Wide-adaptability cigarette packaging adhesive and preparation method thereof

A widely applicable, packaging adhesive technology, applied in the direction of adhesives, adhesive types, unsaturated alcohol copolymer adhesives, etc., can solve the problem of high residual monomer content, environmental protection, inability to adapt to high-speed packaging equipment, acrylate monomer Eliminate the problems of high body odor and other problems, and achieve the effect of lower requirements, lower equipment requirements, and less crust precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] 1. Preparation of polyvinyl alcohol aqueous solution

[0067] At room temperature, weigh 80g of water and add it to the reaction vessel, start stirring, then weigh 20g of polyvinyl alcohol and slowly add it to the reaction vessel, stir and disperse evenly and when there is swelling, start to heat up and heat to 85°C-90°C , keep warm for 2 hours to obtain polyvinyl alcohol aqueous solution.

[0068] Specifically, the degree of alcoholysis of the polyvinyl alcohol is 80-98%, and the degree of polymerization is 500-3000.

[0069] Polyvinyl alcohol aqueous solution has certain viscosity, water solubility, surface activity and cohesiveness, but the above-mentioned properties of polyvinyl alcohol will vary greatly with the degree of alcoholysis, for example, its surface activity and surface colloidal effect will change with alcoholysis The protective colloid ability increases with the increase of molecular weight, while the surface activity decreases with the increase of mol...

Embodiment 2

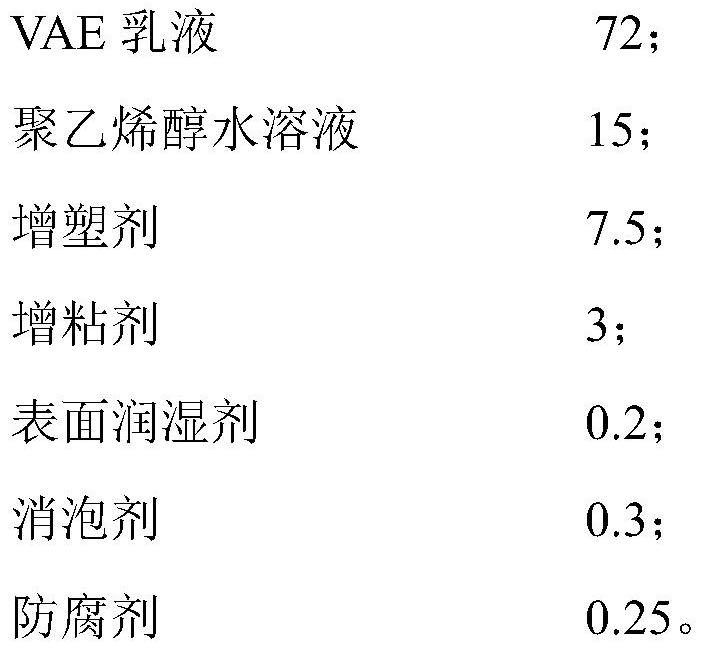

[0086] Except that VAE emulsion, polyvinyl alcohol aqueous solution, plasticizer, tackifier, surface wetting agent, defoamer and preservative are taken by weight in the following proportions, others are all the same as in Example 1:

[0087]

[0088]

Embodiment 3

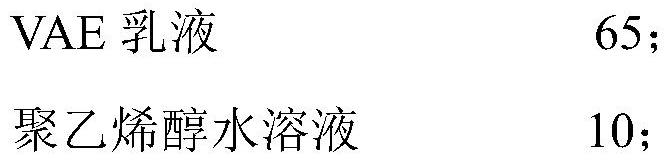

[0090] Except that VAE emulsion, polyvinyl alcohol aqueous solution, plasticizer, tackifier, surface wetting agent, defoamer and preservative are taken by weight in the following proportions, others are all the same as in Example 1:

[0091]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com