MC nylon wheel closed type mold with integrated metal core

A metal core and nylon wheel technology, applied in the field of centrifugal casting molds, can solve the problems of nylon wheel foaming, no casting, high cost, etc., achieve the effects of reducing the generation of air bubbles, wide application range, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

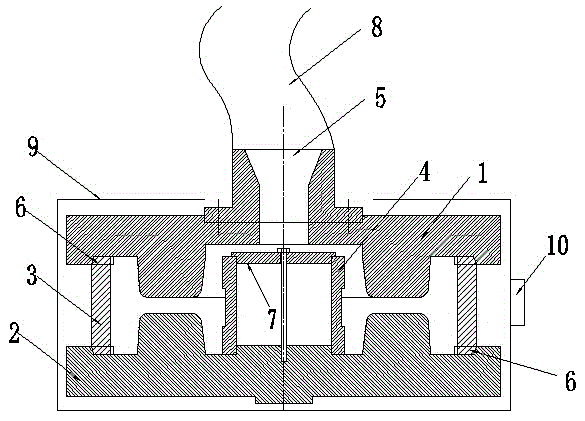

[0010] Such as figure 1 A one-piece metal core MC nylon wheel closed mold is shown, including upper mold 1, lower mold 2, middle ring 3, metal core 4, gate 5, upper mold 1 and lower mold 2 are fixedly connected through middle ring 3 , between the middle ring 3 and the upper mold 1, between the middle ring 3 and the lower mold 2 are provided with a rubber sealing ring 6, the lower mold 2 locates the metal core 4, the upper end of the metal core 4 is provided with a gland 7, and the gate 5 is arranged on the upper The top of the mold 1, the gate 5 is connected to the S-shaped curve 8, and the upper mold 1 and the lower mold 2 are provided with a heating device 9 on the periphery.

[0011] The heating device 9 is made up of several detachable heating plates.

[0012] The heating device 9 is provided with a temperature controller 10 .

[0013] There are rubber sealing rings between the middle ring and the upper mold, and between the lower mold, so that the sealing performance be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com