Medium-frequency coiling soft cable for charging smart energy airport and production process thereof

A technology of smart energy and production technology, applied in the direction of power cables, insulated cables, communication cables, etc., can solve the problems of occupying installation space, large cable outer diameter, low power supply efficiency, etc., and achieve small space occupation, tensile resistance and torsion resistance Excellent performance and the effect of enhancing the electrification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

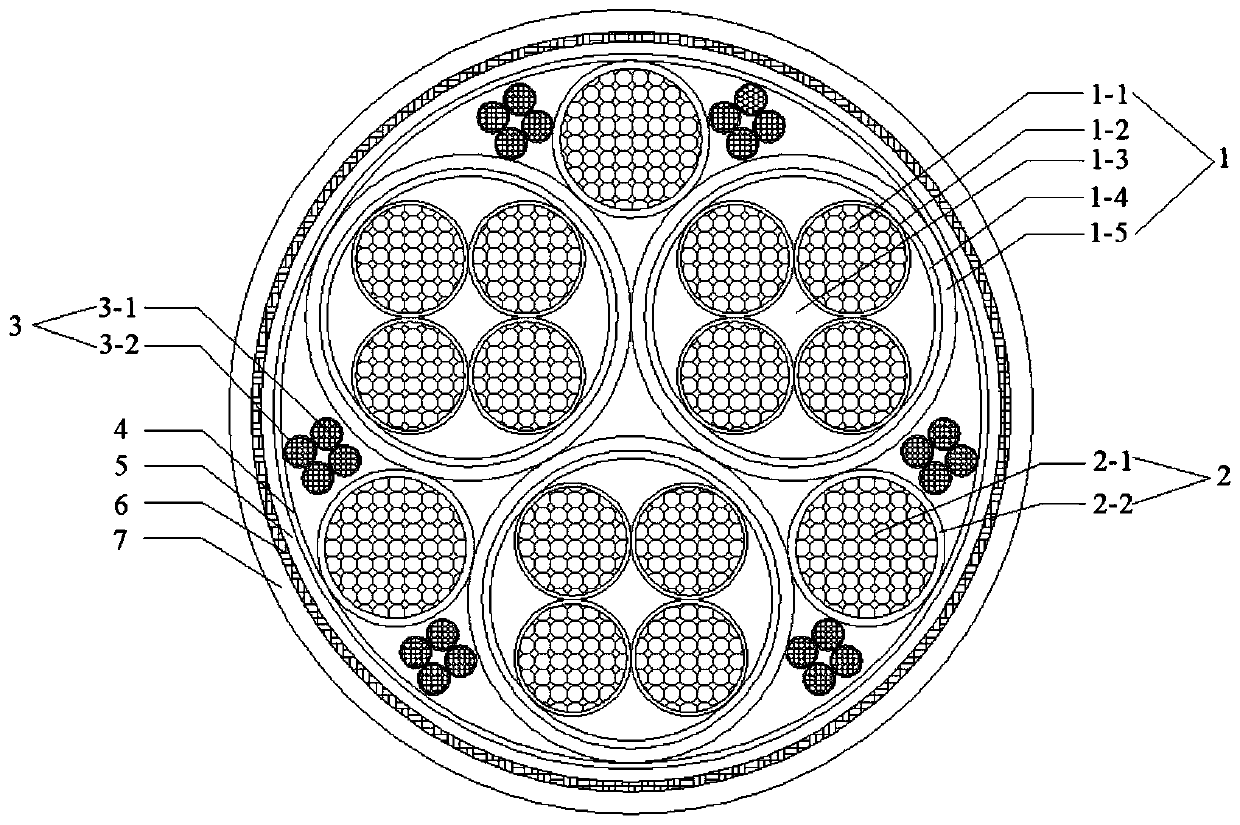

[0035] See figure 1 , the intermediate frequency winding flexible cable for smart energy airport charging in this embodiment and its production process.

[0036] Among them, the intermediate frequency winding flexible cable for smart energy airport charging includes the main cable core, and the non-woven fabric wrapping layer 4, inner lining layer 5, aramid yarn braiding layer 6 and outer sheath 7 wrapped in turn outside the main cable core . Three power cores 1 are arranged in the main cable core around the axis at 120°. A power supply auxiliary core 2 is provided between adjacent power cores 1 . A control wiring harness 3 is provided between adjacent power cores 1 and power supply auxiliary cores 2 . A conductor bundle is arranged inside the power core 1 . The conductor bundle is four conductors 1-1 uniformly distributed along the circumferential direction of the power line core 1 . The conductor bundle is a multi-twisted wire of four twisted conductors 1-1, which can o...

Embodiment 2

[0052] The medium-frequency coiled flexible cable for smart energy airport charging in this embodiment and its production process.

[0053] Among them, the intermediate frequency winding flexible cable for smart energy airport charging includes the main cable core, and the non-woven fabric wrapping layer 4, inner lining layer 5, aramid yarn braiding layer 6 and outer sheath 7 wrapped in turn outside the main cable core . Three power cores 1 are arranged in the main cable core around the axis at 120°. A power supply auxiliary core 2 is provided between adjacent power cores 1 . A control wiring harness 3 is provided between adjacent power cores 1 and power supply auxiliary cores 2 . A conductor bundle is arranged inside the power core 1 . The conductor bundle is four conductors 1-1 uniformly distributed along the circumferential direction of the power line core 1 . The conductor bundle is a multi-stranded wire of four twisted conductors. It can offset the magnetic field gen...

Embodiment 3

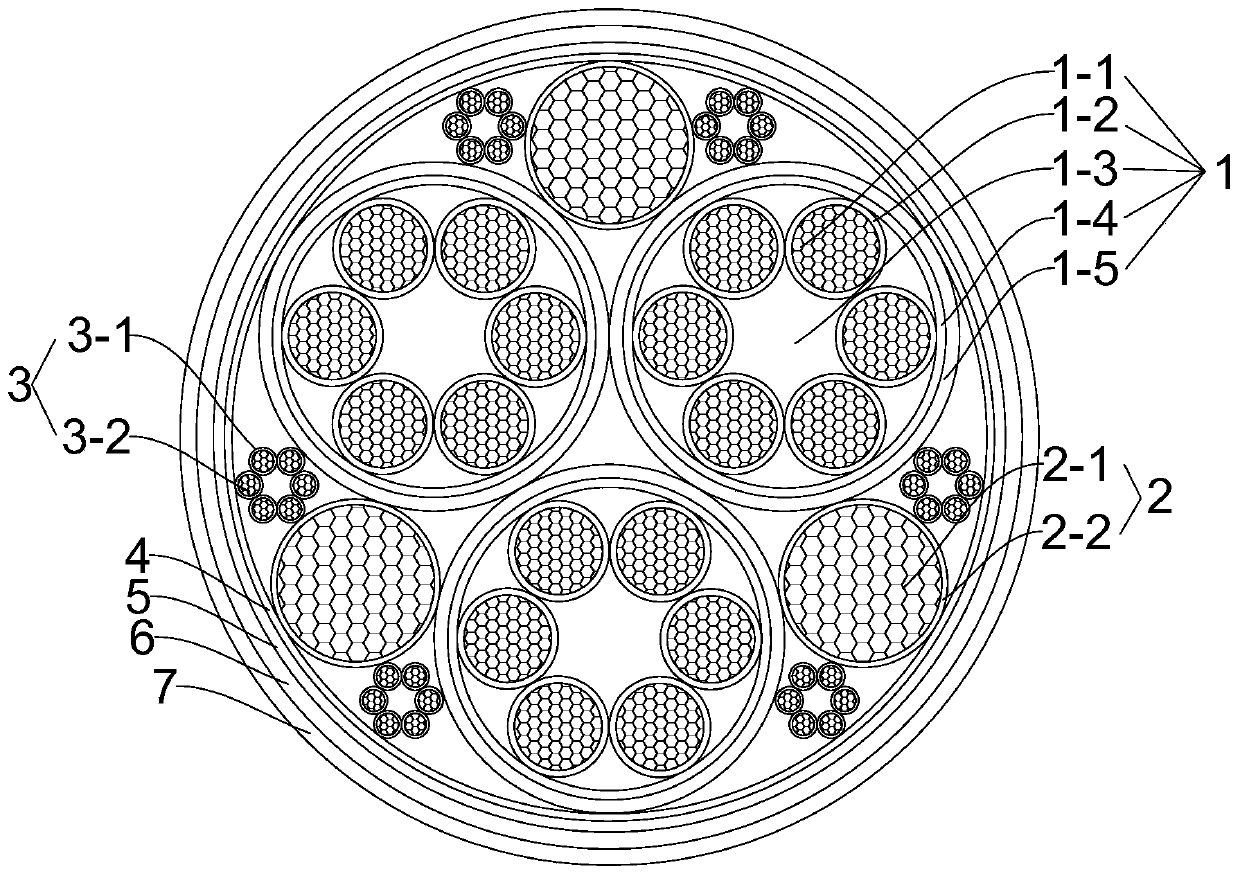

[0069] See figure 2 , the intermediate frequency winding flexible cable for smart energy airport charging in this embodiment and its production process.

[0070] Among them, the intermediate frequency winding flexible cable for smart energy airport charging includes the main cable core, and the non-woven fabric wrapping layer 4, inner lining layer 5, aramid yarn braiding layer 6 and outer sheath 7 wrapped in turn outside the main cable core . Three power cores 1 are arranged in the main cable core around the axis at 120°. A power supply auxiliary core 2 is provided between adjacent power cores 1 . A control wiring harness 3 is provided between adjacent power cores 1 and power supply auxiliary cores 2 . A conductor bundle is arranged inside the power core 1 . The conductor bundle is six conductors 1-1 uniformly distributed along the circumferential direction of the power line core 1 . The conductor bundle is a multi-twisted wire of six twisted conductors, which can offset...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com