Manufacturing method and clamping tool of a combined magnet with low eddy current heating

An eddy current heating and clamping tooling technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as easy generation of air bubbles, affecting the bonding and residual of magnet components, and achieve improved bonding force and simple structure. , reduce the effect of bubble generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Ten-ten combined magnets (ie, combined magnets consist of ten magnet assemblies) were fabricated by electrophoretic coating. The magnet components used are all NdFeB magnets, such as commercially available N42 NdFeB magnets. In this embodiment, the thickness of each magnet assembly is the same, and the size is 26mm×20mm×15mm (the 15mm direction is the orientation direction).

[0043] The fabrication of combined magnets mainly includes four steps, namely magnet assembly pretreatment, electrophoretic coating, lamination and baking.

[0044] The magnet assembly pretreatment includes four steps: degreasing, rust removal, activation and phosphating:

[0045] 1) Degreasing: degreasing in a degreasing tank at 70°C for 5min-10min, followed by ultrasonic cleaning and deionized water cleaning;

[0046] 2) Derusting: After dipping the degreasing NdFeB sample in 4% nitric acid solution for 30s-60s, ultrasonic cleaning and deionized water cleaning were performed;

[0047] 3) Acti...

Embodiment 2

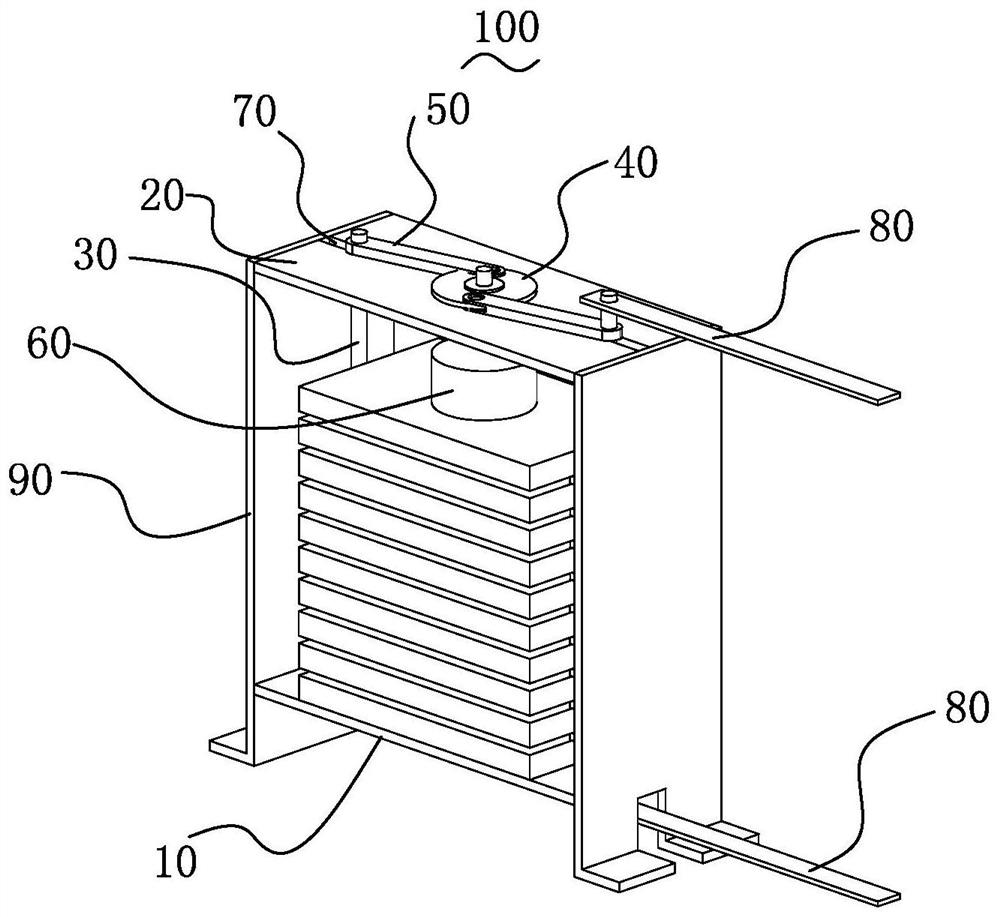

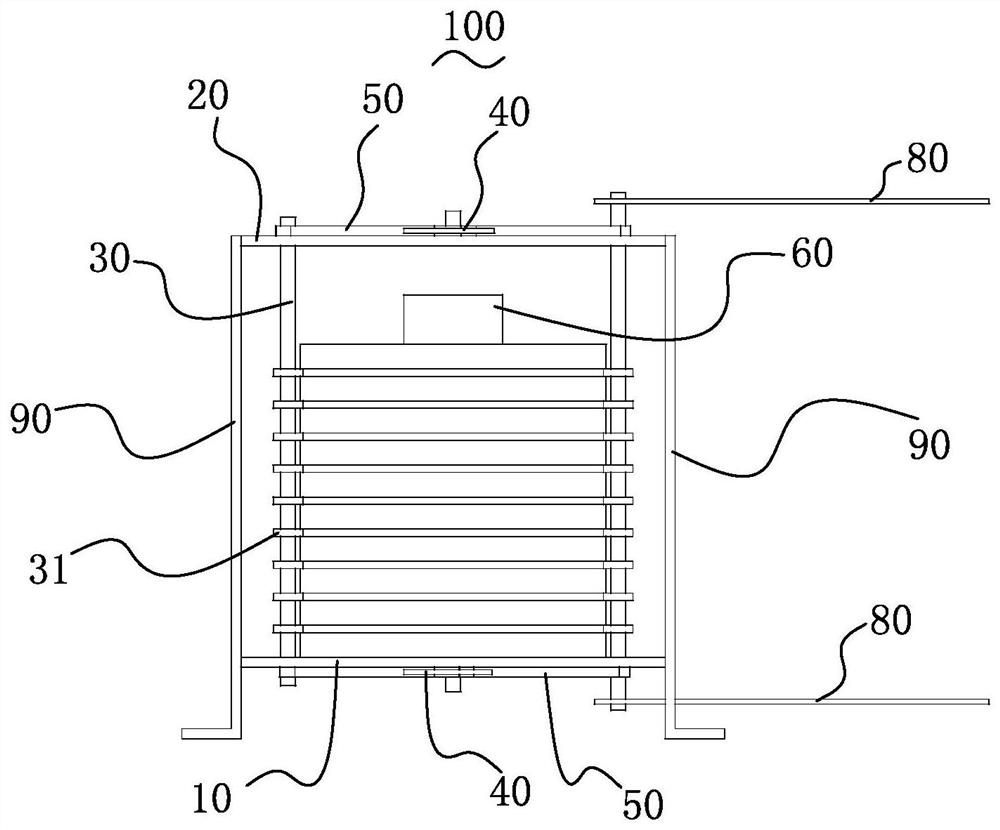

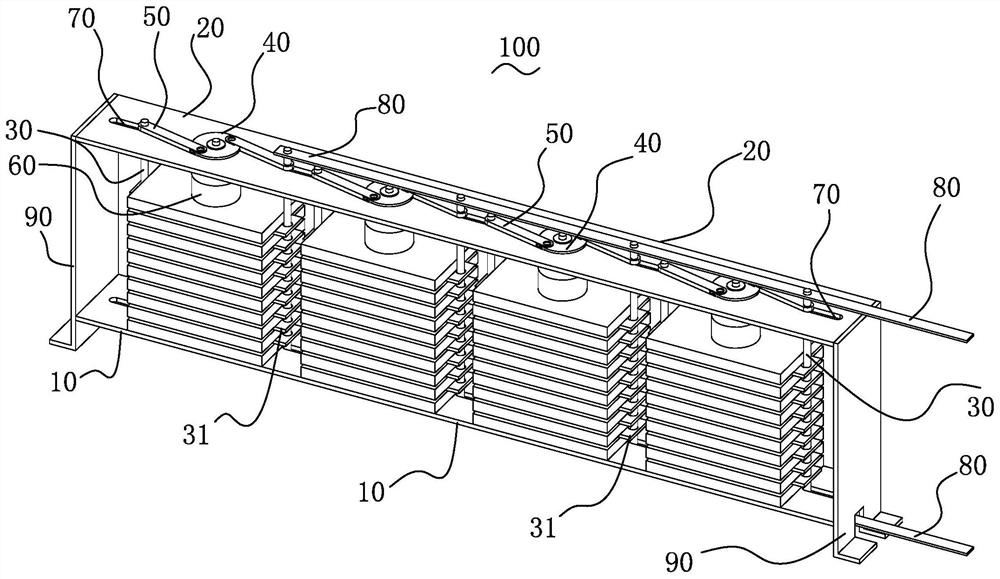

[0065] Ten-ten combined magnets (ie, combined magnets consist of ten magnet assemblies) were fabricated by electrophoretic coating. The magnets used are all NdFeB magnets, such as commercially available N42 NdFeB magnets. The size of each magnet assembly is 26mm×20mm×15mm (the 15mm direction is the orientation direction). The production process is as follows figure 1 shown.

[0066] The fabrication of combined magnets mainly includes four steps, namely magnet assembly pretreatment, electrophoretic coating, lamination and baking.

[0067] The magnet assembly pretreatment includes four steps: degreasing, rust removal, activation and phosphating:

[0068] 1) Degreasing: degreasing in a degreasing tank at 70°C for 5min-10min, followed by ultrasonic cleaning and deionized water cleaning;

[0069] 2) Derusting: After dipping the degreasing NdFeB magnet assembly in 4% nitric acid solution for 30s-60s, ultrasonic cleaning and deionized water cleaning are performed;

[0070] 3) Acti...

Embodiment 3

[0086] Ten-ten combined magnets (ie, combined magnets consisting of ten magnet assemblies) were fabricated by electrophoretic coating. The magnets used are all NdFeB magnets. Commercially available N42 and N48 NdFeB magnets are used. The size of each magnet assembly is 26mm×20mm×15mm (the 15mm direction is the orientation direction).

[0087] The fabrication of combined magnets mainly includes four steps, namely magnet assembly pretreatment, electrophoretic coating, lamination and baking.

[0088] The magnet assembly pretreatment includes four steps: degreasing, rust removal, activation and phosphating:

[0089] 1) Degreasing: Degrease in a degreasing tank at 70°C for 5min-10min, and then perform ultrasonic cleaning and deionized water cleaning;

[0090] 2) Derusting: After dipping the degreasing NdFeB sample in 4% nitric acid solution for 30s-60s, ultrasonic cleaning and deionized water cleaning were performed;

[0091] 3) Activation: The rust-removed NdFeB magnet assembly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com