Patents

Literature

47results about How to "Difference in density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

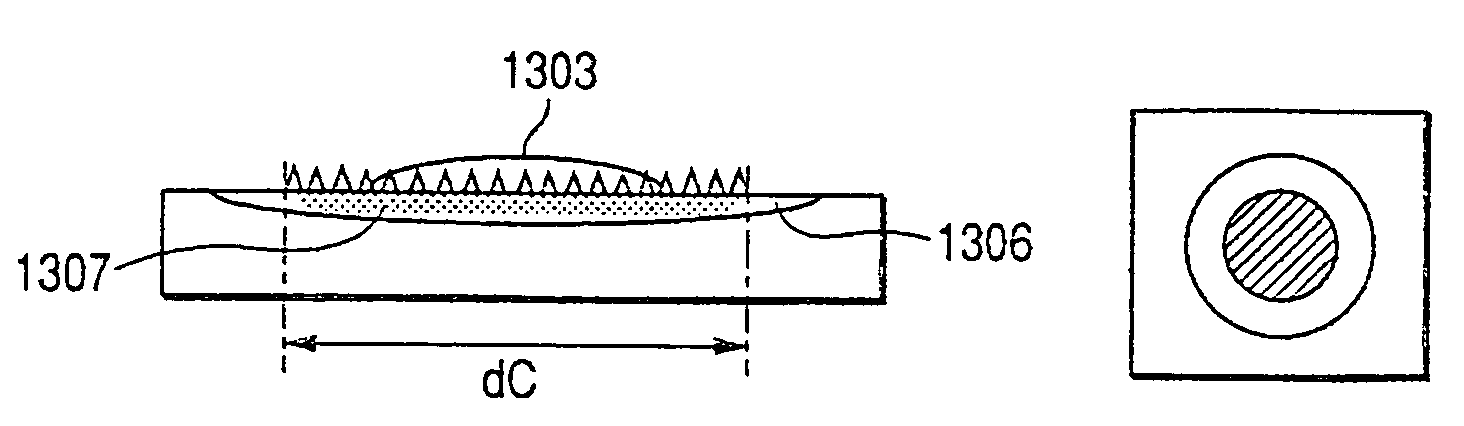

Aqueous ink, ink set, and image-forming method

ActiveUS20060098067A1Large area factorHigh image densityMeasurement apparatus componentsDuplicating/marking methodsOrganic solventWater insoluble

The present invention aims to provide an ink which has a sufficiently large area factor even in a small ink droplet quantity and can obtain images having a high image density, and further has a superior storage stability. According to the present invention, a cyan ink is provided which is used in an ink set having four kinds of aqueous inks consisting of a cyan ink, a magenta ink, a yellow ink and a black ink in which each ink comprises at least water, a water-insoluble coloring material, and a plurality of water-soluble organic solvents having a good medium or good mediums for the water-insoluble coloring material and a poor medium or poor mediums for the water-insoluble coloring material, wherein, the ratio B1 / A1 is from 0.5 or more to 3.0 or less, where A1 denotes the total content (mass %) of the good medium based on the total mass of the cyan ink and B1 denotes the total content (mass %) of the poor medium based on the total mass of the cyan ink, and a water-soluble organic solvent which shows the maximum Ka value among the respective Ka values of the plurality of water-soluble organic solvents as determined by the Bristow method is the poor medium.

Owner:CANON KK

Multiple phase foaming personal cleansing products

InactiveUS20030003069A1Difference in densityEasy to separateCosmetic preparationsHair removalPersonal careCleaning product

The present invention relates to personal care foaming and cleansing products comprising multiple phases which are separate and distinct and comprise at least one surfactant solution having a density or specific gravity of approximately 1.0. In a two-phase composition, a second separated phase may comprise cosmetically acceptable oily materials as emollients / conditioners having a density greater than that of the surfactant solution. In a three phase composition, an additional phase may comprise a low density emollient / conditioning compound(s) as an upper third phase. Thus, two, three or even four phase foaming bath products, shampoos and skin cleansers can be produced that can be differentially colored to enhance the visual separation of the layers and will provide foaming, cleaning, conditioning and emolliency in a unique and attractive manner.

Owner:ALZO INTTERNAT

Aqueous ink, ink set, and image-forming method

ActiveUS7402200B2Increase the areaHigh image densityDuplicating/marking methodsInksOrganic solventWater insoluble

The present invention aims to provide an ink which has a sufficiently large area factor even in a small ink droplet quantity and can obtain images having a high image density, and further has a superior storage stability. According to the present invention, a cyan ink is provided which is used in an ink set having four kinds of aqueous inks consisting of a cyan ink, a magenta ink, a yellow ink and a black ink in which each ink comprises at least water, a water-insoluble coloring material, and a plurality of water-soluble organic solvents having a good medium or good mediums for the water-insoluble coloring material and a poor medium or poor mediums for the water-insoluble coloring material, wherein, the ratio B1 / A1 is from 0.5 or more to 3.0 or less, where A1 denotes the total content (mass %) of the good medium based on the total mass of the cyan ink and B1 denotes the total content (mass %) of the poor medium based on the total mass of the cyan ink, and a water-soluble organic solvent which shows the maximum Ka value among the respective Ka values of the plurality of water-soluble organic solvents as determined by the Bristow method is the poor medium.

Owner:CANON KK

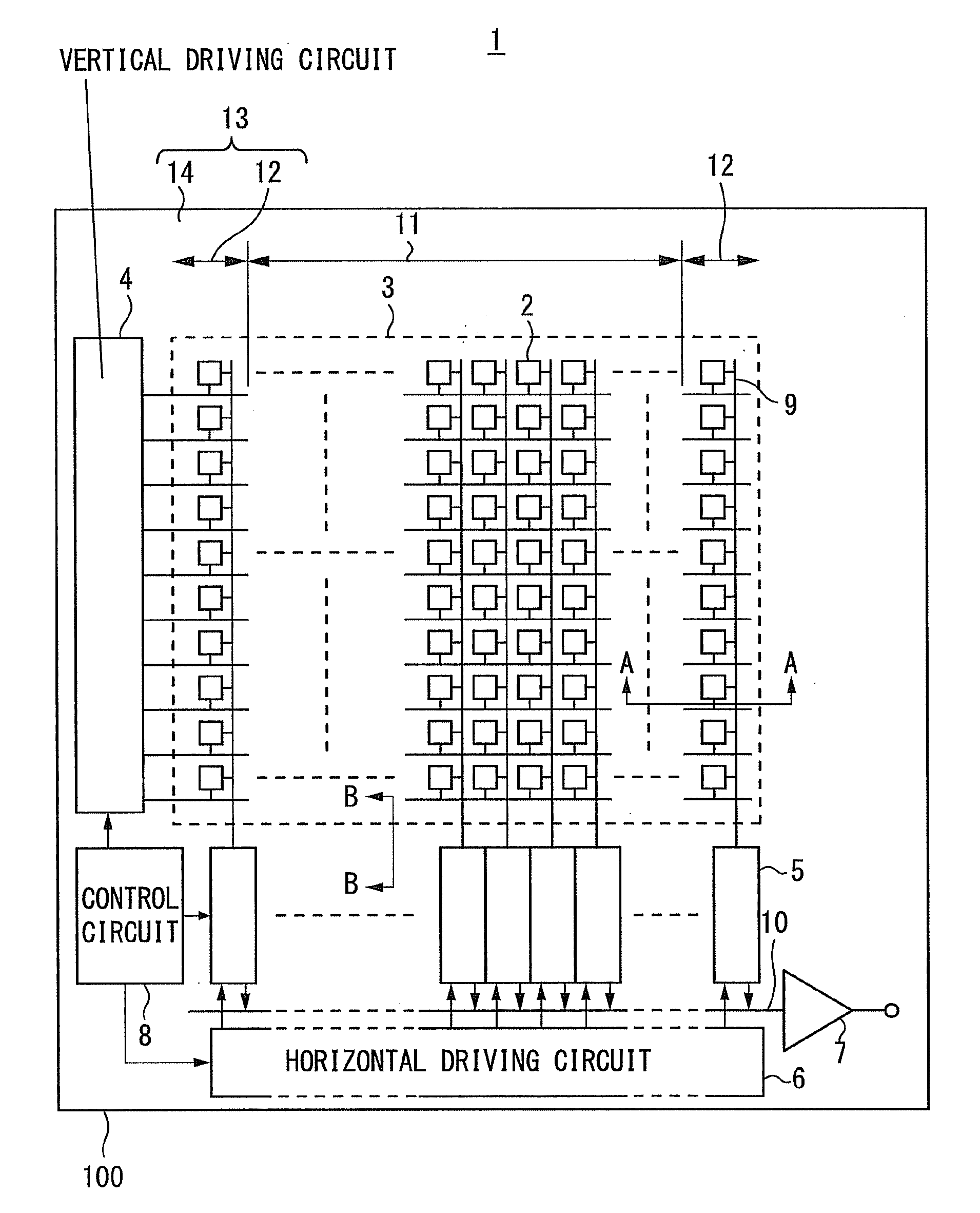

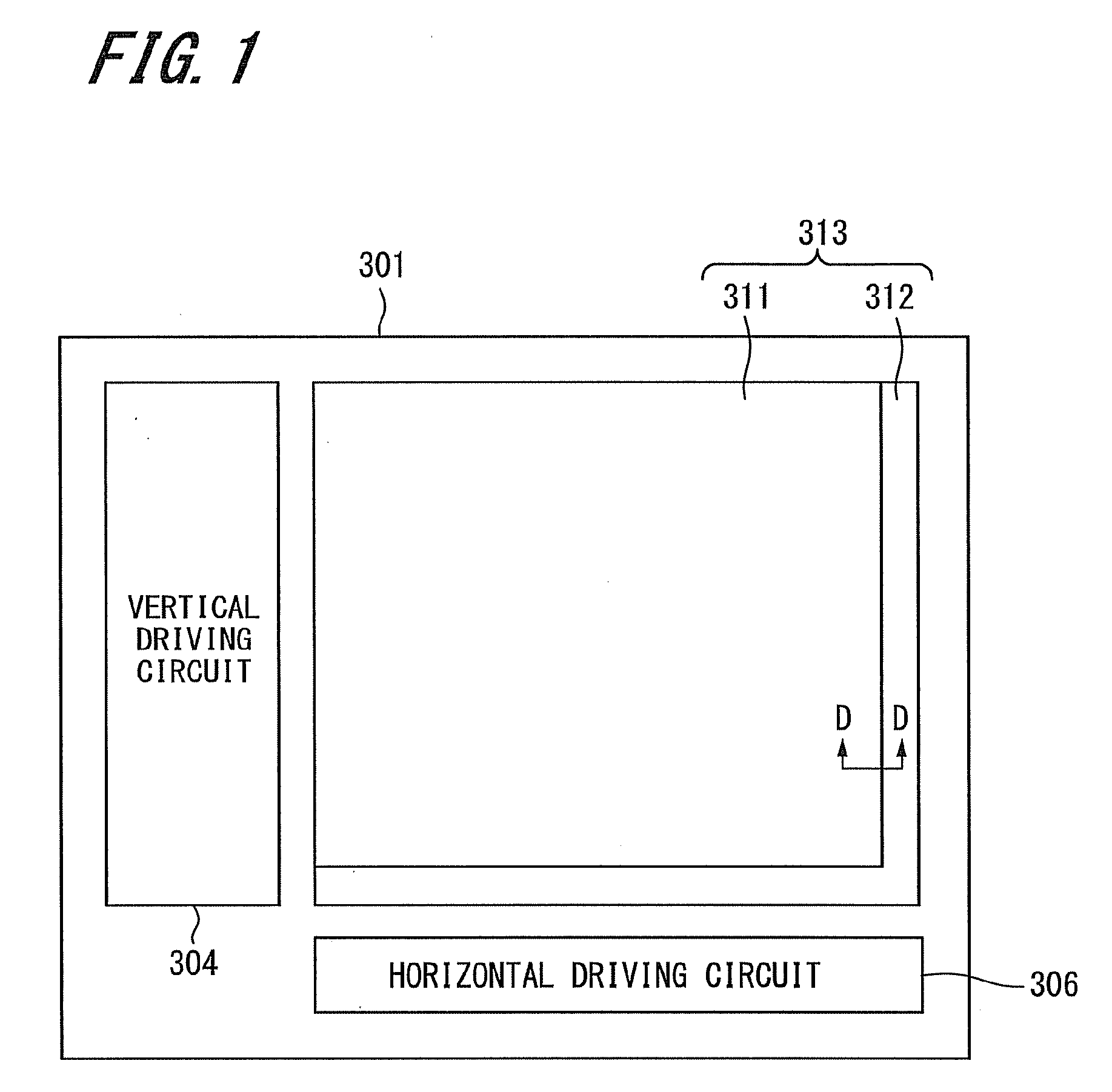

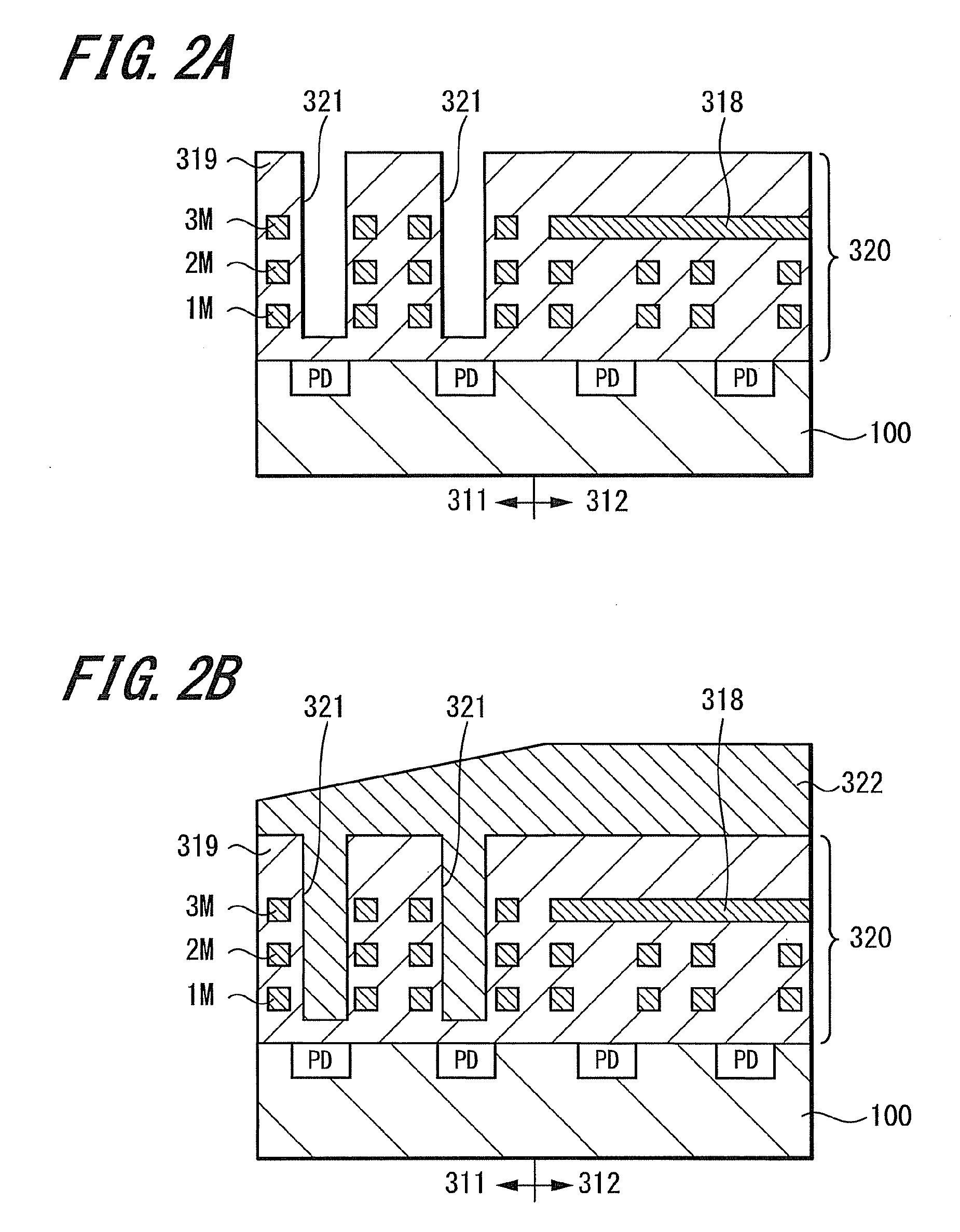

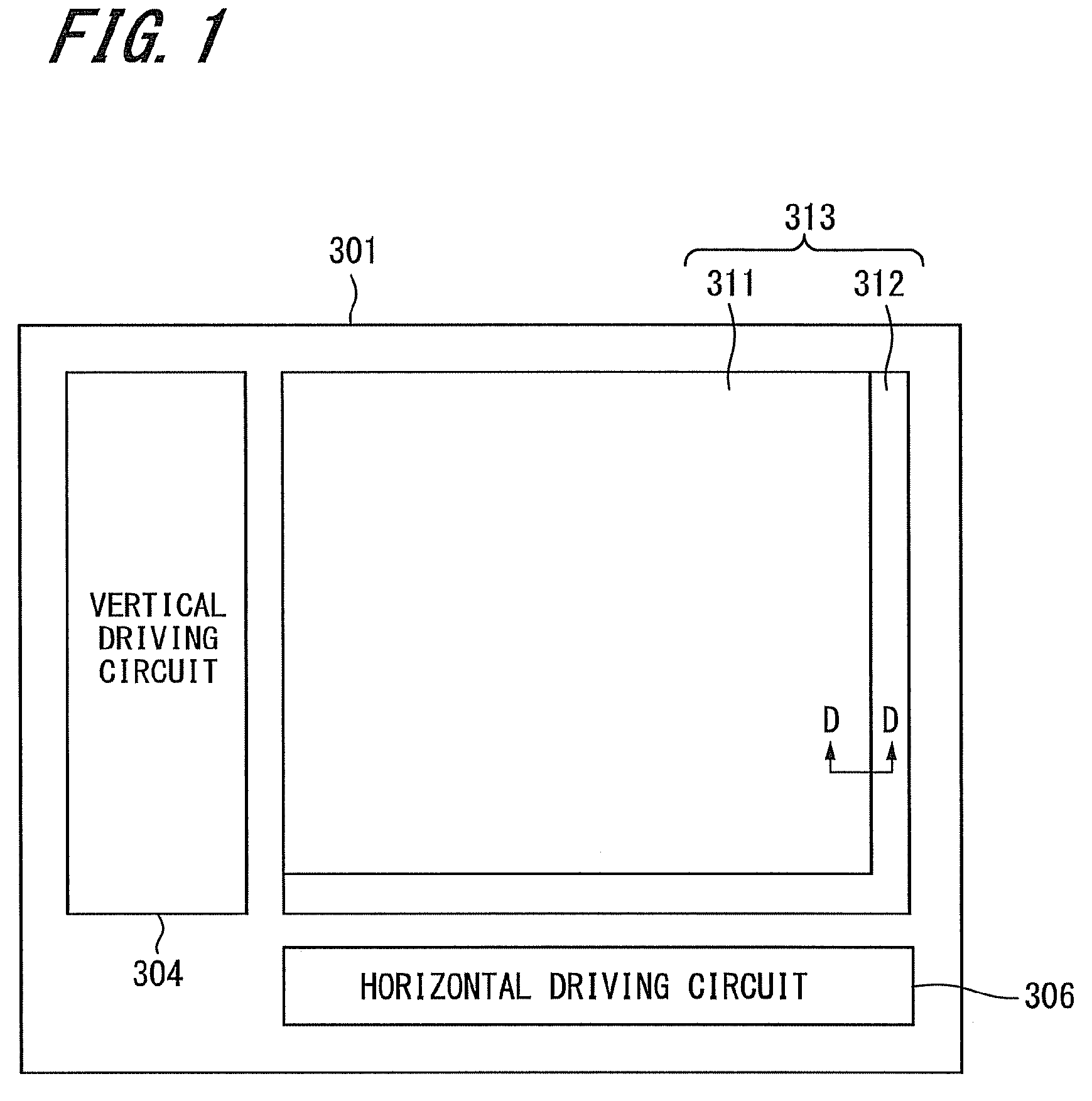

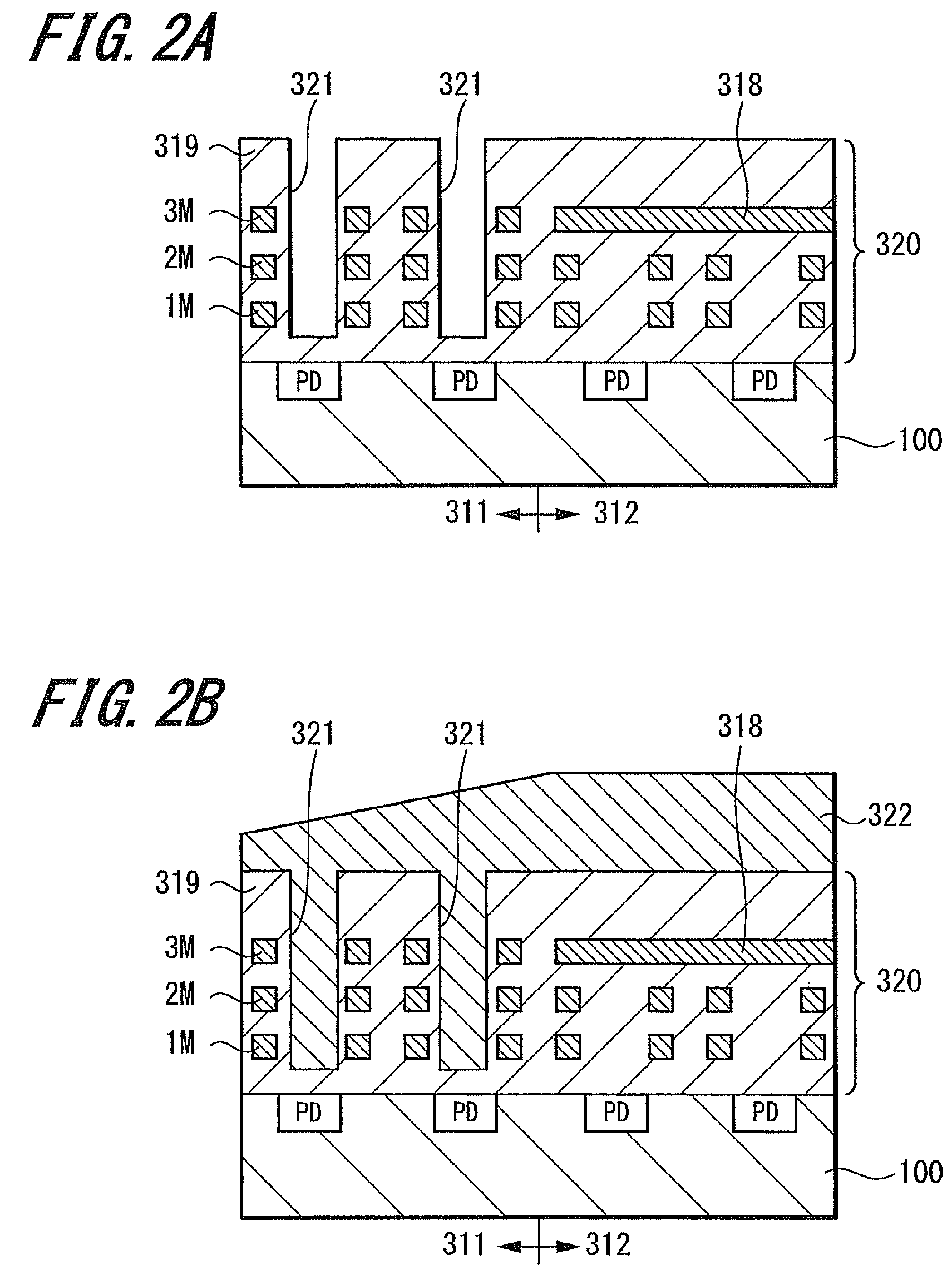

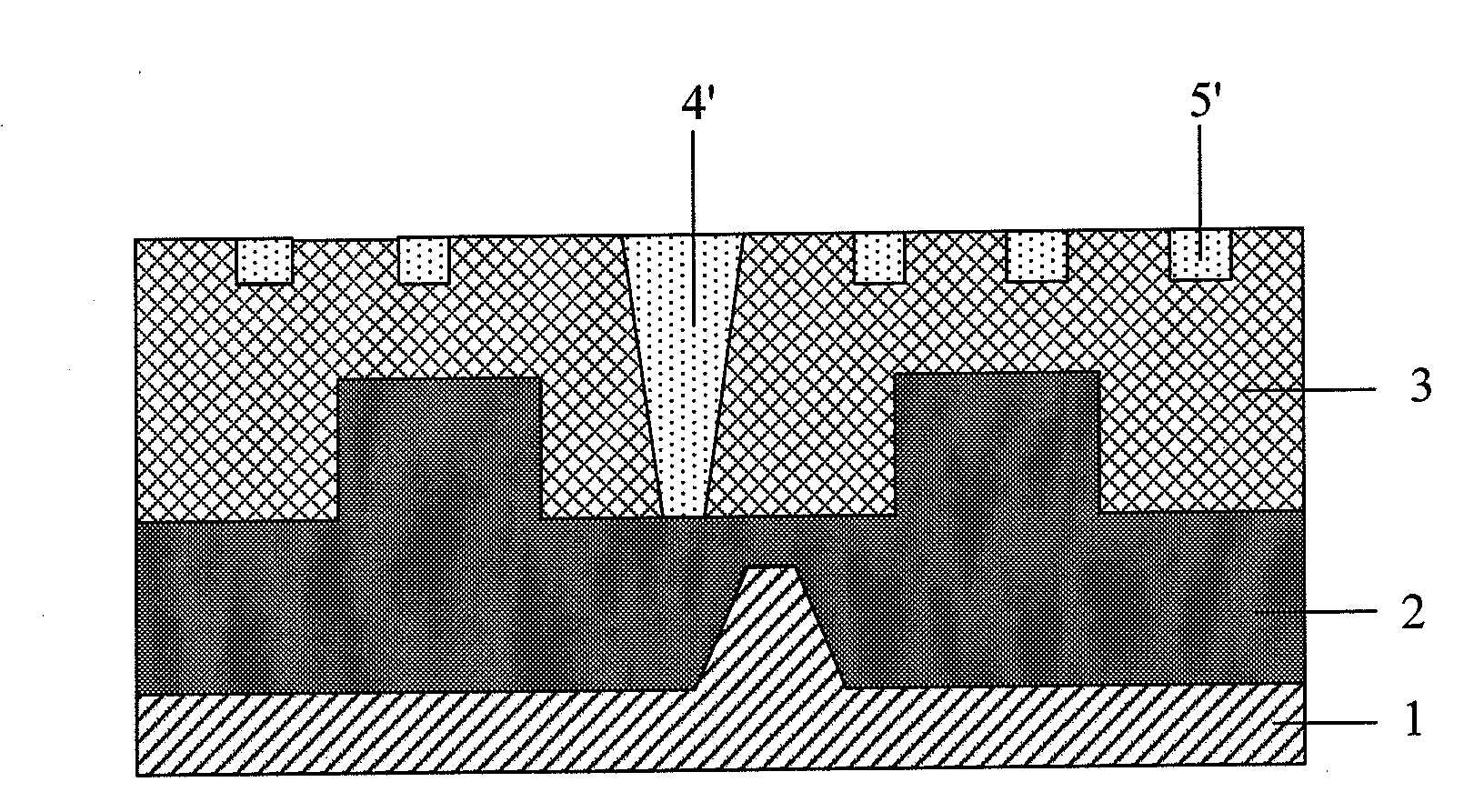

Solid-state imaging device, method of manufacturing the same, and camera and electronic apparatus using the same

InactiveUS20090166783A1Reduce the differenceDecreased sensitivity unevennessTelevision system detailsSolid-state devicesEngineeringPhotoelectric conversion

A method of manufacturing a solid-state imaging device is provided. The method includes: forming an insulating layer extending over an effective pixel region where a plurality of pixels each having a photoelectric conversion element is arranged and a peripheral area adjacent to the effective pixel region; forming an opening in the insulating layer located immediately above the photoelectric conversion element on the effective pixel region; forming a dummy opening in the insulating layer on the peripheral region; and forming a buried layer on the insulating layer to fill the opening and the dummy opening formed in the insulating layer.

Owner:SONY CORP

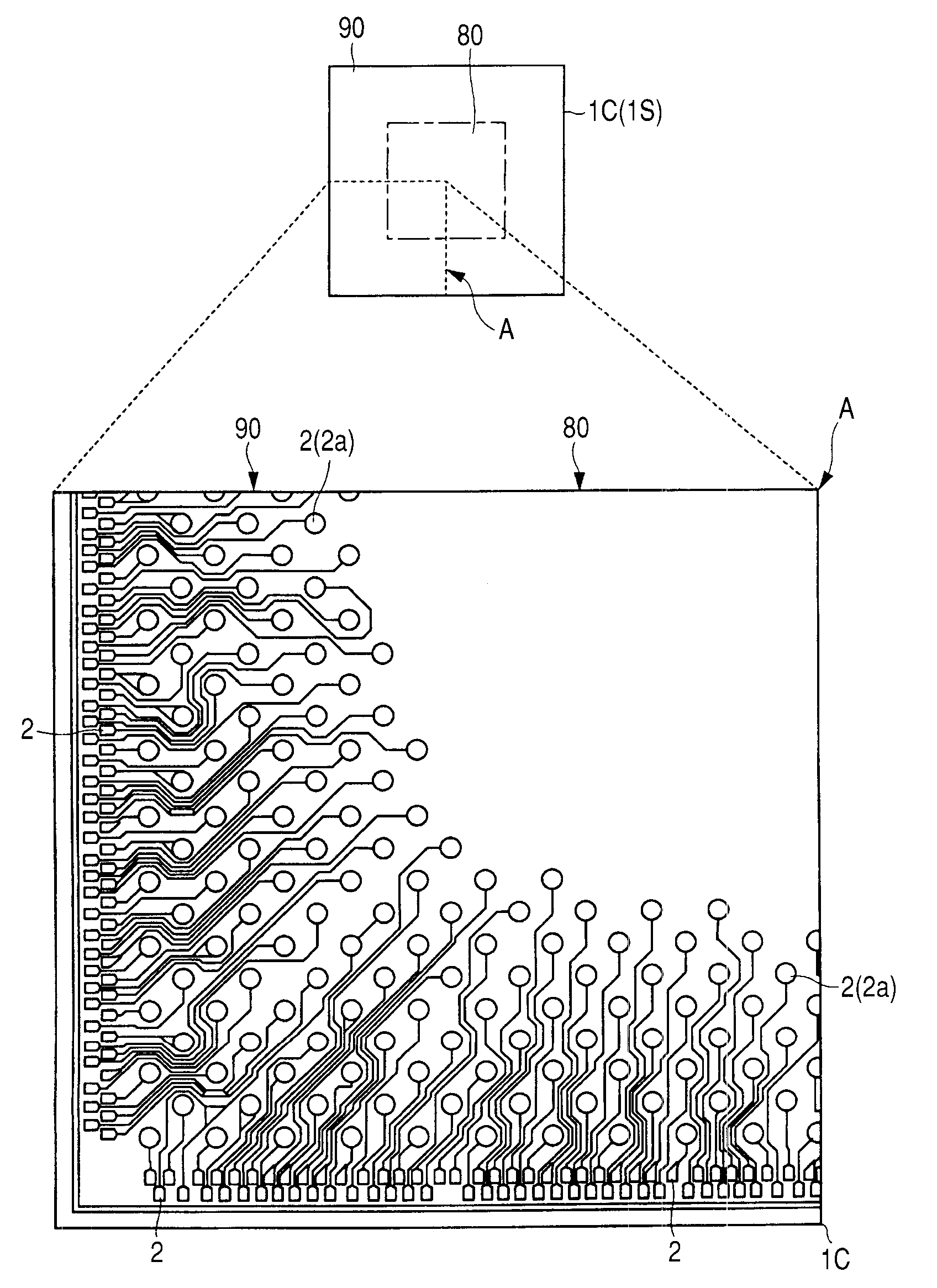

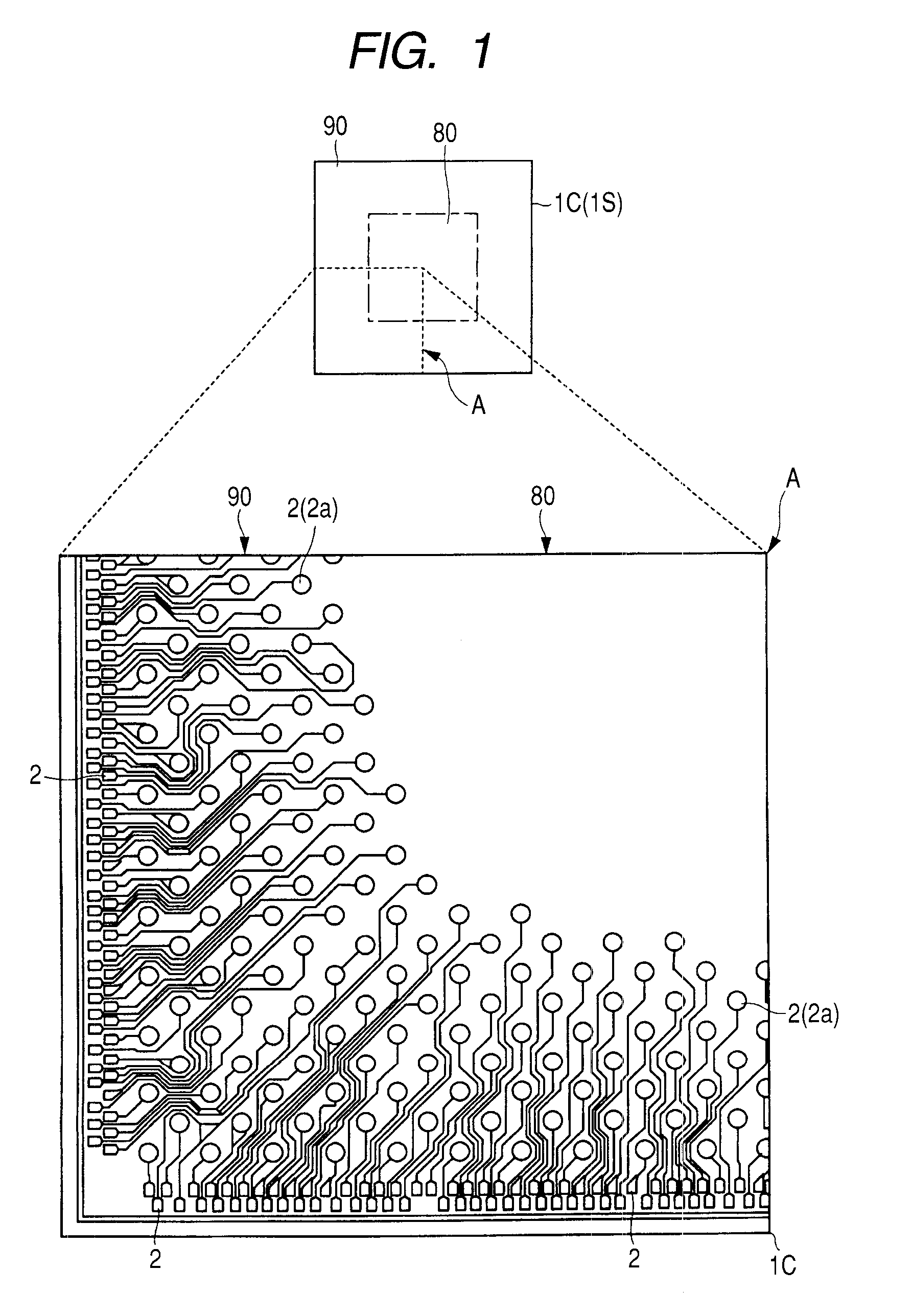

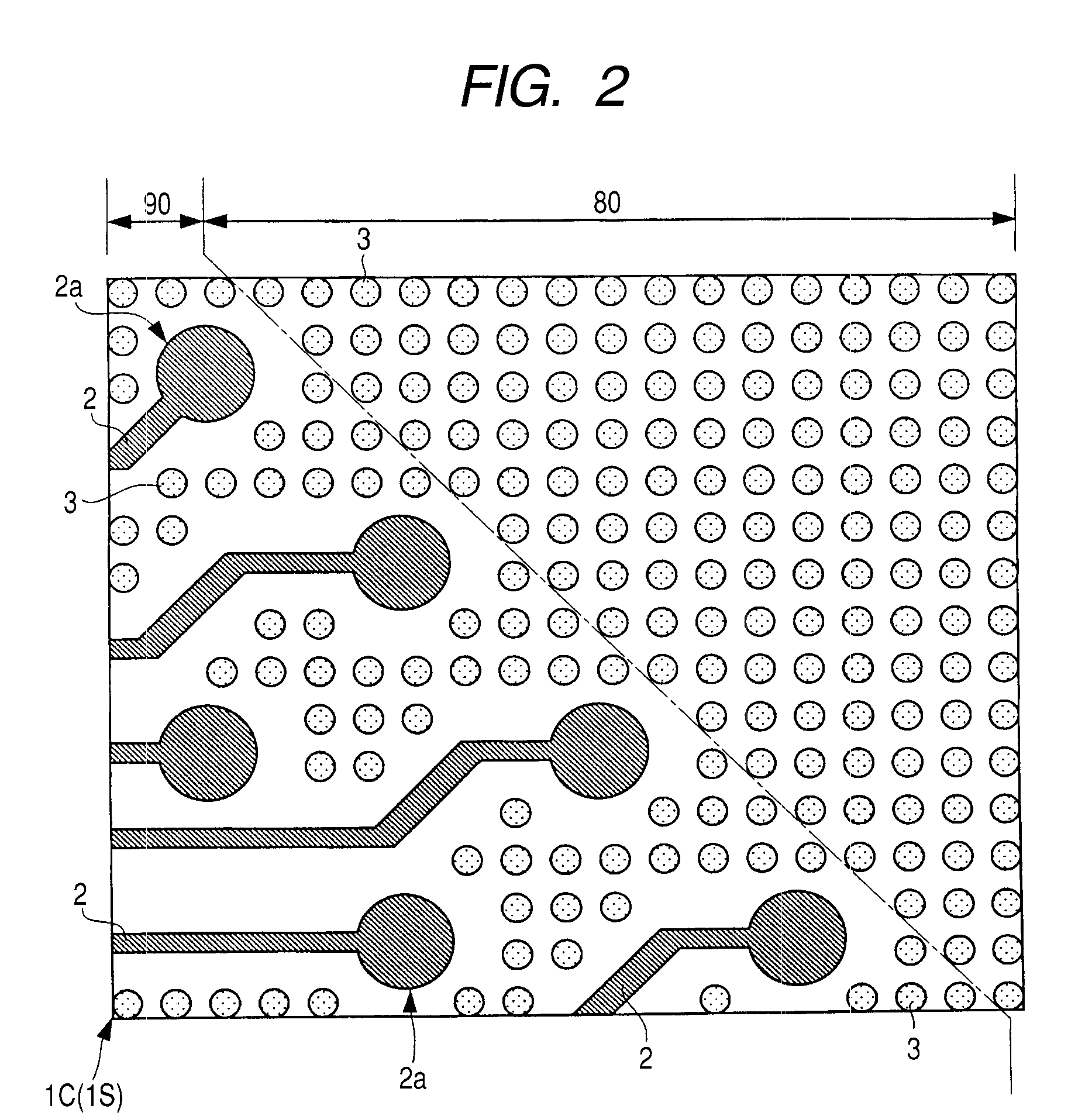

Semiconductor device and a method of manufacturing the sae

ActiveUS20090206490A1Low reliabilityReduce productionSemiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device

A semiconductor device having redistribution interconnects in the WPP technology and improved reliability, wherein the redistribution interconnects have first patterns and second patterns which are electrically separated from each other within the plane of the semiconductor substrate, the first patterns electrically coupled to the multi-layer interconnects and the floating second patterns are coexistent within the plane of the semiconductor substrate, and the occupation ratio of the total of the first patterns and the second patterns within the plane of the semiconductor substrate, that is, the occupation ratio of the redistribution interconnects is 35 to 60%.

Owner:RENESAS ELECTRONICS CORP

Radiation curable resin composition for making colored three dimensional objects

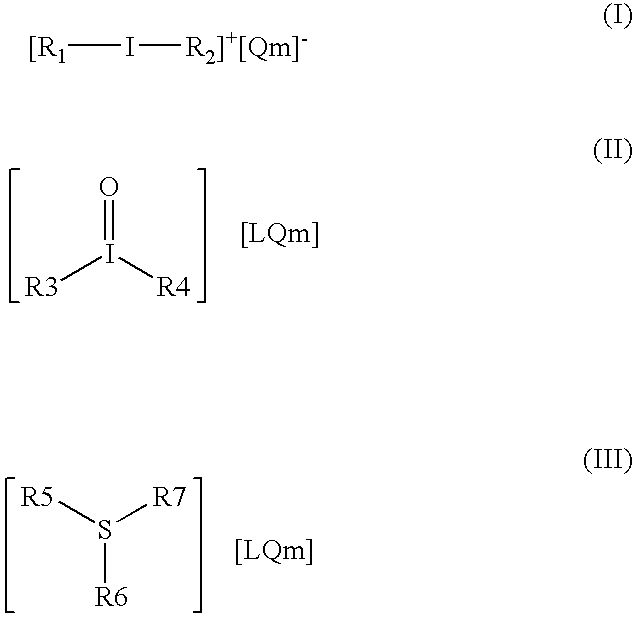

InactiveUS20030149124A1Easy to correctEasy to monitorOrganic chemistryLavatory sanitoryEpoxyPolymer science

A radiation curable resin composition suitable for making three dimensional objects comprising at least one epoxy compound, a cationic photoinitiator, wherein the resin composition has a first color or no color before cure and wherein a three dimensional object made from the resin by subjecting the resin to radiation shows a second color which is different from the color of the resin composition before cure.

Owner:DSM IP ASSETS BV

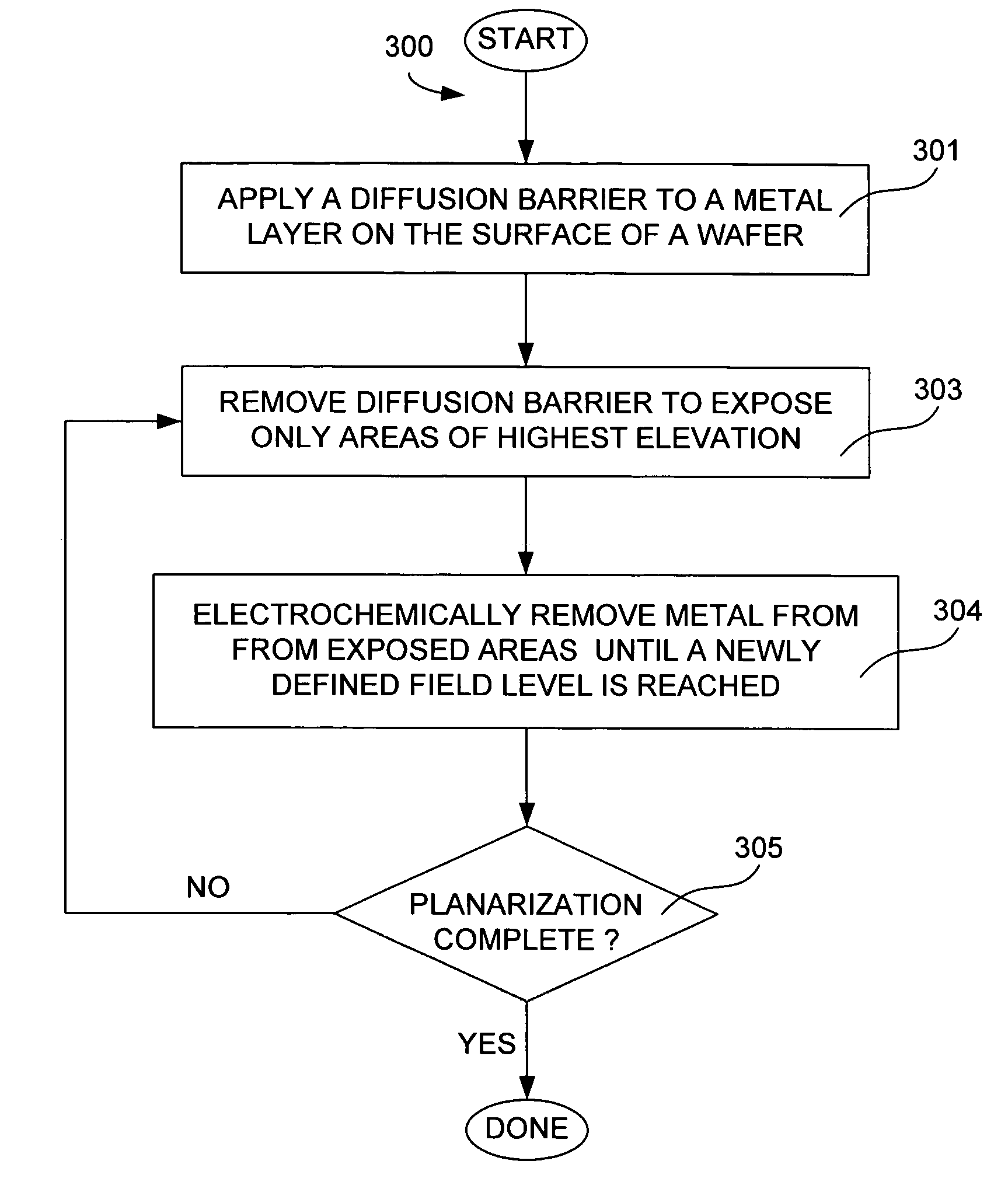

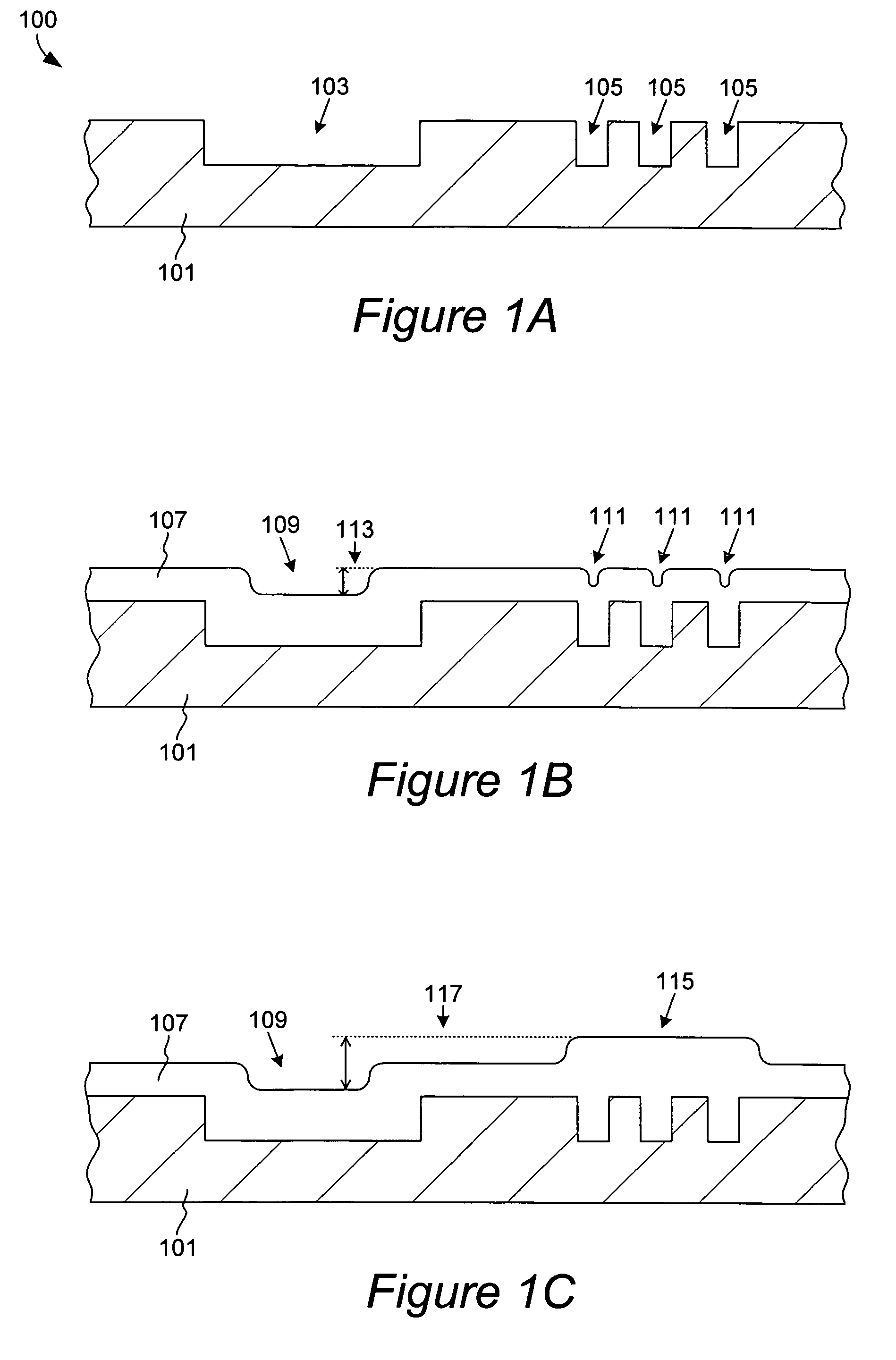

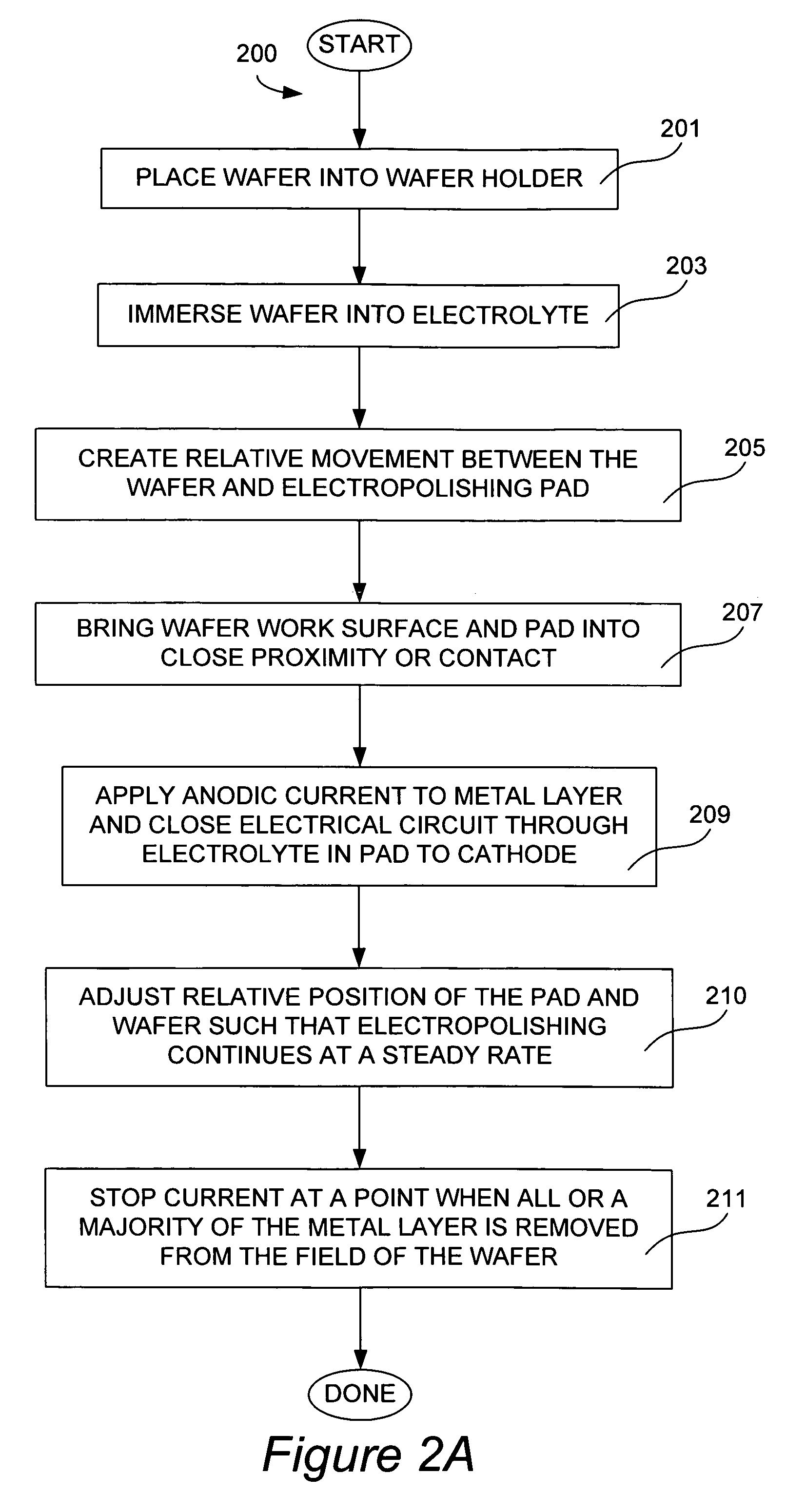

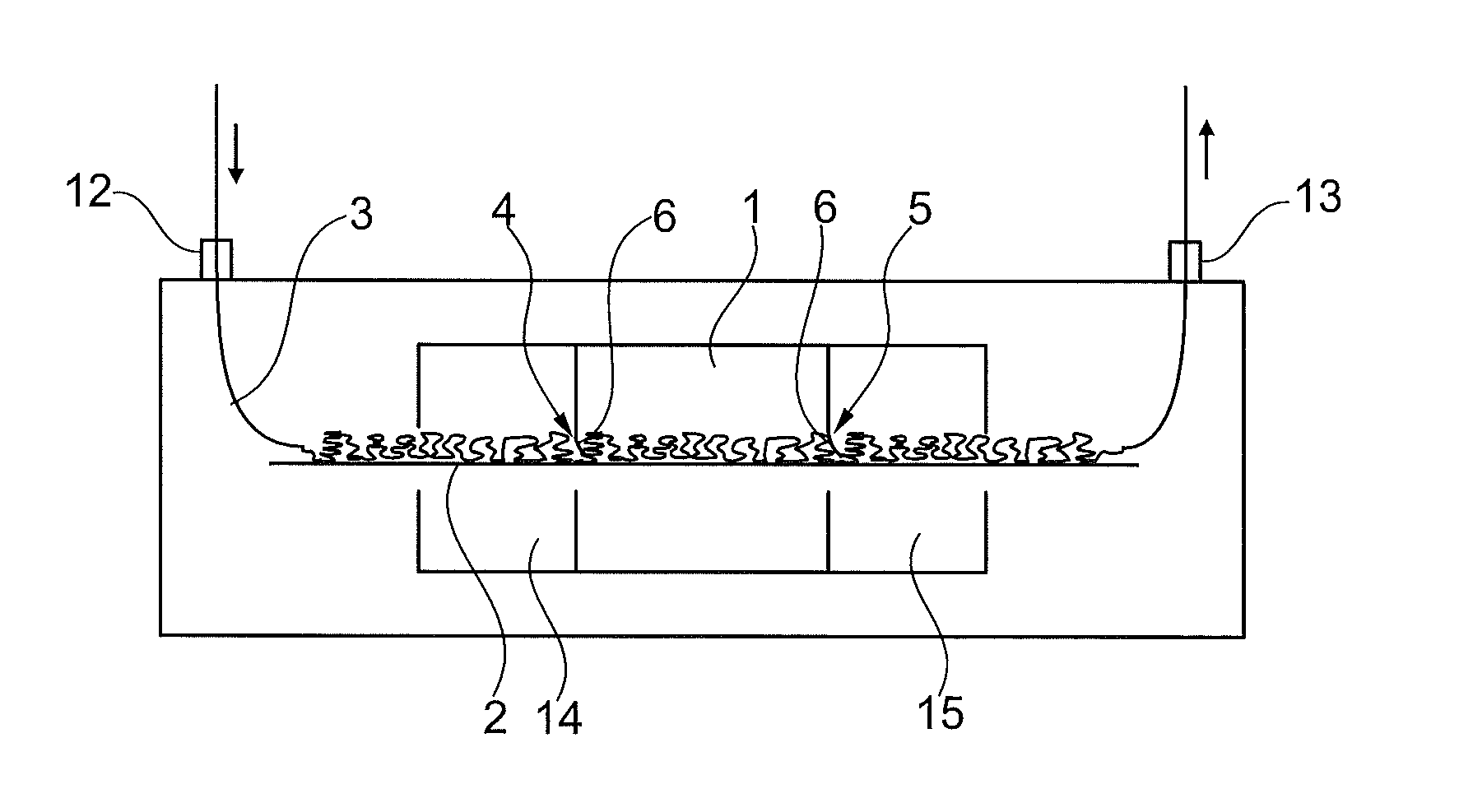

Method and apparatus for uniform electropolishing of damascene IC structures by selective agitation

InactiveUS7531079B1Small apertureSufficiently porousElectrolysis componentsSemiconductor/solid-state device manufacturingBiomedical engineeringLarge range

The present invention pertains to apparatus and methods for planarization of metal surfaces having both recessed and raised features, over a large range of feature sizes. The invention accomplishes this by increasing the fluid agitation in raised regions with respect to recessed regions. That is, the agitation of the electropolishing bath fluid is agitated or exchanged as a function of elevation on the metal film profile. The higher the elevation, the greater the movement or exchange rate of bath fluid. In preferred methods of the invention, this agitation is achieved through the use of a microporous electropolishing pad that moves over (either near or in contact with) the surface of the wafer during the electropolishing process. Thus, methods of the invention are electropolishing methods, which in some cases include mechanical polishing elements.

Owner:NOVELLUS SYSTEMS

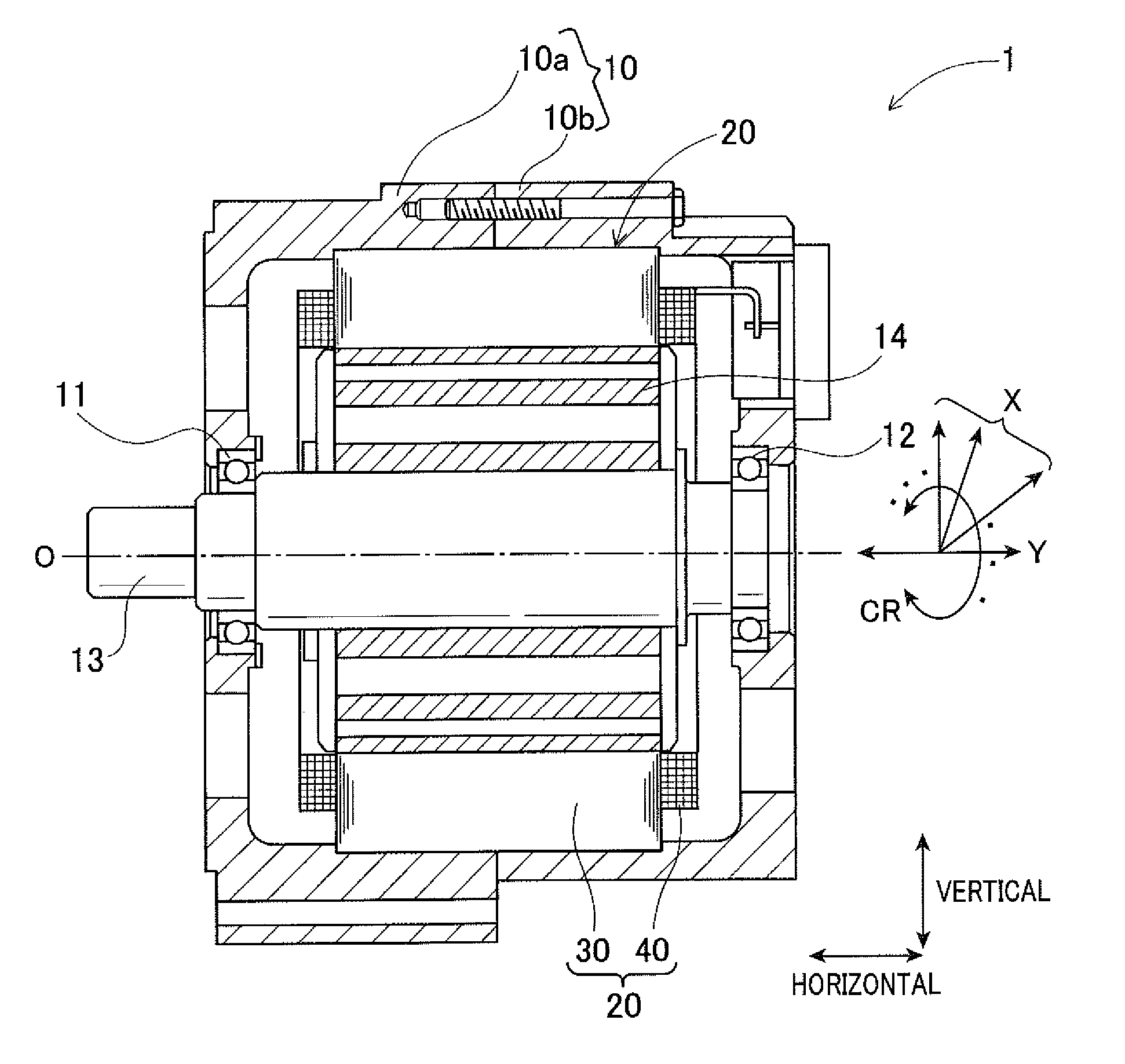

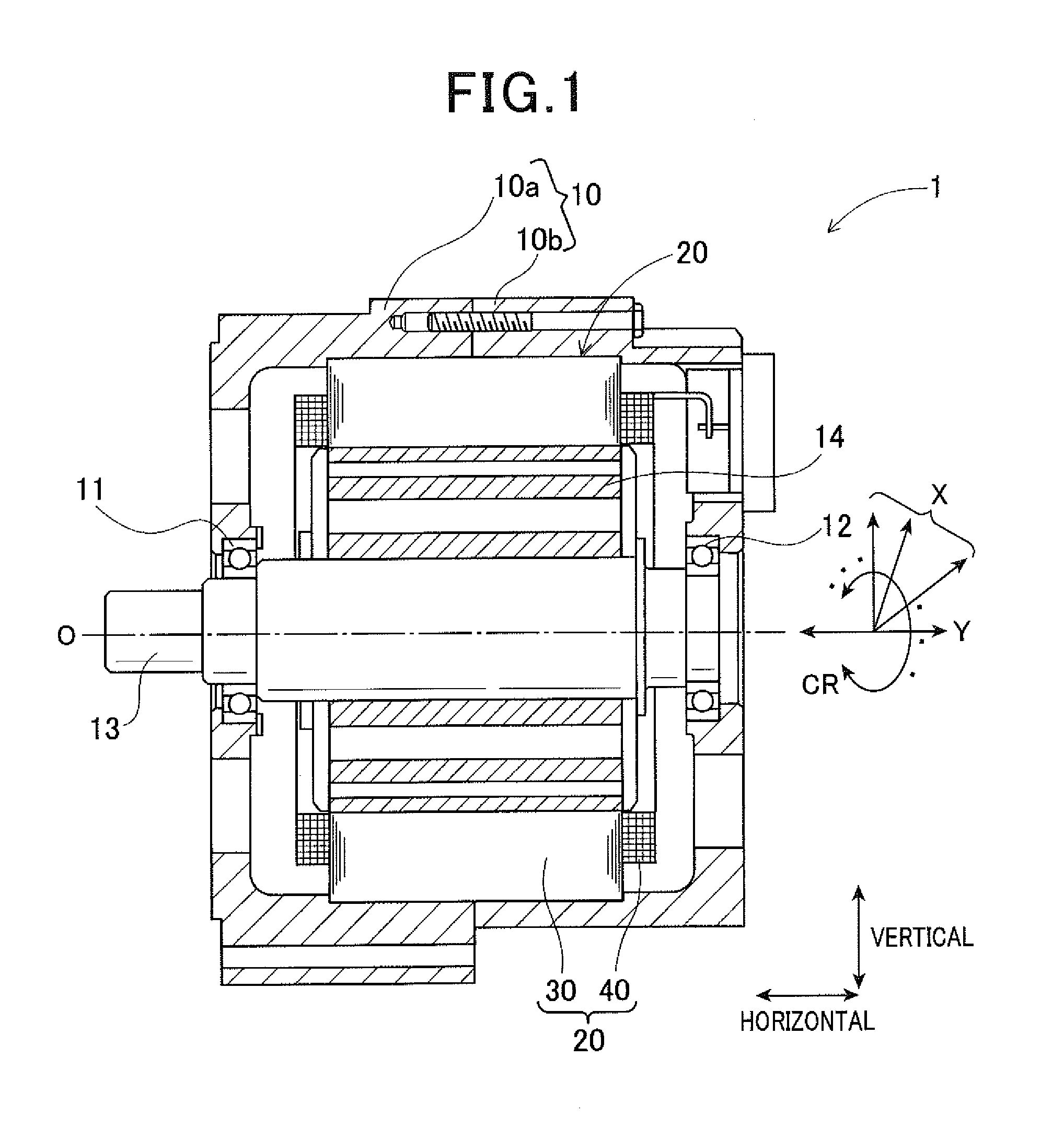

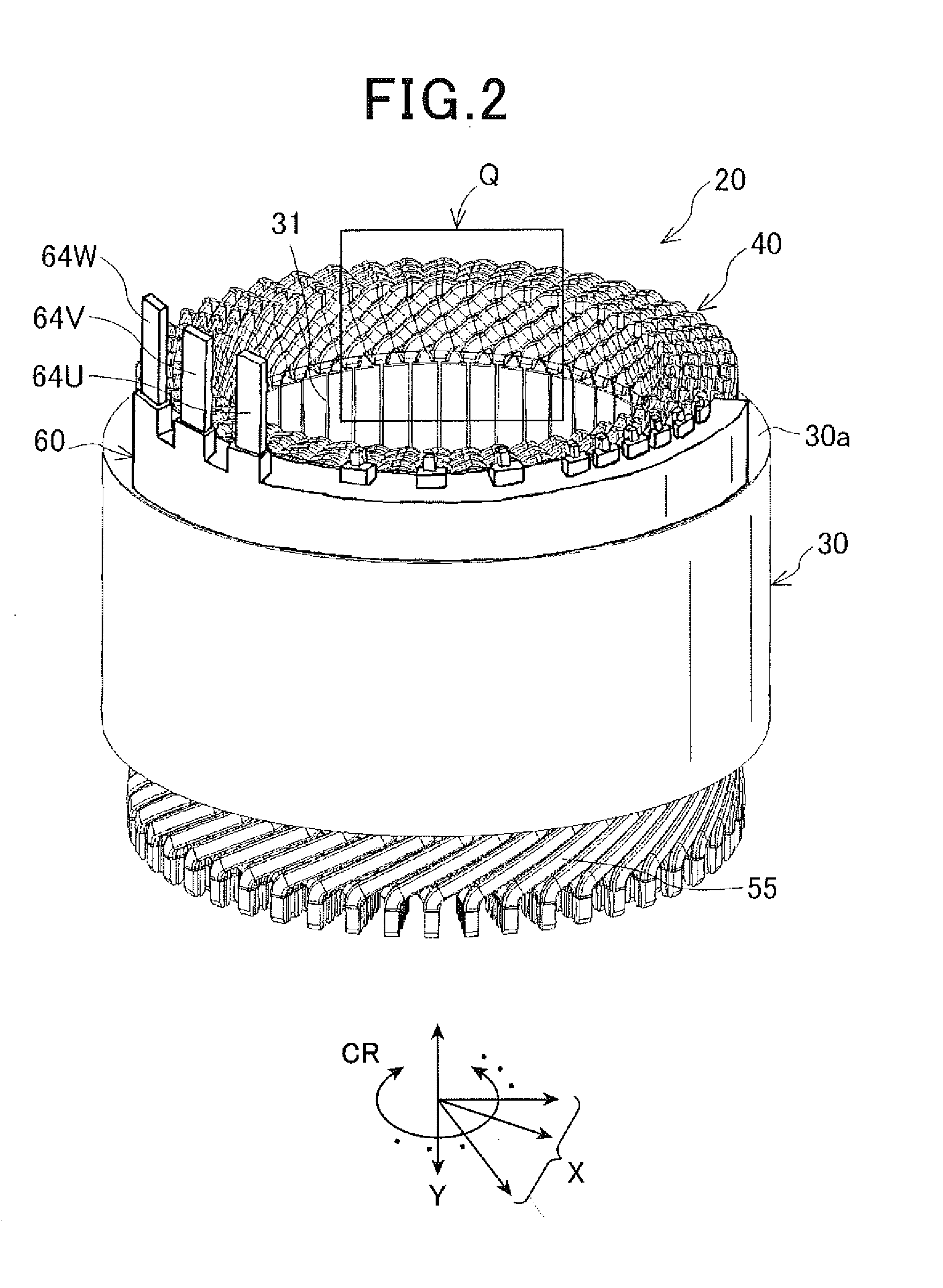

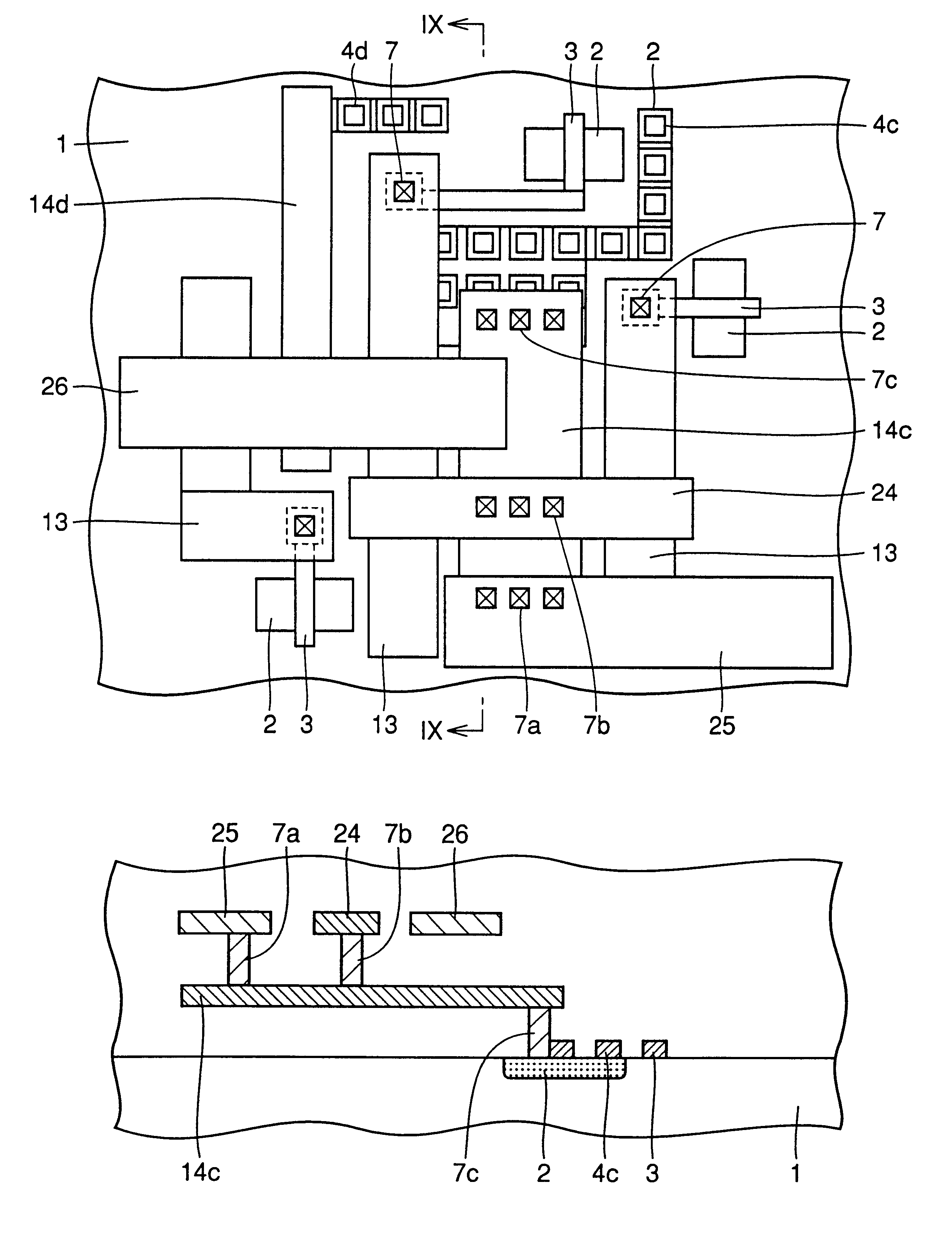

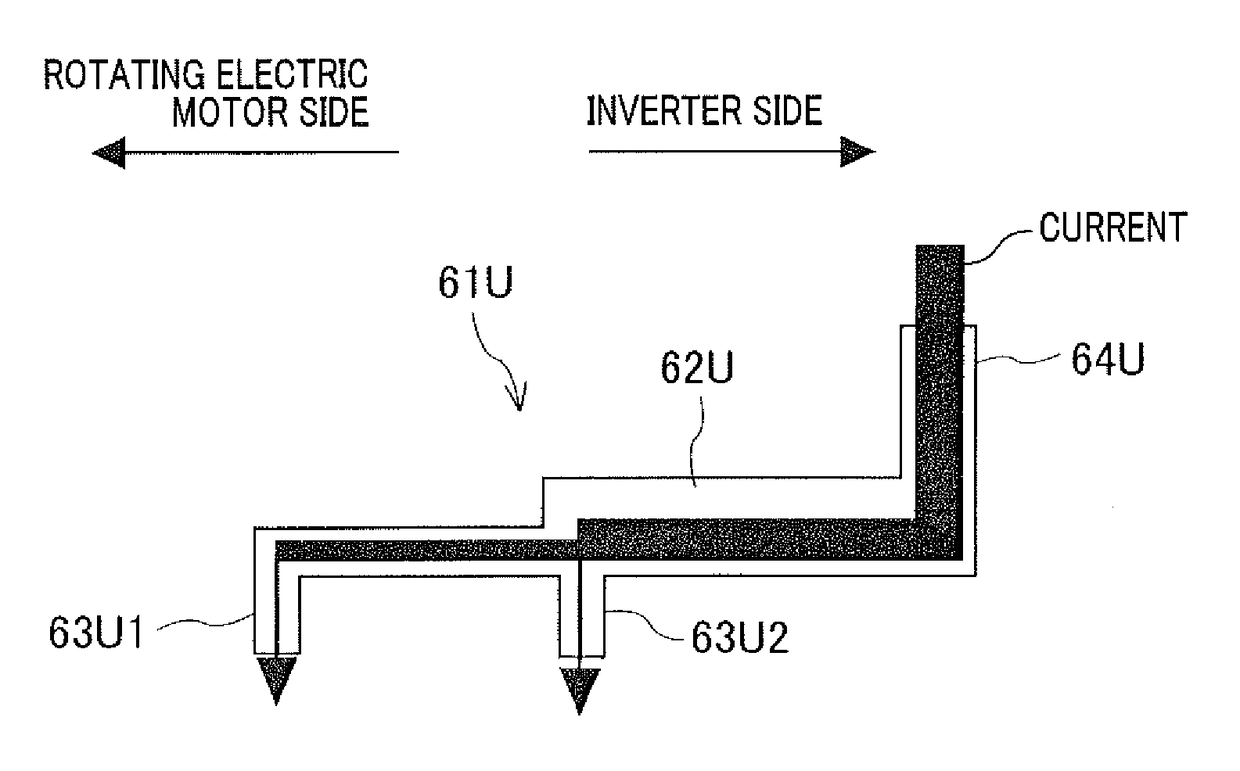

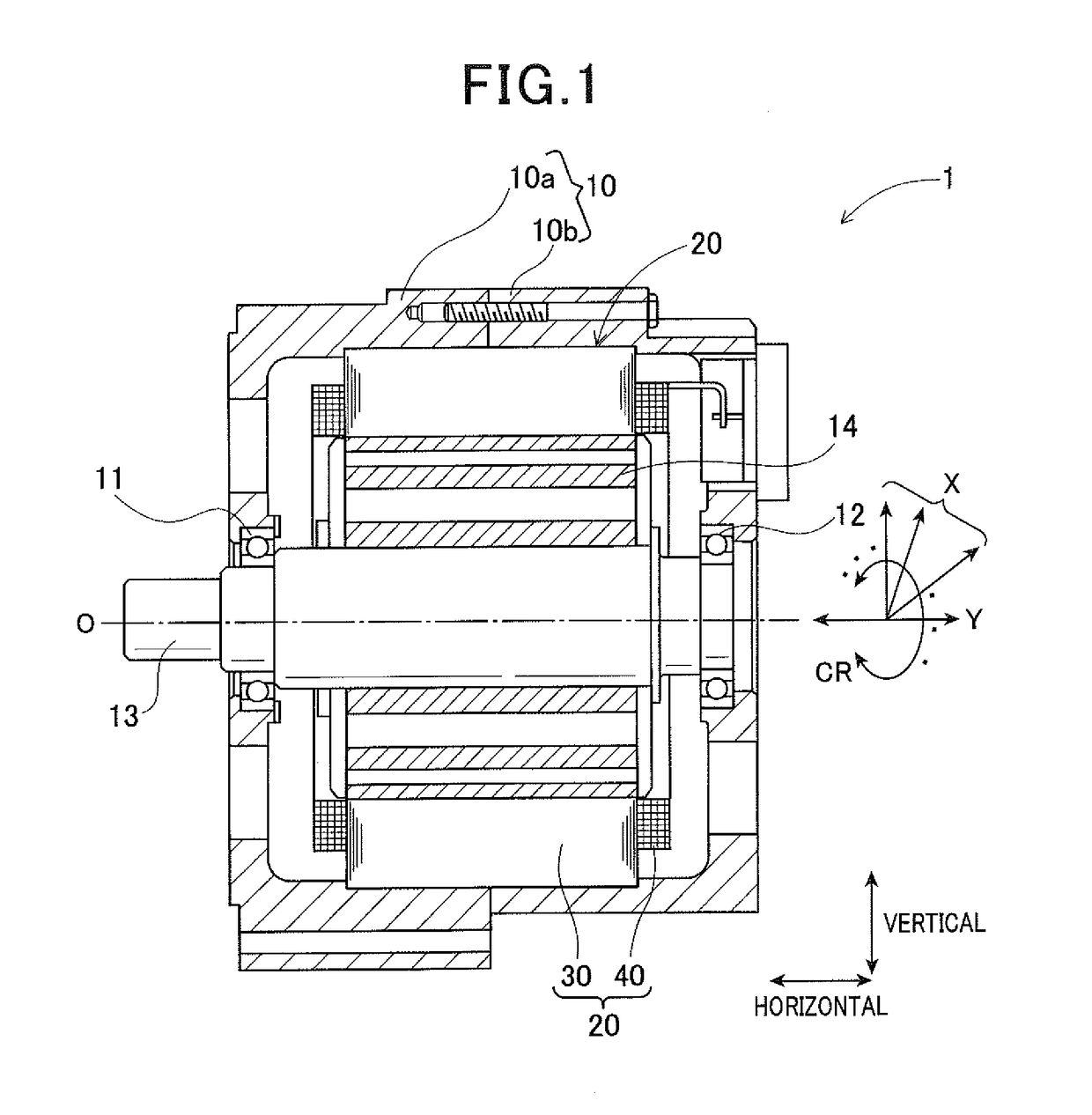

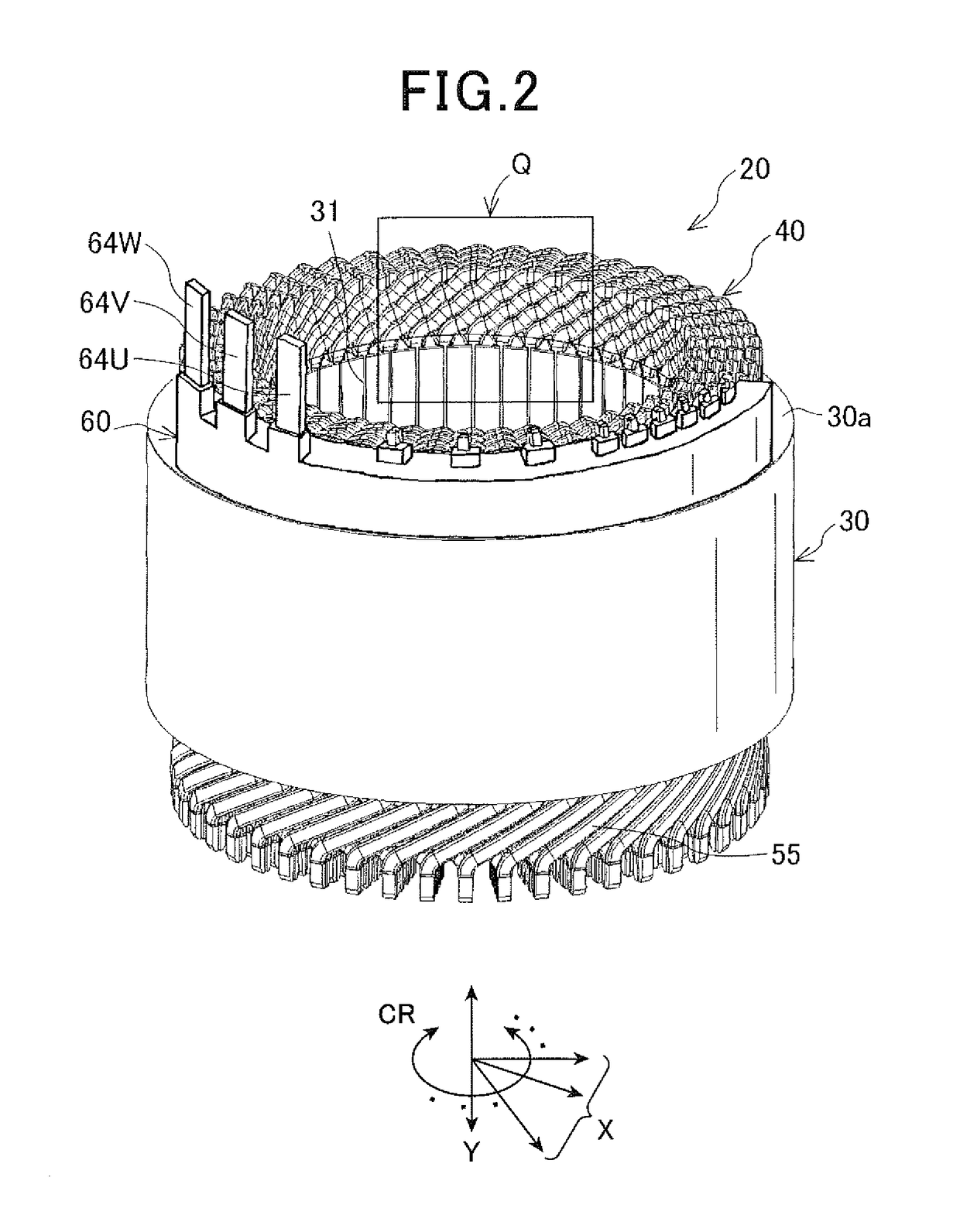

Stator of Rotating Electric Machine

ActiveUS20160020658A1Reduce the temperatureAvoid it happening againCoupling device connectionsCooling/ventillation arrangementElectric machineThree-phase

In a stator of a rotating electric machine, an annular stator core has slots. A stator winding includes phase windings of three phases of differing electrical phases that are housed in the slots and wound around the stator core. Three phase bus bars electrically connect the respective phase windings to an external apparatus. Each of the phase windings are configured by multiple parallel windings. The phase bus bars are integrated with a fixing member to form a bus bar module. Each of the phase bus bars include branch portions and a trunk portion. The branch portions are electrically connected to the respective phase windings. The trunk portion electrically connects together the branch portions, and is configured that a cross-sectional area of an end portion closest to the phase winding is smaller than a cross-sectional area of an end portion closest to the external apparatus.

Owner:DENSO CORP

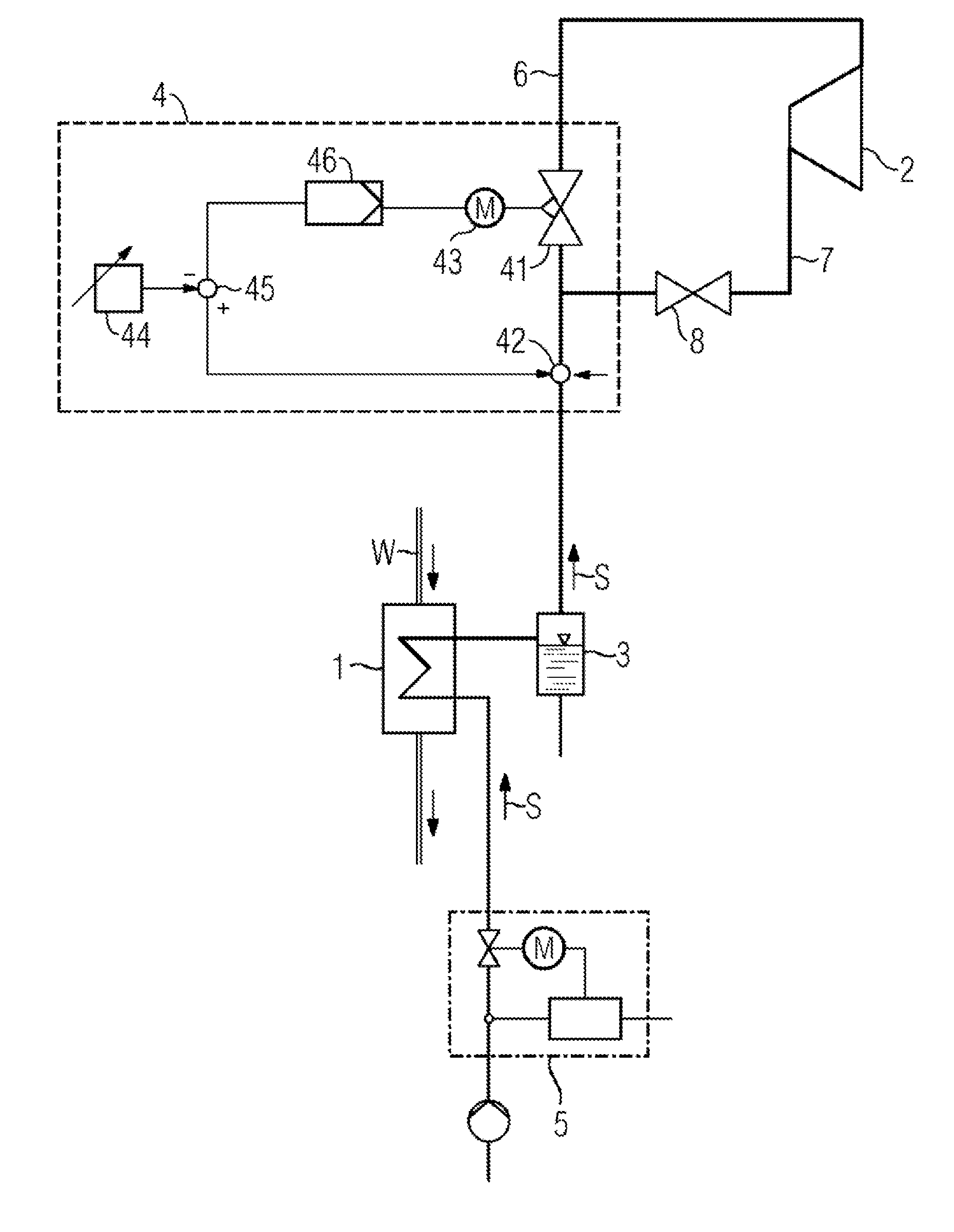

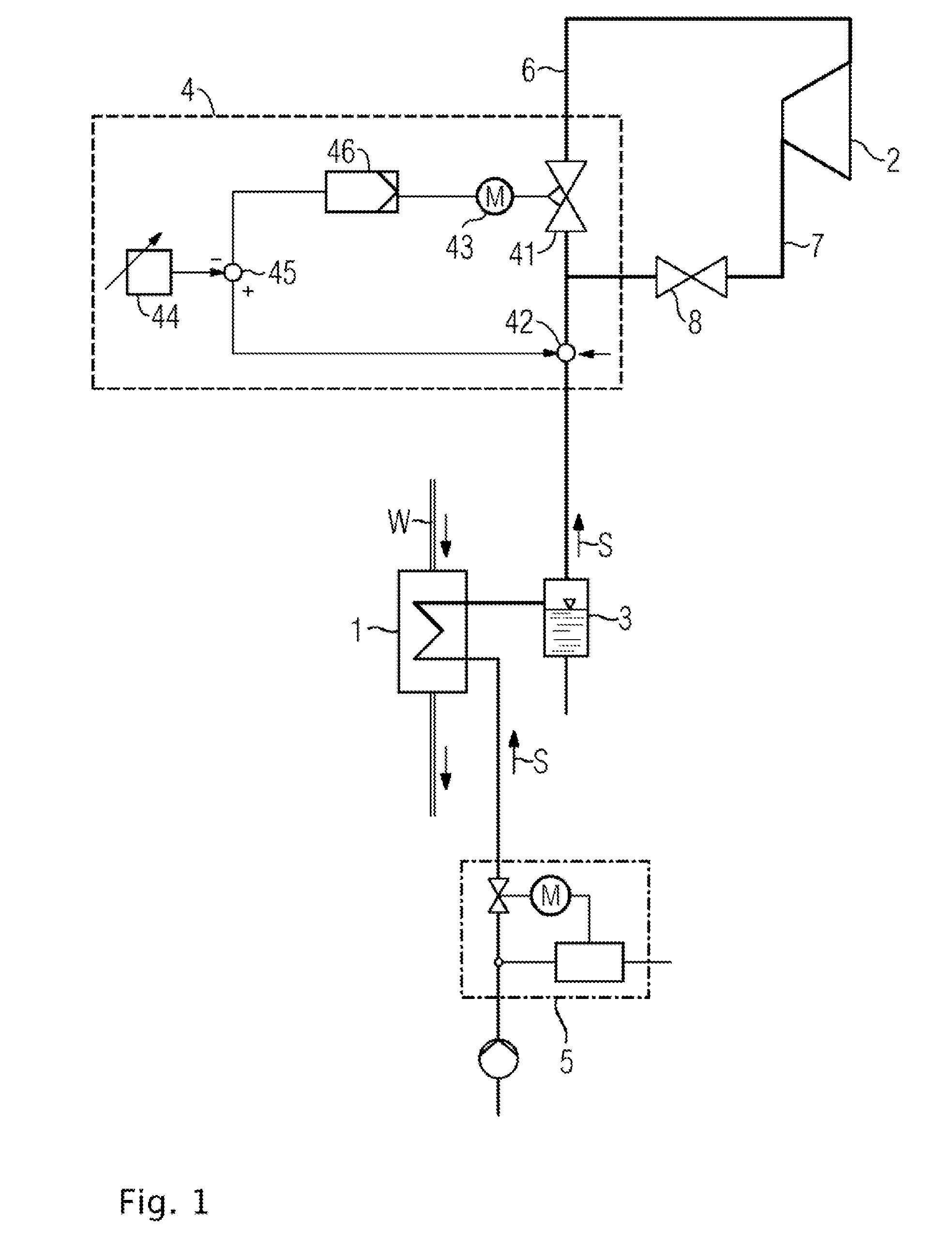

Operating method for starting a once-through steam generator heated using solar thermal energy

InactiveUS20160208657A1Quick implementationDifference in densityFrom solar energyBoiler controlHeat carrierEngineering

An operating method for starting a once-through steam generator heated using solar thermal energy, wherein a flow medium flowing through the once-through steam generator is evaporated and superheated, using a heat carrier medium heated in a solar array, for a steam turbine connected downstream of the once-through steam generator on the flow medium side. In an operating phase under load, a first desired steady pressure value is predetermined, and in a starting phase preceding the operating phase under load, a second desired steady pressure value is predetermined, in which starting phase evaporated flow medium is diverted around the steam turbine via a steam bypass, and controlled by the predetermined second desired steady pressure value.

Owner:SIEMENS AG

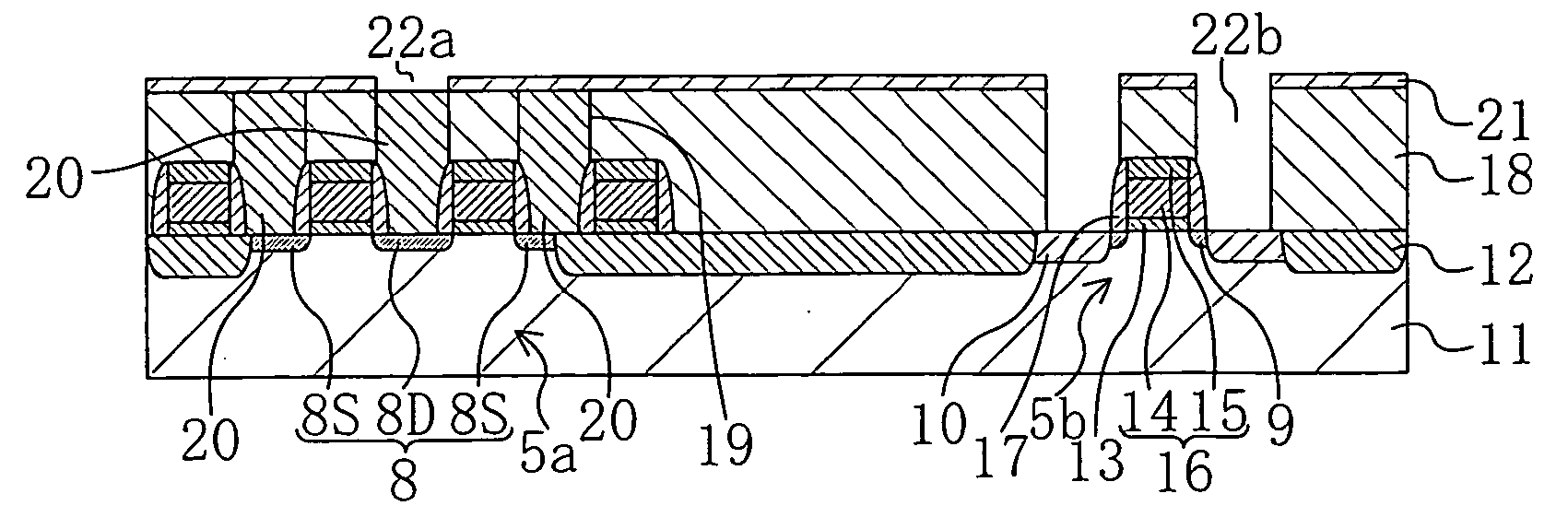

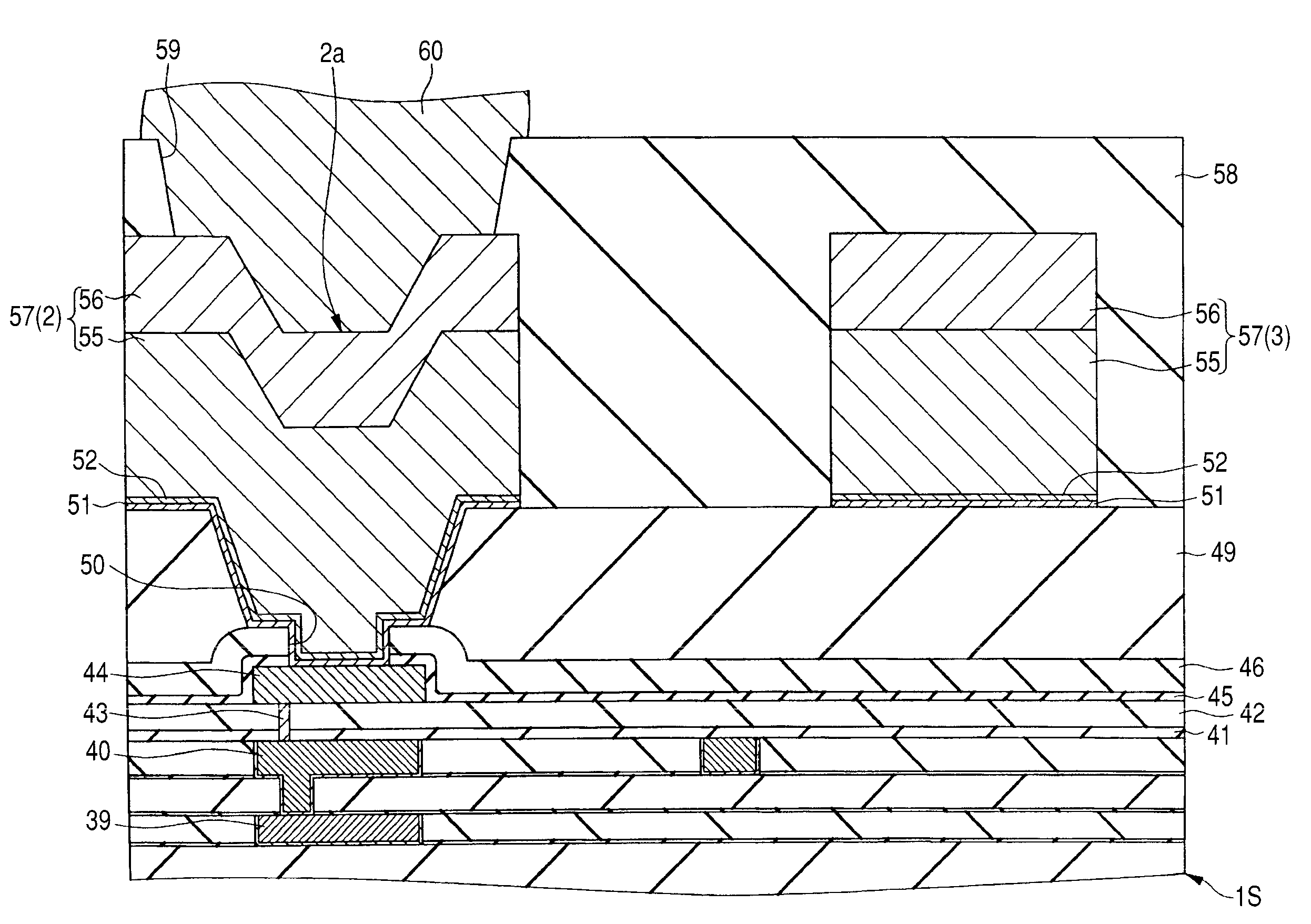

Semiconductor device and method for fabricating the same

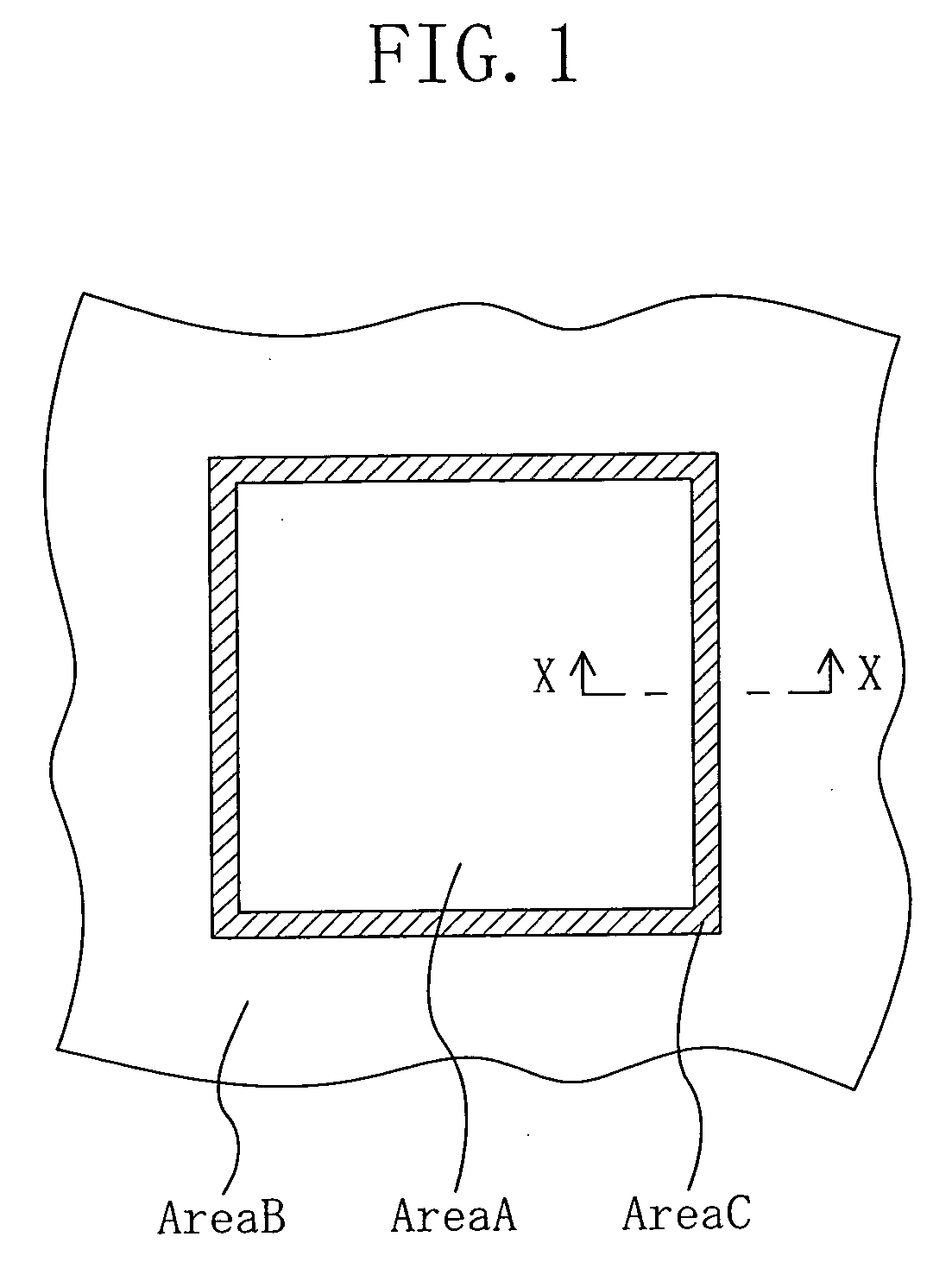

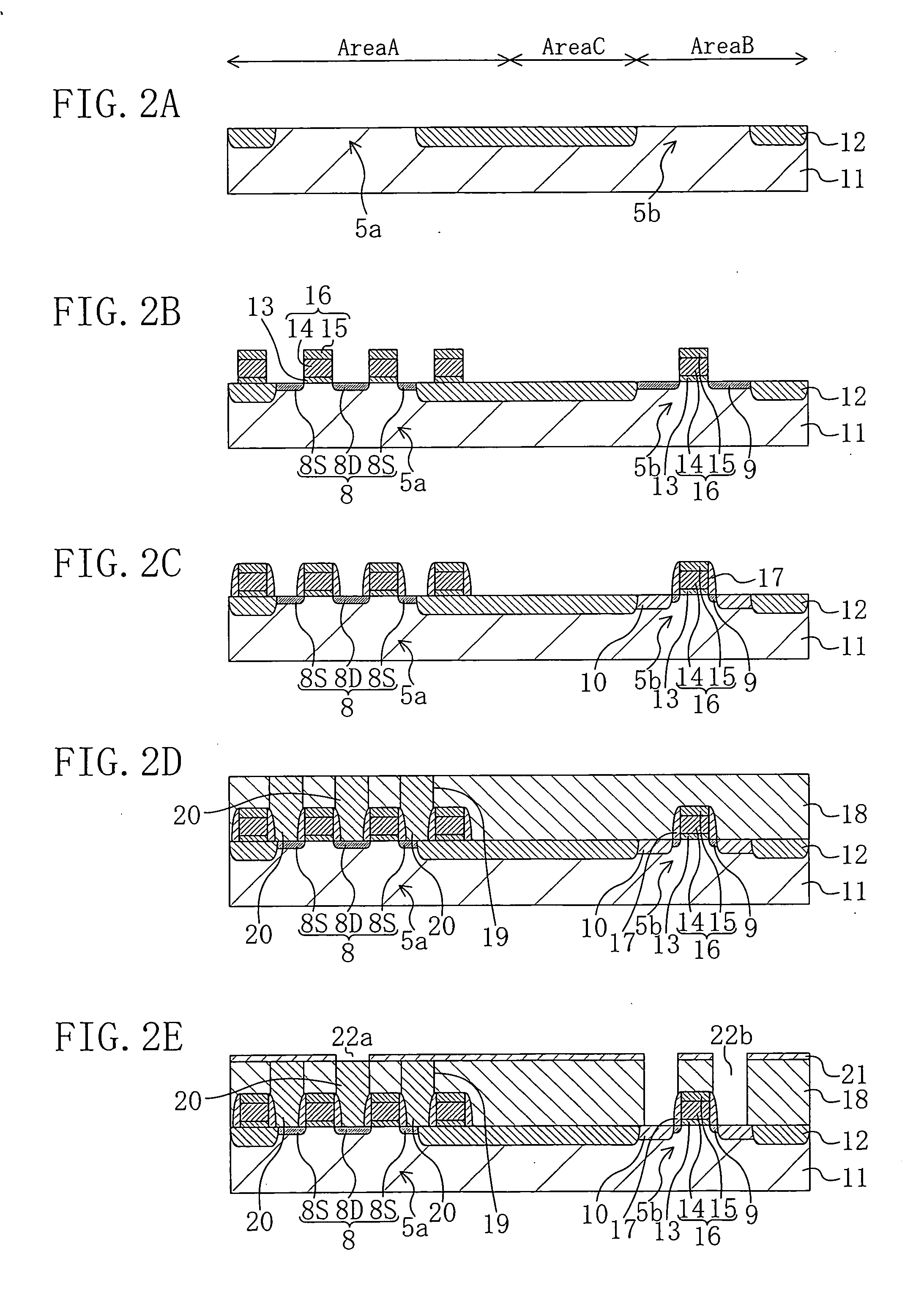

InactiveUS20060011964A1Reduce film formation variationReduce film formation variation and polishing amount variationTransistorSolid-state devicesDielectricDevice material

In a semiconductor device of the present invention, capacitors are formed on a part of an interlayer dielectric (26) located in a memory cell area, and another interlayer dielectric (39) is formed on a part of still another interlayer dielectric (30) located in a peripheral circuit area AreaB. Furthermore, a dummy electrode is formed at the boundary AreaC between the memory cell area AreaA and the peripheral circuit area AreaB to cover one side of the another interlayer dielectric (30) and the top surface of the interlayer dielectric (26).

Owner:PANASONIC CORP

Radiation curable resin composition for making colored three dimensional objects

InactiveUS20050142479A1Easy to correctEasy to monitorPhotosensitive material auxillary/base layers3-dimensional image productionChemistryRadiation

Owner:DSM IP ASSETS BV

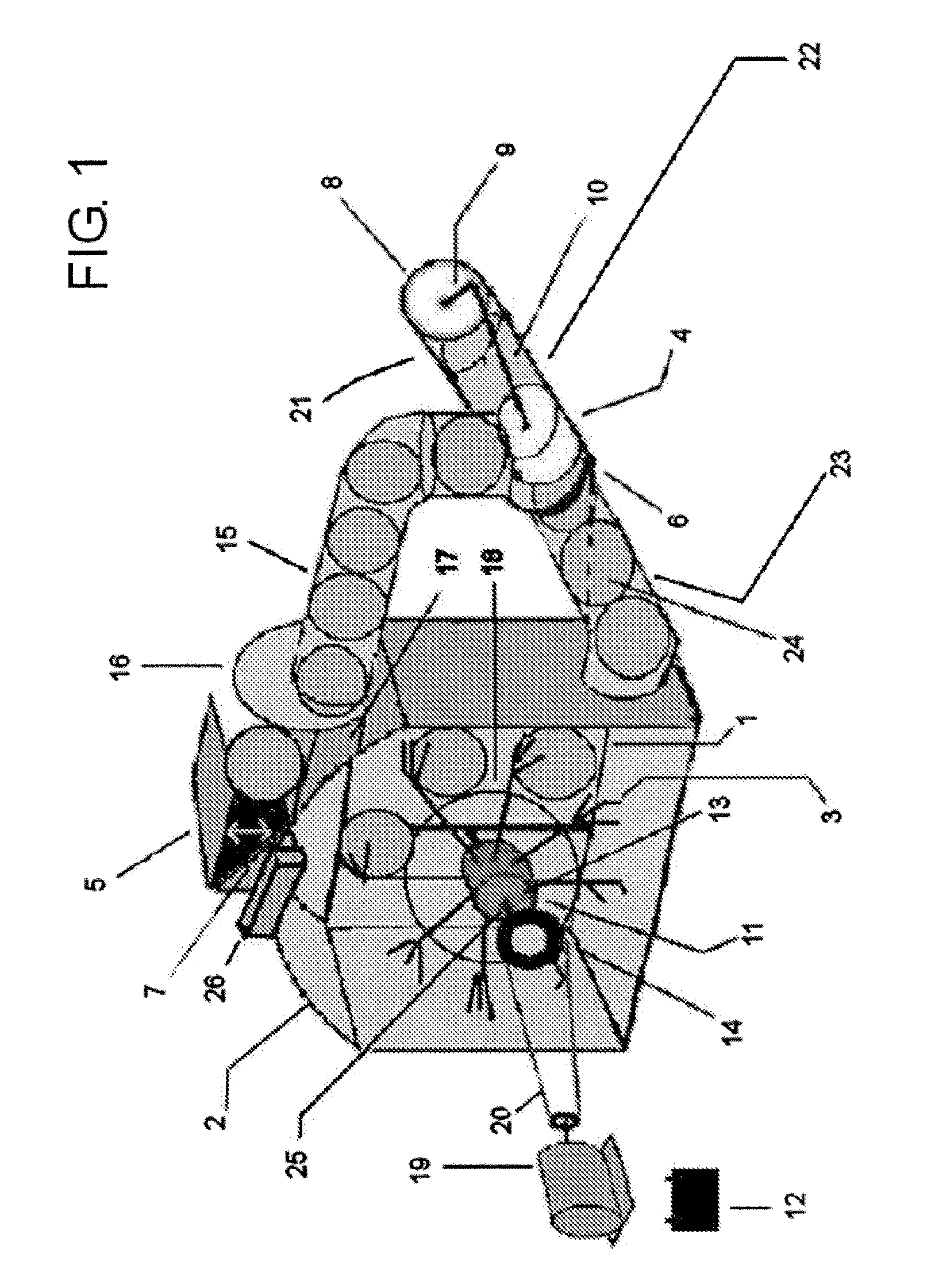

Hydroelectric device for harnessing the buoyant force of an object in a fluid

InactiveUS20090127866A1More momentumDifference in densityHydro energy generationMachines/enginesHydroelectricityElectricity

The present invention provides, in one embodiment, a device for producing electricity, the device including a housing having a volume of fluid therein, a rotor within the housing, the rotor being in fluid communication with the housing and fixedly attached to a shaft. At least one buoy is sized and shaped to move through the fluid in housing, as well as though an inlet and outlet of the housing. An electrical generator is coupled to the shaft to which the rotor is attached. When a buoy moved into the housing through the inlet, it rises in the fluid and is received by the rotor, causing the rotor to turn as the buoy continues to rise. The turning of the rotor operates the electrical generator.

Owner:COOK LARRY

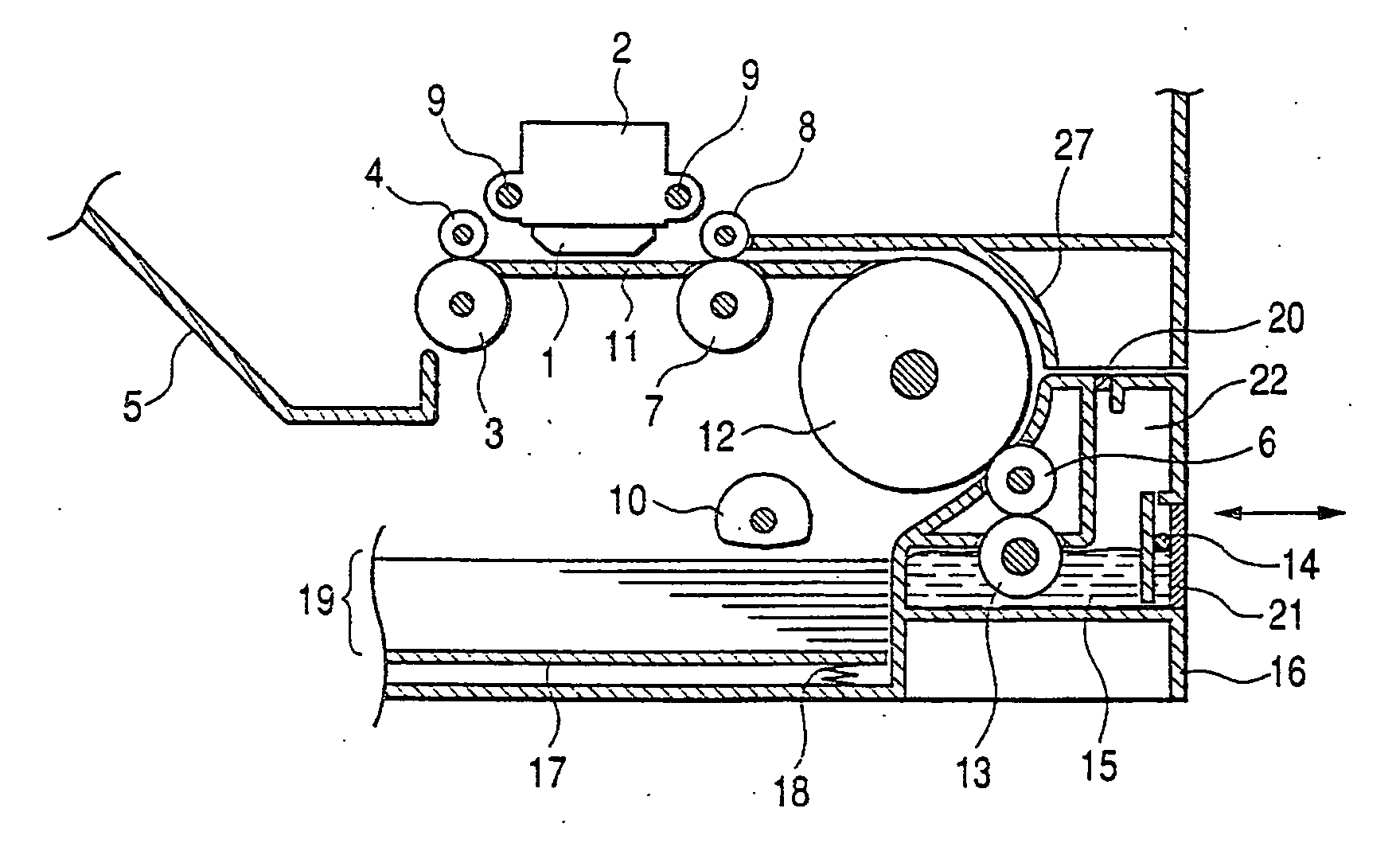

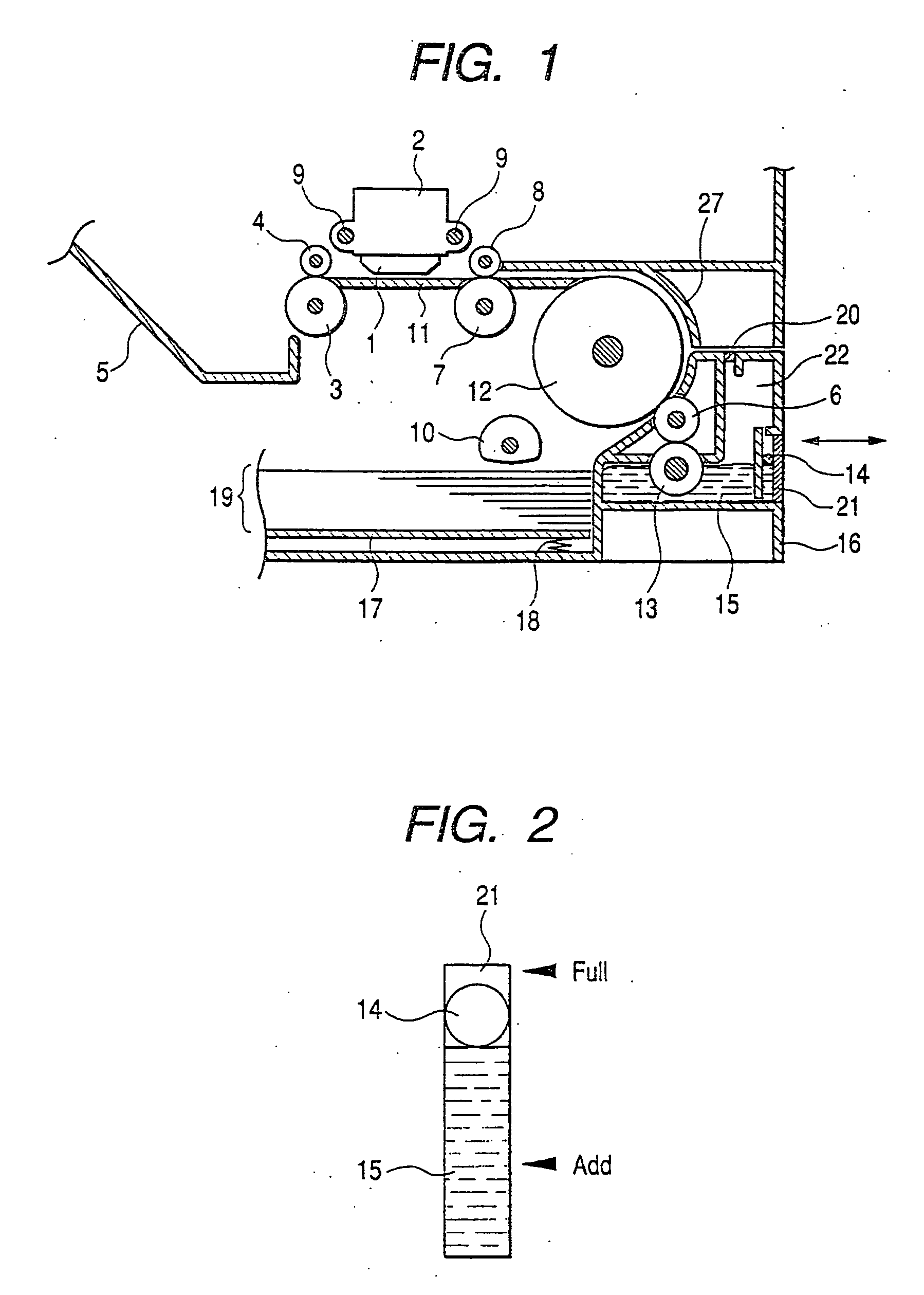

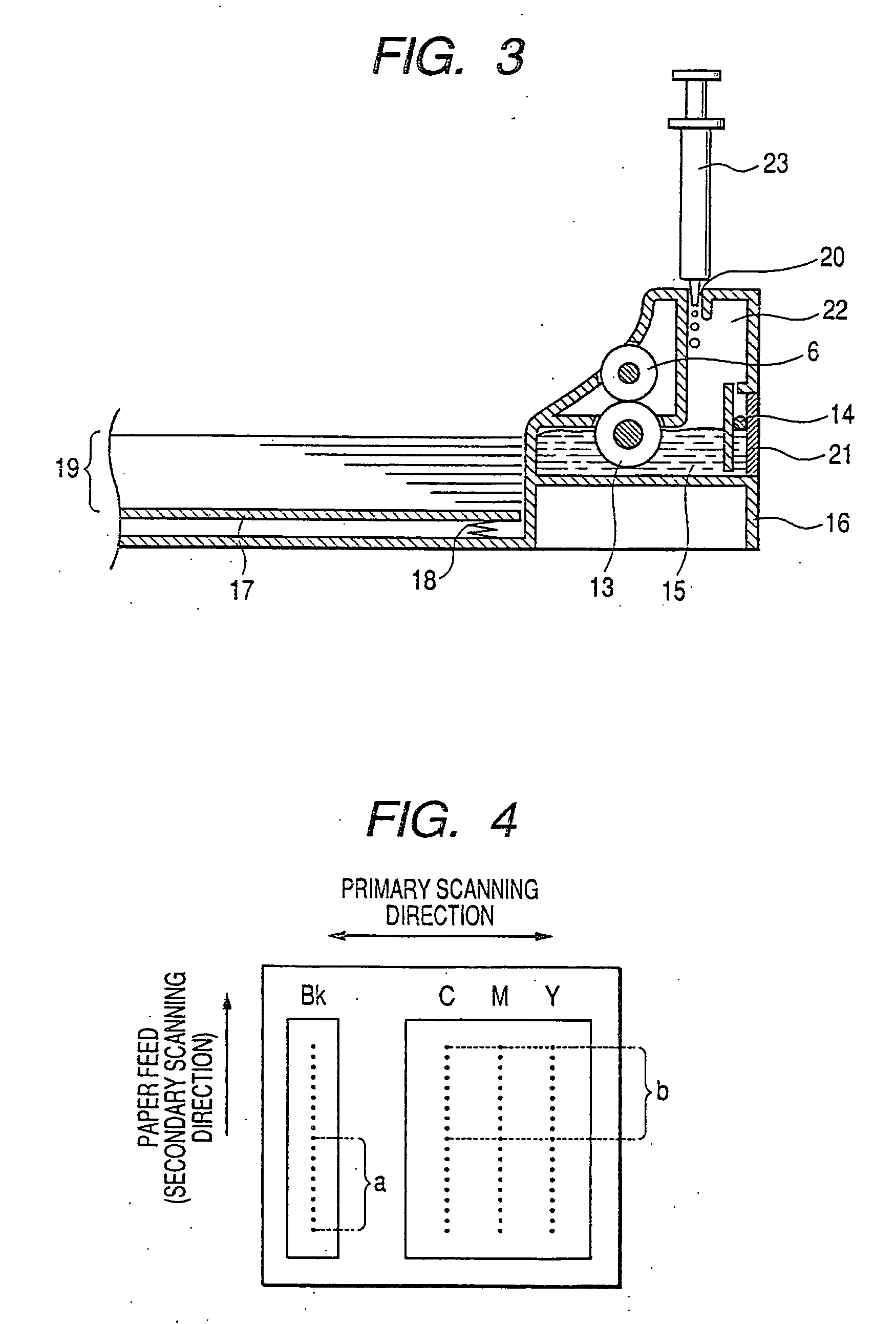

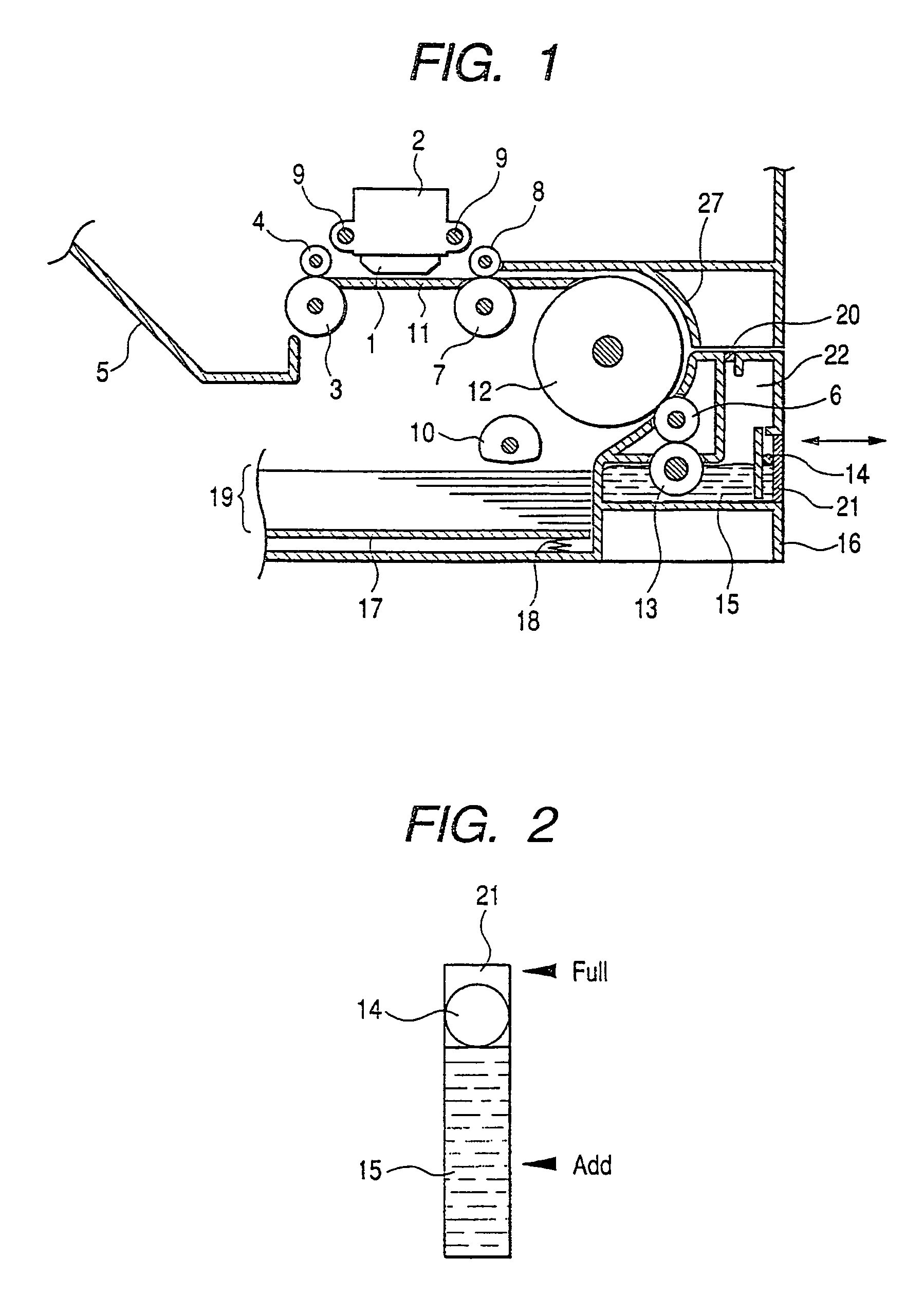

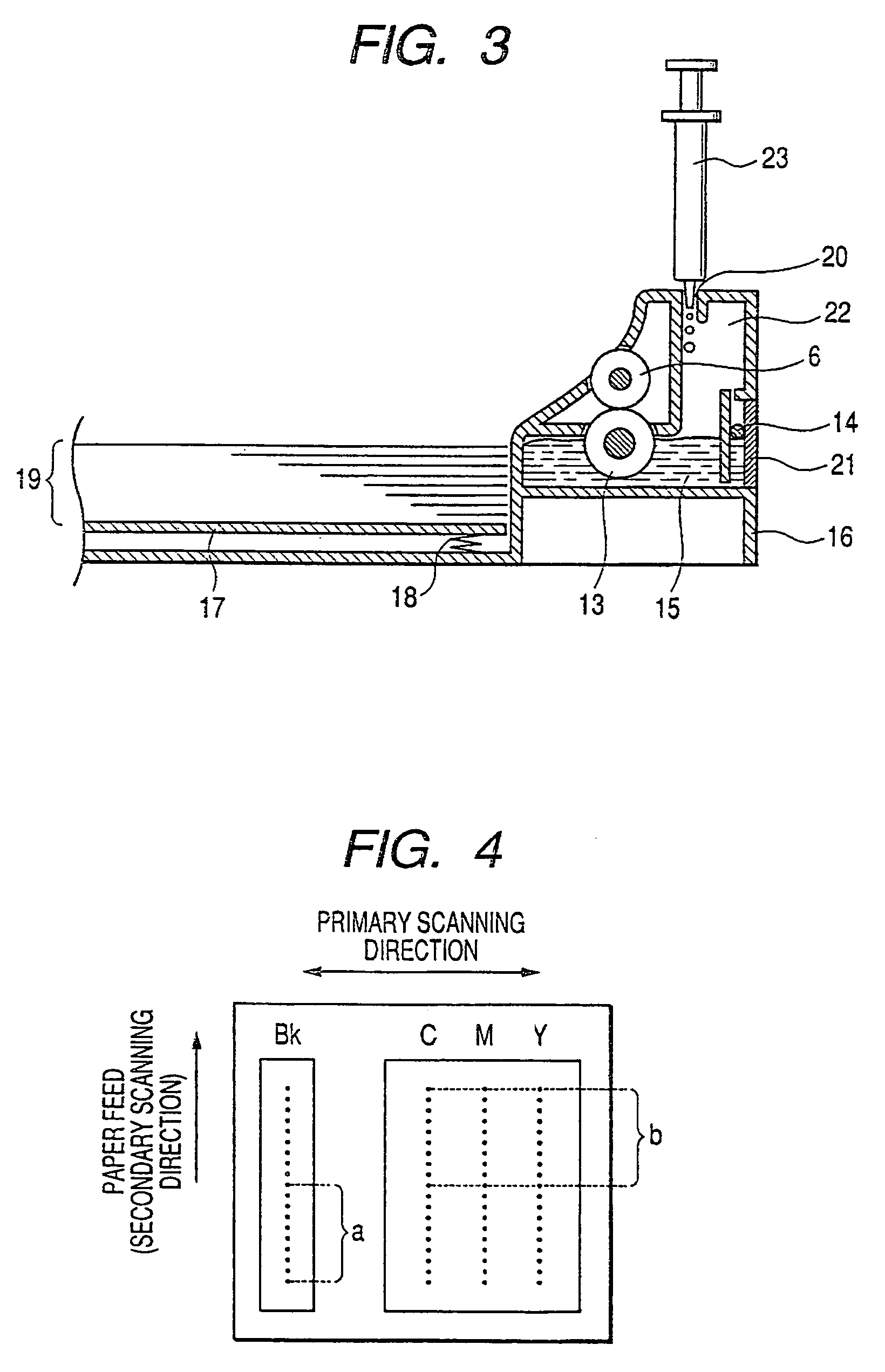

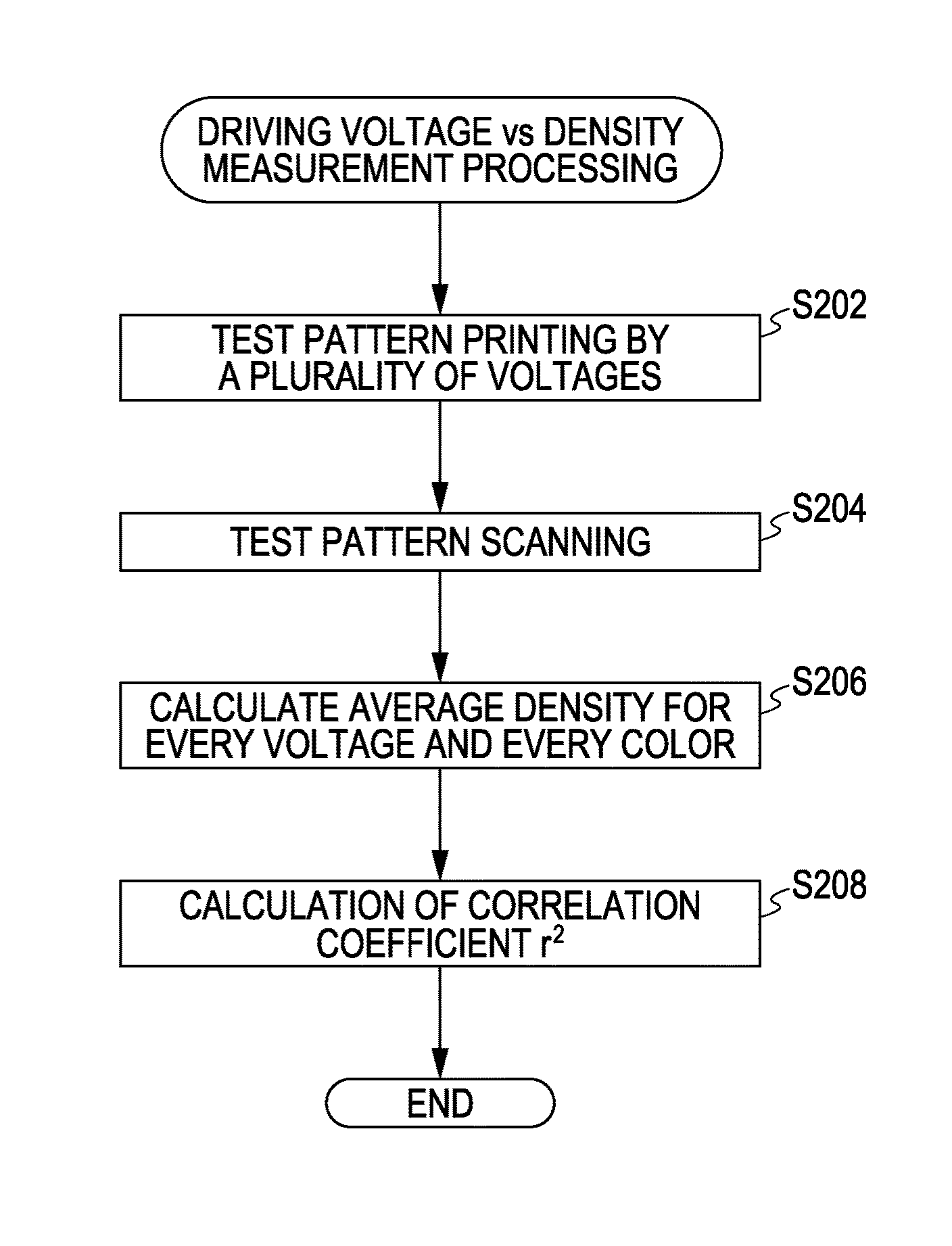

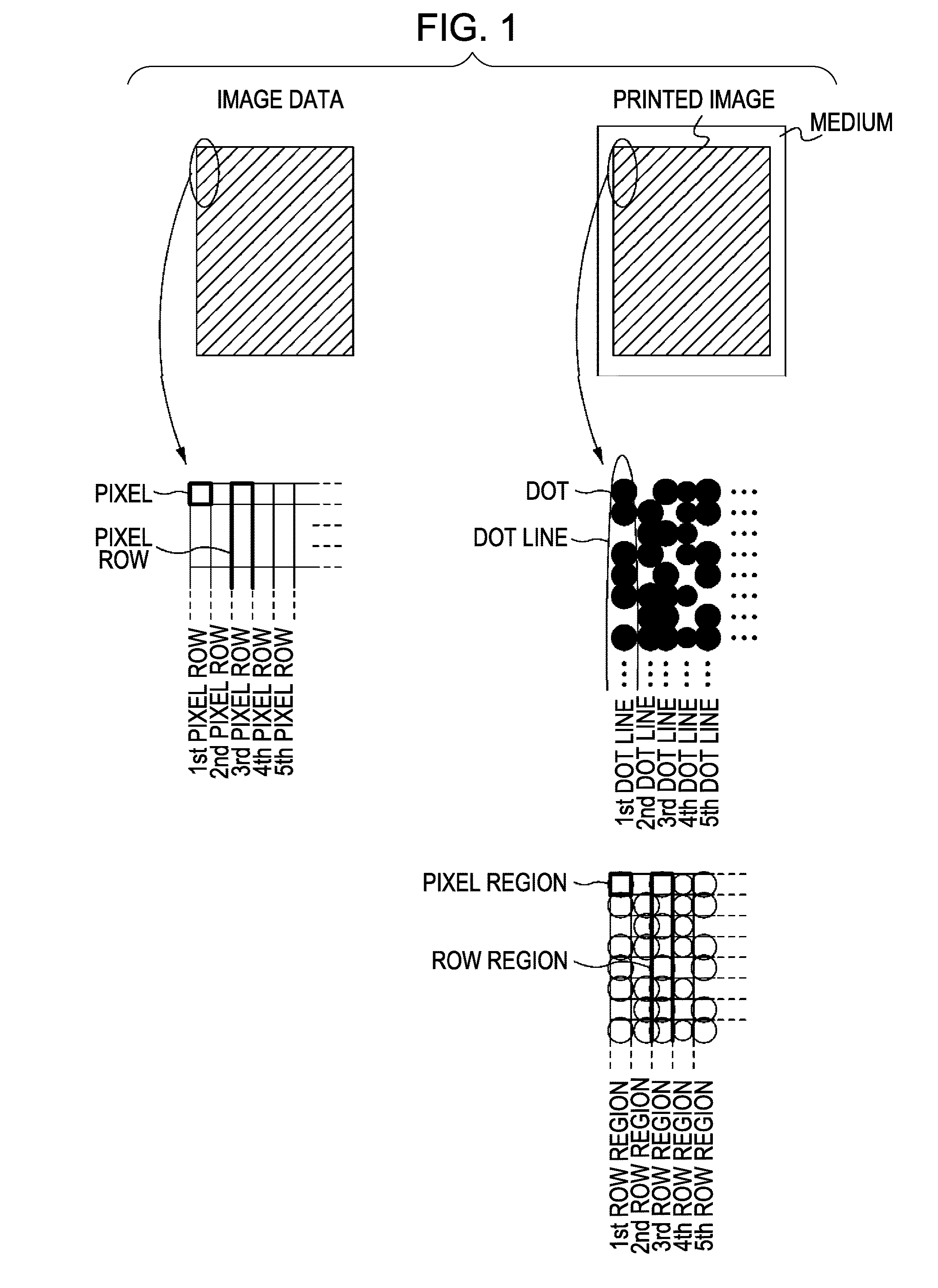

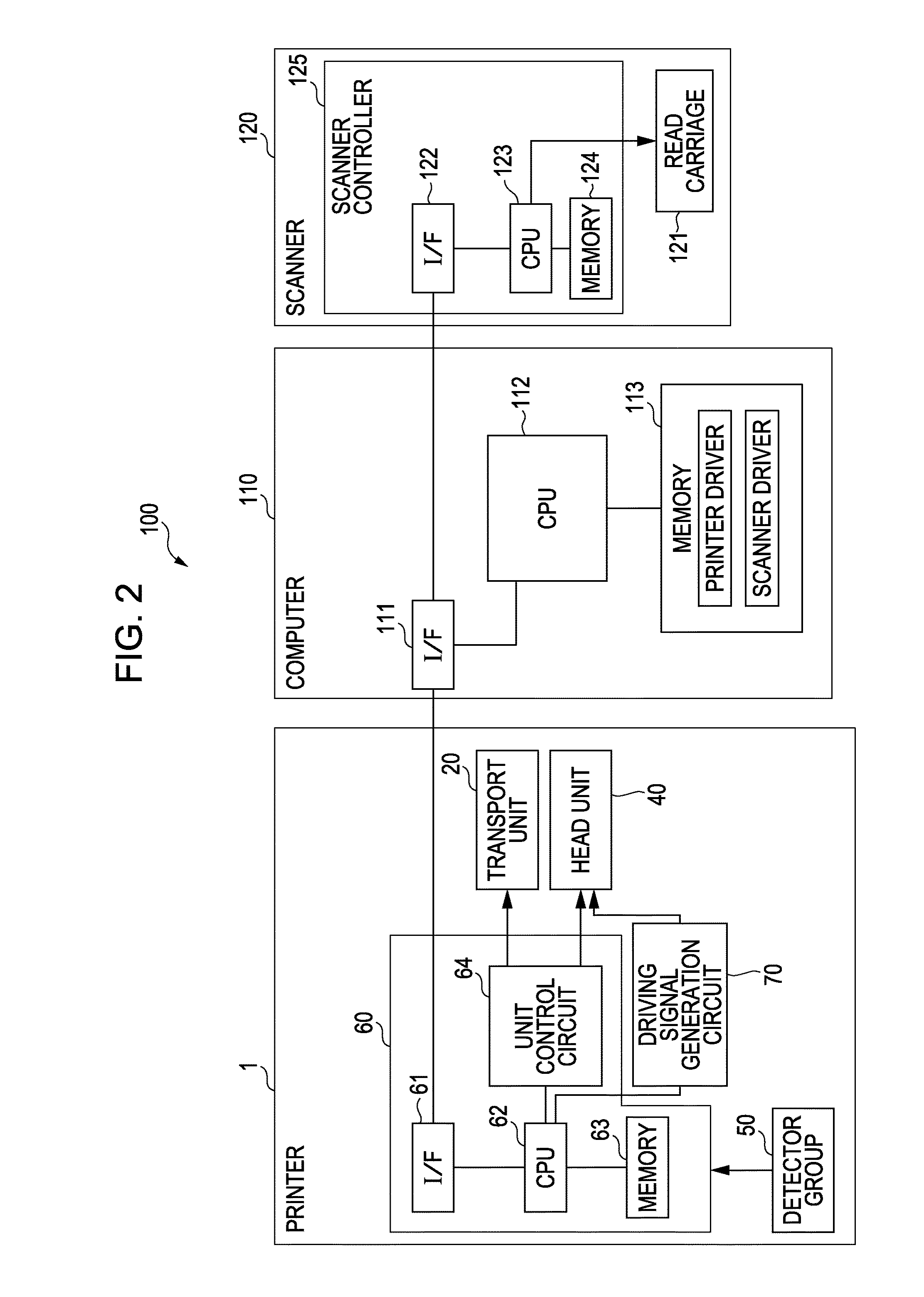

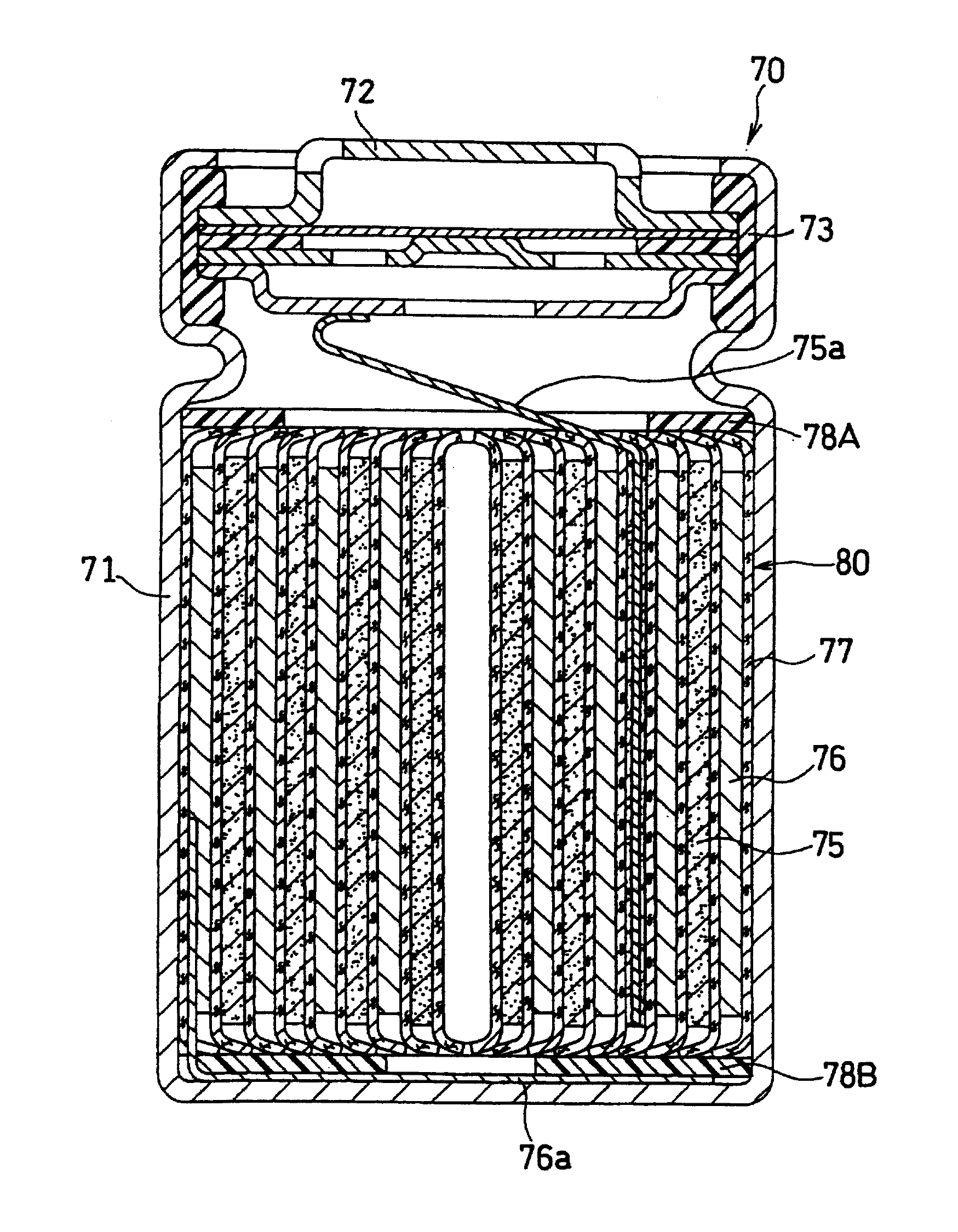

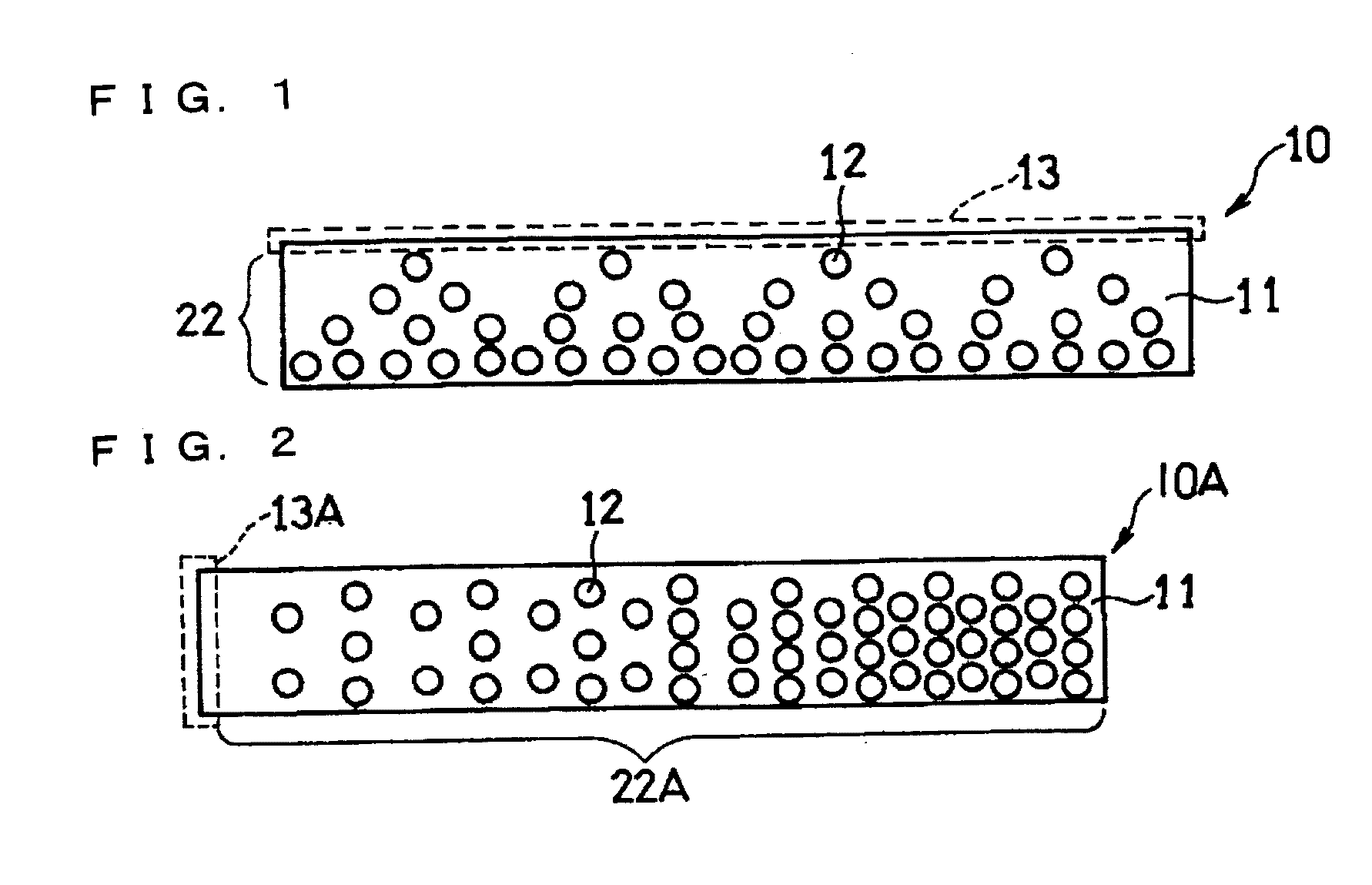

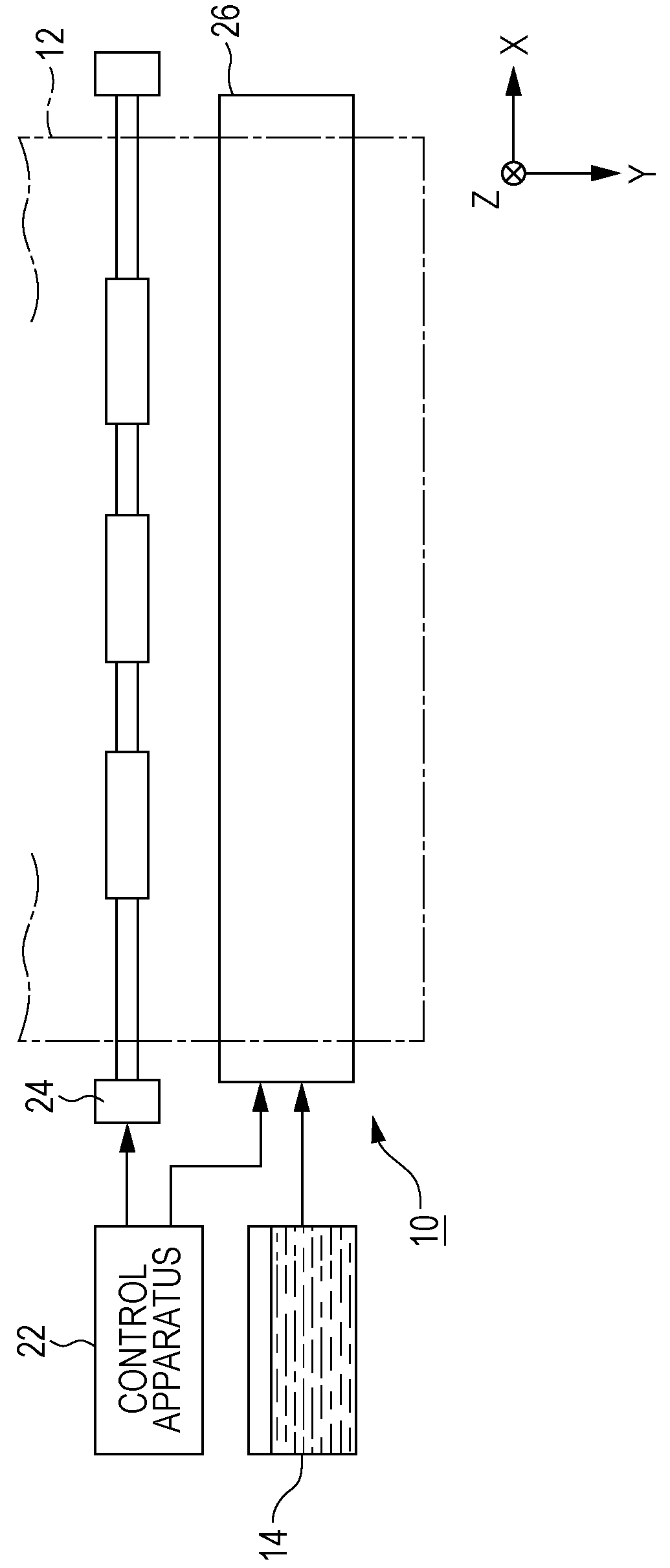

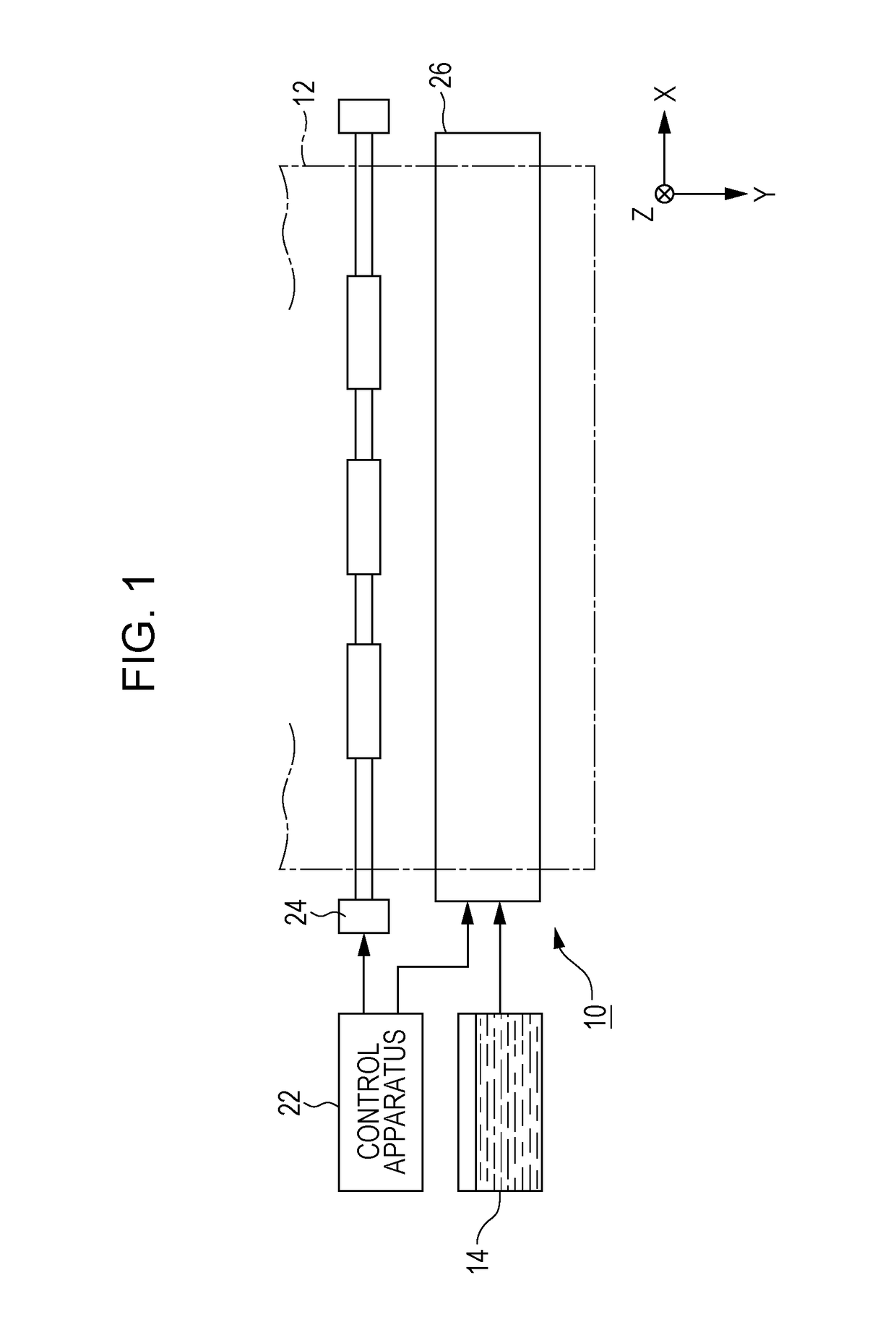

Fluid ejecting apparatus and manufacturing method of fluid ejecting apparatus

InactiveUS20100201726A1Difference in densityWriting implementsMetal-working apparatusEngineeringVolumetric Mass Density

A manufacturing method of a fluid ejecting apparatus includes: forming first and second test patterns by ejecting fluid from first and second nozzle rows which intersect with a relative movement direction of a medium, wherein the first nozzle row forms the first test pattern by ejecting the fluid in accordance with a first driving pulse and the second nozzle row forms the second test pattern by ejecting the fluid in accordance with a second driving pulse; measuring the density of the first test pattern and the density of the second test pattern; and correcting a parameter of the first driving pulse and a parameter of the second driving pulse such that the density of the first test pattern and the density of the second test pattern become a common target density.

Owner:SEIKO EPSON CORP

Current collector for non-aqueous electrolyte secondary battery, electrode, non-aqueous electrolyte secondary battery, and method for producing the same

InactiveUS20110236748A1Reduce the differenceDifference in densityElectrode manufacturing processesFinal product manufactureElectrical resistance and conductanceMetal foil

A current collector includes a metal foil with a plurality of through-holes formed therein. The metal foil is divided into two regions of: a distant region distant from a connection portion to be connected to an external terminal; and a close region being close to the connection portion and having the same area as the distant region. The open area ratio of the distant region of the metal foil is larger than that of the close region. Thus, the electrical resistance of the close region is smaller than that of the distant region. Therefore, production of heat in the close region due to passage of current can be suppressed.

Owner:PANASONIC CORP

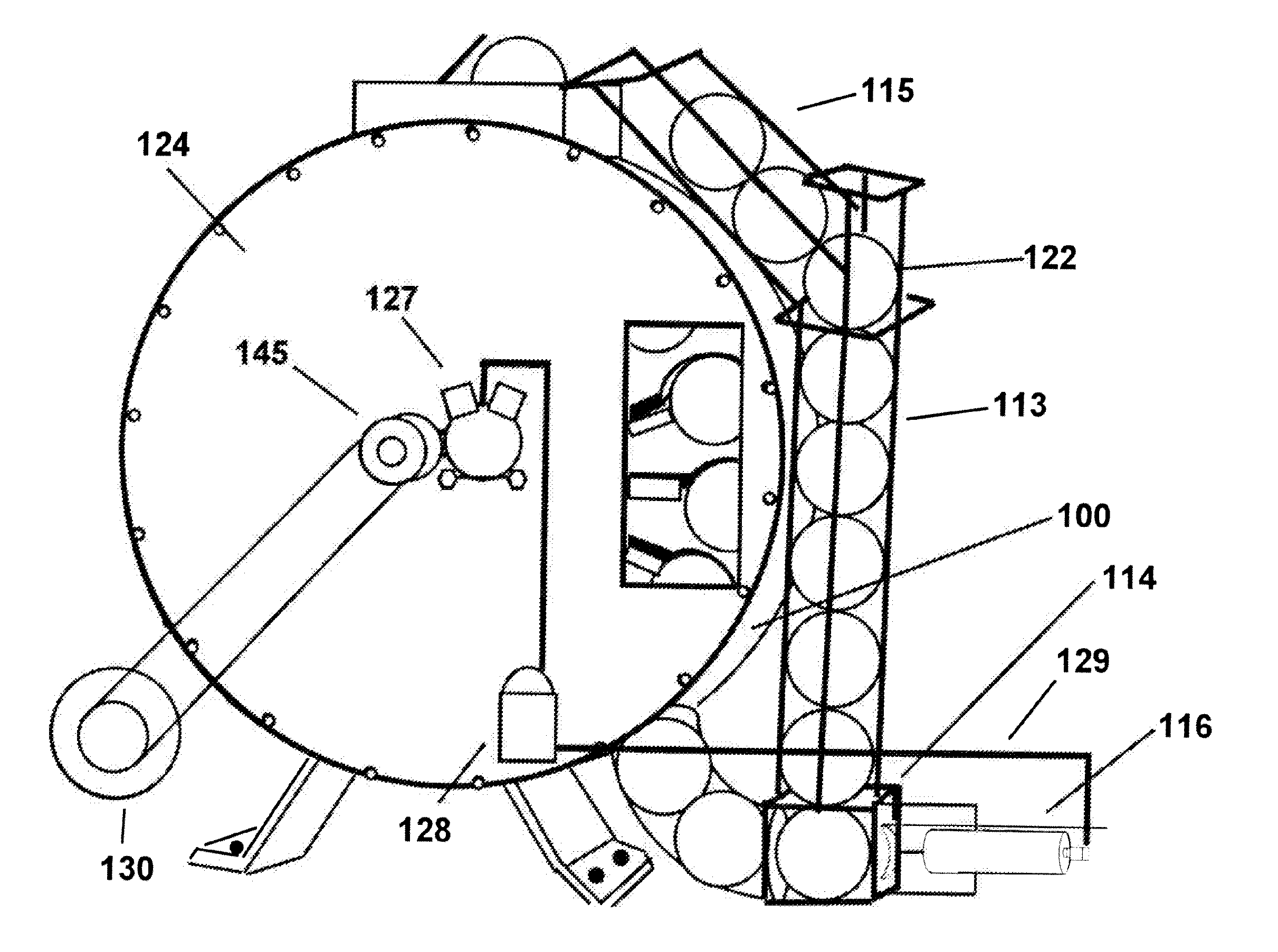

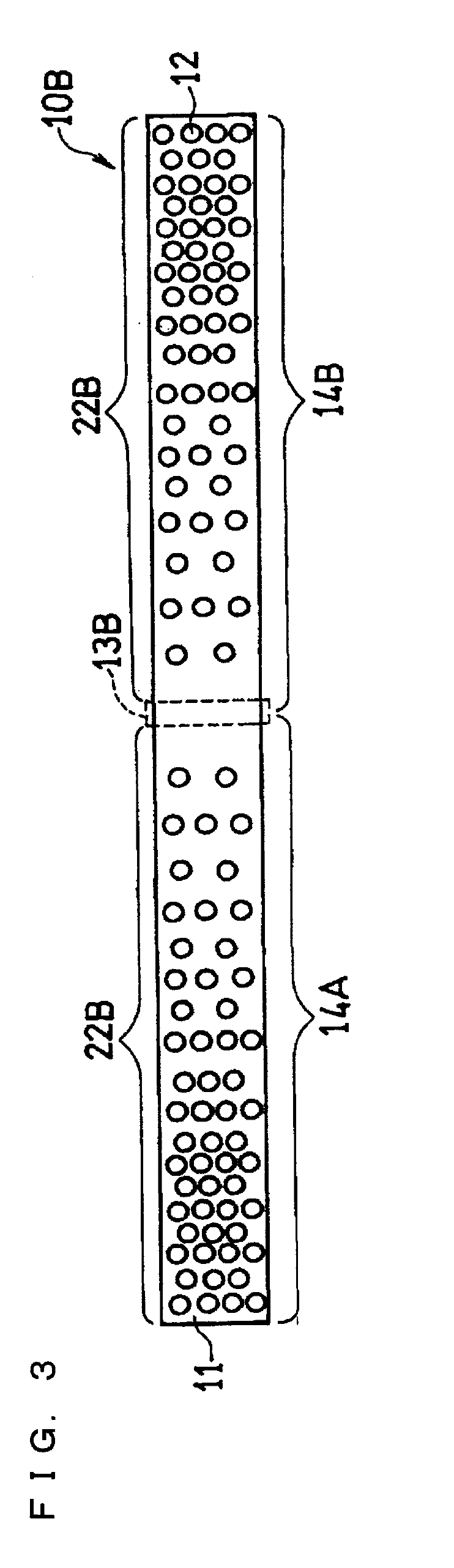

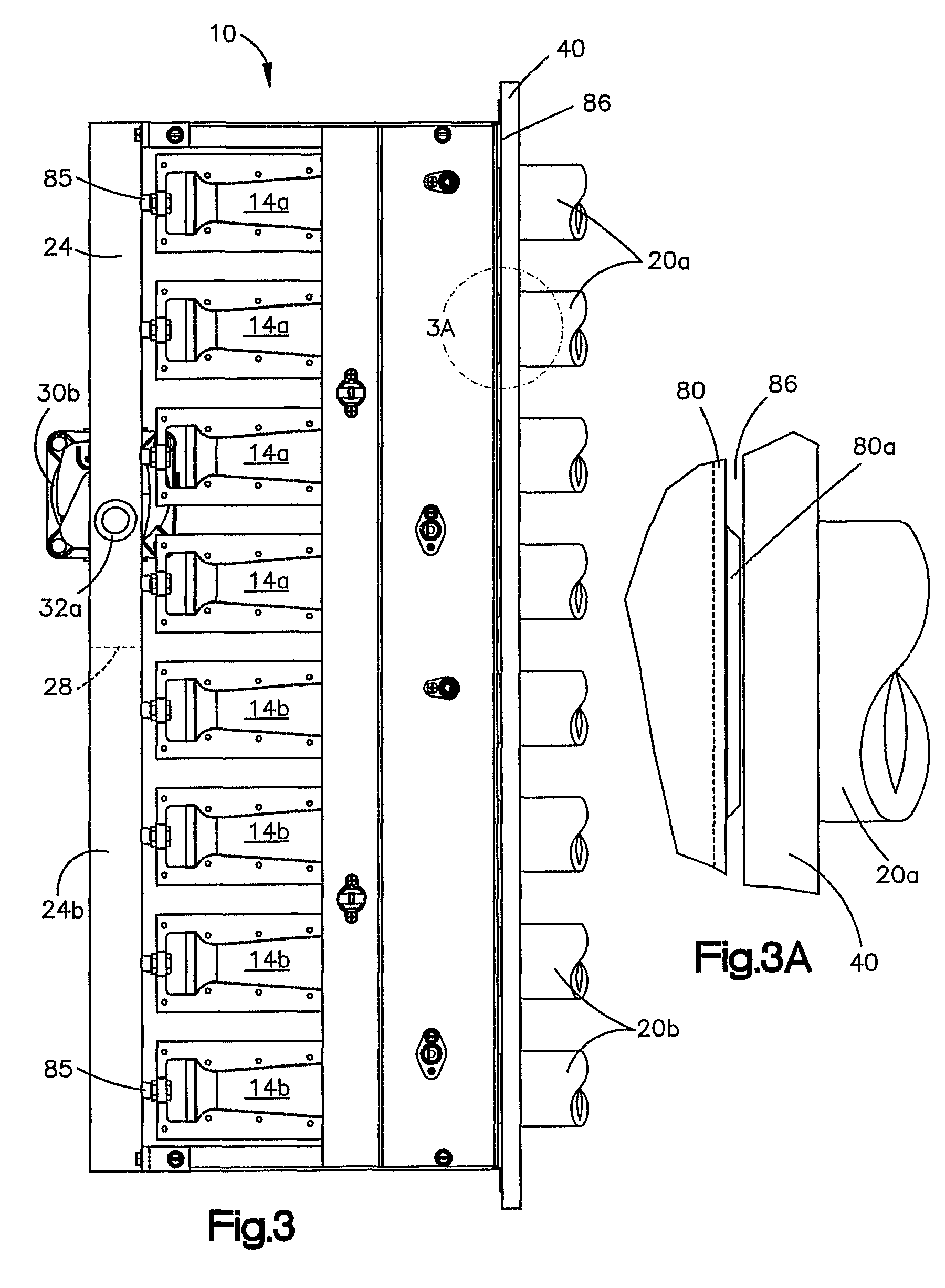

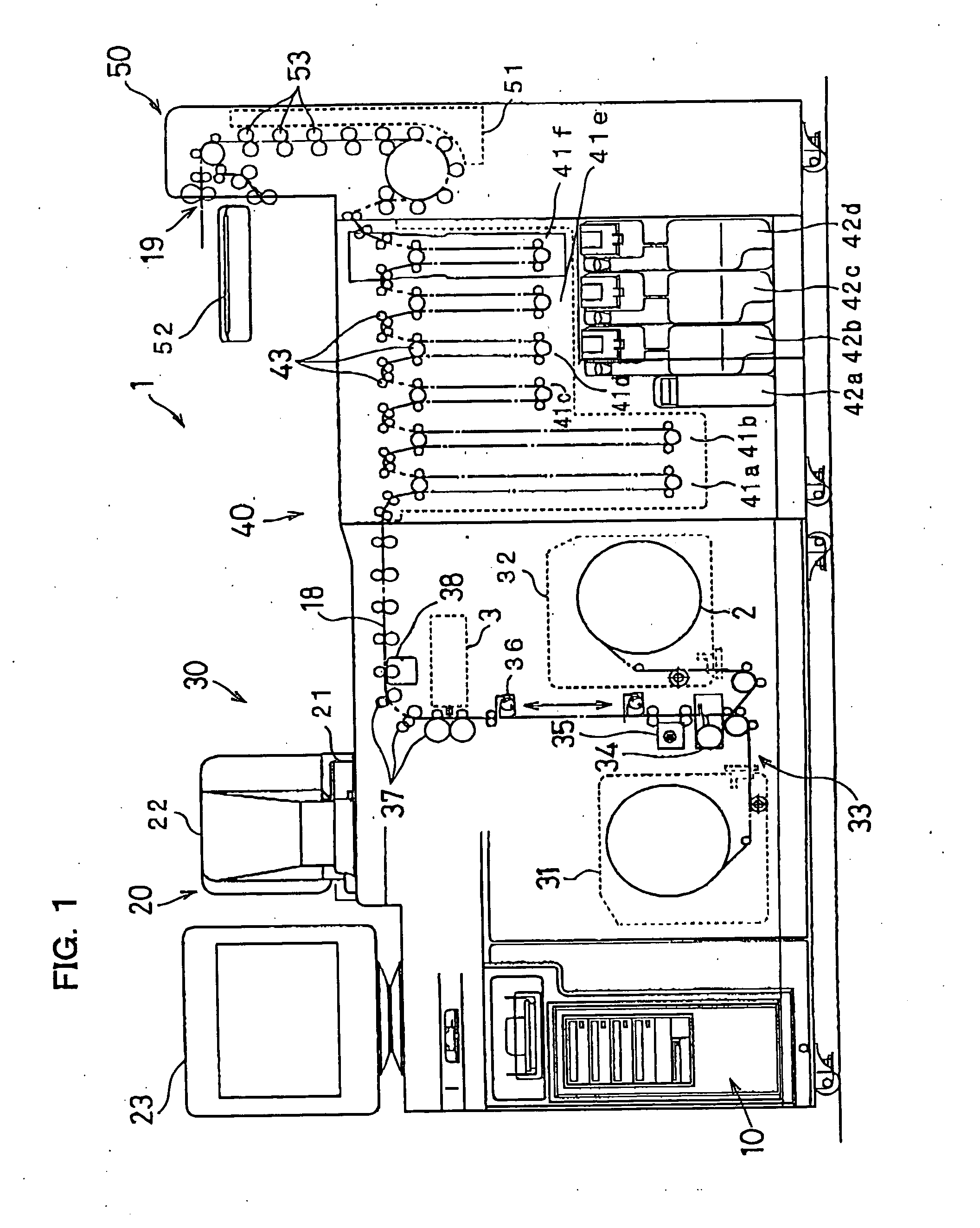

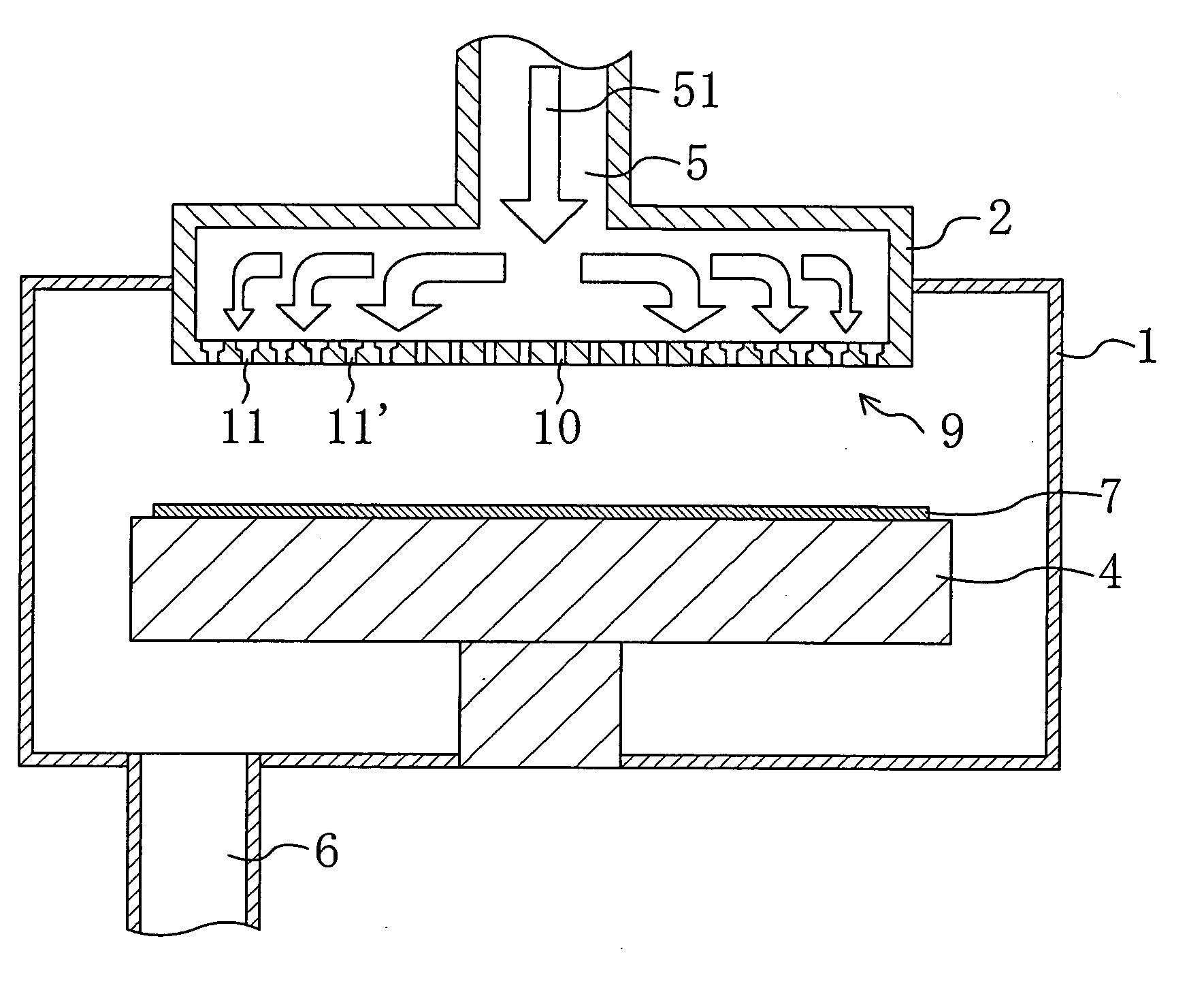

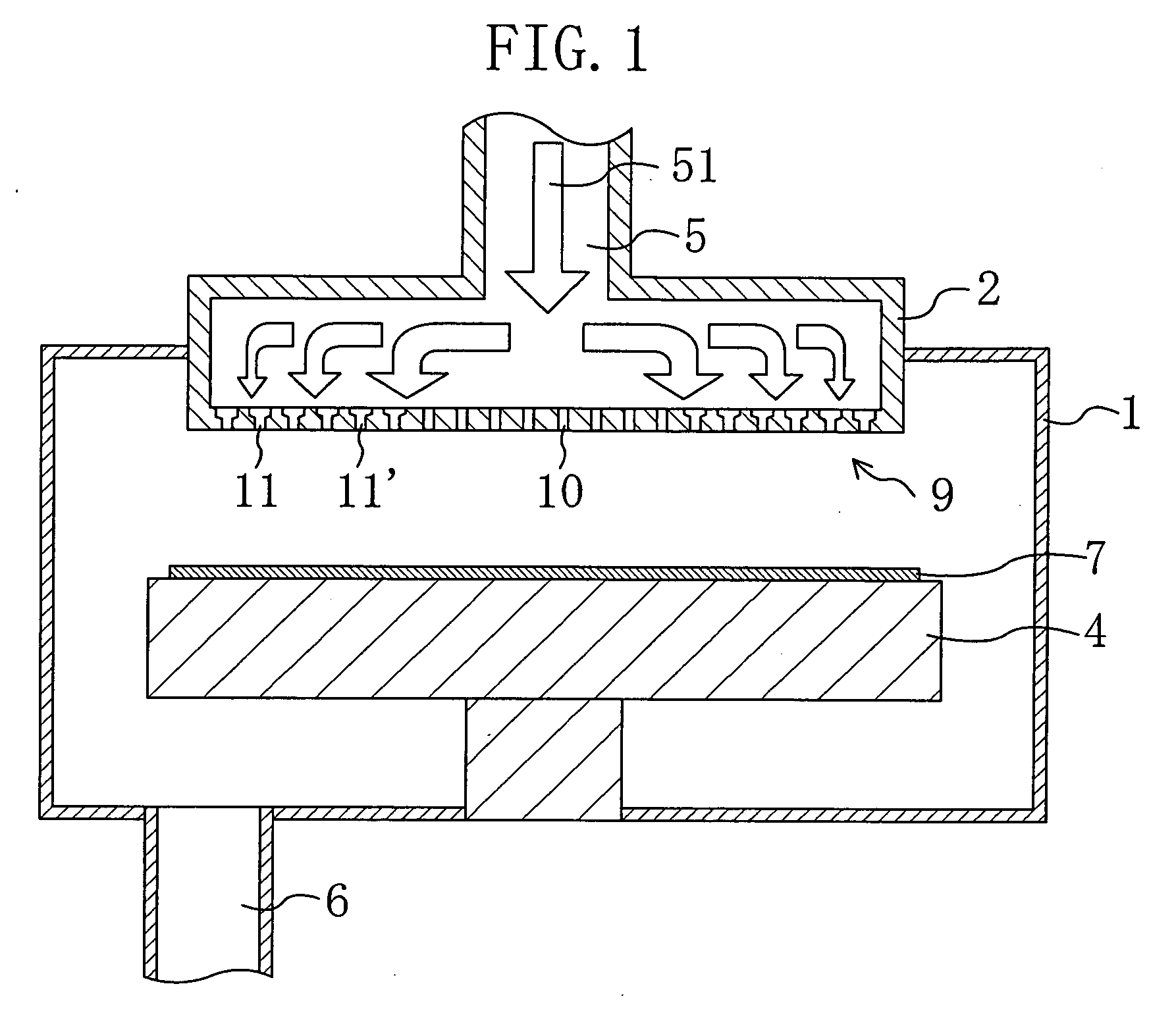

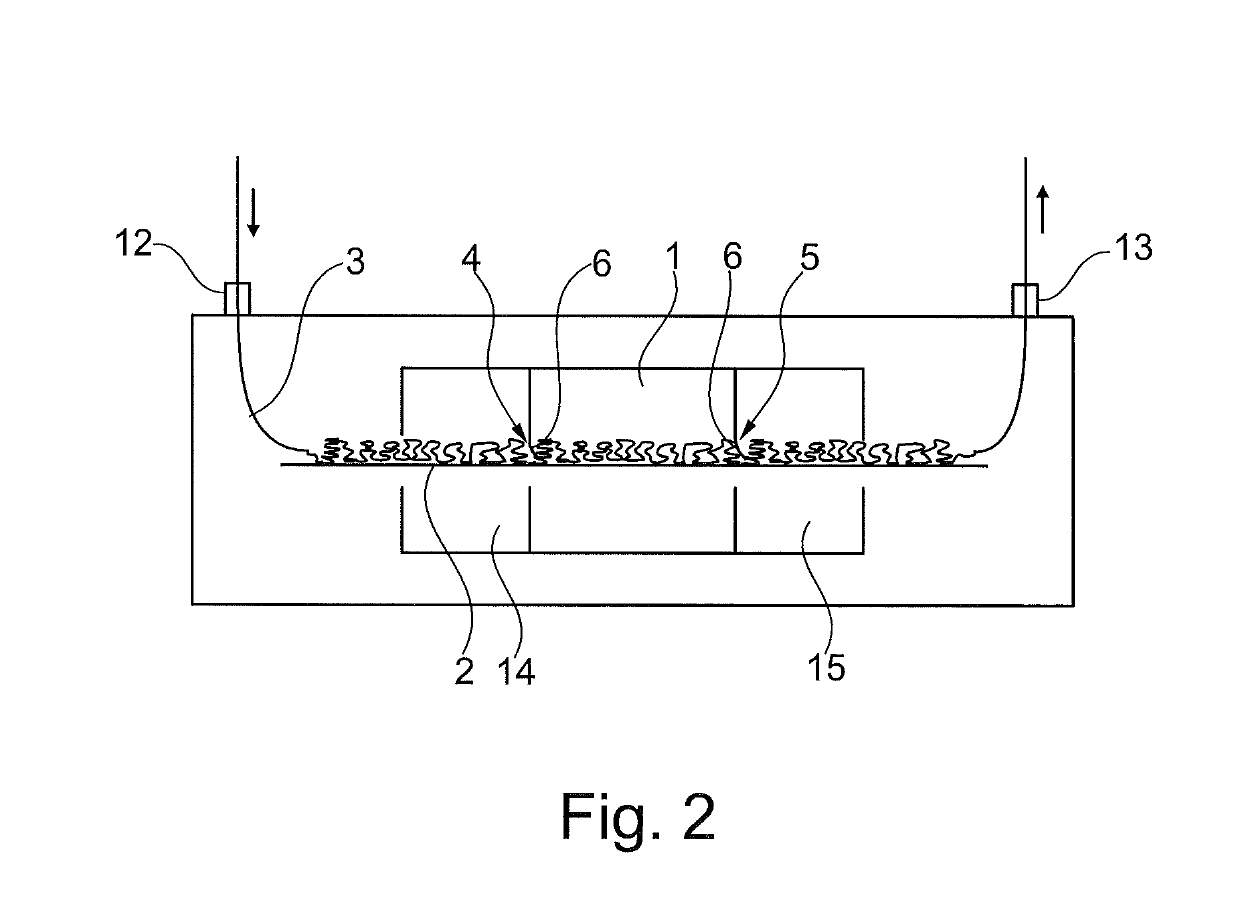

Furnace

ActiveUS7850448B2Difference in densityIncreasing CO emissionAir-treatment apparatus arrangementsAir heatersCombustorControl signal

A gas fired furnace capable of operating with a 16:1 turndown ratio or greater. The furnace includes a plurality of burners (10) grouped into at least (14a) first and second (14b) groups, each group connected to a source of combustible gas through a control valve (30a, 30b, 30c). The control valve (30c) controlling at least one group of burners is of a modulating type having an output proportional to a control signal applied to the valve. The burners fire into associated heat exchange tubes (20a), each tube having an inlet (24) and an outlet. The tube outlets are connected to a collector chamber (44) that includes a baffle plate (60) that divides the collector into two sections, one of the sections communicating with the outlets of the tubes associated with the first group of burners, the other section communicating with the outlets of the heat exchanger tubes associated with the other group of burners.

Owner:BECKETT GAS

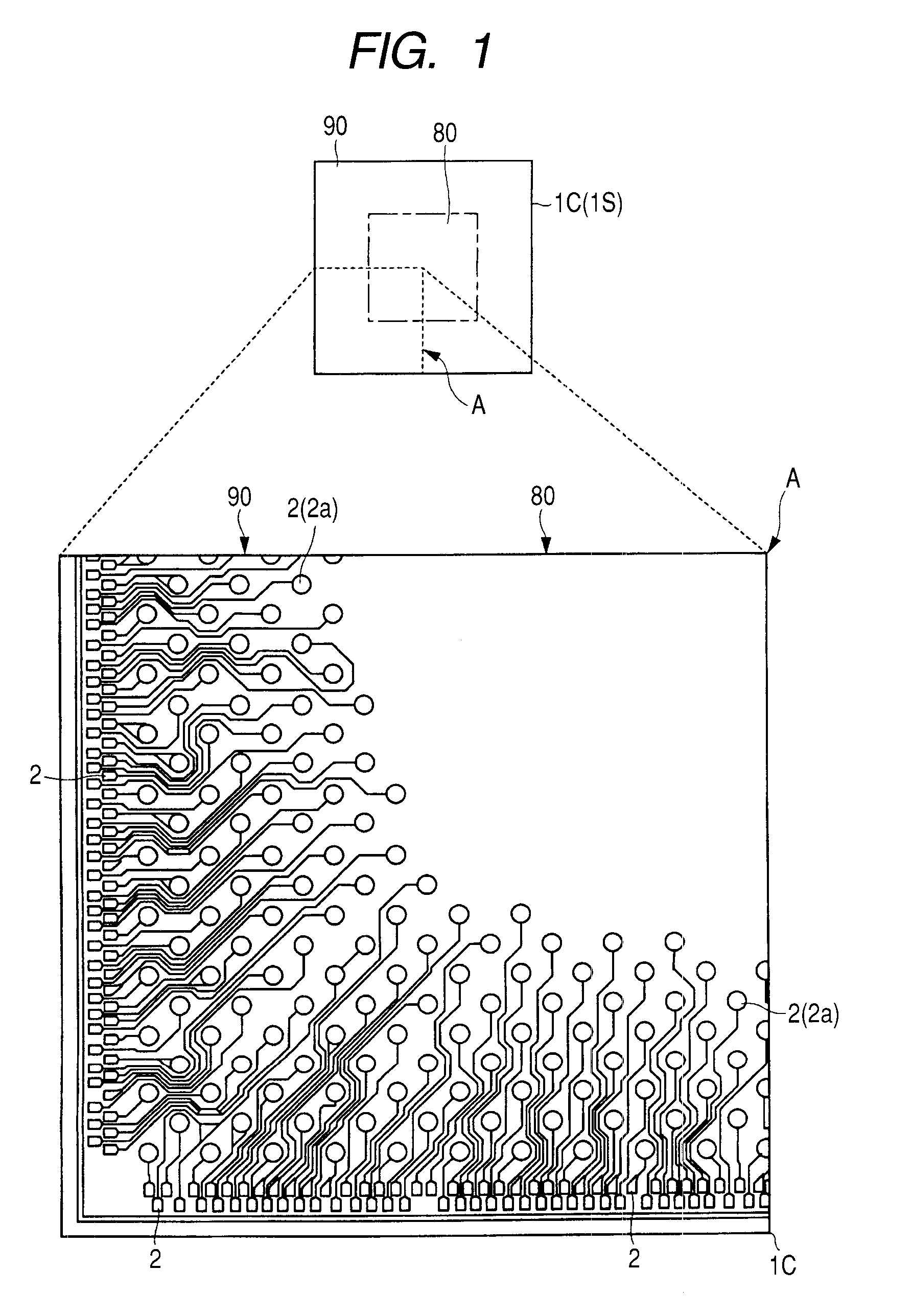

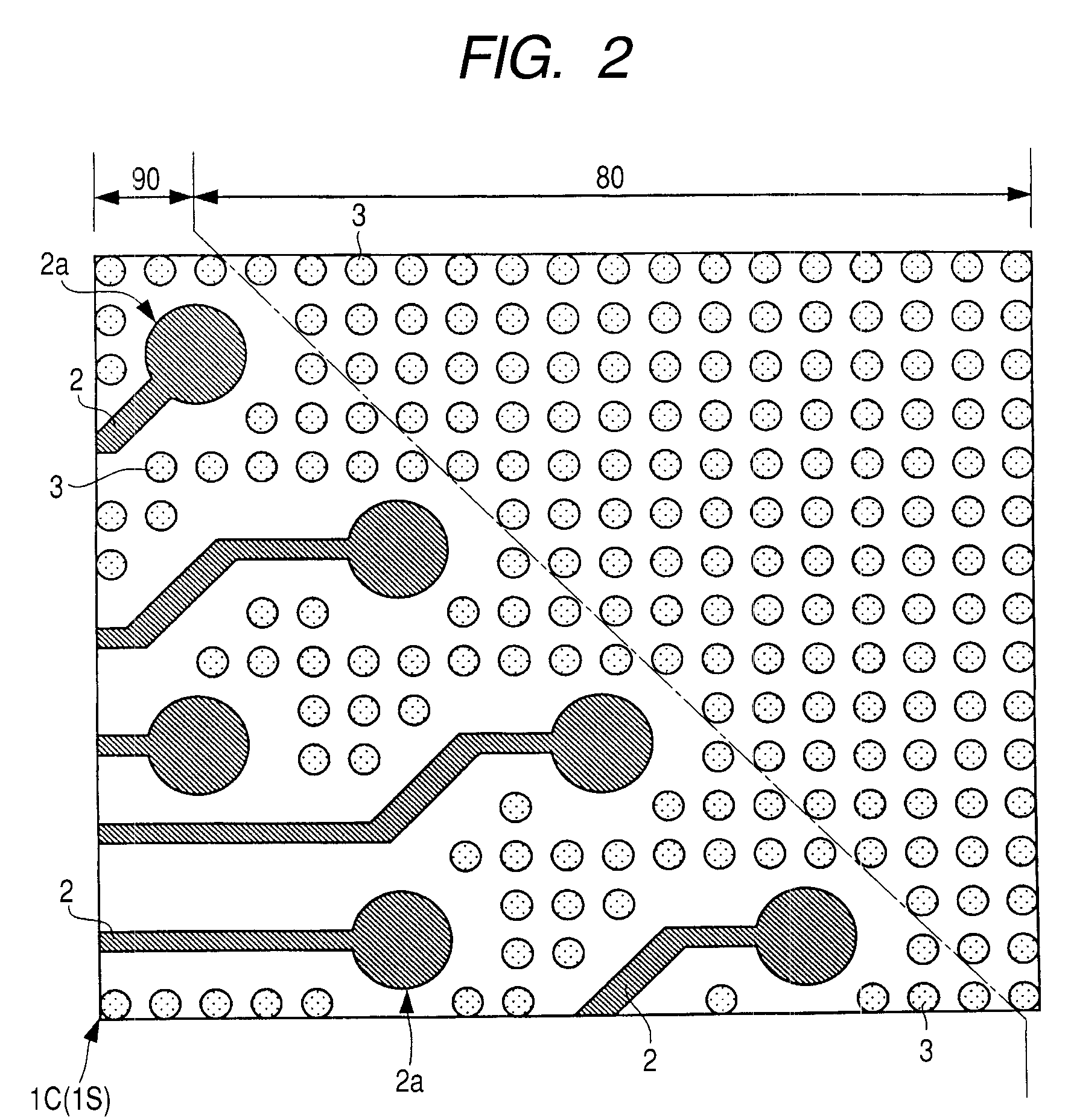

Semiconductor device and a method of manufacturing the same

ActiveUS7812456B2Low reliabilityReduce productionSemiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device

A semiconductor device having redistribution interconnects in the WPP technology and improved reliability, wherein the redistribution interconnects have first patterns and second patterns which are electrically separated from each other within the plane of the semiconductor substrate, the first patterns electrically coupled to the multi-layer interconnects and the floating second patterns are coexistent within the plane of the semiconductor substrate, and the occupation ratio of the total of the first patterns and the second patterns within the plane of the semiconductor substrate, that is, the occupation ratio of the redistribution interconnects is 35 to 60%.

Owner:RENESAS ELECTRONICS CORP

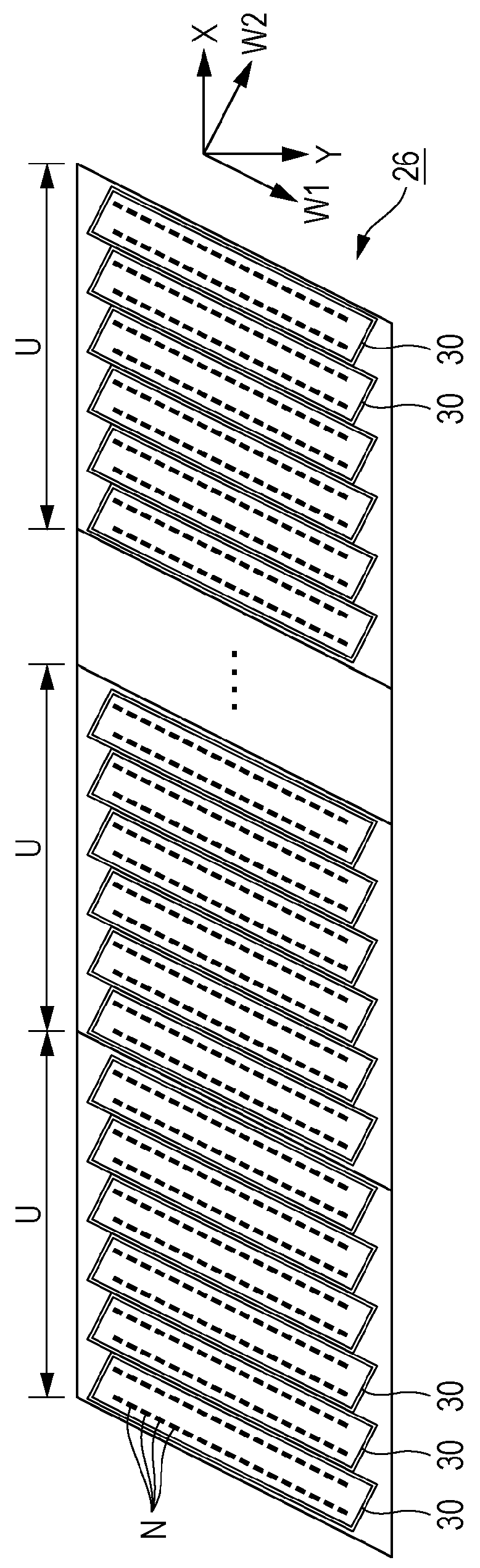

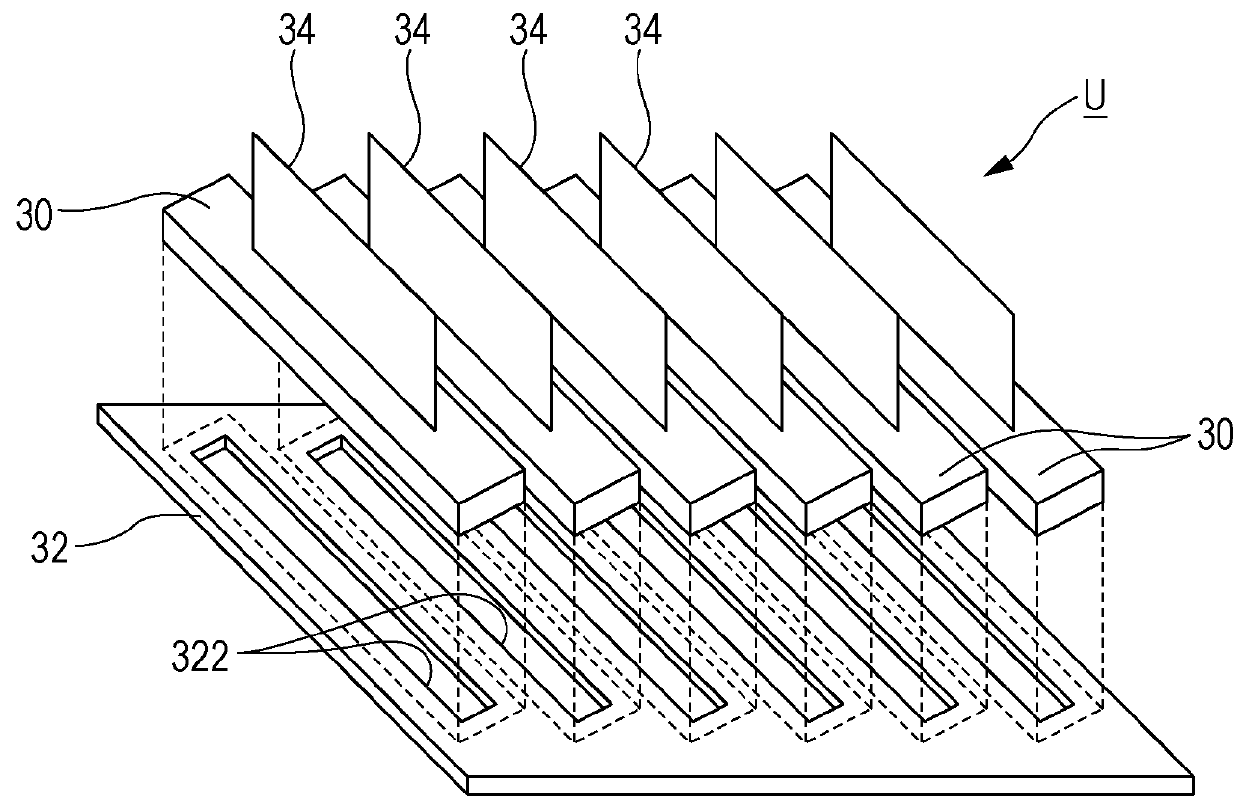

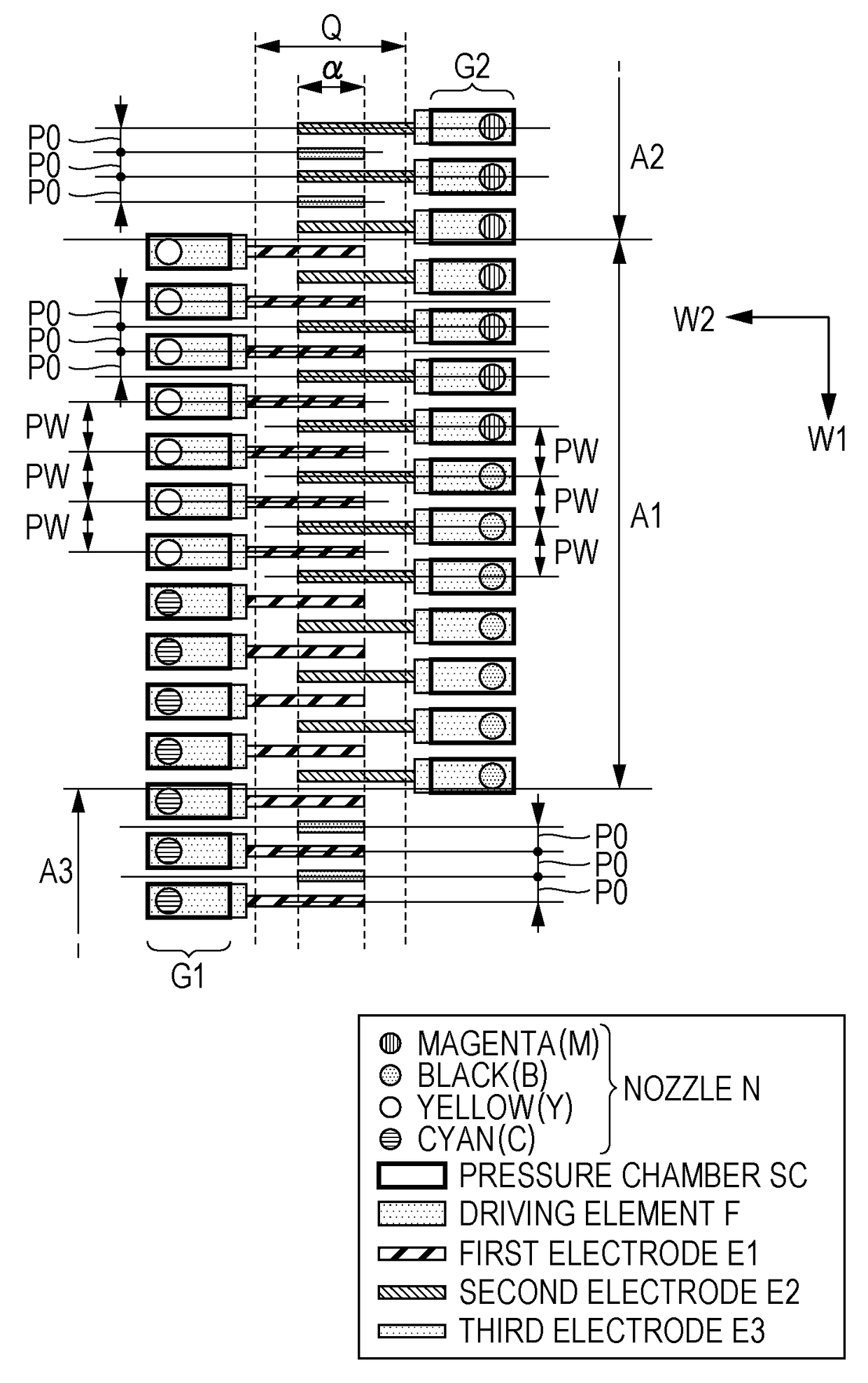

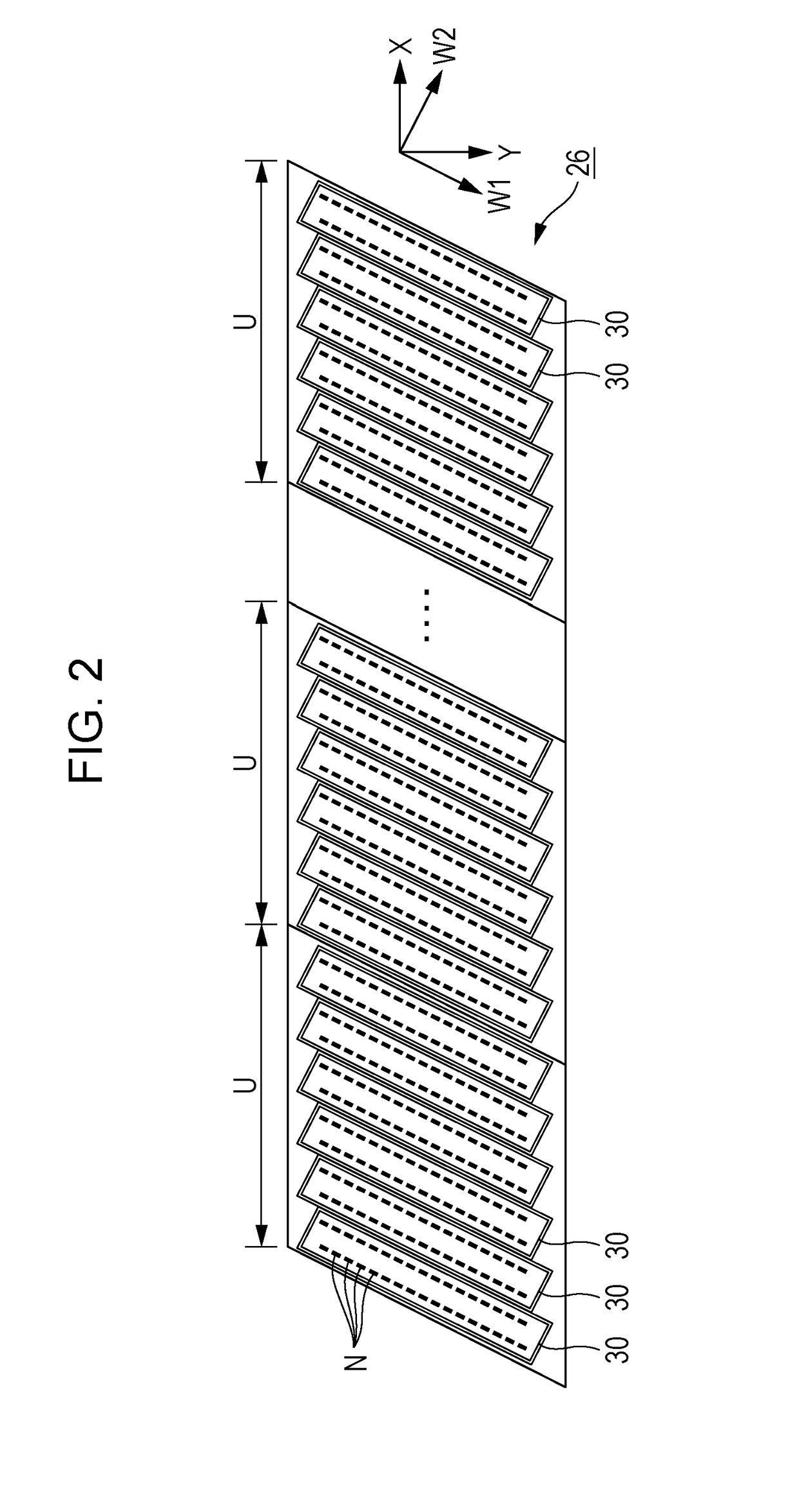

Liquid ejecting head and liquid ejecting apparatus

ActiveUS20160031214A1Uniformize its densityDifference in density of the electrodes between the first region and the second region is reducedInking apparatusDriven elementElectrical and Electronics engineering

A liquid ejecting head includes driving elements and electrodes each extending a second direction for ejecting liquid of pressure chambers through nozzles. The driving elements are classified into a first element group and a second element group. The electrodes are arranged along a first direction intersecting the second direction and are classified into a first electrode group electrically connected to the first element group, a second electrode group electrically connected to the second element group and a third electrode group not contribute to the ejecting liquid.

Owner:SEIKO EPSON CORP

Semiconductor device, designing method and designing device thereof

InactiveUS6838770B2Reduce the differenceDifference in densitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDevice materialSemiconductor

A semiconductor device is provided with dummy patterns at an originally thinner portion of each of layers, and each of these dummy patterns is electrically connected to a reference wire that is either a power-supply wire or a ground wire.

Owner:RENESAS ELECTRONICS CORP

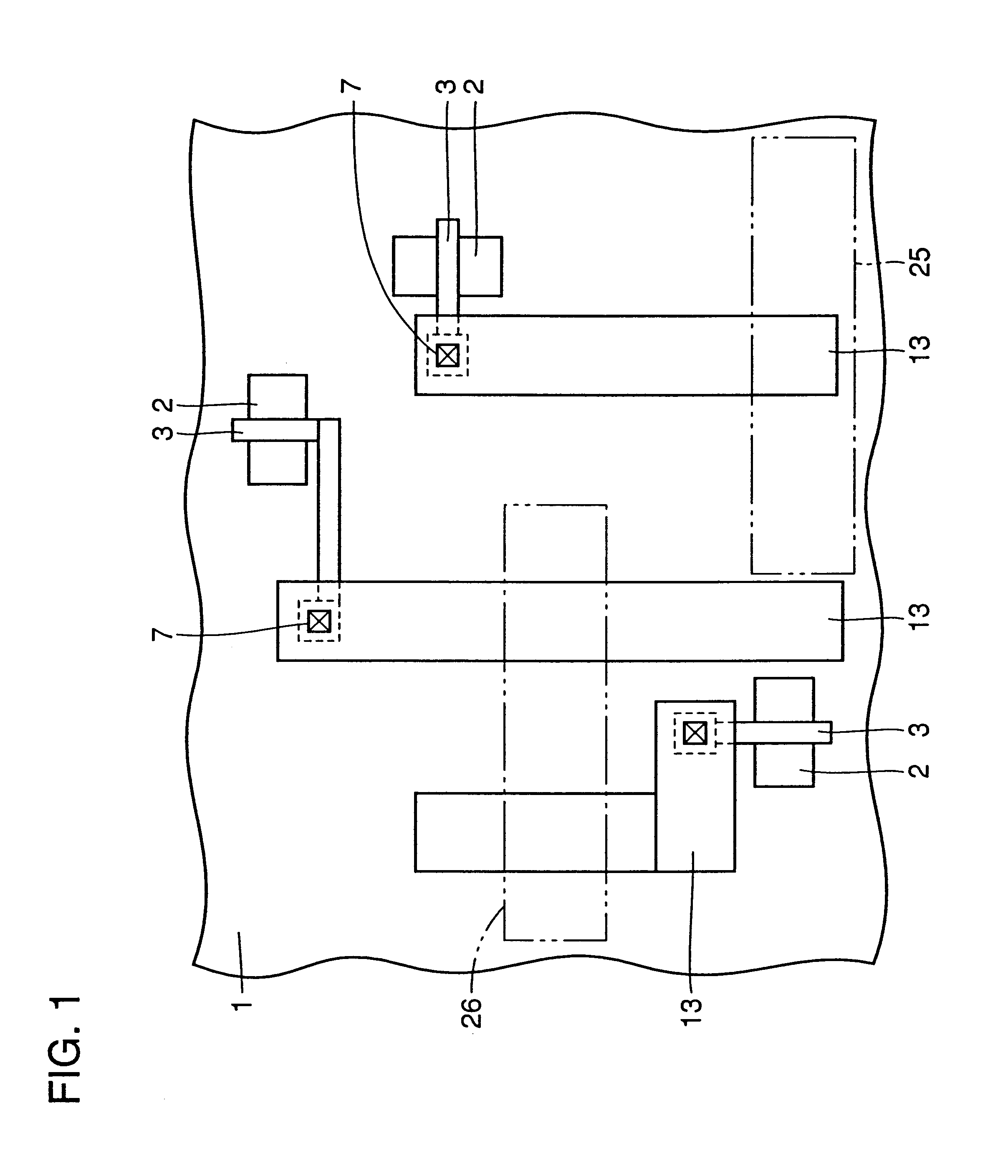

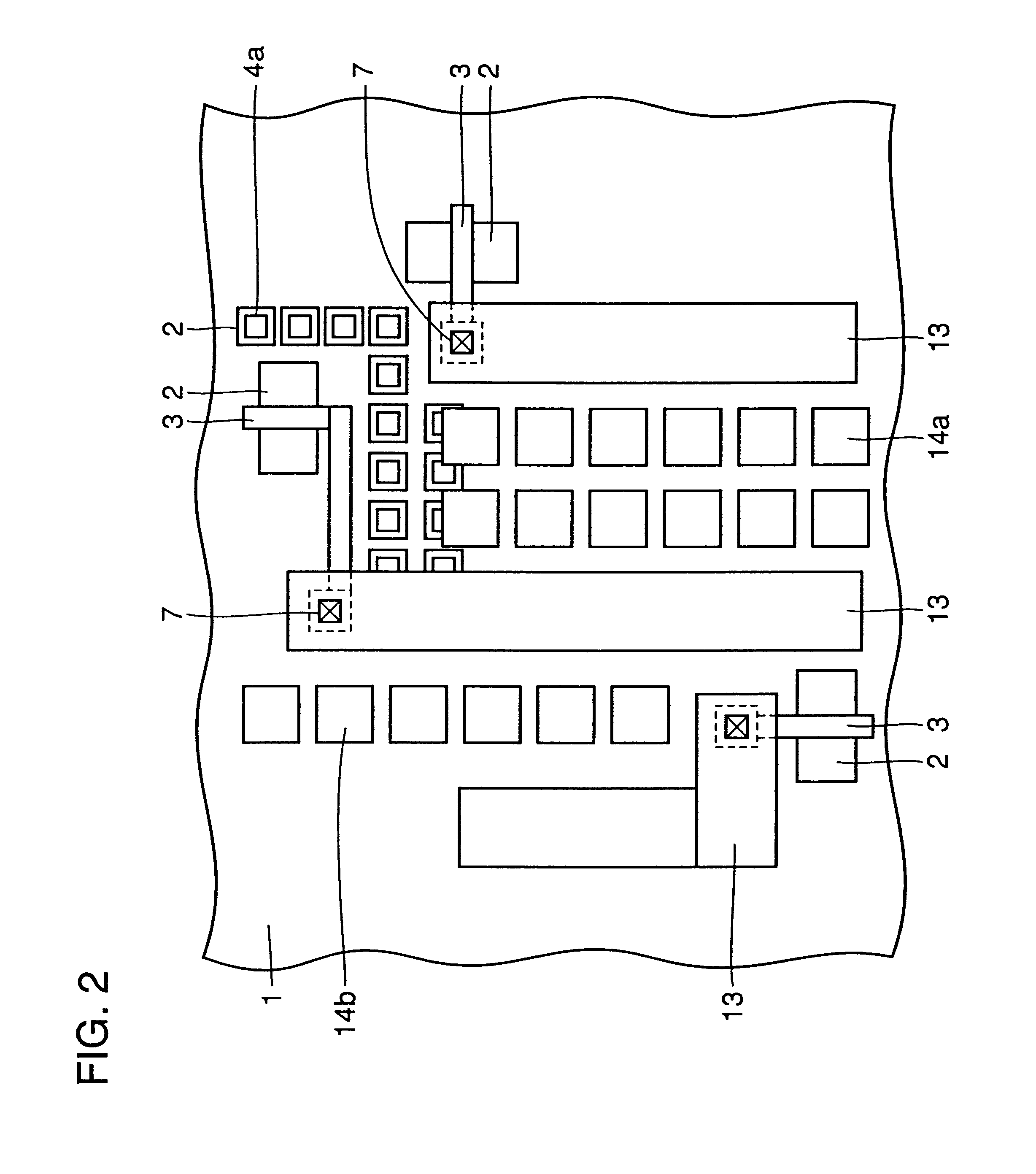

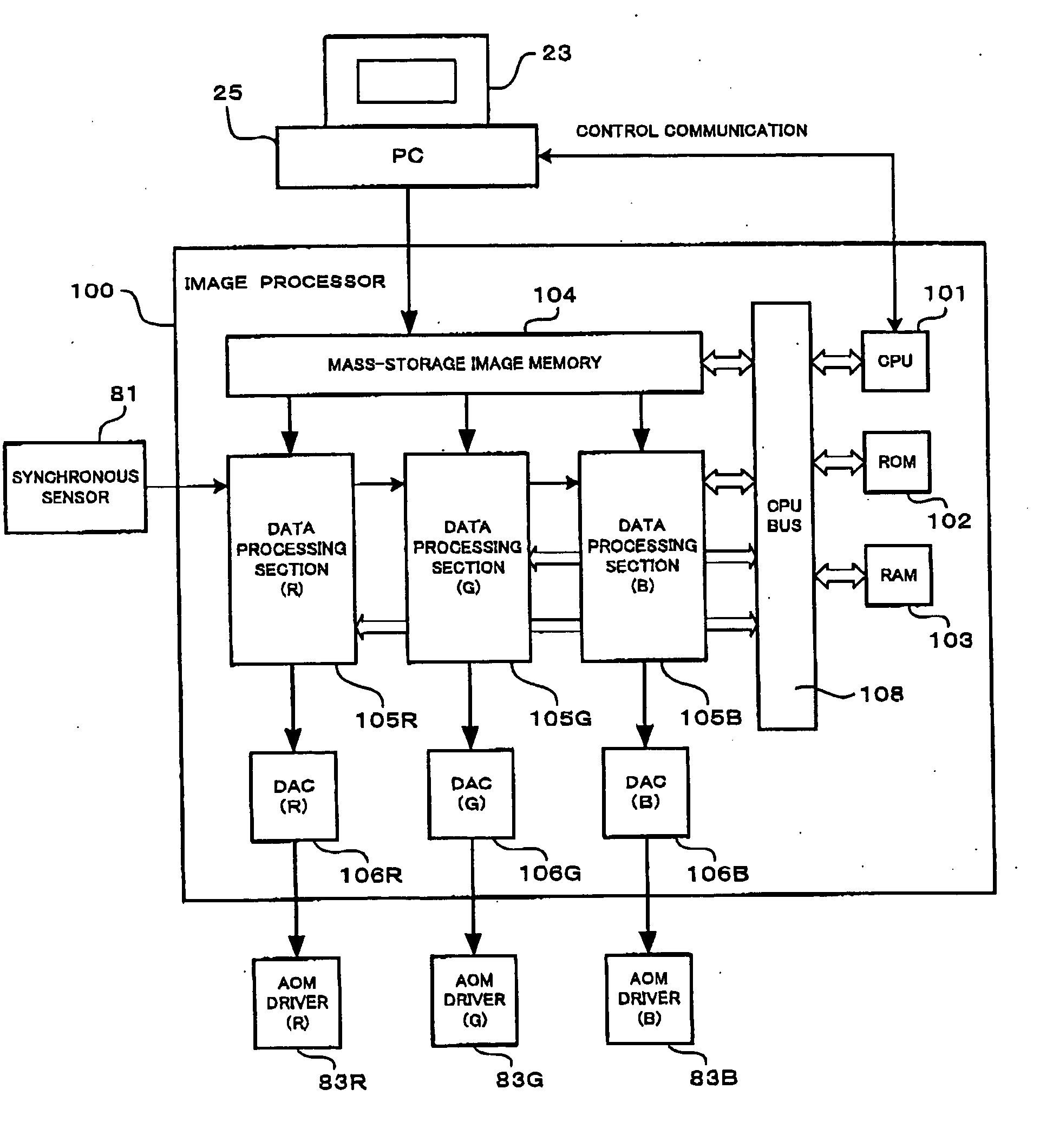

Exposure device and exposure method

InactiveUS20050219644A1Difference in densityImprove image qualityVisual presentation using printersPrintingPhotographic paperComputer science

In an exposure device according to the present invention, a plurality of exposure bands each containing multiple dots is formed on photographic paper by repeating main scanning in a main scanning direction based on image data that contains multiple pixels and the transfer of the photographic paper in a sub scanning direction. Of the multiple dots contained in each of two continuous exposure bands, the mean value of the pixel levels of two pixels corresponding to two dots with the same positional relationship for the main scanning direction is calculated to derive interpolation data. Thus, the region between the two dots neighboring in the sub scanning direction on the photographic paper is exposed on the basis of the interpolation data.

Owner:NK WORKS CO LTD

Stator of rotating electric machine

ActiveUS9941762B2Difference in density of the current flowing through the trunk portionRelieve pressureCooling/ventillation arrangementWindings conductor shape/form/constructionElectric machineThree-phase

Owner:DENSO CORP

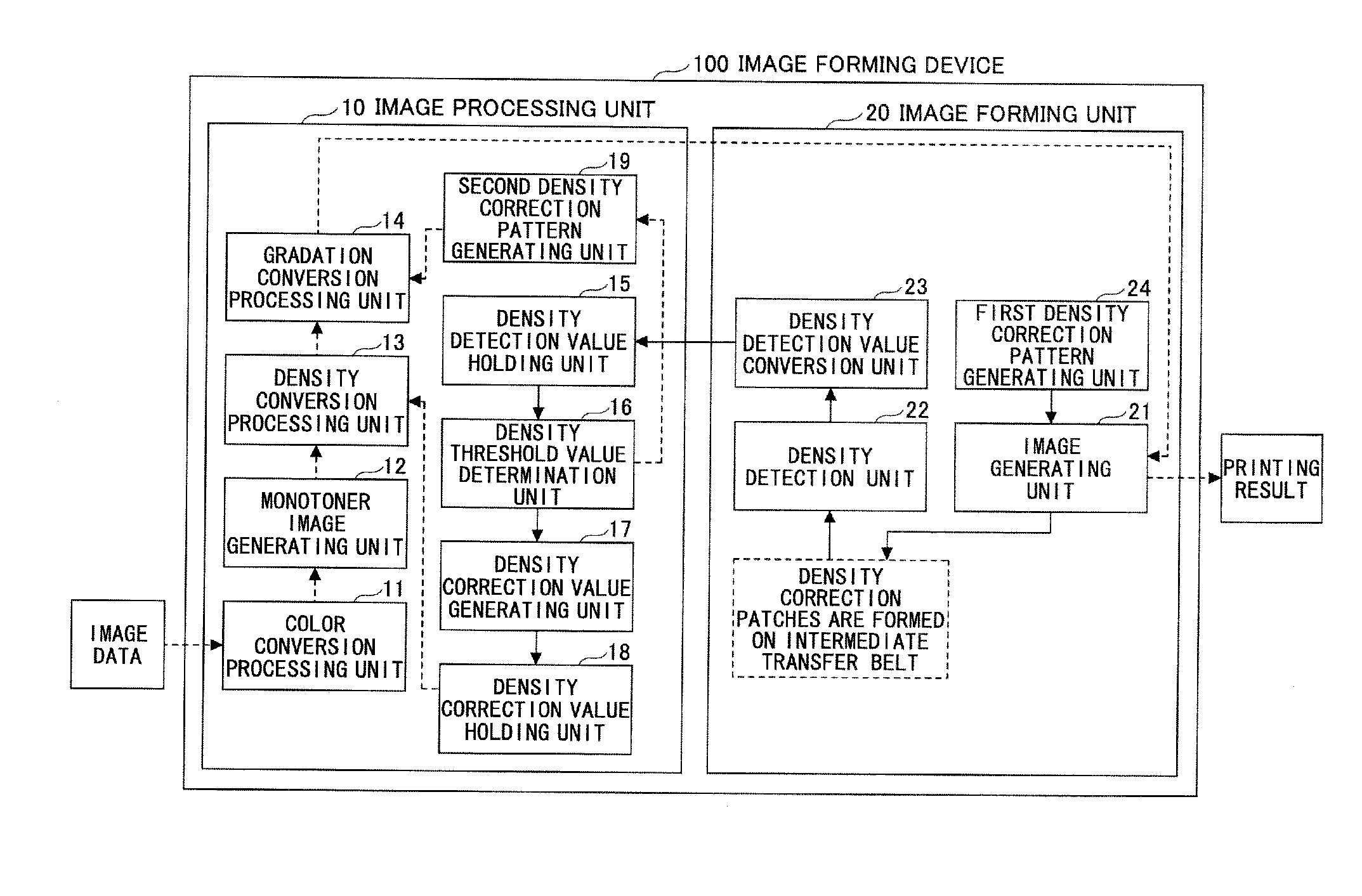

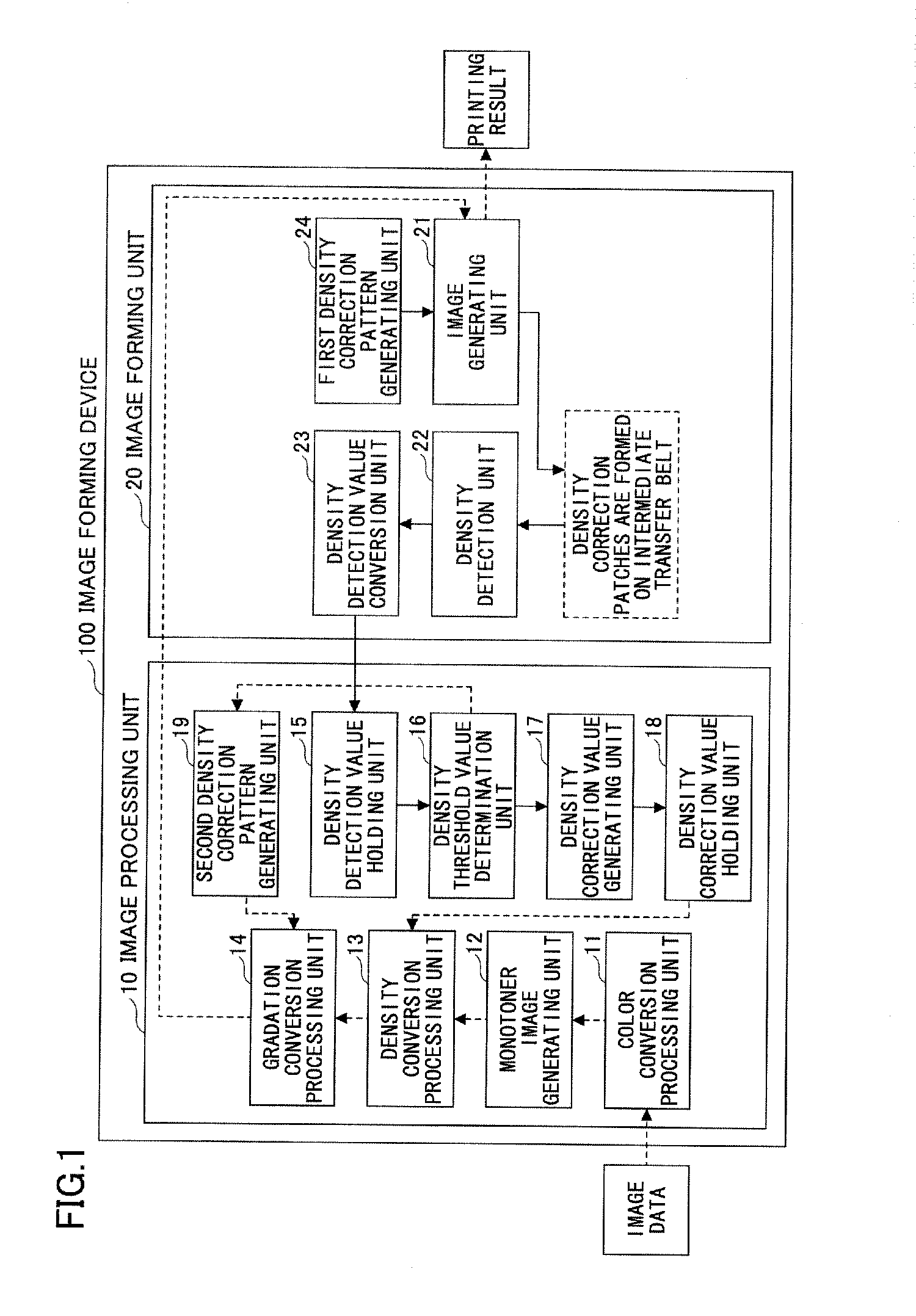

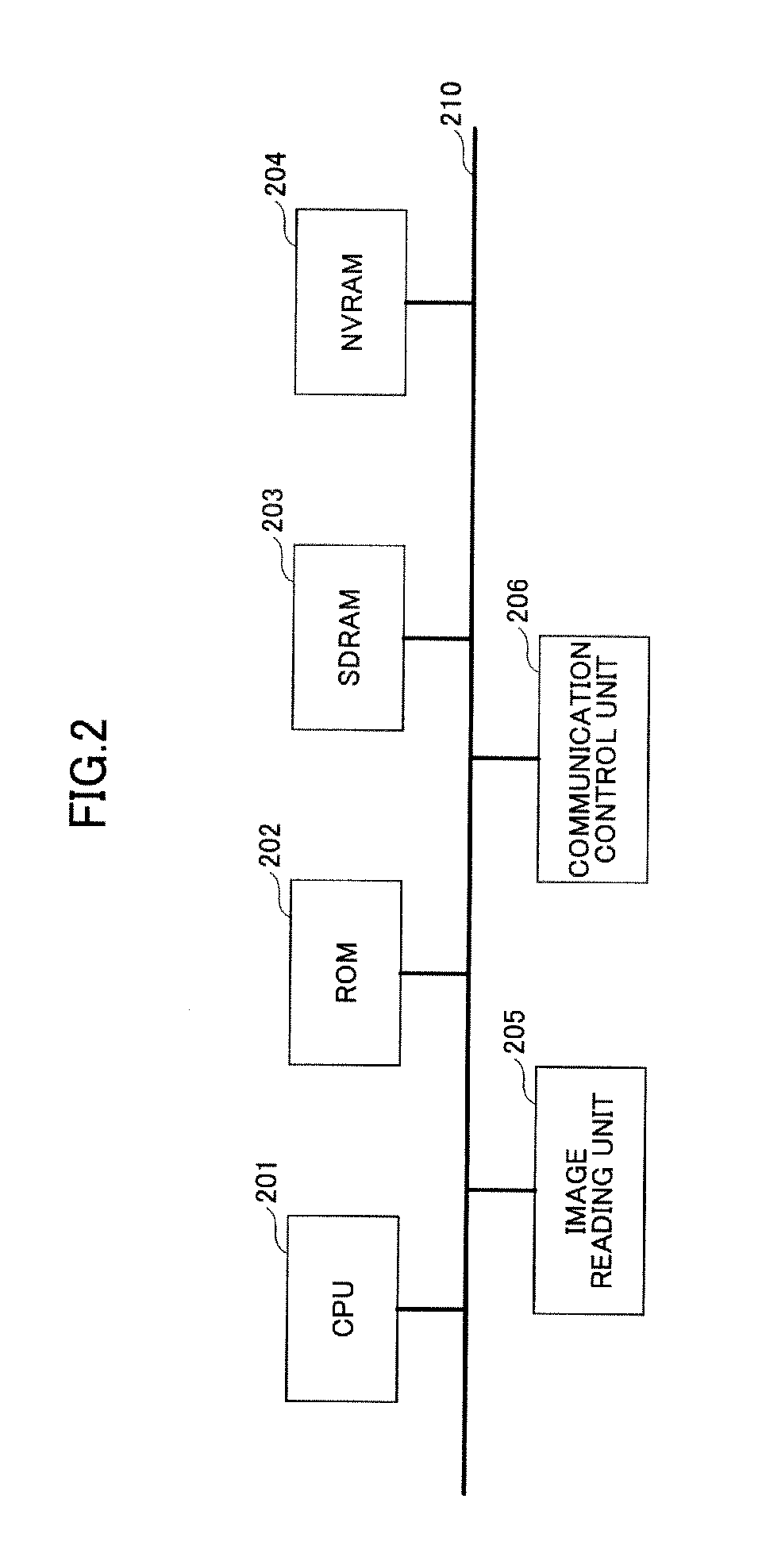

Image forming device, density correction method, and non-transistory computer readable storage medium storing program

InactiveUS20140253930A1Reduce excessive correctionReduce level difference in gradationDigitally marking record carriersVisual presentation using printersImage resolutionImage formation

An image forming device includes a density correction unit that corrects density based on a density detection value of the density correction pattern; a first density correction pattern generating unit that generates a first density correction pattern having low resolution; and a second density correction pattern generating unit that generates a second density correction pattern having high resolution. When a first density detection value of the first density correction pattern is greater than a predetermined threshold value, the density correction unit corrects the density by determining a density correction reflection rate, based on the first density detection value. When the first density detection value is less than or equal to the predetermined threshold value, the density correction unit corrects the density by determining the density correction reflection rate, based on a second density detection value of the second density correction pattern.

Owner:RICOH KK

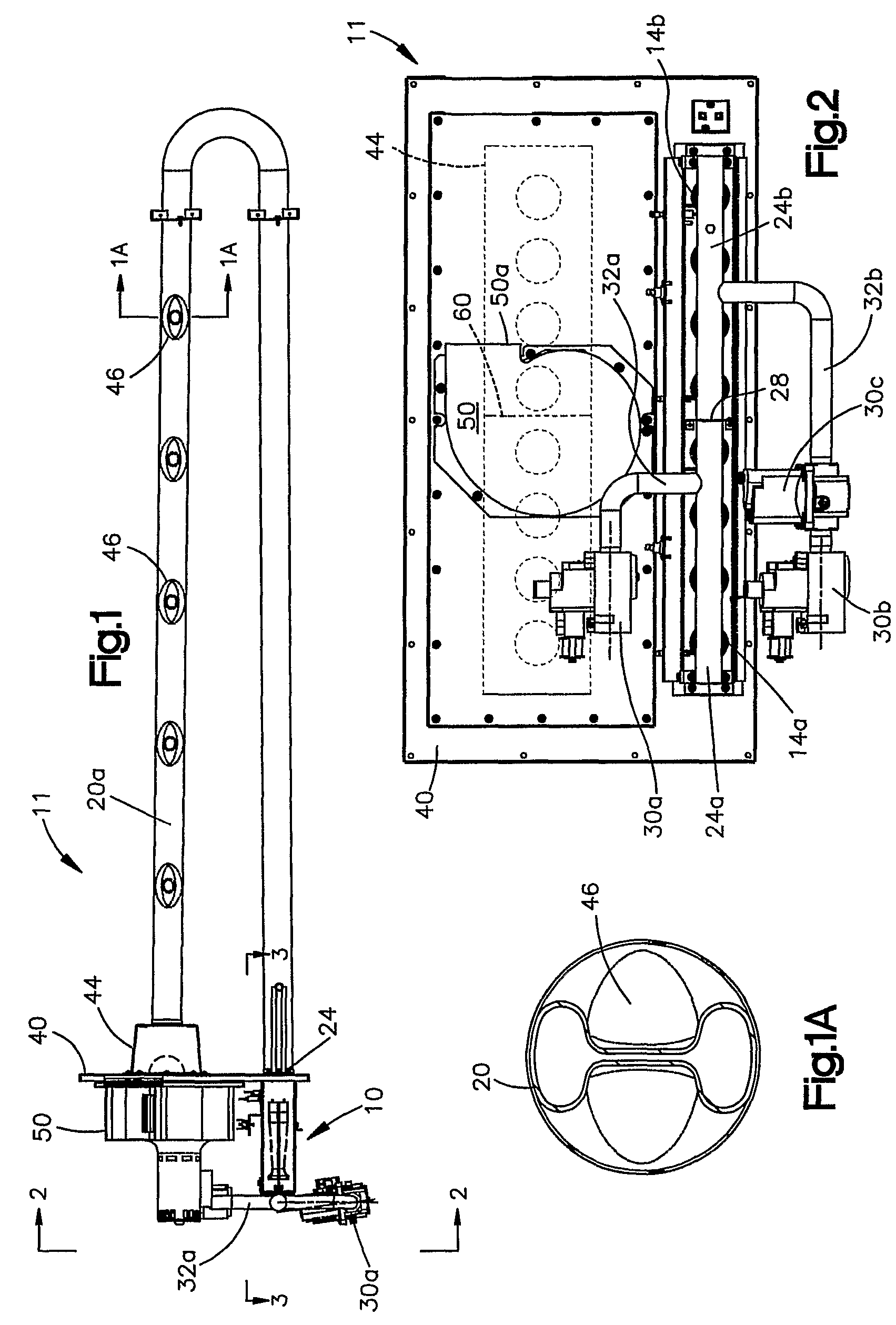

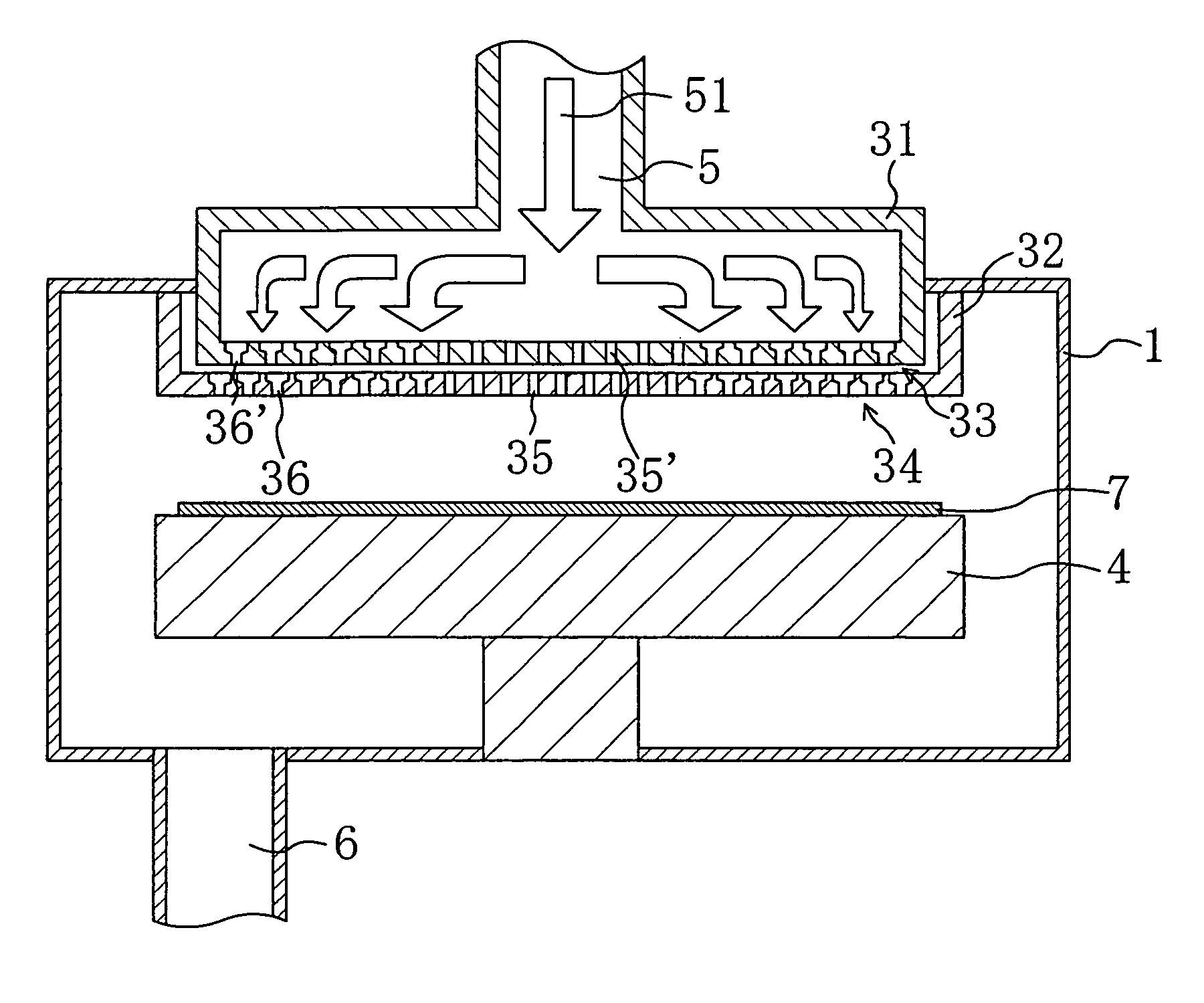

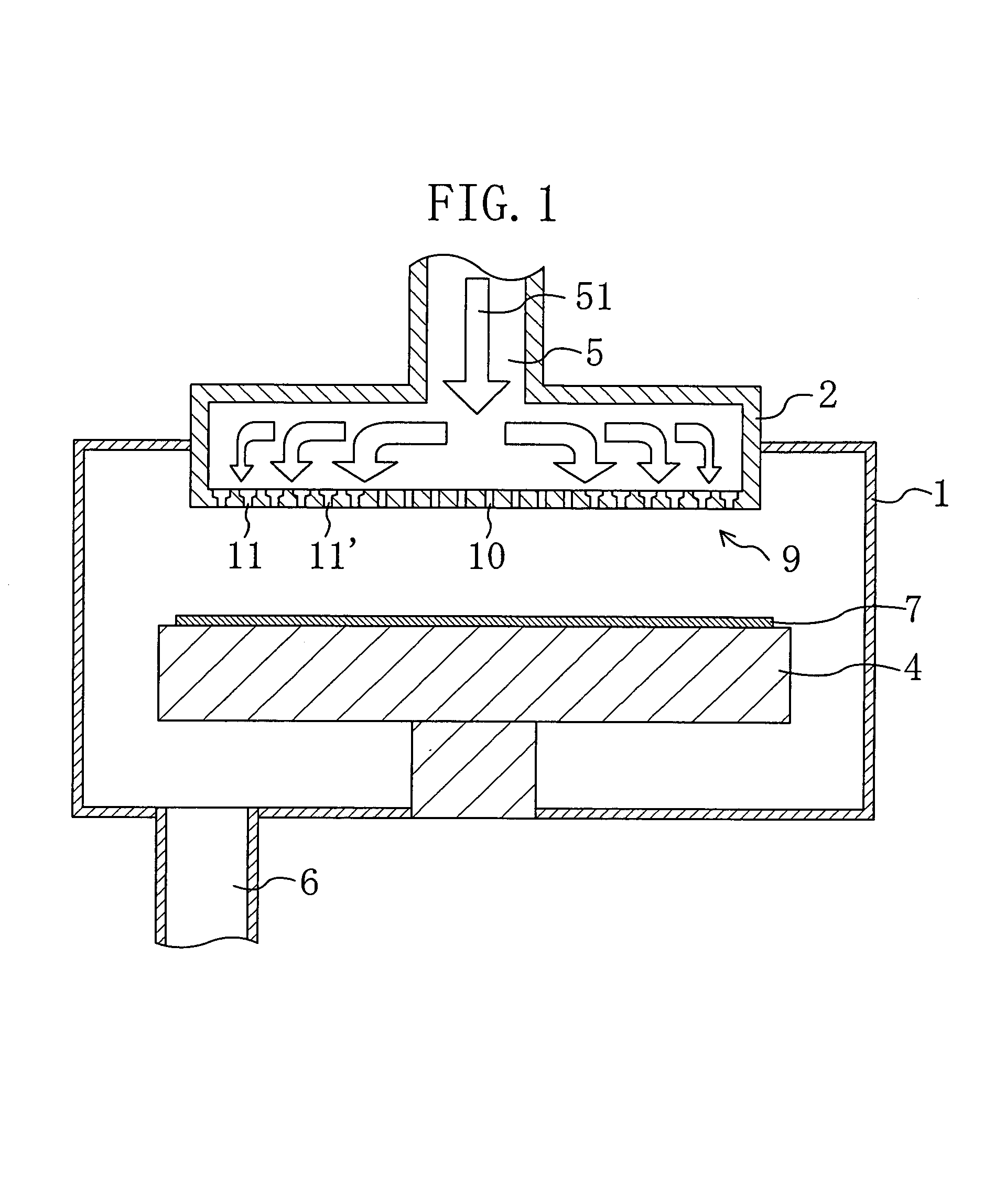

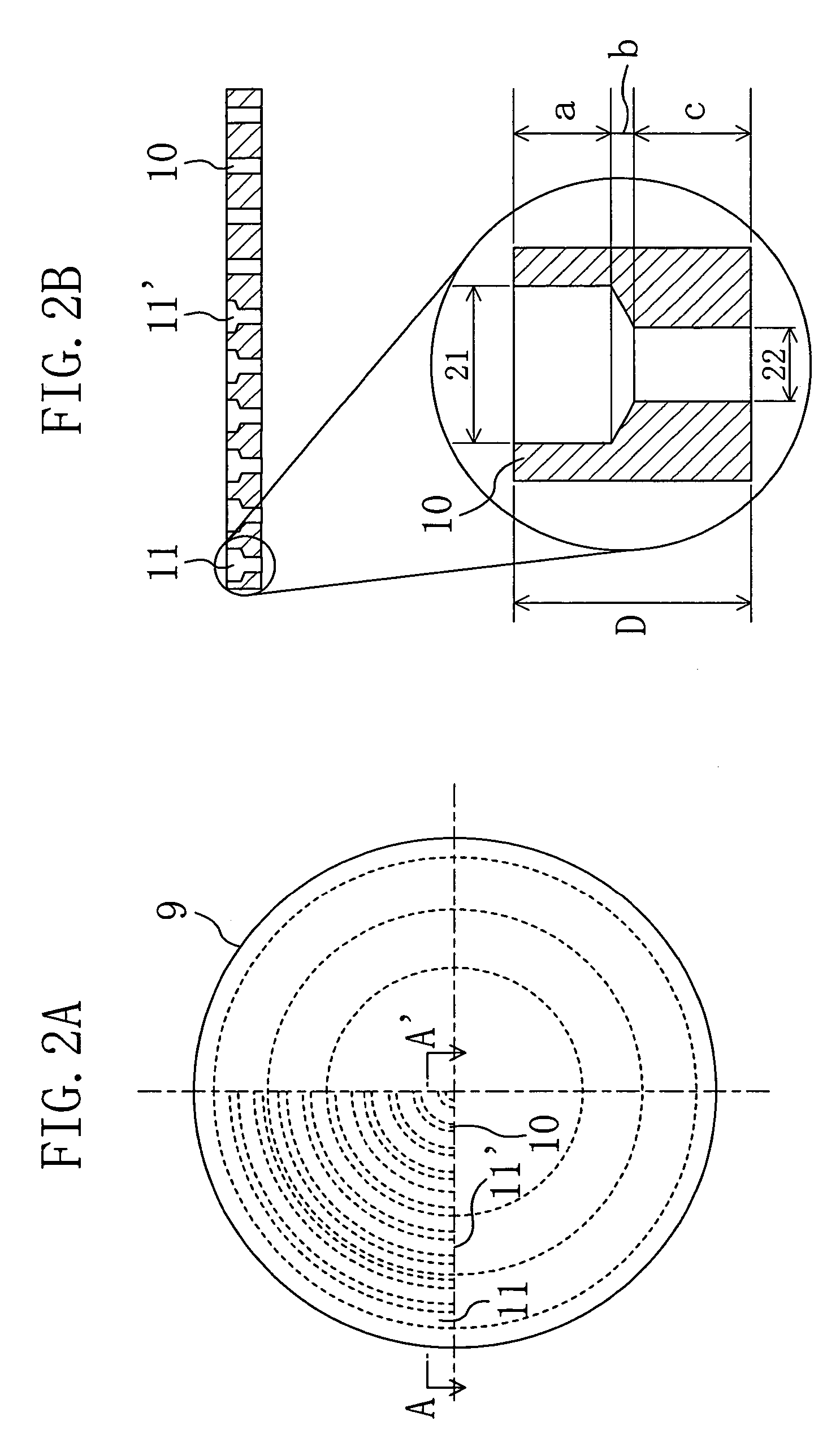

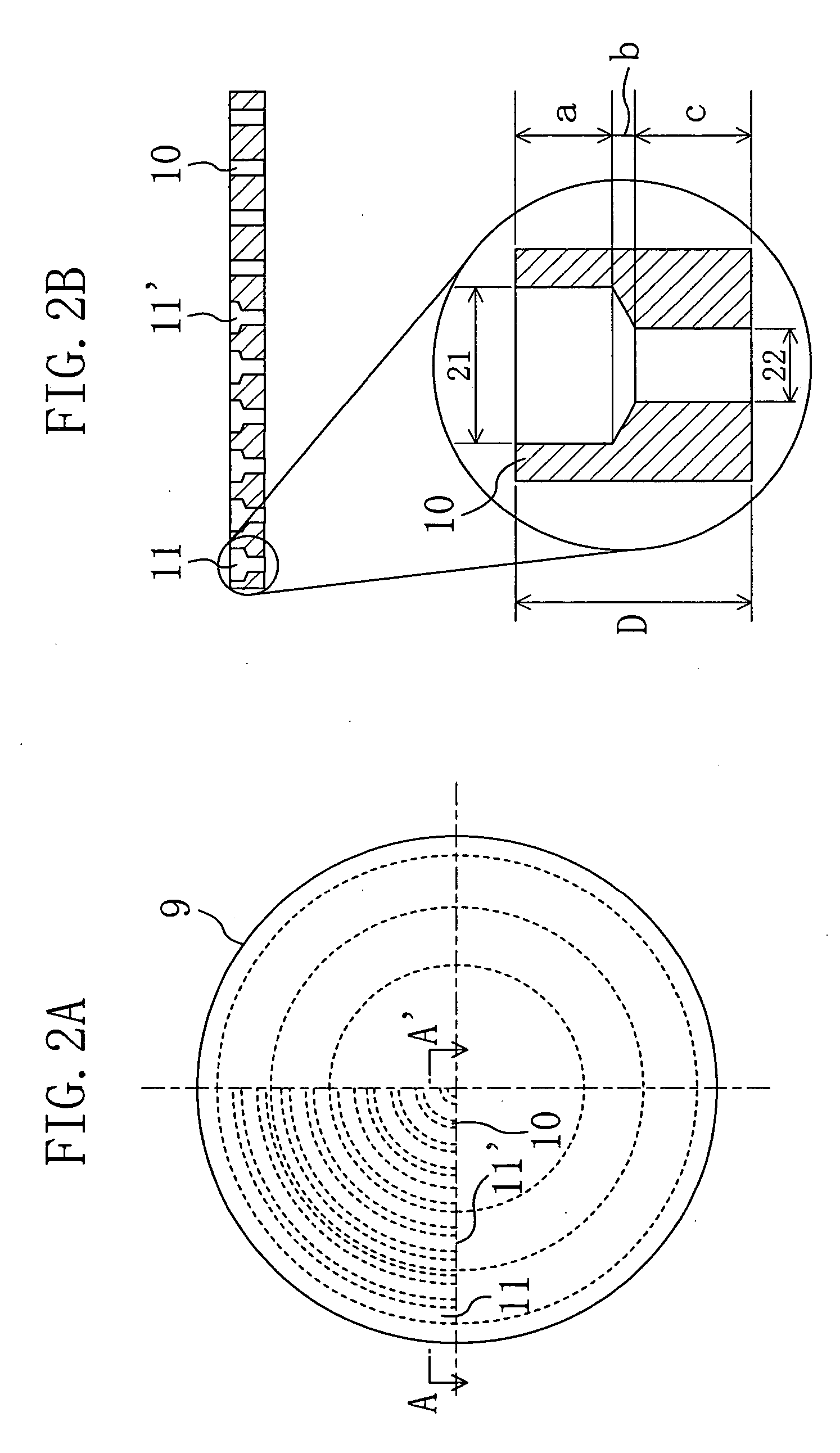

Substrate processing apparatus and substrate processing method

ActiveUS7368398B2Large amount of processingUniform processingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEtchingEngineering

A substrate processing apparatus includes a reaction chamber with a structure allowing pressure reduction, a shower head for supplying a processing gas into the reaction chamber including a gas diffusion plate in which through holes are formed, and a substrate support for placing a substrate. Each ones of through holes provided in a peripheral region of the gas diffusion plate is formed so that an area of an inlet thereof is larger than an area of an outlet thereof. With use of the substrate processing apparatus, a processing gas can be supplied uniformly in the gas diffusion plate. Therefore, substrate processing such as film deposition and film etching can be uniformly performed.

Owner:PANNOVA SEMIC

Substrate processing apparatus and substrate processing method

ActiveUS20060086463A1Large amount of processingUniform processingDecorative surface effectsSemiconductor/solid-state device manufacturingEtchingEngineering

A substrate processing apparatus includes a reaction chamber with a structure allowing pressure reduction, a shower head for supplying a processing gas into the reaction chamber including a gas diffusion plate in which through holes are formed, and a substrate support for placing a substrate. Each ones of through holes provided in a peripheral region of the gas diffusion plate is formed so that an area of an inlet thereof is larger than an area of an outlet thereof. With use of the substrate processing apparatus, a processing gas can be supplied uniformly in the gas diffusion plate. Therefore, substrate processing such as film deposition and film etching can be uniformly performed.

Owner:PANNOVA SEMIC

Solid-state imaging device, method of manufacturing the same, and camera and electronic apparatus using the same

InactiveUS8508010B2Reduce sensitivityReduce the differenceTelevision system detailsSolid-state devicesPhotoelectric conversionEngineering

A method of manufacturing a solid-state imaging device is provided. The method includes: forming an insulating layer extending over an effective pixel region where a plurality of pixels each having a photoelectric conversion element is arranged and a peripheral area adjacent to the effective pixel region; forming an opening in the insulating layer located immediately above the photoelectric conversion element on the effective pixel region; forming a dummy opening in the insulating layer on the peripheral region; and forming a buried layer on the insulating layer to fill the opening and the dummy opening formed in the insulating layer.

Owner:SONY CORP

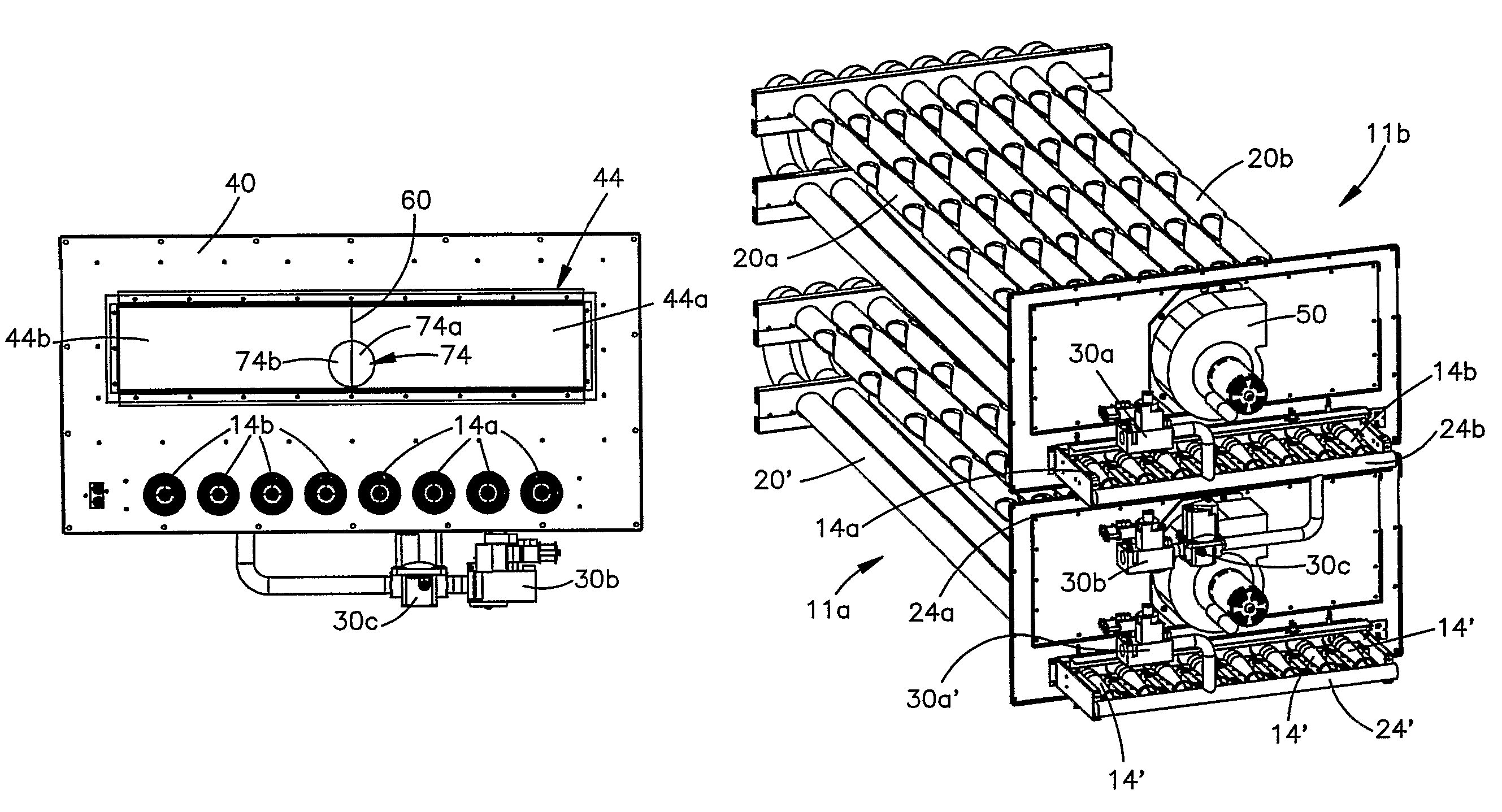

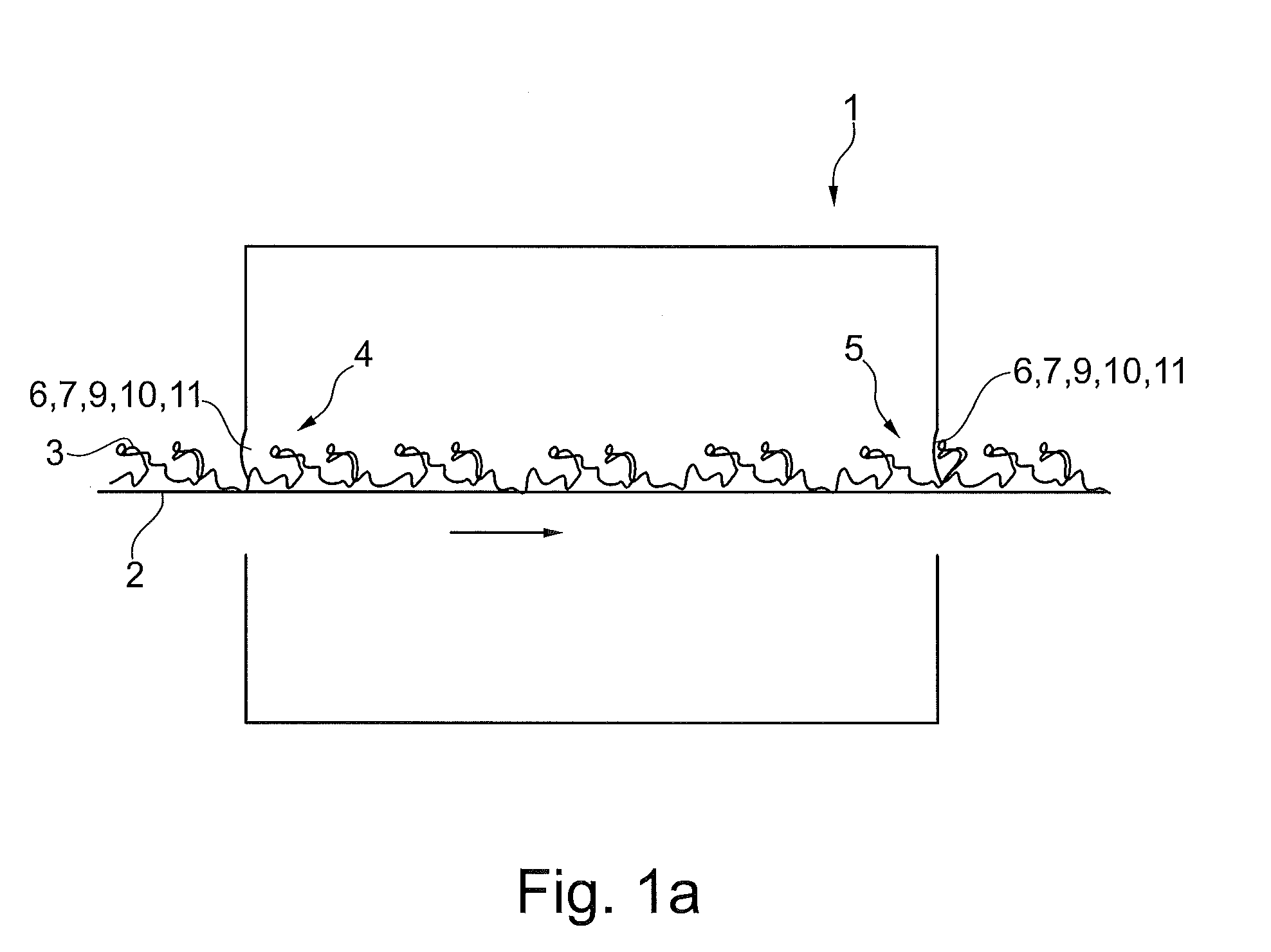

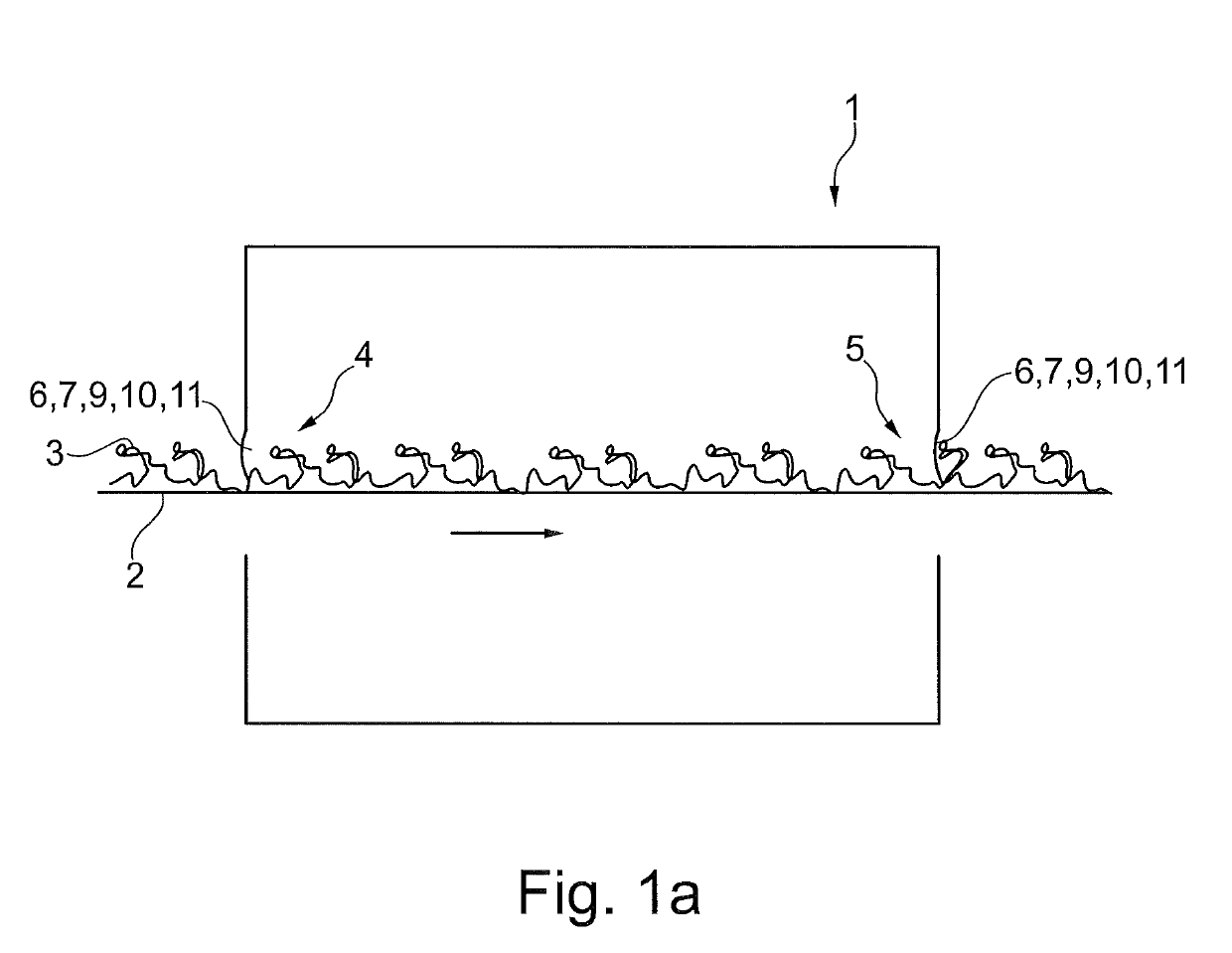

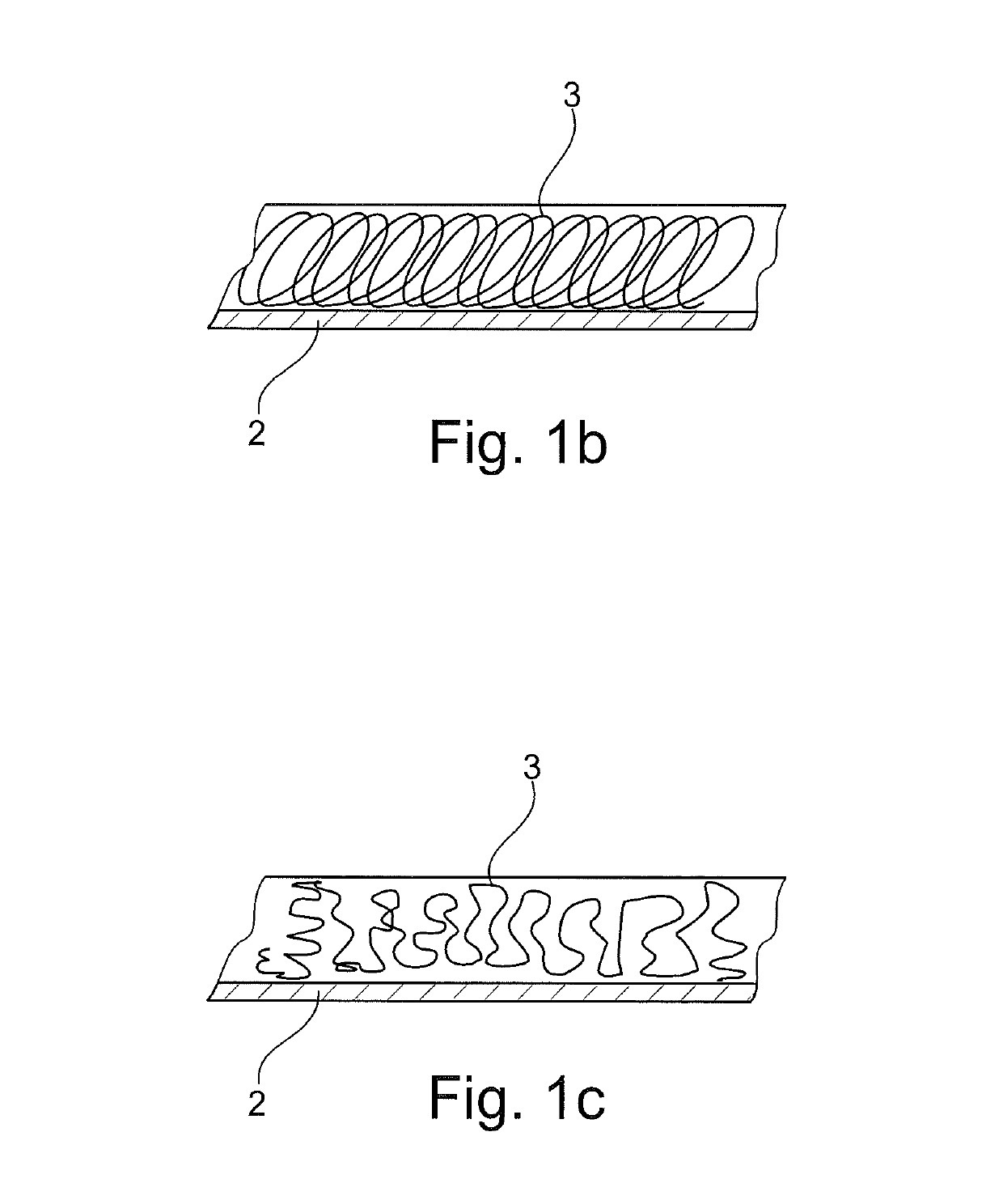

Device for the thermal treatment of yarns

ActiveUS20160040324A1Low in its friction propertyImprove wear resistanceTextile treatment containersTextile storage in helical formYarnConveyor belt

A device for the thermal treatment of yarns comprising at least one inlet opening and at least one outlet opening for at least one transport means, which transports the yarn through the device, and comprising separating elements at the inlet opening and the outlet opening for thermal shielding, in order to minimise the exchange of media to the environment. The separating elements are configured to have a low bending rigidity and are arranged such that a surface load is applied onto the yarn lying on the transport means, for example a conveyor belt, which is not greater than 0.005 kg*cm−2.

Owner:SAURER TECH GMBH & CO KG

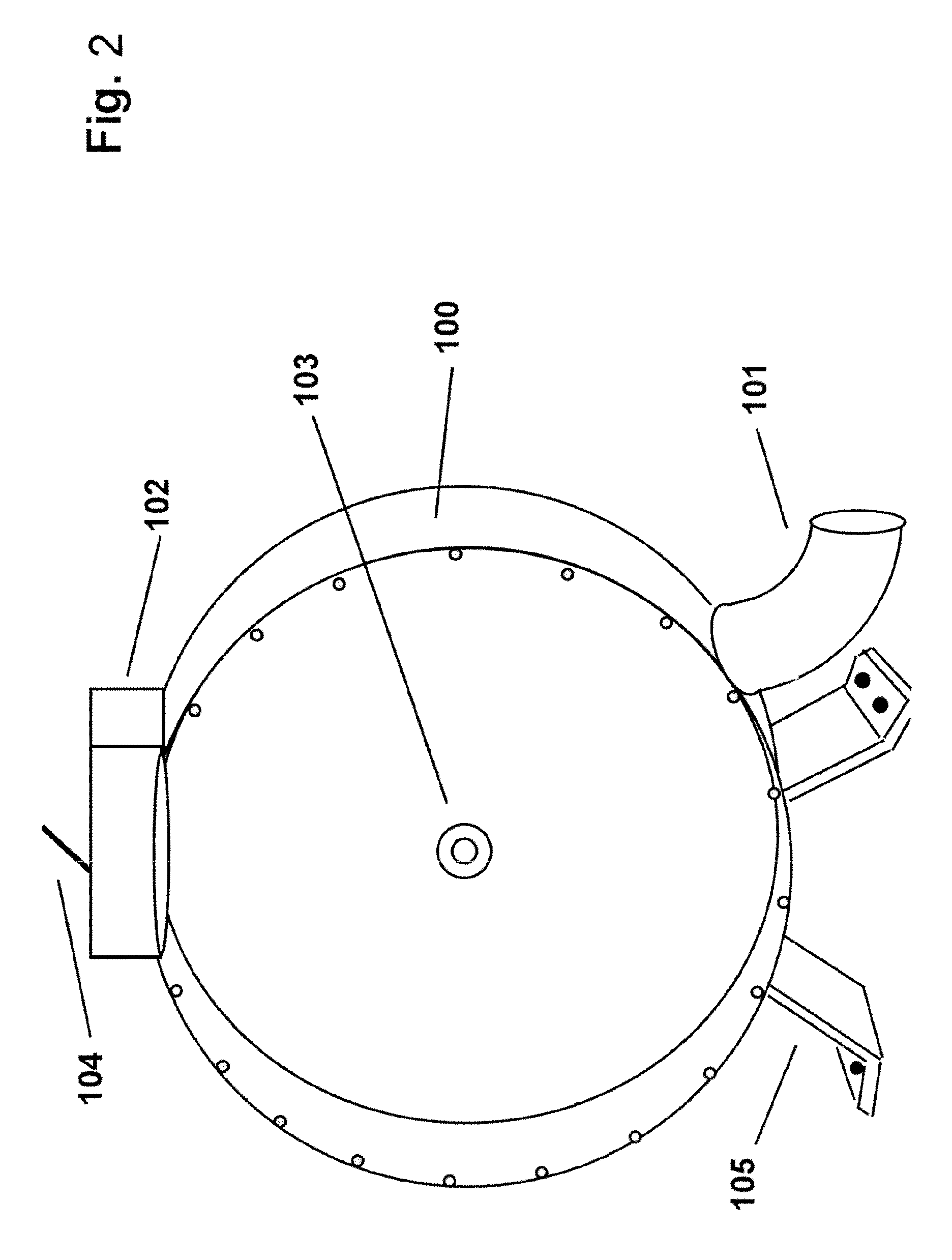

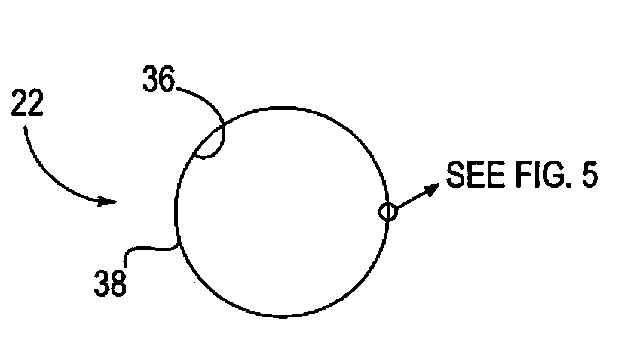

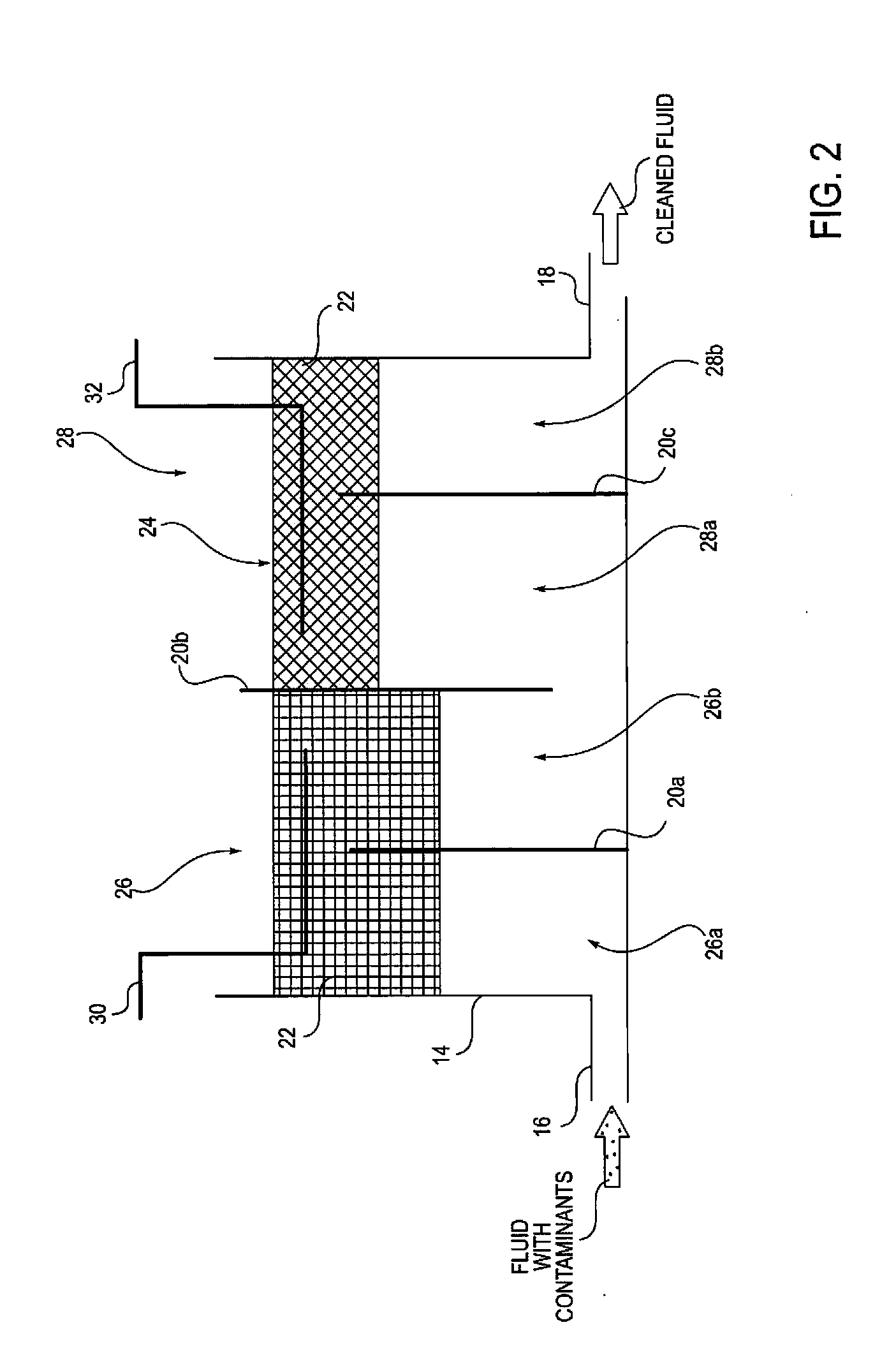

Method and system for removing contaminants from a fluid

ActiveUS20090277797A1Facilitates removal of contaminantDifference in densityWaste water treatment from quariesElectrostatic separationMicrostructureEnvironmental chemistry

A method and system for removing contaminants from a fluid are provided. The method can generally include providing microstructures in the fluid. At least some of the contaminants in the fluid are attracted to the microstructures and adhered to the microstructures. With the contaminants attached to the microstructures, the microstructures can be separated from the fluid so that the contaminants are thereby removed from the fluid.

Owner:CHEVROU USA INC

Liquid ejecting head and liquid ejecting apparatus

ActiveUS9840076B2Uniformize its densityDifference in density of the electrodes between the first region and the second region is reducedInking apparatusLiquid jetEngineering

A liquid ejecting head includes driving elements and electrodes each extending a second direction for ejecting liquid of pressure chambers through nozzles. The driving elements are classified into a first element group and a second element group. The electrodes are arranged along a first direction intersecting the second direction and are classified into a first electrode group electrically connected to the first element group, a second electrode group electrically connected to the second element group and a third electrode group not contribute to the ejecting liquid.

Owner:SEIKO EPSON CORP

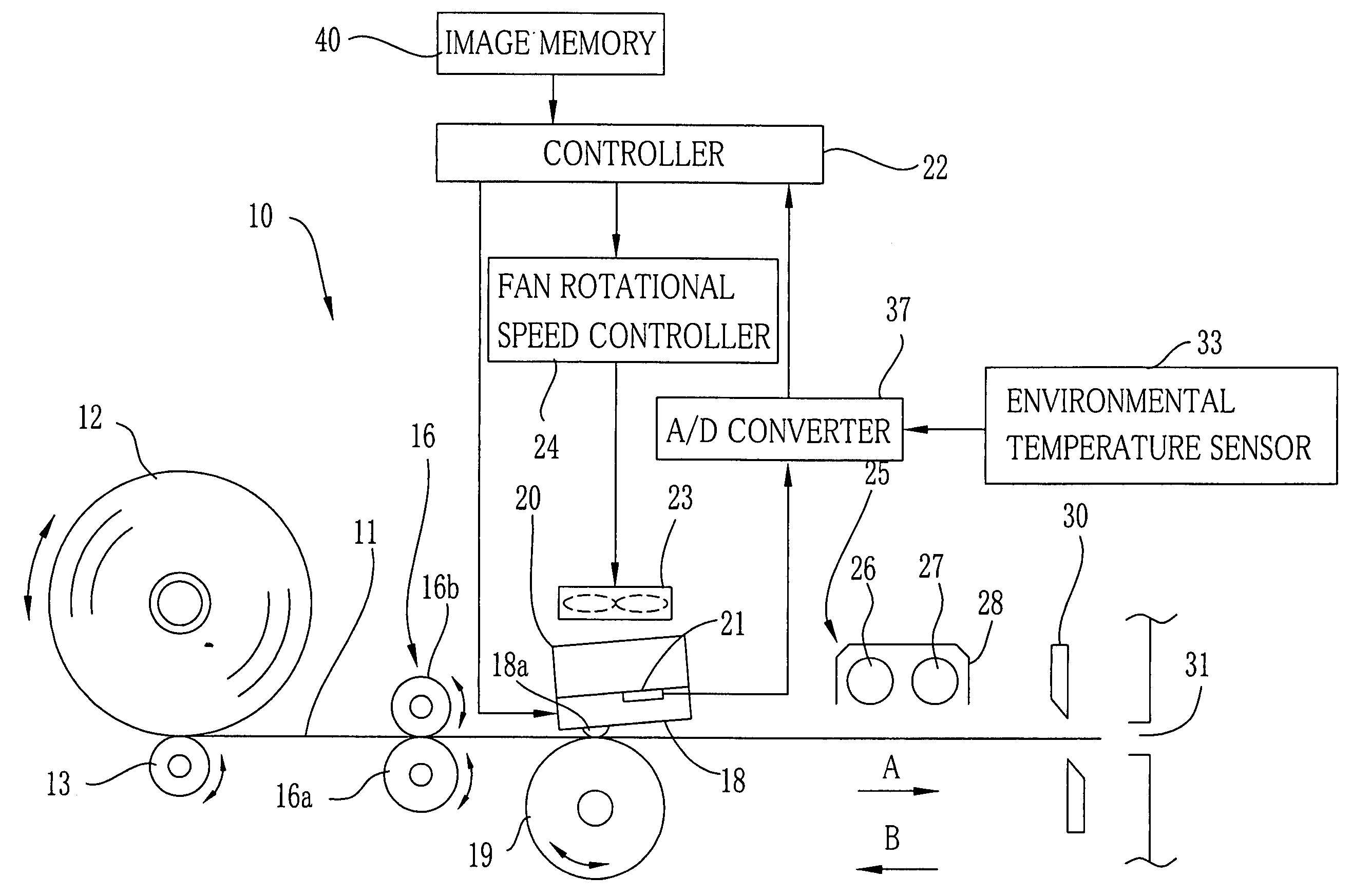

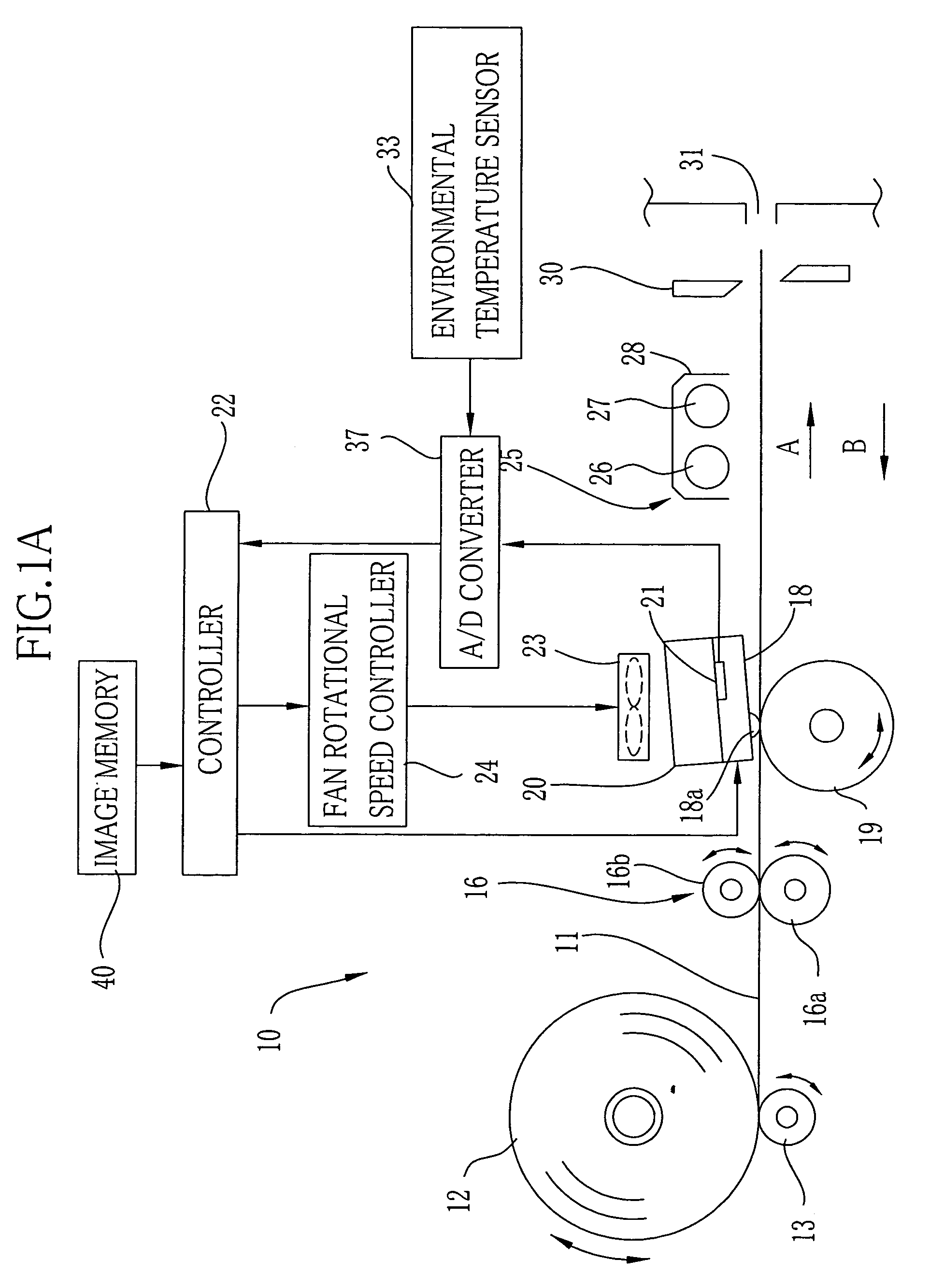

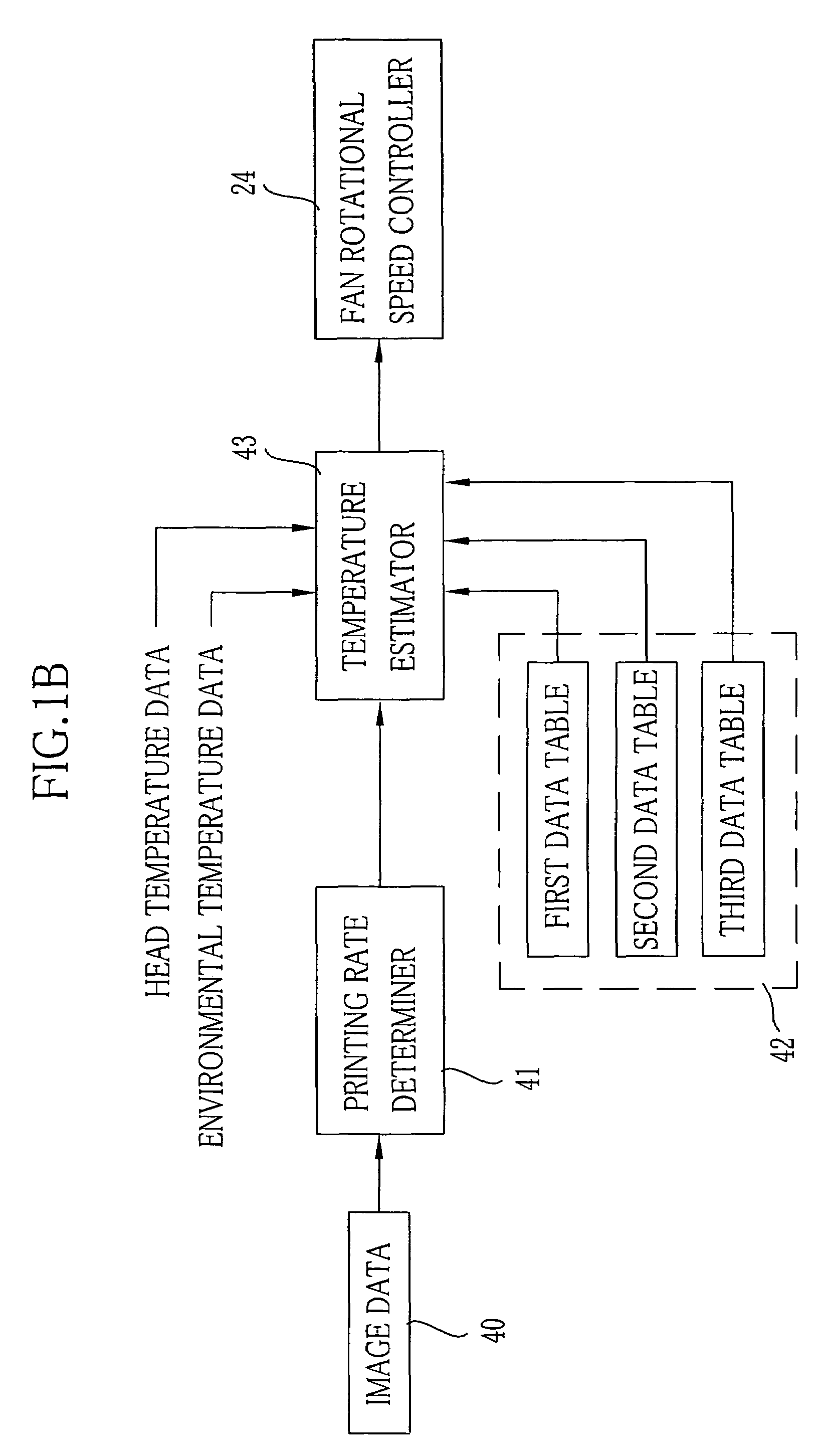

Thermal printer and control method of controlling cooling fan

InactiveUS7030898B2Difference in densityTemperatue controlOther printing apparatusDelayed timeImaging data

A color thermal printer is provided with a cooling fan for cooling a thermal head and a fan rotational speed controller for controlling the rotation speed of the cooling fan, a head temperature sensor for measuring a temperature of the thermal head and an environmental temperature sensor for measuring an environmental temperature around the thermal head. A controller predicts the head temperature in each recording position based on the printing rate (printing density) calculated from the image data, a measured temperature of the thermal head and a measured environmental temperature, and also predicts a delay time of a heat transmitting system and a measuring system based on a fluctuation of the printing rate. The controller controls an air amount of the cooling fan in each recording position based on the predicted temperature and the delay time.

Owner:FUJIFILM CORP +1

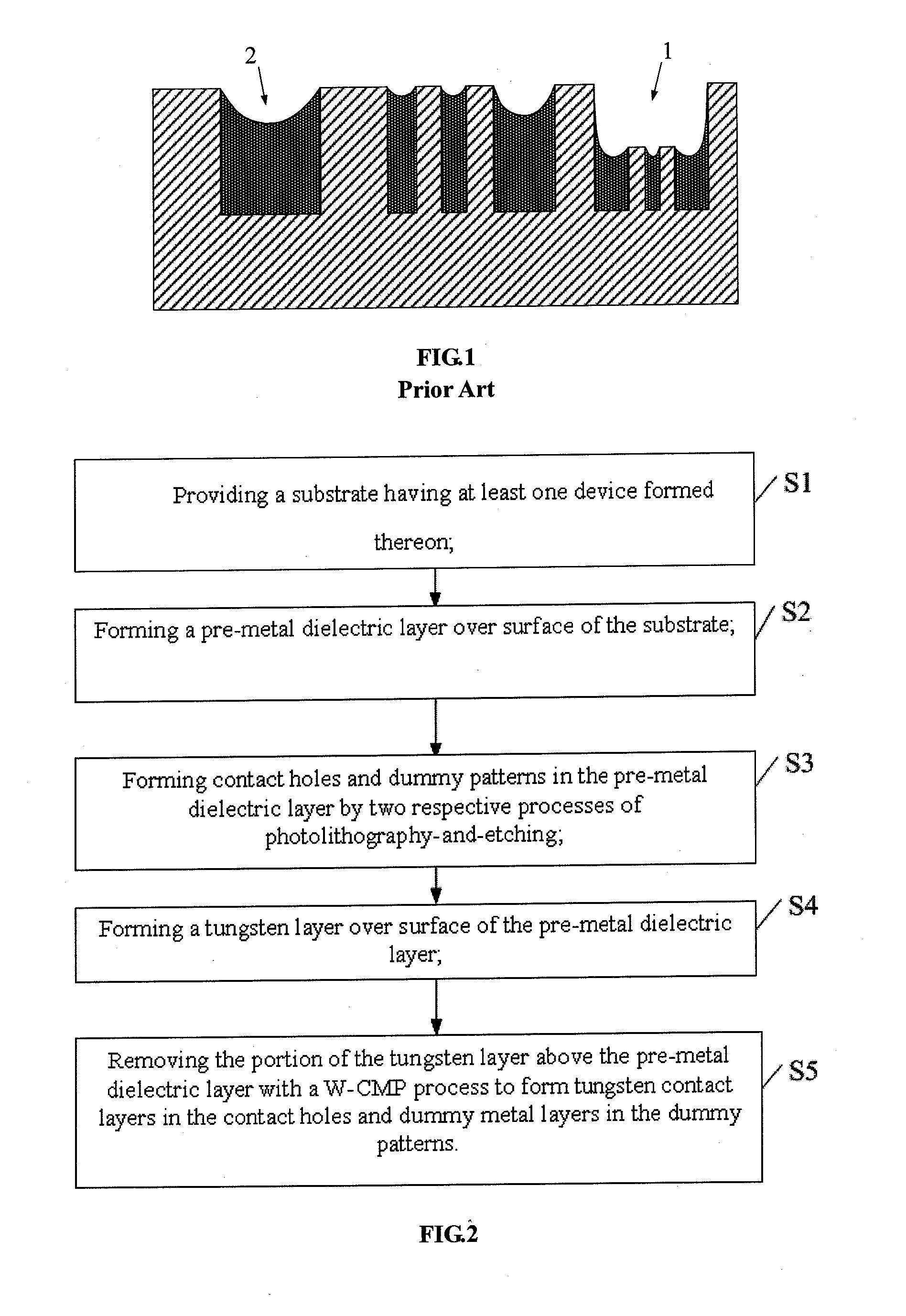

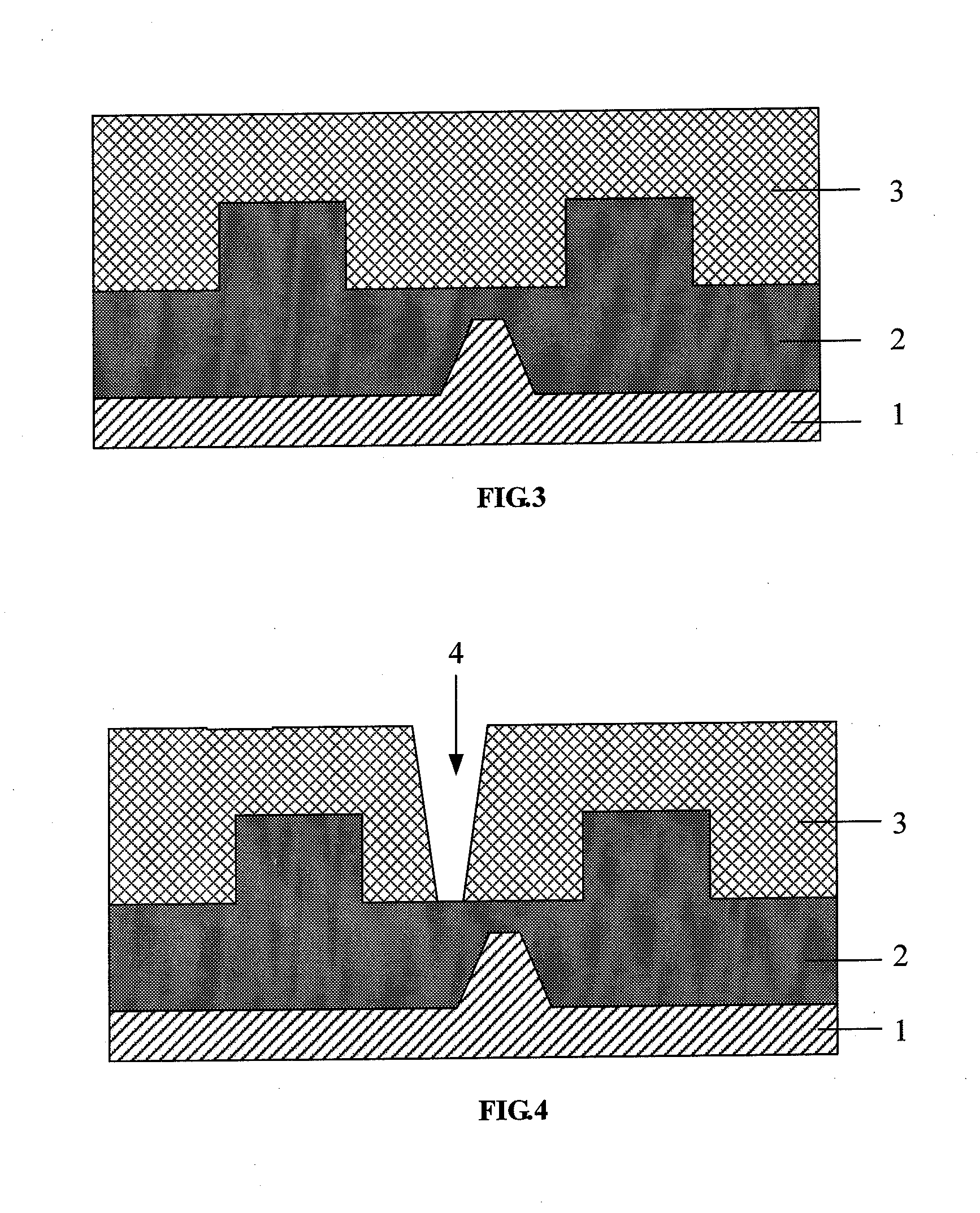

Fabrication method for improving surface planarity after tungsten chemical mechanical polishing

ActiveUS20130224949A1Improves planarity of surfaceNot affect performance of deviceSemiconductor/solid-state device detailsSolid-state devicesTungstenPhotolithography

A fabrication method for improving surface planarity after tungsten chemical mechanical polishing (W-CMP) is disclosed. The method forms contact holes and dummy patterns by performing two respective photolithography-and-etching processes to ensure that the dummy patterns have a depth smaller than that of the contact holes. Then the method fills tungsten into the contact holes and dummy patterns and removes the redundant tungsten by a W-CMP process. With such a method, difference of wiring density between areas can be reduced by the dummy patterns, and hence a better surface planarity of the contact hole layer can be achieved. Besides, as the dummy patterns are formed in a pre-metal dielectric layer and their depth is well controlled, tungsten filled in the dummy patterns will not contact with the device area below the pre-metal dielectric layer, and thus will not affect the performance of the device.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Device for the thermal treatment of yarns

InactiveUS10465313B2Reduce mechanical loadPositive effect on the quality of the processed threadTextile treatment containersTextile storage in helical formYarnEngineering

A device for the thermal treatment of yarns comprising at least one inlet opening and at least one outlet opening for at least one transport means, which transports the yarn through the device, and comprising separating elements at the inlet opening and the outlet opening for thermal shielding, in order to minimise the exchange of media to the environment. The separating elements are configured to have a low bending rigidity and are arranged such that a surface load is applied onto the yarn lying on the transport means, for example a conveyor belt, which is not greater than 0.005 kg*cm−2.

Owner:SAURER TECH GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com