Improved bioreactor

A bioreactor, an improved technology, applied in bioreactor/fermenter combinations, specific-purpose bioreactors/fermenters, biochemical instruments, etc., can solve the problem of cleaning dead corners, adding residual liquid in liquid pipelines, and difficult pipeline installation. and other problems, to achieve the effect of convenient movement and reducing the generation of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0010] In the prior art, the liquid feeding pipeline of the improved bioreactor usually uses a pipe directly extending from the top of the tank to the bottom of the tank. Such a structure will cause many bubbles to cause damage to the cells when adding liquid. It will cause problems such as cleaning dead ends, residual liquid remaining in the pipeline, and installation difficulties.

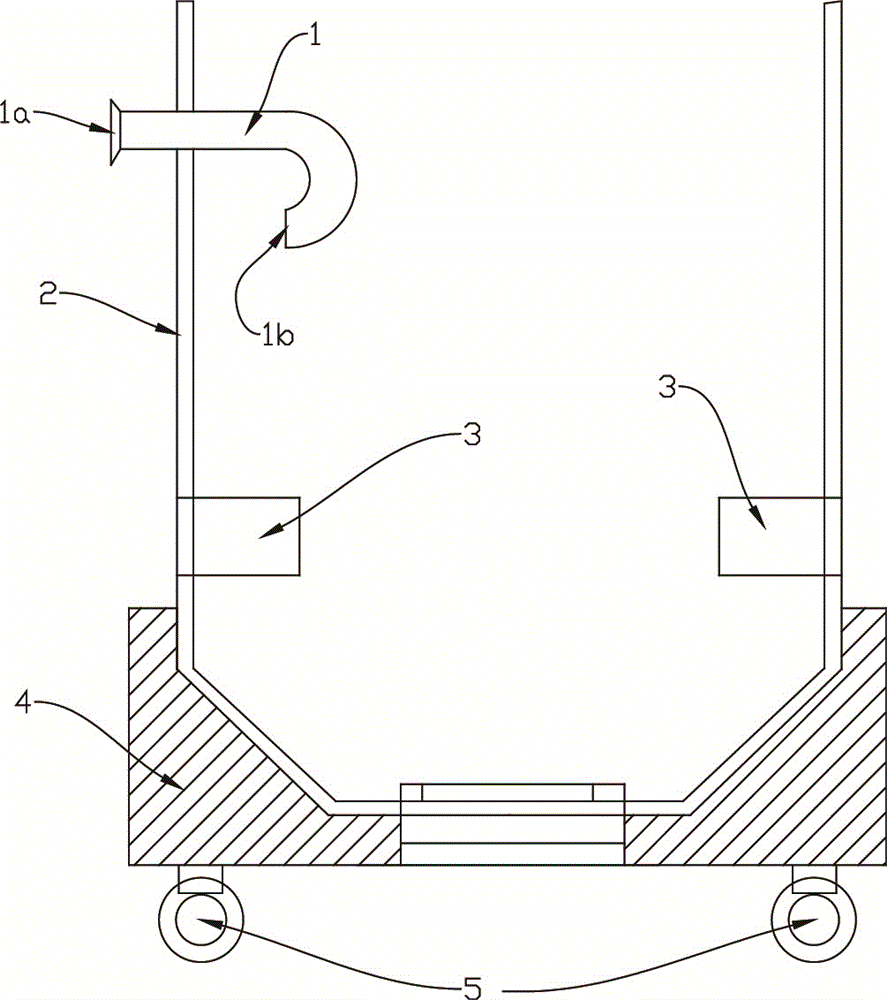

[0011] The improved bioreactor of the invention can realize the way of adding liquid adhered to the wall and reduce the generation of air bubbles when adding liquid. See figure 1 , the improved bioreactor of the present invention includes a tank body 2 and a liquid-feeding pipeline 1, wherein the liquid-feeding pipeline 1 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com