Reaction device and method for producing aluminum oxide

A reaction device and alumina technology, applied in chemical instruments and methods, inorganic chemistry, aluminum compounds, etc., can solve problems such as long service life, achieve long service life, promote heat exchange, and facilitate disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

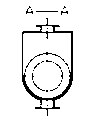

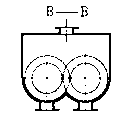

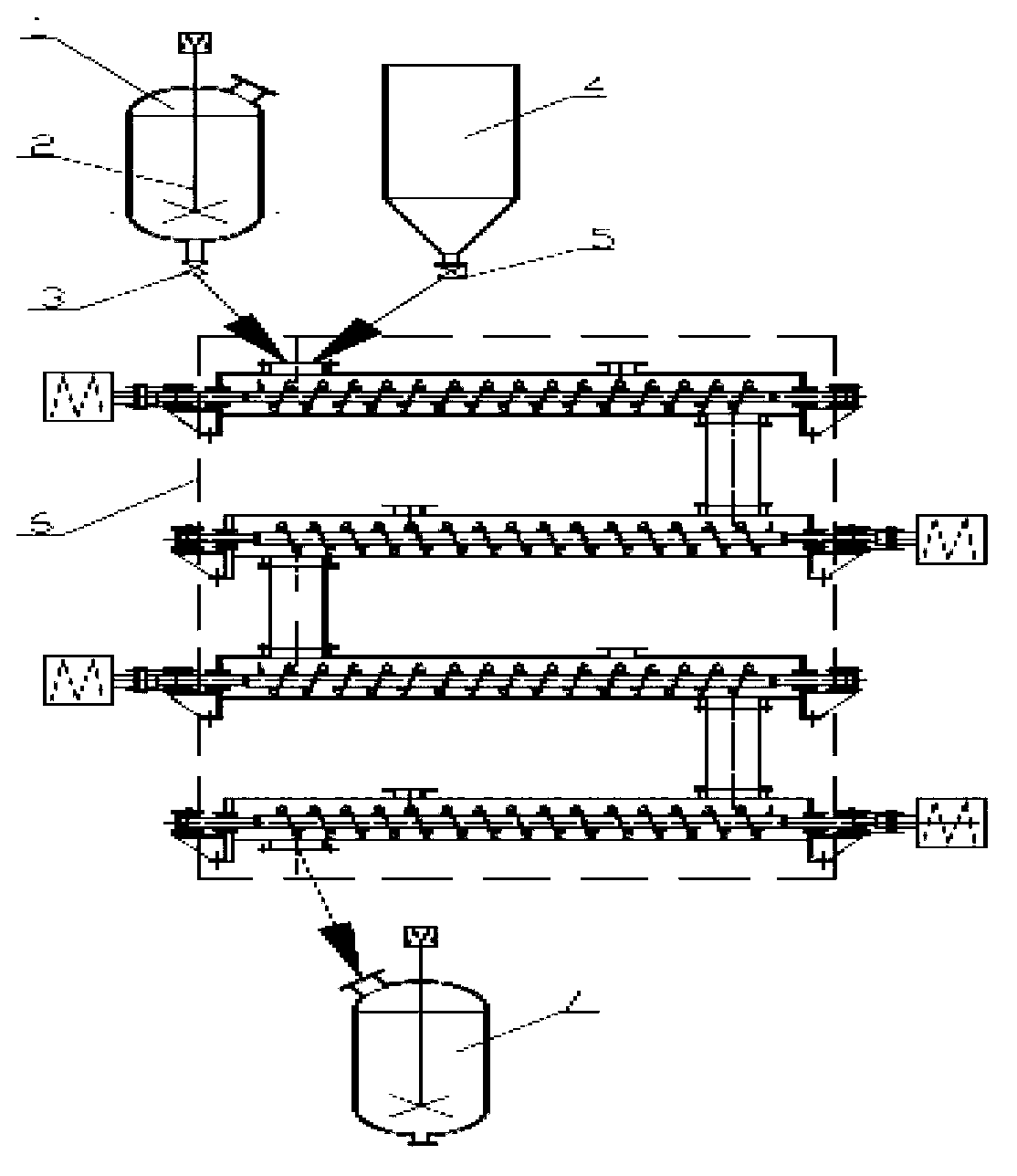

[0049] Put heat transfer oil or molten salt into the outer jacket (13) to preheat the combined spiral reactor (6), when the temperature inside the combined spiral tube reactor (6) reaches 280°C, turn on the drive motor ( 12) Ready to feed. Ammonium sulfate is added to the combined spiral reactor (6) through the metering feeding device (3) at the bottom of the ammonium sulfate premixing metering tank (1); according to the ratio of ammonium sulfate:fly ash of 1:1, the pulverized coal The ash is fed into the combined spiral reactor (6) from the fly ash storage metering bin (4) through the gravimetric feeder (5). The combined spiral reactor (6) is composed of 5 spiral tube reactors (8), including 2 single-screw reactors (11), and its dimensions are: length 5m, width 0.4m, height 0.6m, 3 A twin-screw reactor (12), whose external dimensions are: length 5m, width 0.6m, height 0.6m. The ammonia gas released by the reaction decomposition enters the gas collection pipe (9) through the...

Embodiment 2

[0052] Put heat transfer oil or molten salt into the outer jacket to preheat the combined spiral reactor. When the temperature inside the combined spiral reactor reaches 310°C, turn on the drive motor to prepare for feeding. Ammonium sulfate is added to the combined spiral reactor through the metering feeding device at the bottom of the ammonium sulfate premixing metering tank; according to the ratio of ammonium sulfate: fly ash of 1.5:1, the fly ash is stored from the fly ash storage metering bin through The gravimetric feeder is added to the combined screw reactor. The combined spiral reactor consists of 10 helical tube reactors, including 5 single-screw reactors, whose dimensions are: length 8m, width 0.6m, height 0.9m, and 5 twin-screw reactors, whose dimensions It is: length 8m, width 1.1m, height 0.9m. The ammonia gas released by the reaction decomposition enters the gas collection pipe through the gas outlet pipe on the upper part of each spiral tube reactor and leads ...

Embodiment 3

[0055] Put heat transfer oil or molten salt into the outer jacket to preheat the combined spiral reactor. When the temperature inside the combined spiral reactor reaches 350°C, turn on the drive motor to prepare for feeding. Ammonium sulfate is added into the combined spiral reactor through the metering feeding device at the bottom of the ammonium sulfate premixing metering tank; according to the ratio of ammonium sulfate: fly ash is 2.5:1, the fly ash is stored from the fly ash storage metering bin through The gravimetric feeder is added to the combined screw reactor. The combined spiral reactor consists of 13 helical tube reactors, including 9 single-screw reactors, whose dimensions are: length 8m, width 0.7m, height 1m, and 4 twin-screw reactors, whose dimensions are : Length 8m, width 1m, height 1m. The ammonia gas released by the reaction decomposition enters the gas collection pipe through the gas outlet pipe on the upper part of each spiral tube reactor and leads to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com