Resin adhesive tape casting film forming method

A technology of cast film forming and resin glue, which is applied in the field of epoxy resin film production technology, can solve the problems that the resin film is easy to have pores and difficult to operate, and achieve the effect of reducing the generation of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

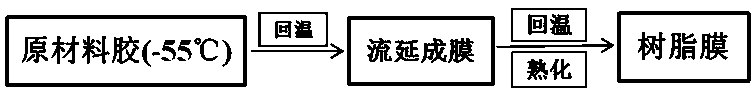

[0018] The process method of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] refer to figure 1 Shown in, the method for cast resin film of the present invention comprises the following steps:

[0020] 1), choose the coefficient of thermal expansion as 20-80 (10 -6 / °C) epoxy resin-based adhesives are used as raw materials and stored in a temperature environment below -40°C for later use; it is preferable to freeze the epoxy resin-based adhesives in the refrigerator to -55°C.

[0021] 2) Take out the epoxy resin-based adhesive and place it in a normal temperature environment to thaw to a normal flowable state. The thawing time should not exceed 2 hours; preferably, the epoxy resin-based adhesive will start to flow after being taken out of the refrigerator and returned to the temperature for 1 hour. Delay, return to temperature for 1 hour and the resin glue will thaw to a normal flowable sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com