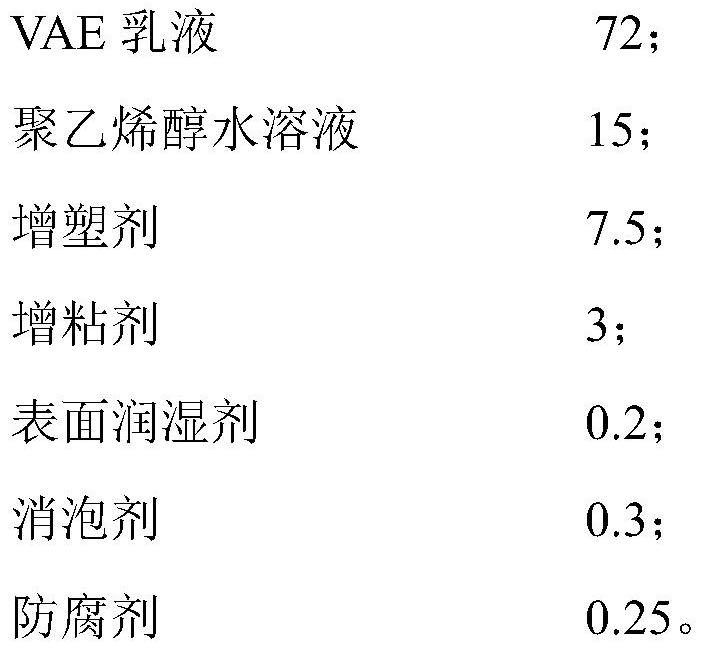

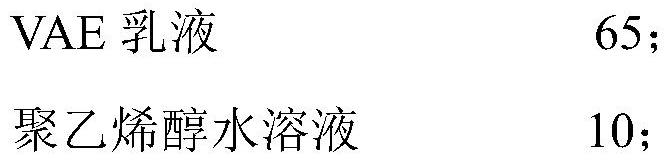

Wide-adaptability cigarette packaging adhesive and preparation method thereof

InactiveCN112574698AImprove initial tackReduce the generation of air bubblesUnsaturated alcohol polymer adhesivesEmulsionAntifoam agent

The invention discloses a wide-adaptability cigarette packaging adhesive and a preparation method thereof, and relates to the technical field of adhesives, and the packaging adhesive disclosed by theinvention comprises an antifoaming agent added into a VAE emulsion and a polyvinyl alcohol aqueous solution, a preservative and an auxiliary agent, wherein the auxiliary agent comprises the followingcomponents in parts by weight: 5-10 parts of a plasticizer, 0-5 parts of a tackifier, and 0.1-0.5 part of a surface wetting agent. According to the present invention, the components are respectively added to the VAE emulsion to carry out different stirring so as to obtain the wide-adaptability cigarette packaging adhesive. The preparation method is simple, the cost is low, the requirement on the material is low, and the excellent adhesion effect can be provided even for the packaging material with the small effective adhesion area; and particularly, the shutdown frequency and nozzle blockage in the cigarette production process are reduced, and the influence of temperature is not likely to happen.

Owner:北京长润化工有限公司

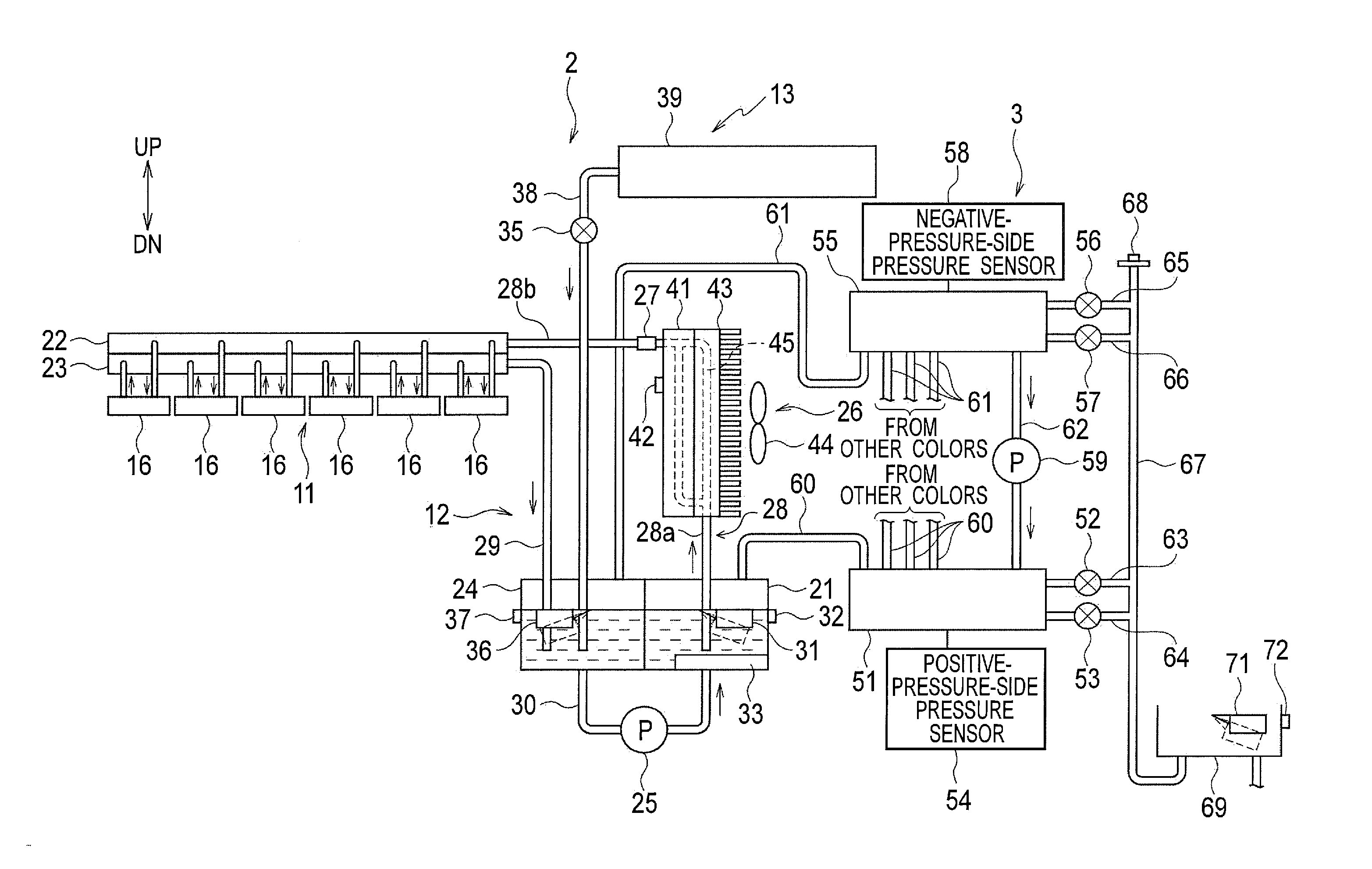

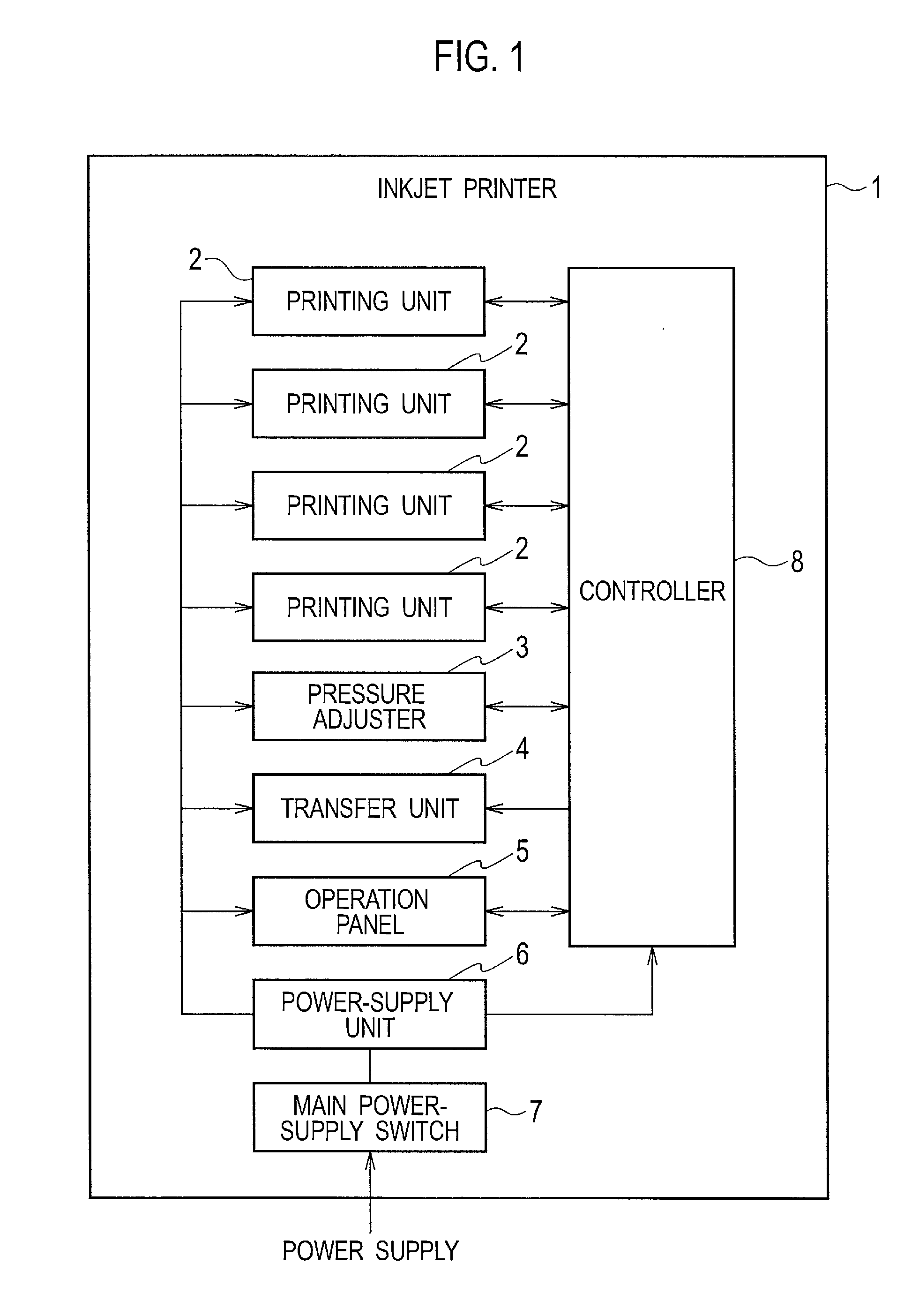

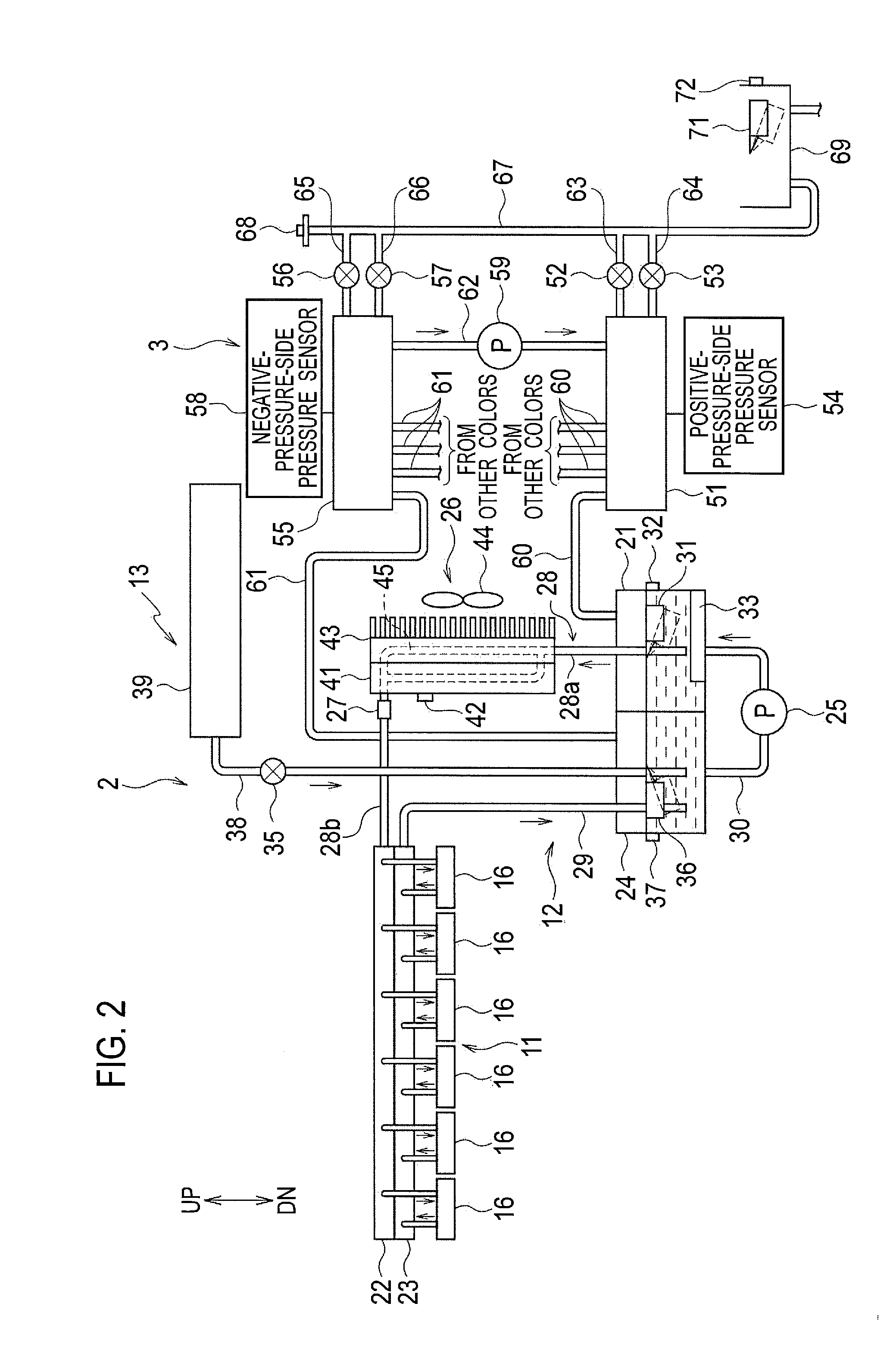

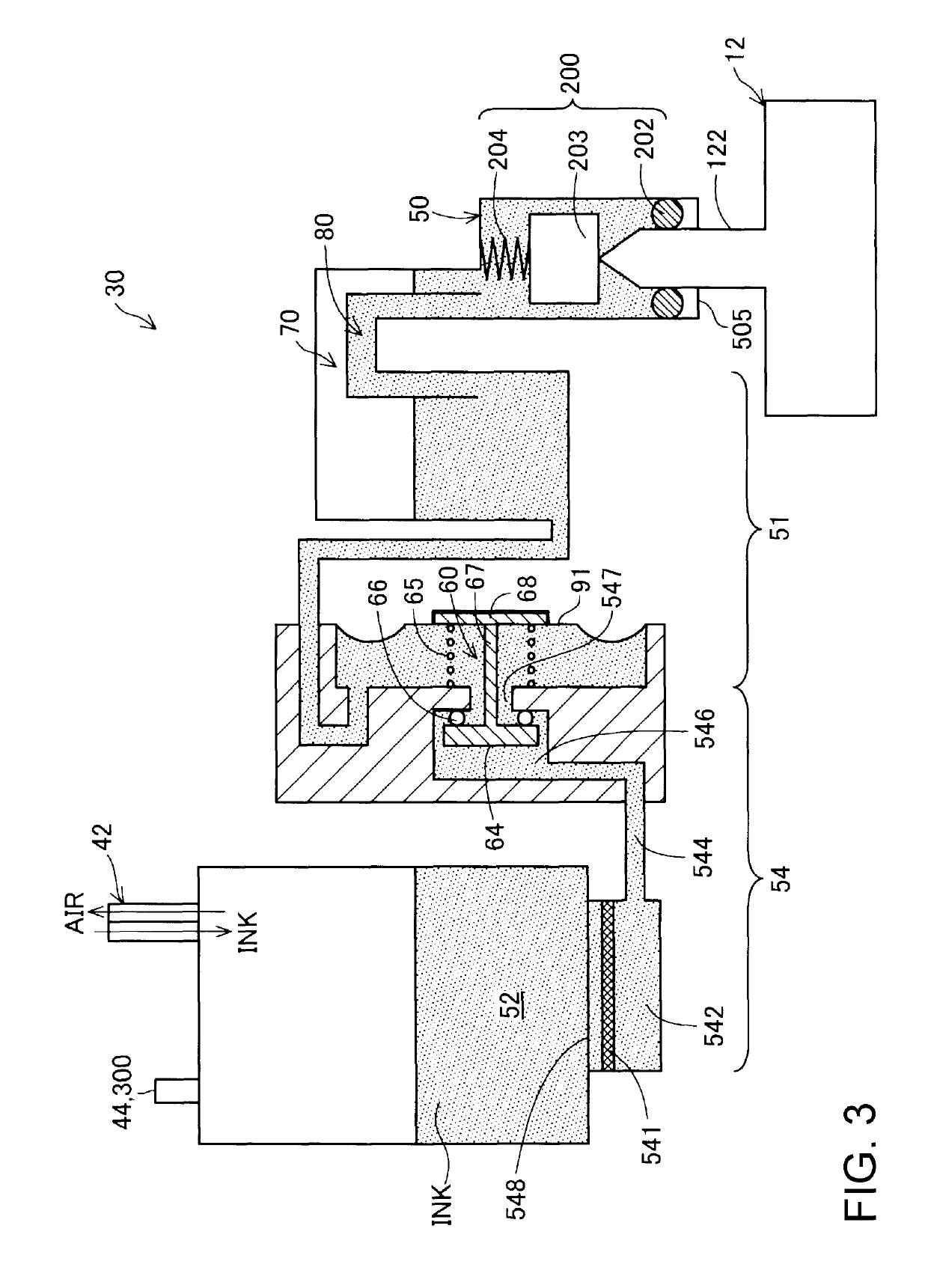

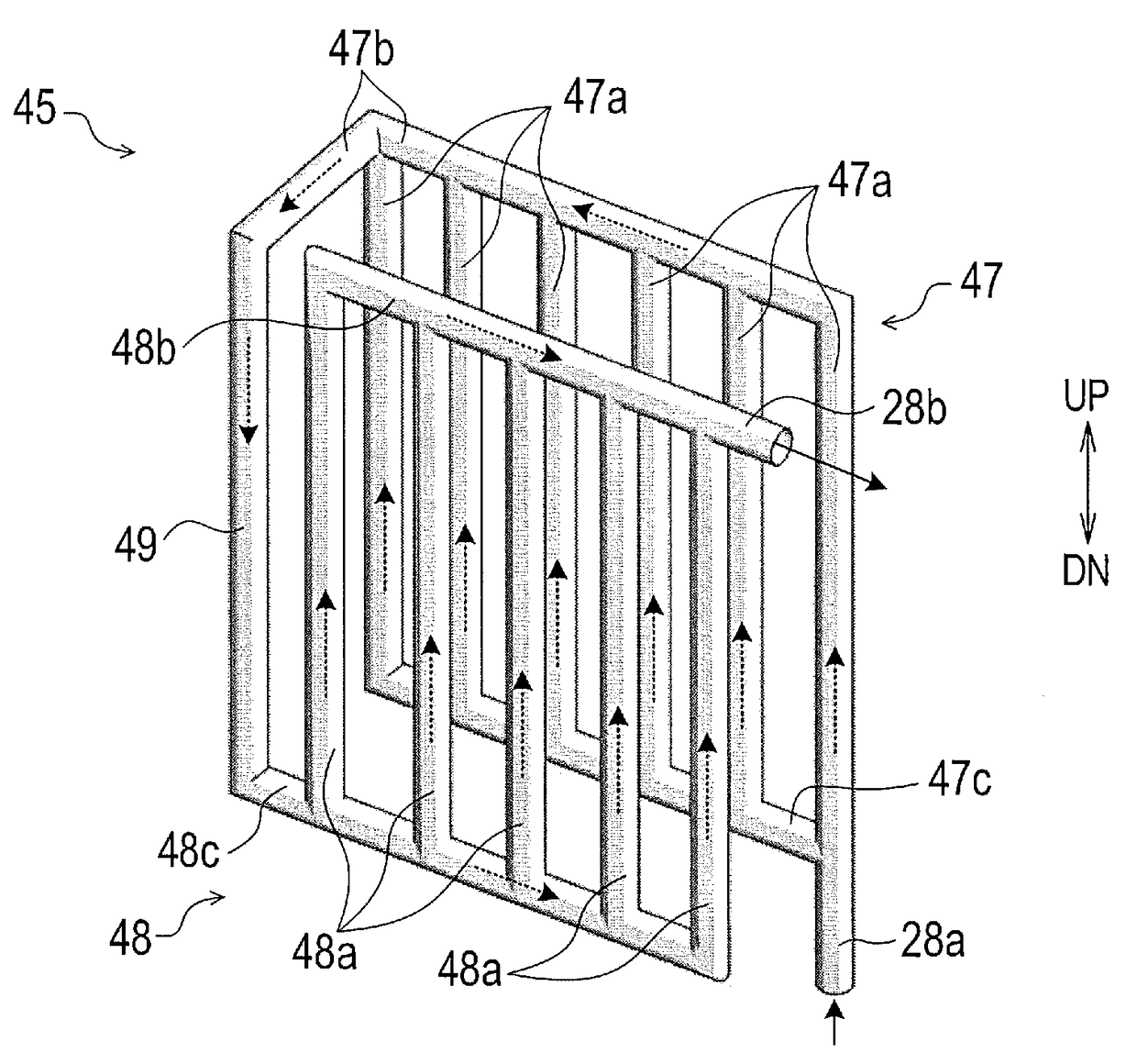

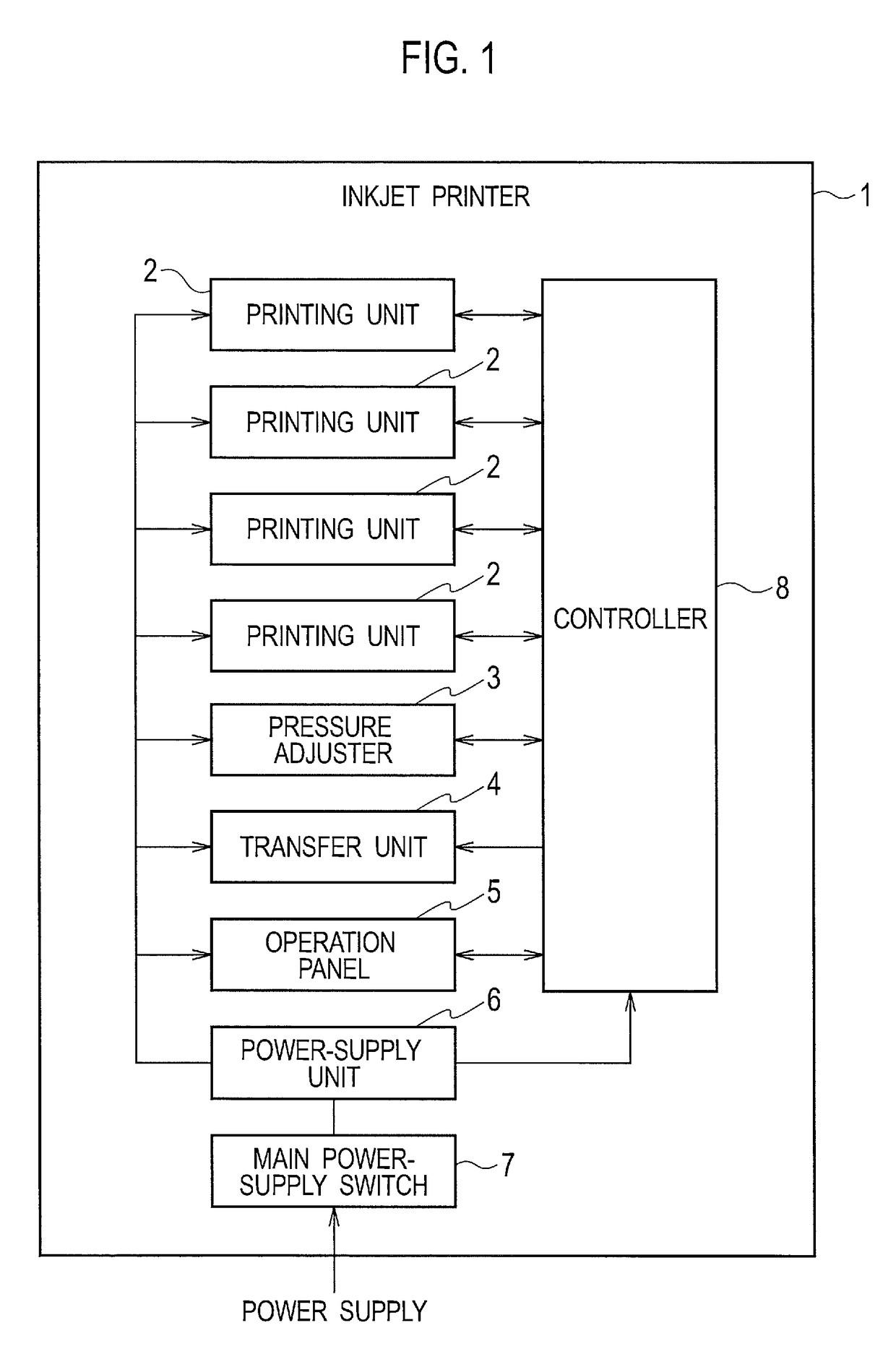

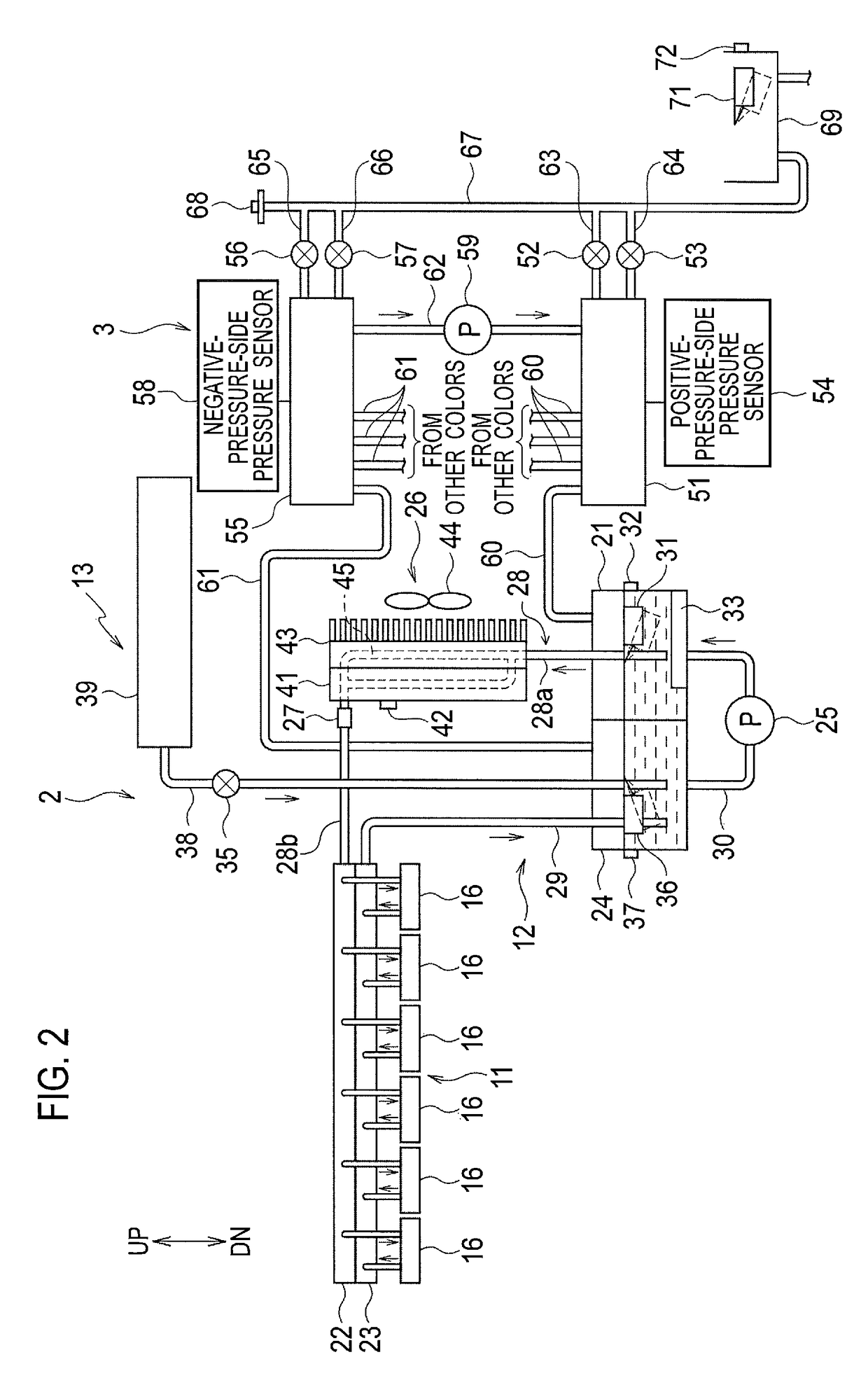

Ink temperature adjustment device and ink circulation type inkjet printer having the same

Owner:RISO KAGAKU CORP

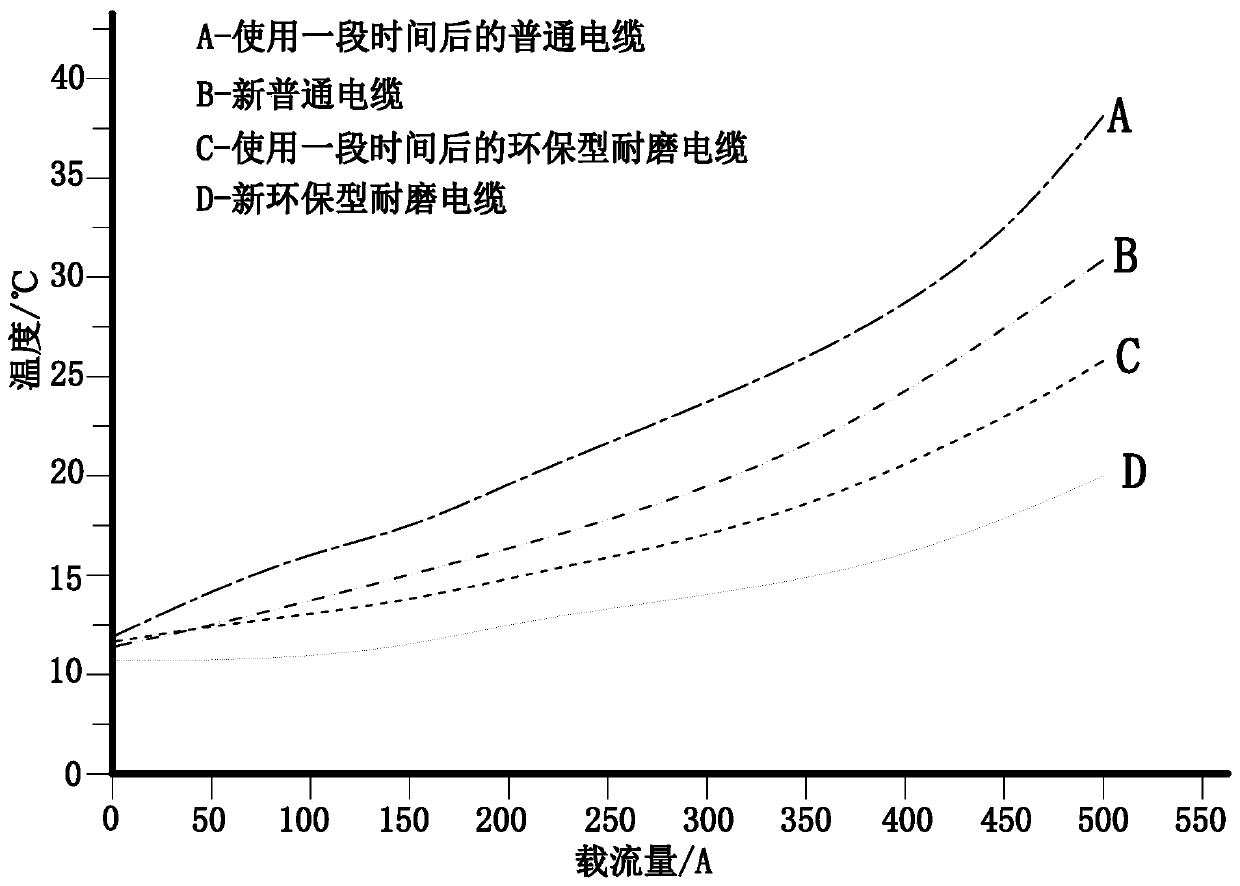

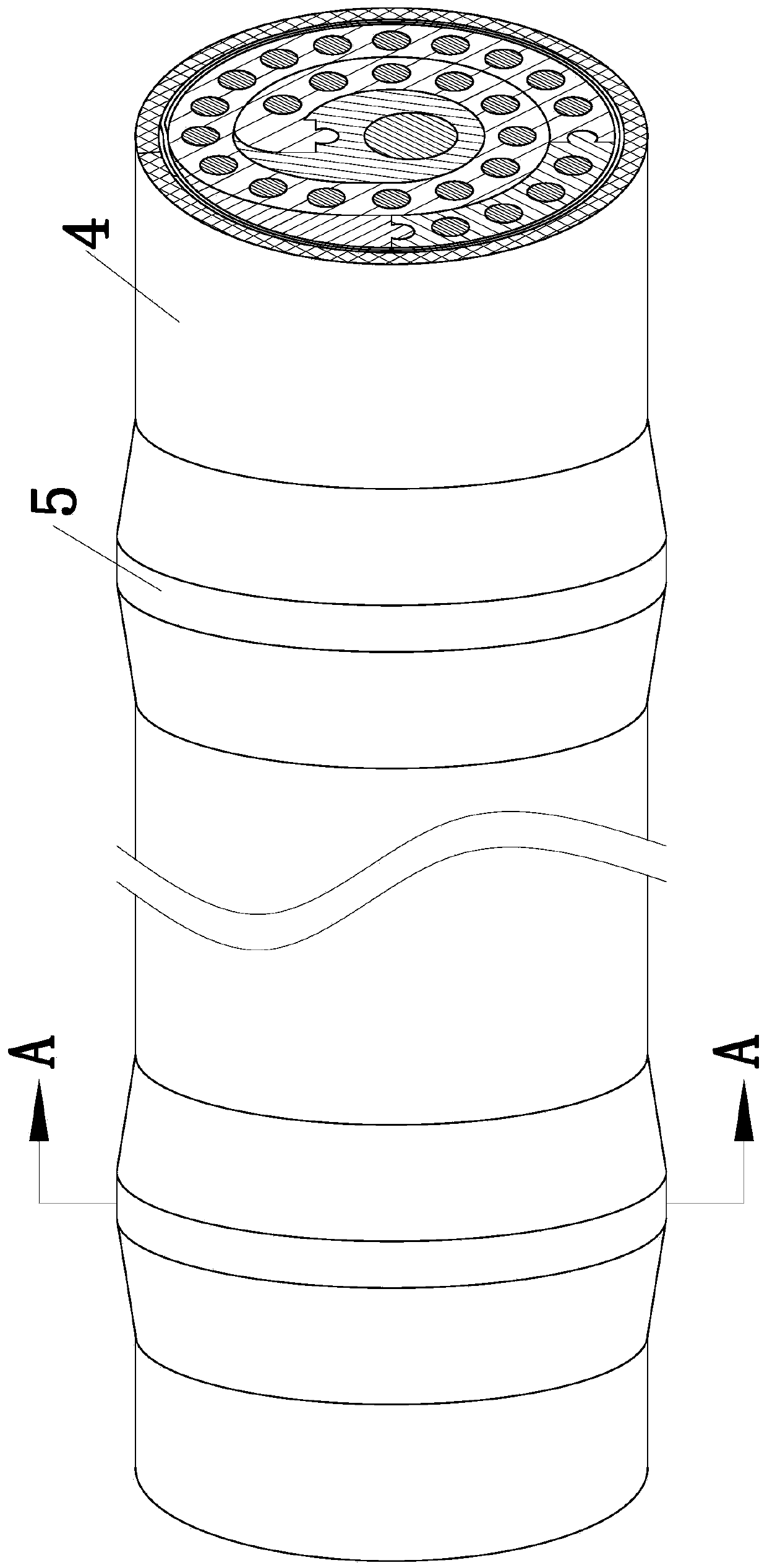

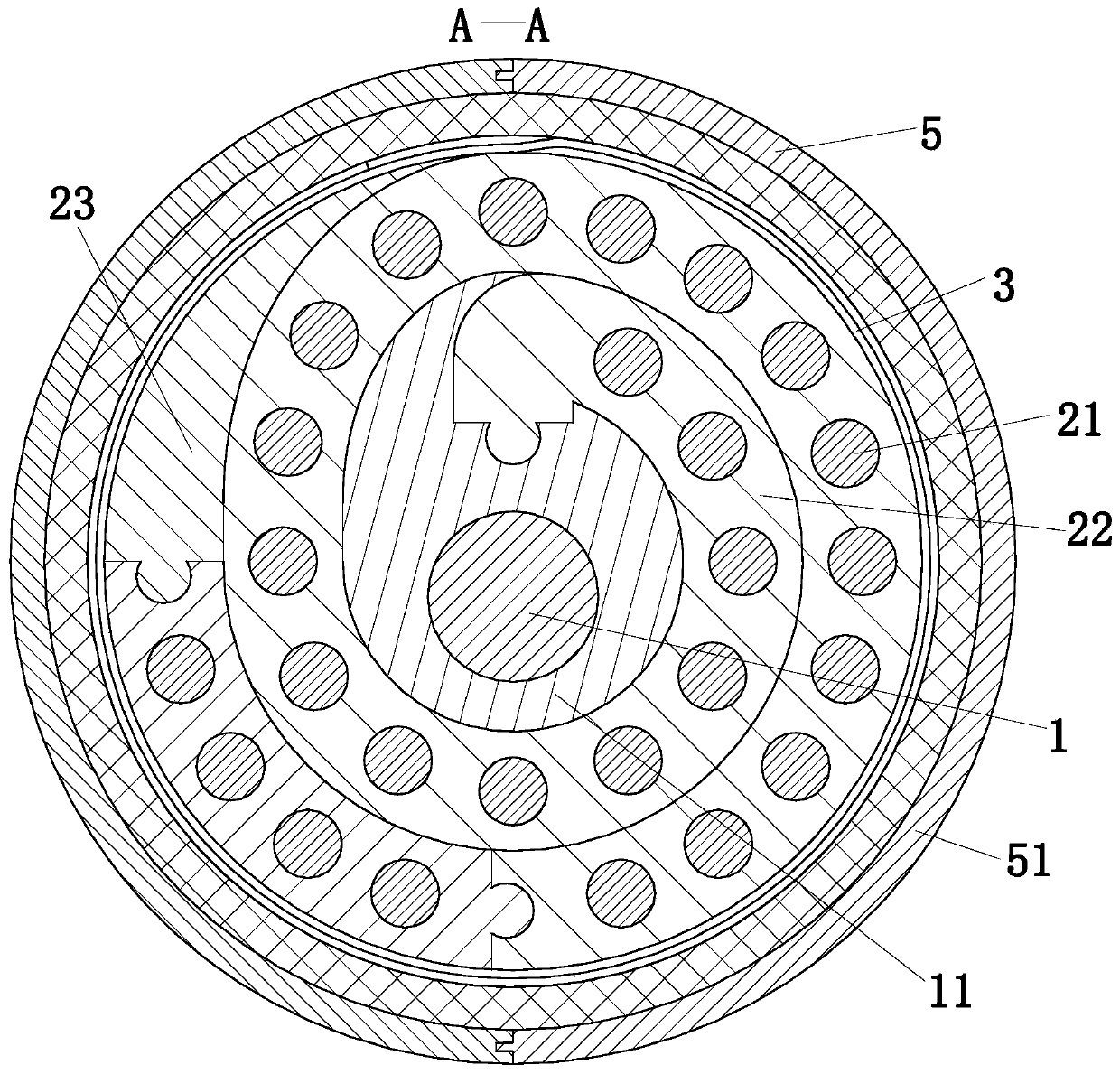

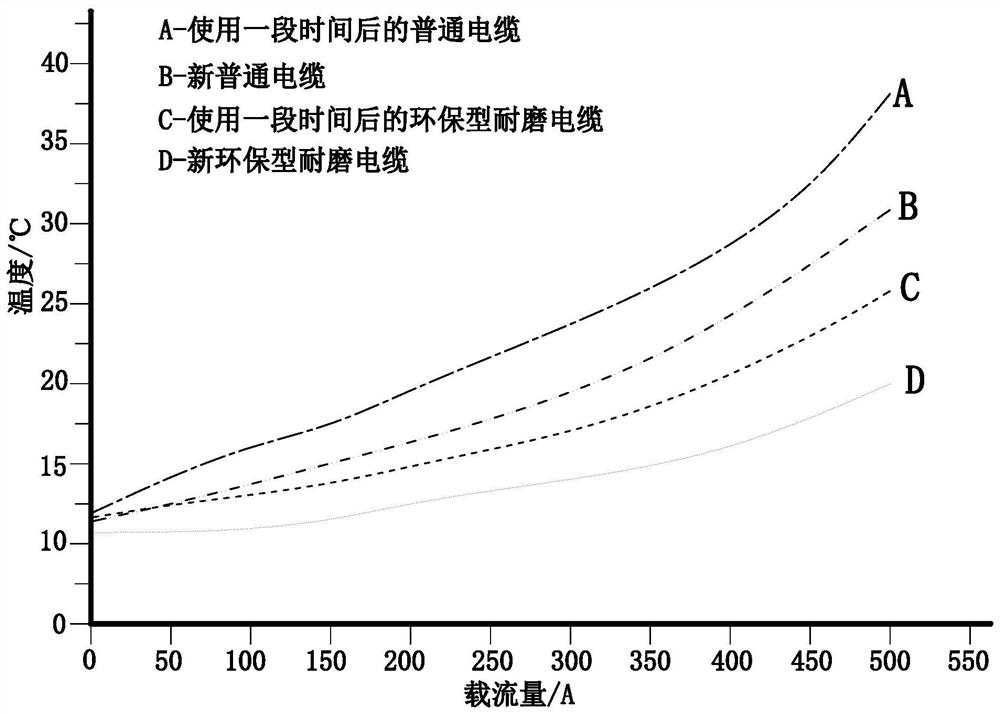

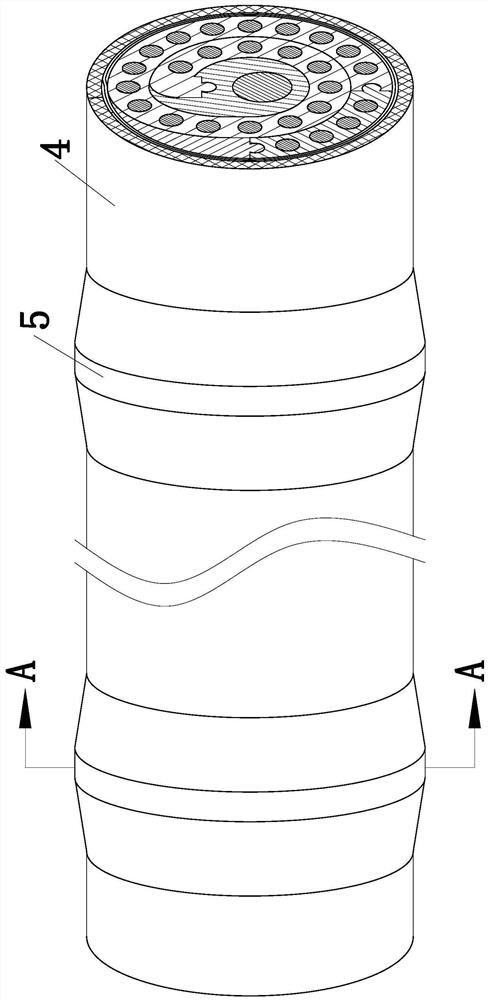

Environment-friendly wear-resistant cable

ActiveCN110591190AImprove heat resistanceImprove toughnessInsulated cablesCoatingsElectrical conductorWear resistant

The invention belongs to the technical field of cables, and particularly relates to an environment-friendly wear-resistant cable. The environment-friendly wear-resistant cable comprises a main conductor with a surface wrapped with a first insulating layer and comprises auxiliary conductors with surfaces wrapped with second insulating layers, wherein the adjacent auxiliary conductors are arranged in parallel and connected into a whole through the second insulating layers to form a flat wire group; one edge of the first insulating layer is provided with a concave part, and the concave part is located inside the first insulating layer; the outer side surface of the second insulating layer at one side surface of the wire group is provided with a convex part, and the convex part is matched withthe concave part of the first insulating layer; the wire group is annularly wound outside the main conductor and is fixed through gluing; a plurality of layers of wear-resistant waterproof cloth arewound outside the fixed wire group and are fixed through gluing; and the waterproof cloth is wrapped with a wear-resistant rubber layer. According to the production method of the environment-friendlywear-resistant cable, the wear-resistant and tear-resistant cable can be produced, and meanwhile, the cable can be used to solve the problem that the cable conductors cannot be distinguished when thenumber of the cable conductors is large.

Owner:阳谷鑫辉电缆有限公司

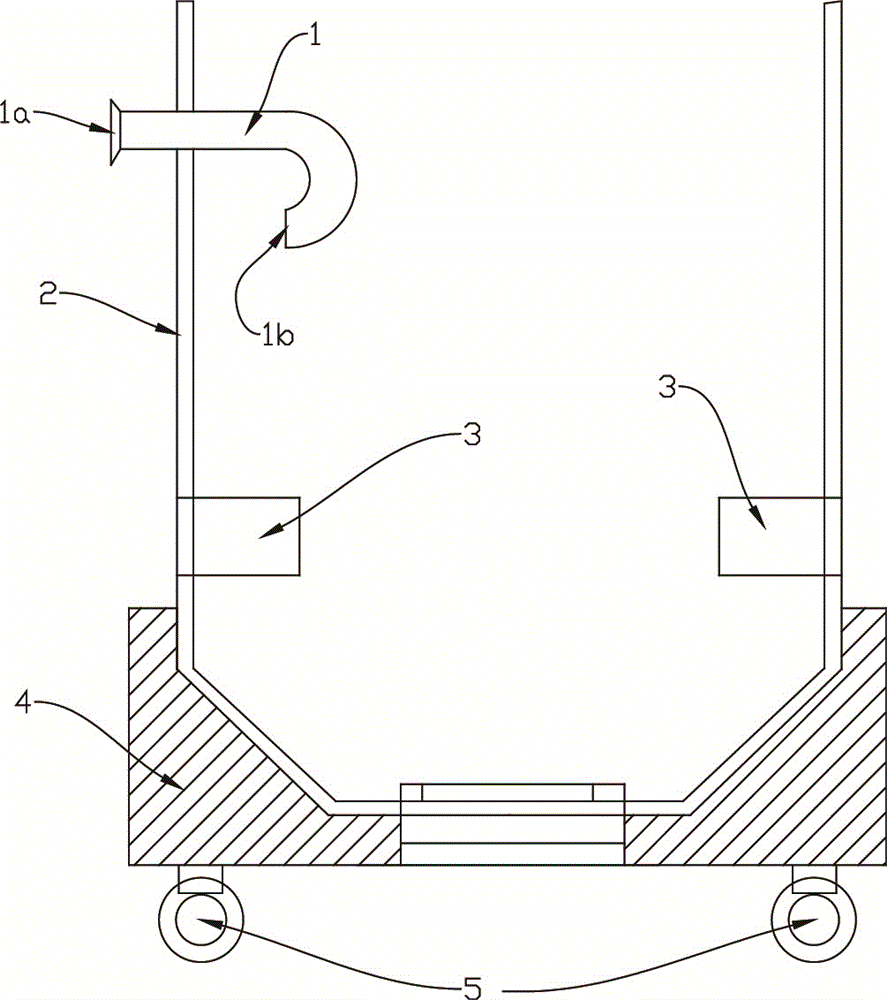

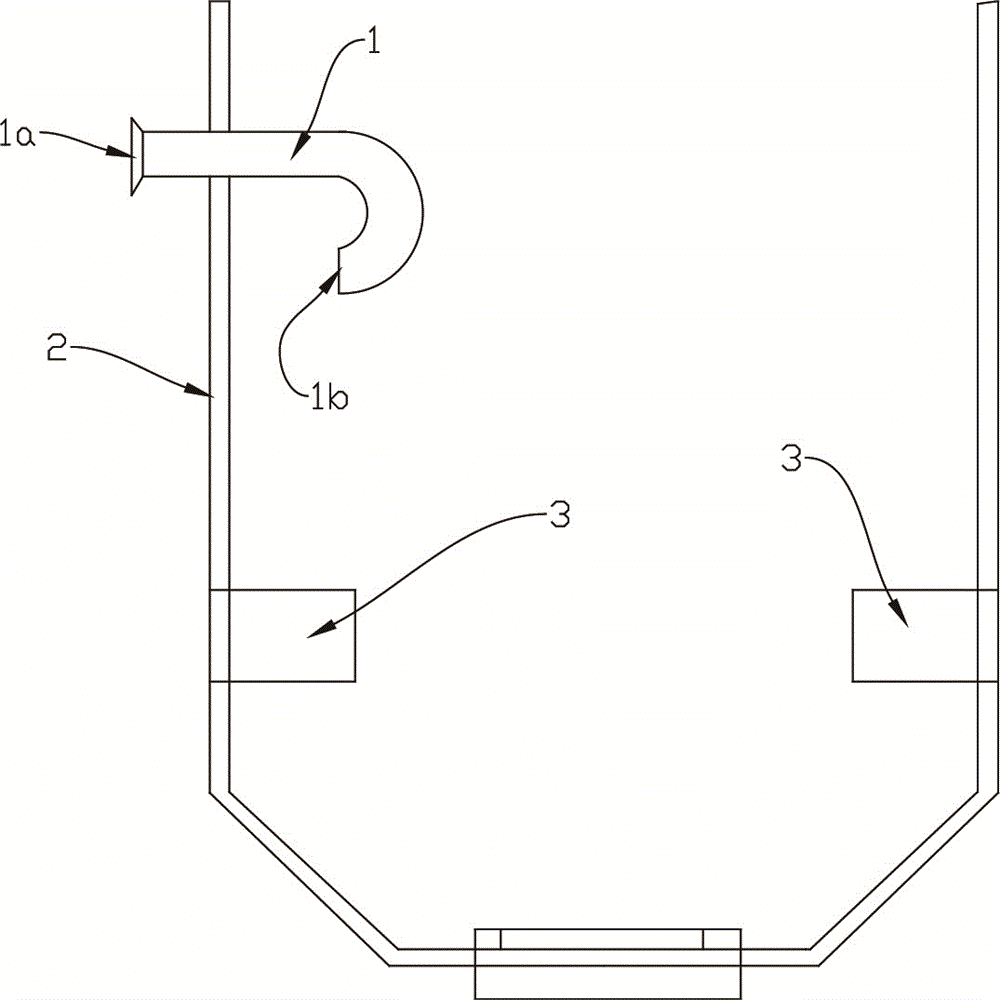

Improved bioreactor

InactiveCN105385565AReduce the generation of air bubblesEasy to moveBioreactor/fermenter combinationsBiological substance pretreatmentsCulture fluidBioreactor

An improved bioreactor comprises a tank body and a liquid adding pipeline. The liquid adding pipeline is fixed on the upper portion of the tank body, a liquid inlet of the liquid adding pipeline stretches out of the tank body, and a liquid outlet of the liquid adding pipeline is located in the tank body and faces the inner wall of the tank body; two heating modules are symmetrically arranged in the tank body, the tank body is arranged in a base, and the lower portion of the base is provided with wheels. According to the improved bioreactor, culture liquid can flow to the bottom of the tank body along the inner wall of the tank body when the liquid is added, and therefore bubble generation is effectively reduced; in addition, moving is convenient.

Owner:NINGBO DINGYUAN SOFTWARE TECH CO LTD

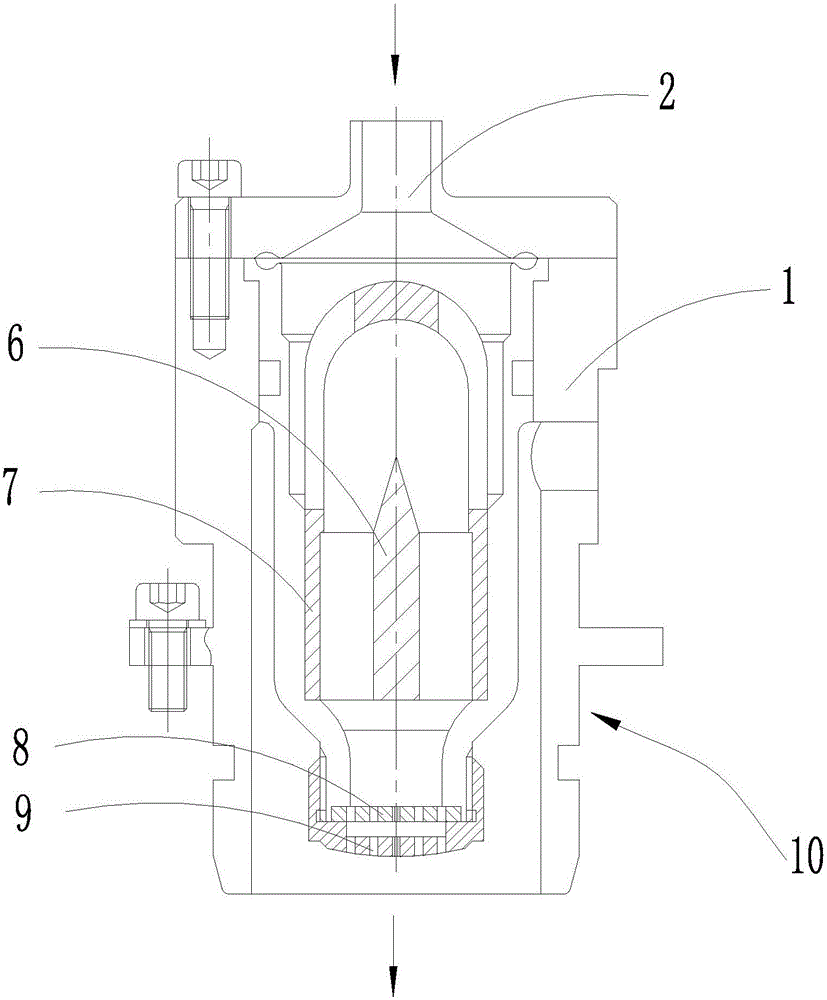

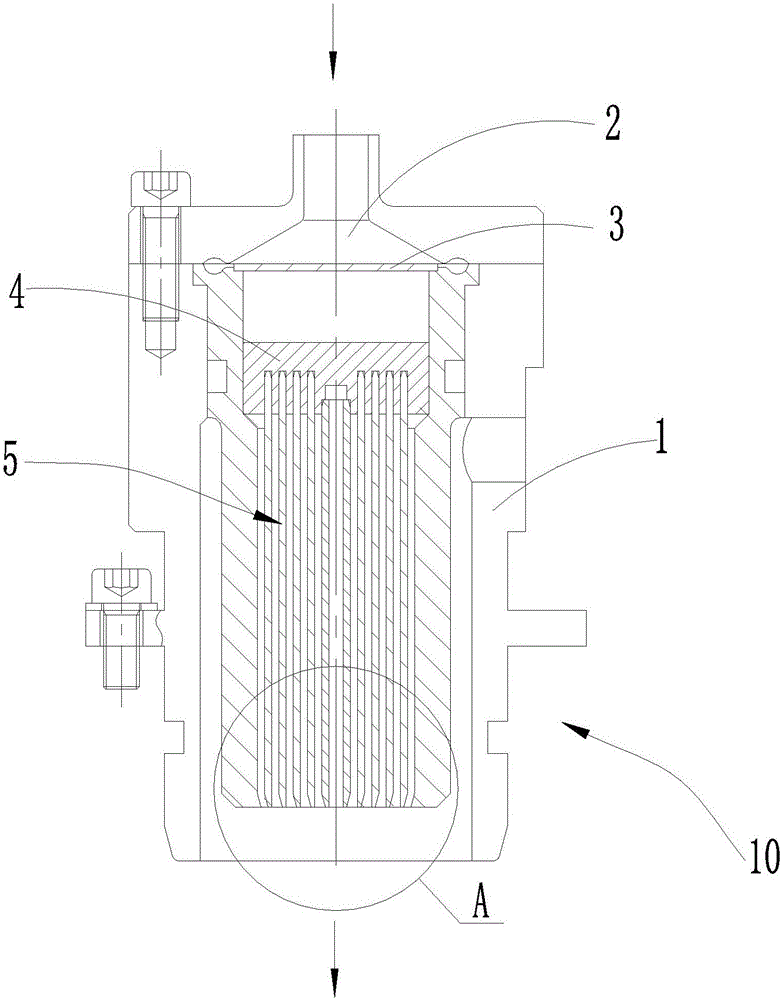

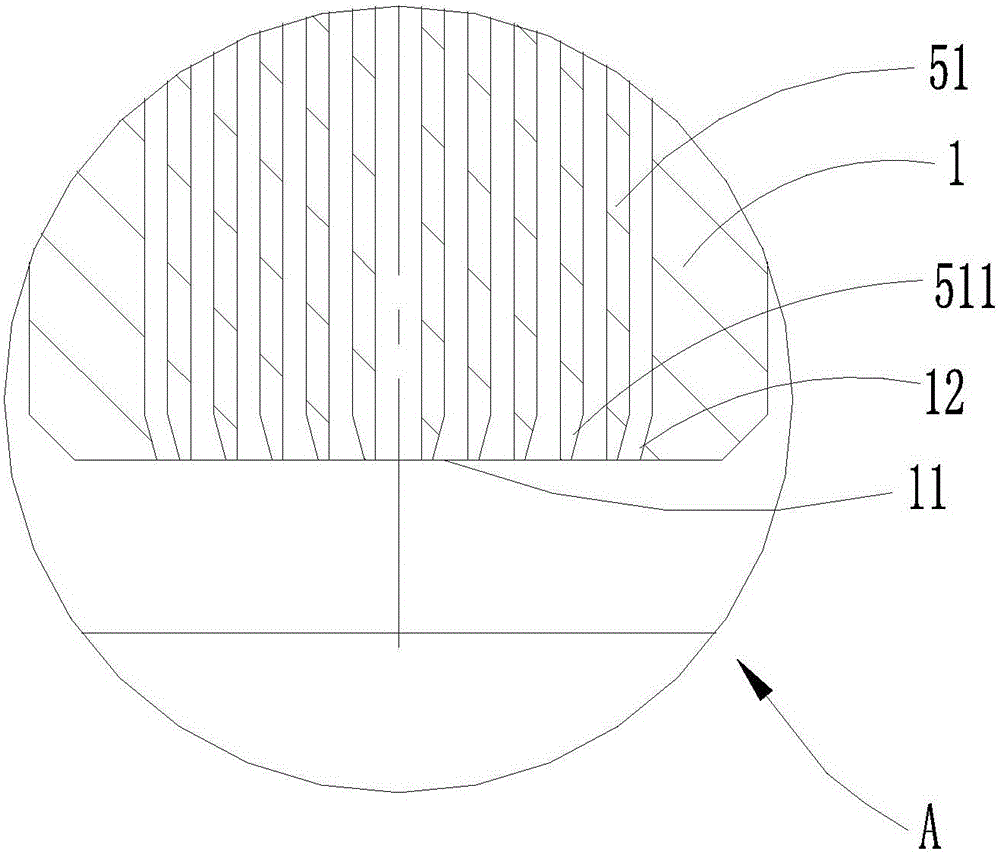

Novel sterile filling valve

InactiveCN104986710AReduce the generation of air bubblesPrevent splashLiquid bottlingPhysicsEngineering

The invention discloses a novel sterile filling valve. The novel sterile filling valve comprises a valve body with an inner cavity, a feeding pipe arranged at the upper end of the valve body and communicated with the inner cavity of the valve body and a discharging port formed in the bottom of the valve body, and the filling valve further comprises a splitter plate arranged in the inner cavity of the valve body, a valve core located below the splitter plate and a support located between the splitter plate and the valve core, wherein splitter holes are formed in the splitter plate, and the support is used for allowing the valve core to be installed therein, the valve core comprises a plurality of guide cylinders with different diameters, the guide cylinders are arrayed in the radial direction, reverse foot portions are arranged at the bottom ends of the side walls of parts of all the guide cylinders including the guide cylinder at the outermost side, and the diameters of the reverse foot portions decrease gradually in the direction close to the discharging direction of the discharging port. The novel sterile filling valve has the advantages that the structure is simple, the machining required precision is low, the production cost is low, through the arrangement of the reverse foot portions, the liquid flowing out from the discharging port is more regular and centralized, and liquid splashing and the occurrence of foams are effectively avoided.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

Manufacturing method and clamping tool of a combined magnet with low eddy current heating

ActiveCN110942908BPlay a binding roleImprove bindingInductances/transformers/magnets manufactureEngineeringLaboratory oven

Owner:FUJIAN CHANGTING GOLDEN DRAGON RARE EARTH CO LTD

Preparation method of sodium hexametaphosphate detergent

PendingCN112980610AReduce the generation of air bubblesPrevent material failureInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium phosphatesBenzenesulfinic acid

The invention discloses a sodium hexametaphosphate detergent preparation method, which comprises: 1, stirring sodium hexametaphosphate, Tween and sodium sulfonate to obtain a system A; 2, adding isopropylamine benzenesulfonate into the system A, and stirring to obtain a system B; 3, stirring betaine, phenoxyethanol and methylisothiazolinone to react for 2-5 h at the temperature of 30-60 DEG C to obtain a system C; 4, mixing the system B and the system C to obtain a mixture, and adding deionized water into the mixture under a stirring condition; and 5, cooling and sub-packaging to obtain the sodium hexametaphosphate detergent. According to the preparation method of the detergent, the material A and the material B are prepared respectively, generation of bubbles in the preparation process can be effectively reduced, material failure is prevented, sodium hexametaphosphate serves as a main component, grease residues can be effectively removed through the adsorption performance of sodium hexametaphosphate, and the detergent has the effects of efficient decontamination, bacteriostasis and sterilization and the like.

Owner:梁景辉

An environment-friendly wear-resistant cable

ActiveCN110591190BWith wear resistanceStable structureInsulated cablesCoatingsElectrical conductorStructural engineering

The invention belongs to the technical field of electric cables, and is specifically an environment-friendly wear-resistant cable, which includes a main conductor whose surface is wrapped with a No. 1 insulating layer, and a secondary conductor whose surface is wrapped with a No. 2 insulating layer. Arranged and connected through the second insulating layer to form a flat wire group; one edge of the first insulating layer is provided with a concave part, and the concave part is located inside the first insulating layer; the outer side of the second insulating layer on one side of the wire group is set There is a convex part, and the convex part is suitable for the concave part of the No. 1 insulating layer; the wire group is wrapped around the outside of the main conductor and solidified by gluing; the outer side of the solid wire group is wrapped with multi-layer wear-resistant waterproof cloth and It is solidified by gluing; the waterproof cloth is wrapped with a wear-resistant rubber layer; the present invention can produce cables with wear resistance and tear resistance through the production method of environmentally friendly wear-resistant cables. The problem of indistinguishability when the number of conductors is large.

Owner:阳谷鑫辉电缆有限公司

FFC slurry for ceramic production

The invention relates to the technical field of manufacturing of sanitary ceramics, in particular to FFC slurry for ceramic production, which is specifically applied to large basin type water tank products. On the basis of the original imported FFC mud raw material, other mud materials are added, and the technical key points are as follows: the raw material dry material comprises the following components: 8%-11% of imported FFC-A material, 6%-12% of imported FFC clinker, 55%-61% of kaolin 1 # material, 10%-15% of kaolin 2 # material and 12%-14% of quartz. The FFC slurry provided by the invention retains the advantages of low buckling deformation rate, low shrinkage rate and good regularity of the original FFC ceramic, reduces the risks of wind frightening and glaze defects, and greatly reduces the production cost.

Owner:TANGSHAN MONOPY CERAMIC

Lamination apparatus

ActiveUS20220009214A1Reduce decreaseReduce the generation of air bubblesLaminationLamination apparatusEngineeringMechanical engineering

Owner:SAMSUNG DISPLAY CO LTD

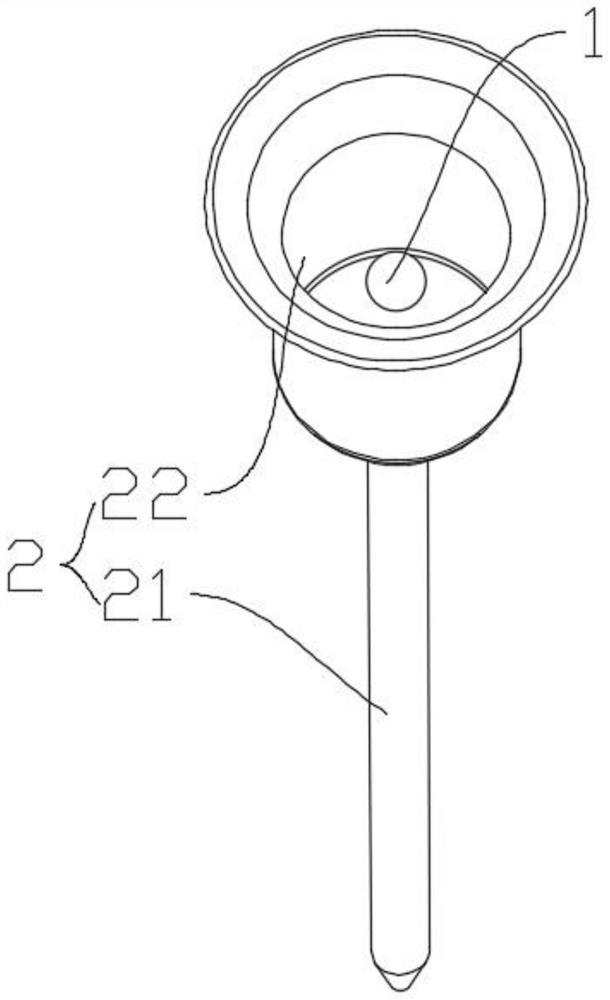

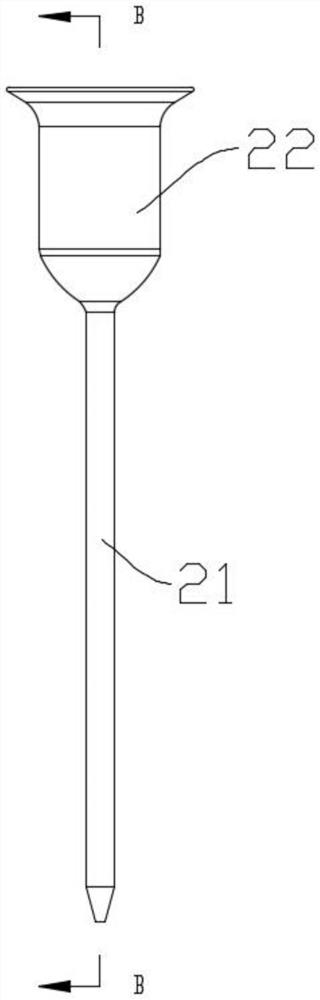

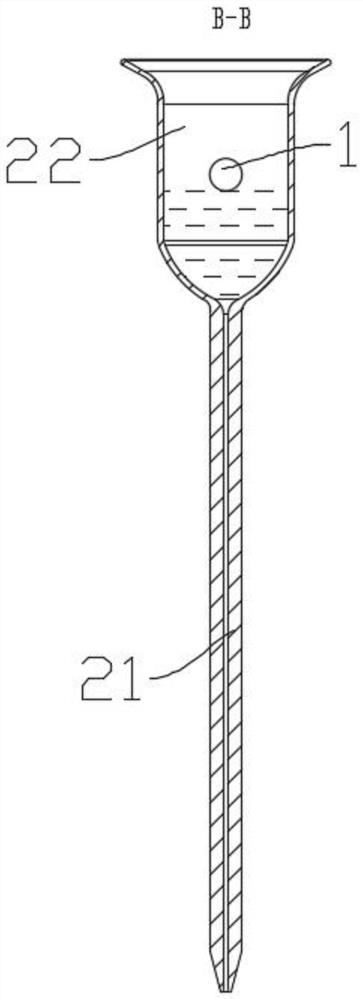

Thorn tube and method for eliminating bubbles in thistle tube of thistle tube type ferrograph

PendingCN114371105AReasonable structureReduce the generation of air bubblesMaterial analysisEngineeringMechanical engineering

The invention discloses a thistle tube and a method for eliminating bubbles in the thistle tube of a thistle tube type ferrograph, the thistle tube comprises a thistle type glass tube, the thistle type glass tube comprises a funnel and a conduit which are communicated with each other, a suspension part is movably arranged in the funnel, the density of the suspension part is not greater than the density of an oil sample and a cleaning agent, and the suspension part is hermetically matched with an inlet of the conduit. The thistle pipe and the method for eliminating the bubbles in the thistle pipe type ferrograph are reasonable, the suspension part changes along with the liquid level of the oil sample, when the oil sample in the funnel flows out, the suspension part blocks the inlet of the guide pipe, and the flow speed of oil in the guide pipe is reduced, so that the bubbles in the oil can be effectively reduced.

Owner:中国核工业电机运行技术开发有限公司

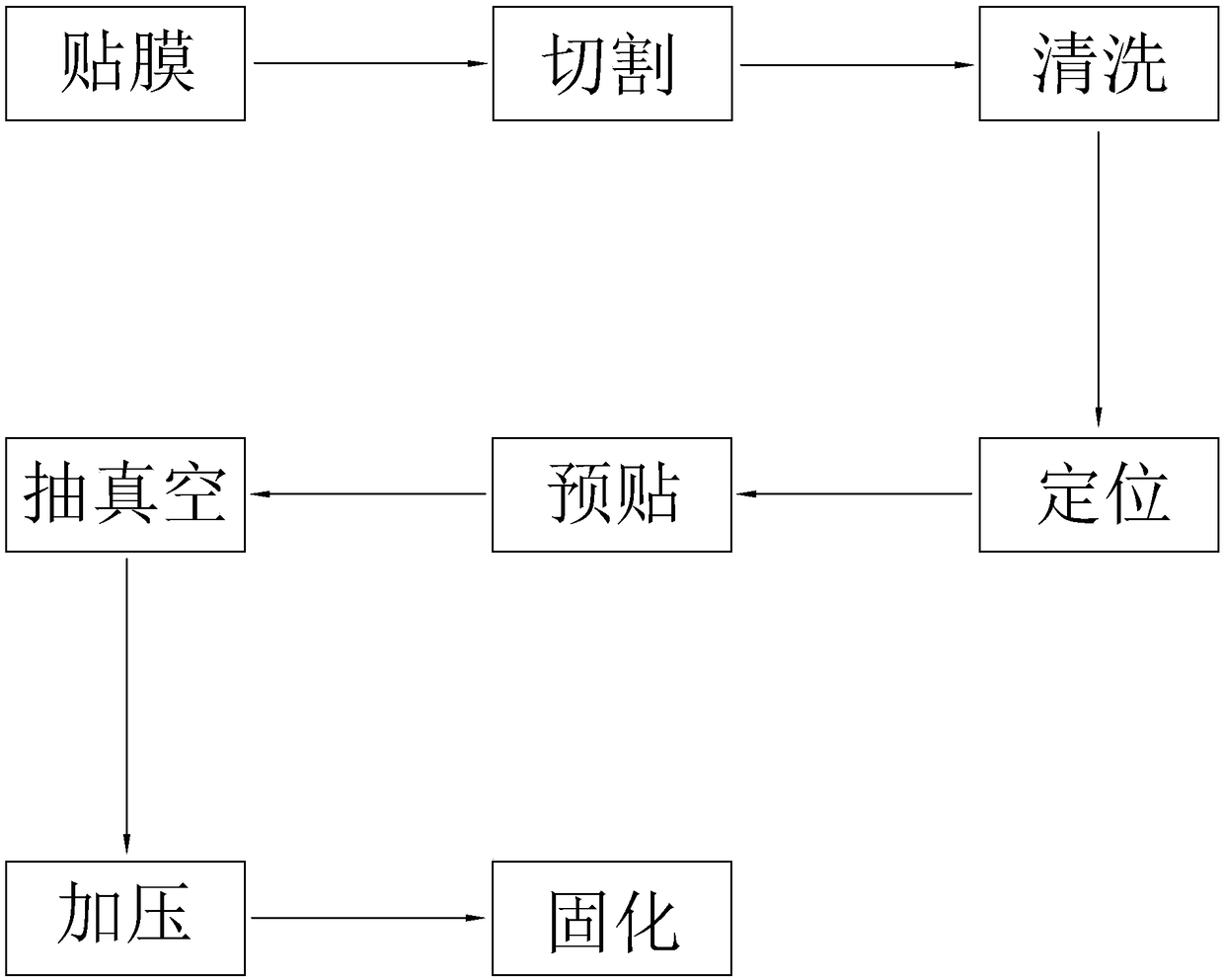

Film attachment method and system

InactiveCN108859087AReduce the generation of air bubblesReduce dents or damageOptical articlesDomestic articlesFilm materialAdhesive

The invention discloses a film attachment method and system. The film attachment method comprises the steps of conducting locating and attachment on a substrate and a film material, so that an attachment combined body is obtained; conducting predetermined-position heating on the attachment combined body at the side, opposite to the substrate, of the film material, so that the attachment combined body is bonded at a predetermined position; and aligning the substrate with the film material, then, attaching the film material to the substrate, and locally heating the film material. Due to the factthat an attachment face of the film material is provided with a hot melting adhesive film, adhesive is generated after the attachment face is heated, and thus, the film material can be bonded to thesubstrate at the heated position; and the film material can be preliminarily fixed to the substrate conveniently. Compared with the existing mode that a film material is extruded and fixed to a substrate in all directions, air bubbles generated between the film material and the substrate are reduced; meanwhile, the problem that the pressing marks are generated or the film material is damaged in the mechanical extruding process is reduced; positional information of the film material and positional information of the substrate are collected separately, so that locating precision is high, and thelocation dimension is highly unified and stable; and product quality is guaranteed, and the production cost is lowered.

Owner:三得应用材料(深圳)有限公司

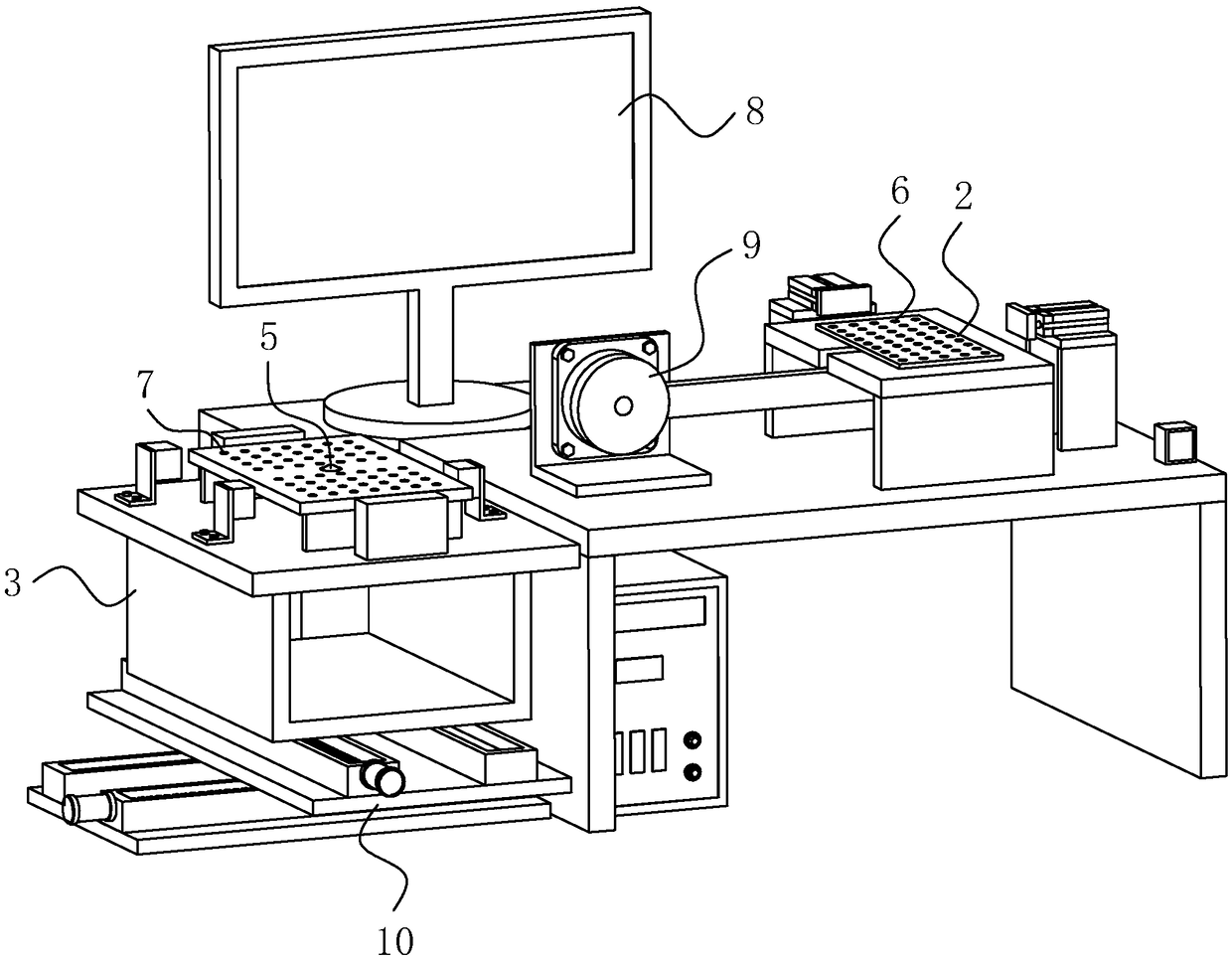

Resin adhesive tape casting film forming method

ActiveCN109352887AReduce the generation of air bubblesReduce generationFlat articlesCoatingsEngineeringAir bubble

The invention discloses a resin adhesive tape casting film forming method, and relates to the technical field of epoxy resin film production processes for chip packaging. The method solves the problemthat an existing epoxy resin-based adhesive is high in operation difficulty when an epoxy resin film is manufactured, and an air hole is easily formed in the formed resin film. The method comprises the following steps of 1), selecting the epoxy resin-based adhesive with the coefficient of thermal expansion being 20-80 (10 < -6 > / DEG C) as raw mateiral, and storing the raw material in a temperature environment of -40 DEG C or below for later use; 2), taking out the epoxy resin-based adhesive, and unfreezing the epoxy resin-based adhesive in a normal-temperature environment until the epoxy resin-based adhesive returns to a normal flow state; 3 ) guiding the epoxy resin-based adhesive into a knife edge of a tape casting machine from one direction to prevent too much air from being brought into the raw material, and discharging excess air after the epoxy resin-based adhesive fully fills the knife edge and placed to stand, wherein the length of the standing time is proper when the epoxy resin-based adhesive does not flow out of the knife edge. Redundant air is discharged, the generation of bubbles in the casting process is reduced, and the resin film with the uniform thickness is prepared.

Owner:SHENZHEN MICROGATE TECH

Working fluid injection apparatus for a fluid dynamic pressure bearing

InactiveUS7905019B2Simple and easy stepReduce the generation of air bubblesProportioning devicesBearing componentsWorking fluidEngineering

A working fluid injection apparatus for injecting a working fluid into a gap between a housing and a shaft of a bearing unit of a fluid dynamic pressure bearing. The apparatus has an adapter configured to support the bearing unit in a state in which an end portion of the shaft protrudes from an open portion of the housing. A cover member has an upper opening, a lower opening, and a tapered inner surface with a radial dimension that increases gradually from the lower opening to the upper opening. The cover member is configured to be mounted in contact with an upper surface of the housing when the bearing unit is supported by the adapter so that the lower opening of the cover member surrounds the open portion of the housing and so that the protruding end portion of the shaft and the tapered inner surface of the cover member form a reservoir portion that communicates with the open portion of the housing and that is configured to store a working fluid.

Owner:SEIKO INSTR INC

Anticorrosion sound-insulating glass fiber and preparation method thereof

InactiveCN108585448AImprove corrosion resistanceImprove sound insulationGlass shaping apparatusStrontium carbonateGlass fiber

The invention provides an anticorrosion sound-insulating glass fiber and a preparation method thereof and relates to the technical field of glass preparation. The anticorrosion sound-insulating glassfiber is made from nano silicon dioxide, quartz sand, strontium carbonate, aluminum oxide, kaolin, sodium phosphate, potassium oxide, barium oxide, cobalt oxide, manganese dioxide, and anhydrous ethylalcohol. Glass products made with the anticorrosion sound-insulating glass fiber have good corrosion resistance and sound-insulating effect, and can effectively prevent noise pollution; all the materials used are existing low-cost materials in the market so that the manufacture cost is low; the preparation method is simple and easy to perform; quartz sand added herein has good sound-insulating property so that the sound-sounding effect is significant.

Owner:天长市天意玻璃制品有限公司

Lamination apparatus

ActiveUS11485123B2Reduce the generation of air bubblesMinimize and reduce generation of air bubbleLaminationLamination apparatusEngineeringMechanical engineering

Owner:SAMSUNG DISPLAY CO LTD

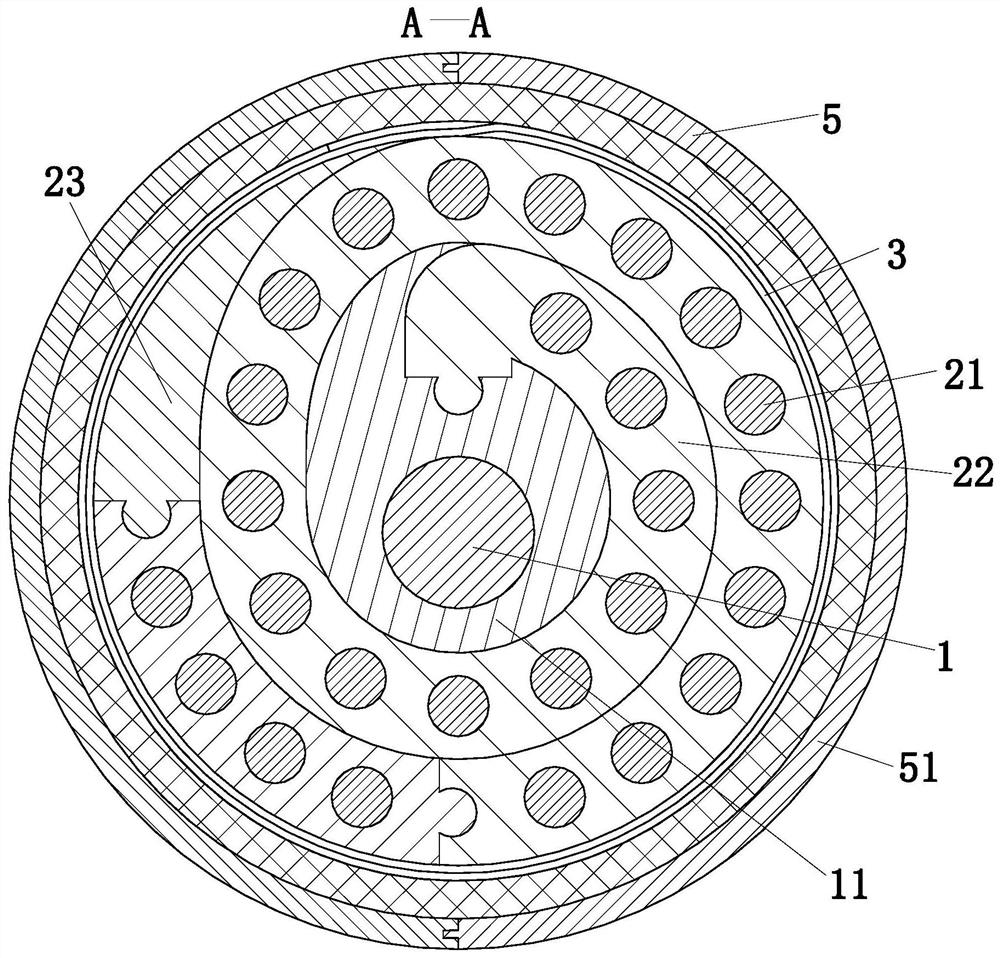

MC nylon wheel closed type mold with integrated metal core

The invention provides a MC nylon wheel closed type mold with an integrated metal core. The MC nylon wheel closed type mold with the integrated metal core comprises an upper mold, a lower mold, a central washer, the metal core and a pouring gate, wherein the upper mold is fixedly connected to the lower mold by the central washer; rubber seal rings are arranged between the central washer and the upper mold and between the central washer and the lower mold; the metal core is located by the lower mold; a gland is arranged at the upper end of the metal core; the pouring gate is arranged at the top of the upper mold and is connected to a S-shaped bending channel; a heating device is arranged on the peripheries of the upper mold and the lower mold; seal properties between the central washer and the upper mold and between the central washer and the lower mold are reinforced due to arrangement of the rubber seal rings; and the S-shaped bending channel enables the speed of a pouring material entering the mold to be effectively controlled, thereby reducing generated air bubbles and improving the quality of nylon wheels. The mold is simple to operate, wide in application range and suitable for pouring elevator rope wheels, crane pulleys and various wheel bodies.

Owner:YANGZHOU MAISHANG PLASTIC

Liquid tank

Provided is a technique for reducing the likelihood of air bubbles flowing to a liquid ejection head, in a liquid tank mounted on a carriage. The liquid tank mounted on the carriage movable in a Y direction includes a liquid chamber, a liquid inlet port, an atmospheric air introduction portion, a liquid outlet, and a division wall arranged in the liquid chamber. The division wall has first division walls perpendicular to the Y direction in a mounted state on the carriage, and the liquid chamber includes a plurality of small liquid chambers partitioned by the first division walls, an upper communication portion allowing the small liquid chambers to be in communication with each other, and a lower communication portion positioned below the upper communication, and allowing the small liquid chambers to be in communication with each other.

Owner:SEIKO EPSON CORP

Ink temperature adjustment device and ink circulation type inkjet printer having the same

Owner:RISO KAGAKU CORP

Bioreactor

InactiveCN105385566AReduce the generation of air bubblesEasy to installBioreactor/fermenter combinationsBiological substance pretreatmentsCulture fluidBioreactor

The invention discloses a bioreactor. The bioreactor comprises a tank and a liquid adding pipe. The liquid adding pipe is fixed to the upper portion of the tank, a liquid inlet of the liquid adding pipe extends out of the tank, a liquid outlet of the liquid adding pipe is located in the tank and faces the inner wall of the tank, and two heating modules are further symmetrically arranged in the tank. According to the bioreactor, culture liquid can flow to the bottom of the tank along the inner wall of the tank when added, and bubbles are effectively reduced; in addition, the bioreactor has the advantages of being convenient to install, high in liquid adding speed, free of residual liquid, free of cleaning dead angles and the like.

Owner:NINGBO DINGYUAN SOFTWARE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com