Electronic paper unit, cutting device and manufacture method for electronic paper unit

A technology of cutting equipment and manufacturing method, which is applied in the field of electronic paper, can solve the problems that the glass substrate process cannot be fully applied, and achieve the effects of reducing water vapor intrusion into the electronic ink layer, increasing adhesion, and reducing the occurrence of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

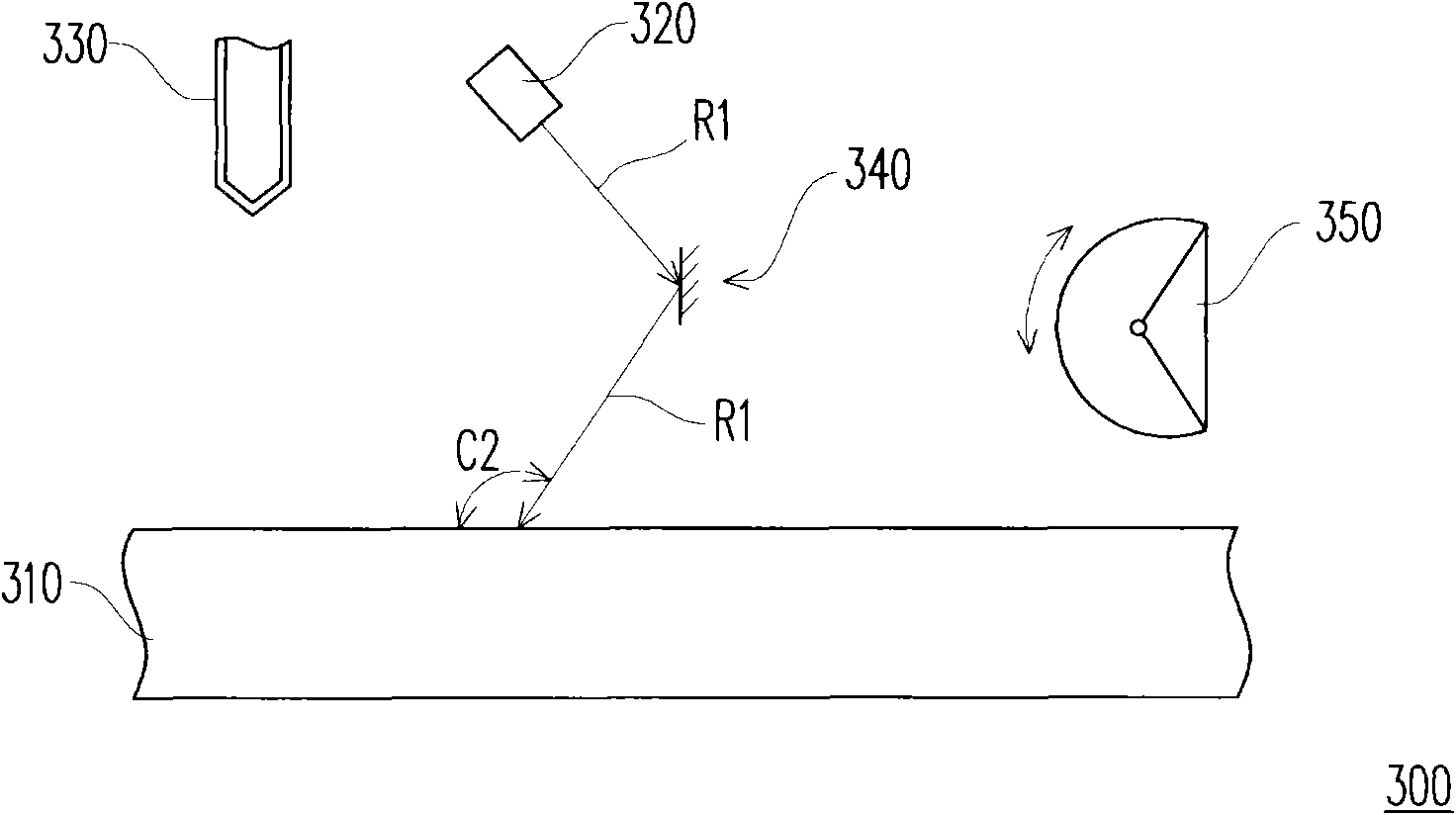

[0045] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

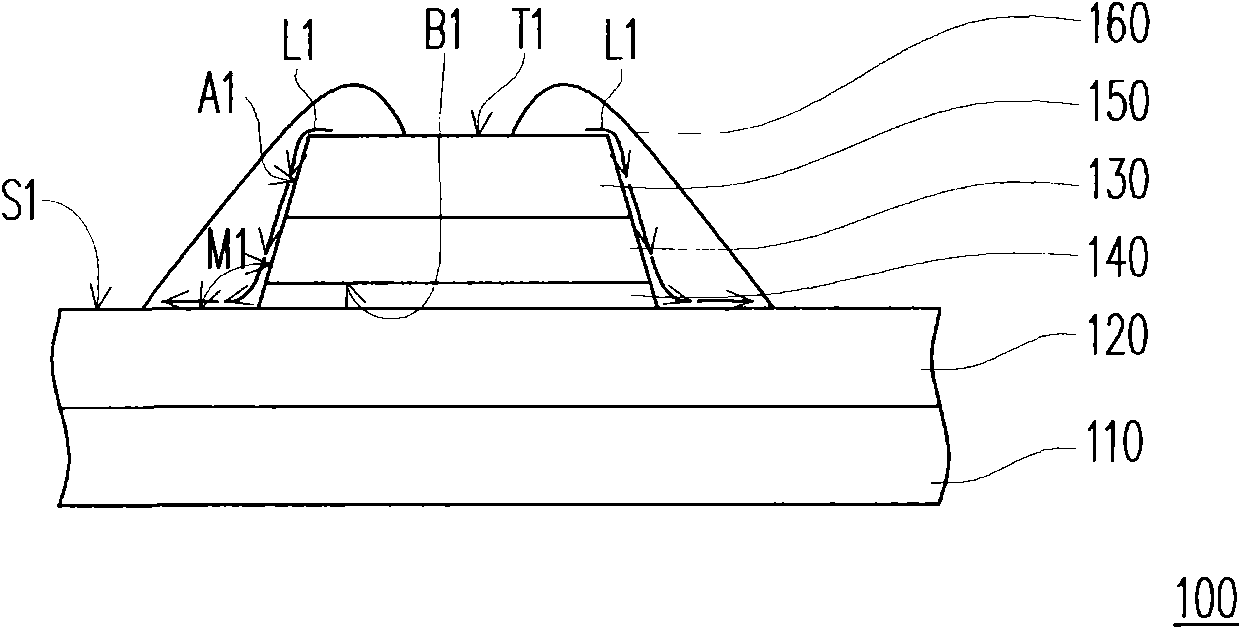

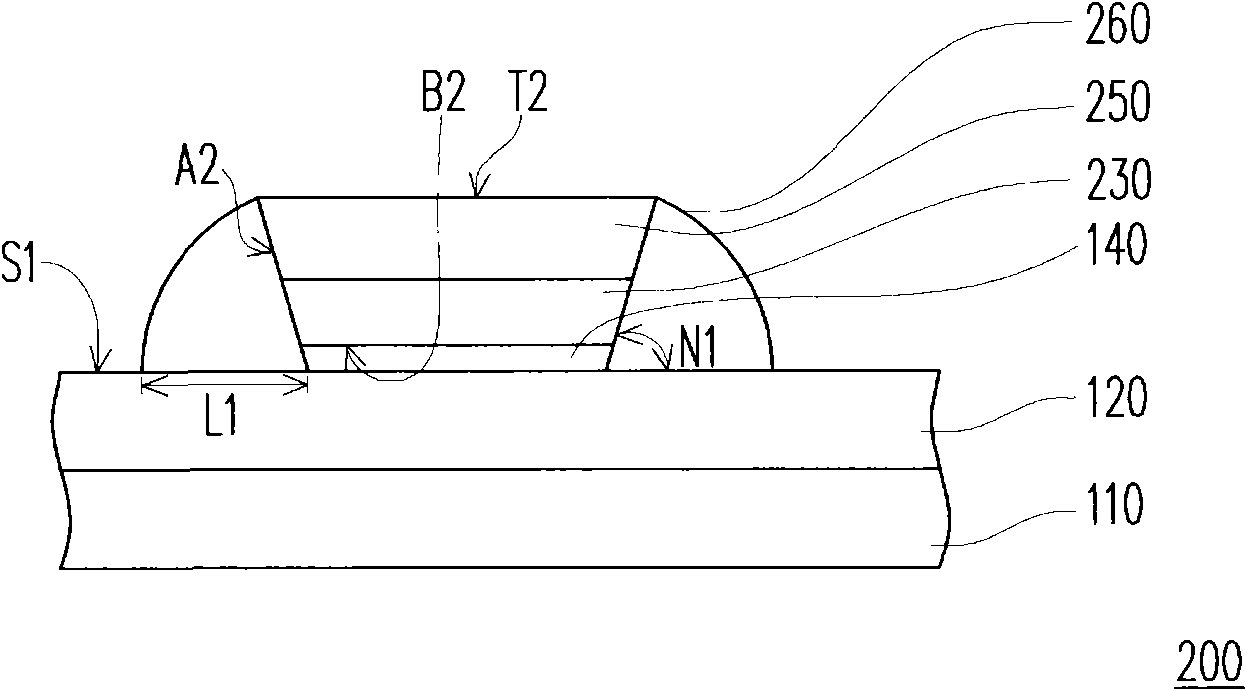

[0046] figure 1 is a schematic diagram of an electronic paper unit according to an embodiment of the present invention. Please refer to figure 1 , in this embodiment, the electronic paper unit 100 may include a flexible substrate 110 , a thin film transistor layer 120 , an electronic ink layer 130 , an adhesive layer 140 , a waterproof layer 150 and a frame glue 160 . The flexible substrate 110 may be a film substrate made of polyimide. The thin film transistor layer 120 is disposed on the flexible substrate 110 . The electronic ink layer 130 is disposed on a surface S1 of the thin film transistor layer 120, wherein the electronic ink layer 130 and the thin film transistor layer 120 can be connected together by an adhesive layer 140, and the electronic ink layer 130 can be an electrophoretic (EP) The film is displayed, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com