Metal pressure casting releasing agent and preparing method thereof

A release agent and metal technology, which is used in metal processing equipment, casting equipment, molds, etc., can solve the problems of stability and high temperature resistance that need to be further improved, and the release effect of the release agent and the deterioration of lubricating performance. , to achieve the effect of low preparation cost, good lubricity and mold release performance, and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

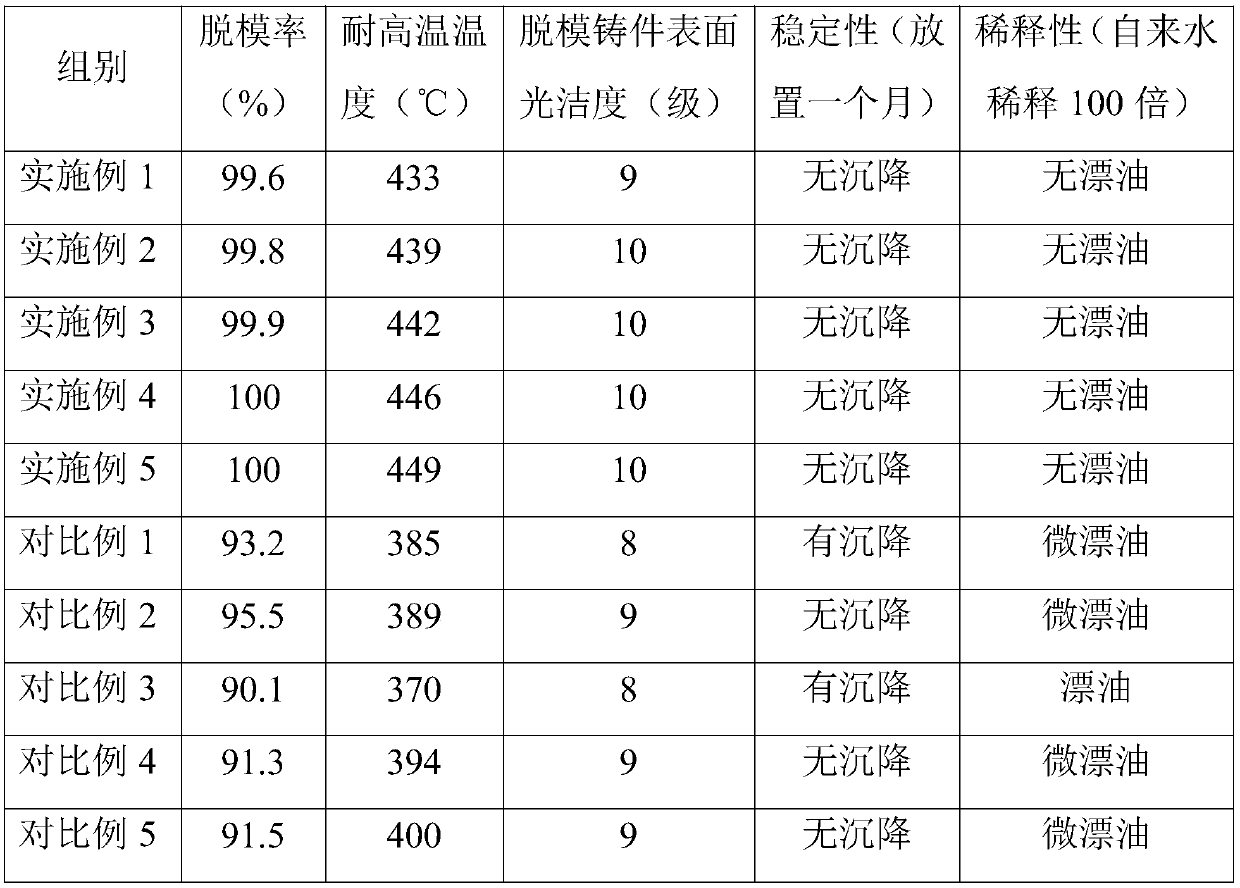

Examples

Embodiment 1

[0027] A metal die-casting release agent, according to mass percentage, is composed of the following components: 8% of epoxidized soybean oil-modified aminosilicone oil, 20% of Tween 80-cetyl ricinoleate-xindepine glucuronide copolymer , N,N-dimethyl-N-(2-hydroxyethyl) 2-hydroxyhexadecyl ammonium chloride 2%, aminopropanol ascorbyl phosphate 1%, emulsifier OP-102%, polyoxyethylene Polyoxypropanolamine ether 0.5%, and the balance is water.

[0028] The preparation method of the epoxidized soybean oil-modified amino silicone oil includes the following steps: adding 100 g of epoxidized soybean oil and 300 g of amino silicone oil to 1000 g of acetone, then adding 30 g of sodium hydroxide to it, and stirring and reacting at 50° C. for 6 hours , filtered to remove insoluble salts, and then rotary-evaporated to remove acetone to obtain epoxidized soybean oil-modified aminosilicone oil.

[0029] The preparation method of the Tween 80-cetyl ricinoleate-xindepine glucuronide copolymer ...

Embodiment 2

[0032] A metal die-casting release agent, according to the mass percentage, is composed of the following components: 9% of epoxidized soybean oil modified aminosilicone oil, 22% of Tween 80-cetyl ricinoleate-xindepine glucuronide copolymer , N,N-dimethyl-N-(2-hydroxyethyl) 2-hydroxyhexadecyl ammonium chloride 3%, aminopropanol ascorbyl phosphate 2%, Tween-80 2.5%, polyoxypropylene glycerin Ether 0.7%, the balance is water.

[0033] The preparation method of the epoxidized soybean oil-modified amino silicone oil includes the following steps: adding 100 g of epoxidized soybean oil and 300 g of amino silicone oil to 1100 g of acetone, then adding 35 g of potassium hydroxide to it, and stirring and reacting at 55° C. for 6.5 hours , filtered to remove insoluble salts, and then rotary-evaporated to remove acetone to obtain epoxidized soybean oil-modified aminosilicone oil.

[0034] The preparation method of the Tween 80-cetyl ricinoleate-xindepine glucuronide copolymer comprises t...

Embodiment 3

[0037] A metal die-casting release agent, according to the mass percentage, is composed of the following components: 11% of epoxidized soybean oil modified amino silicone oil, 25% of Tween 80-cetyl ricinoleate-xindepine glucuronide copolymer , N,N-dimethyl-N-(2-hydroxyethyl) 2-hydroxyhexadecyl ammonium chloride 3.5%, aminopropanol ascorbyl phosphate 3%, laureth 3%, Foaming agent ShinchemAF 31680.8%, the balance is water.

[0038] The preparation method of the epoxidized soybean oil-modified amino silicone oil includes the following steps: adding 100 g of epoxidized soybean oil and 300 g of amino silicone oil to 1300 g of acetone, then adding 40 g of sodium carbonate therein, and stirring and reacting at 60° C. for 7 hours, After filtering to remove insoluble salts, and then rotary evaporation to remove acetone, the epoxidized soybean oil modified amino silicone oil was obtained.

[0039] The preparation method of the Tween 80-cetyl ricinoleate-xindepine glucuronide copolymer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com