Urea mixer of SCR system

A mixer and urea technology, applied in the direction of machine/engine, muffler, engine components, etc., can solve the problems of increasing the back pressure of the exhaust system, blocking the exhaust pipe, and taking away the exhaust gas flow, so as to enhance the agitation, reduce the Crystallization and avoidance of ammonia leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

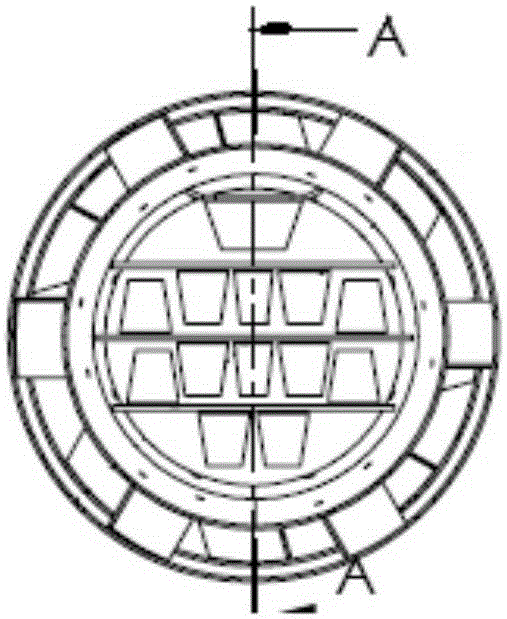

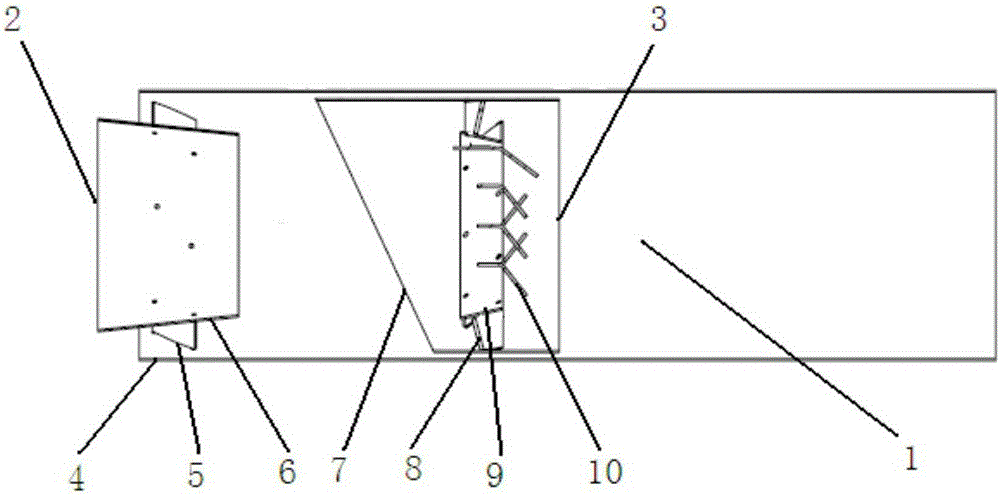

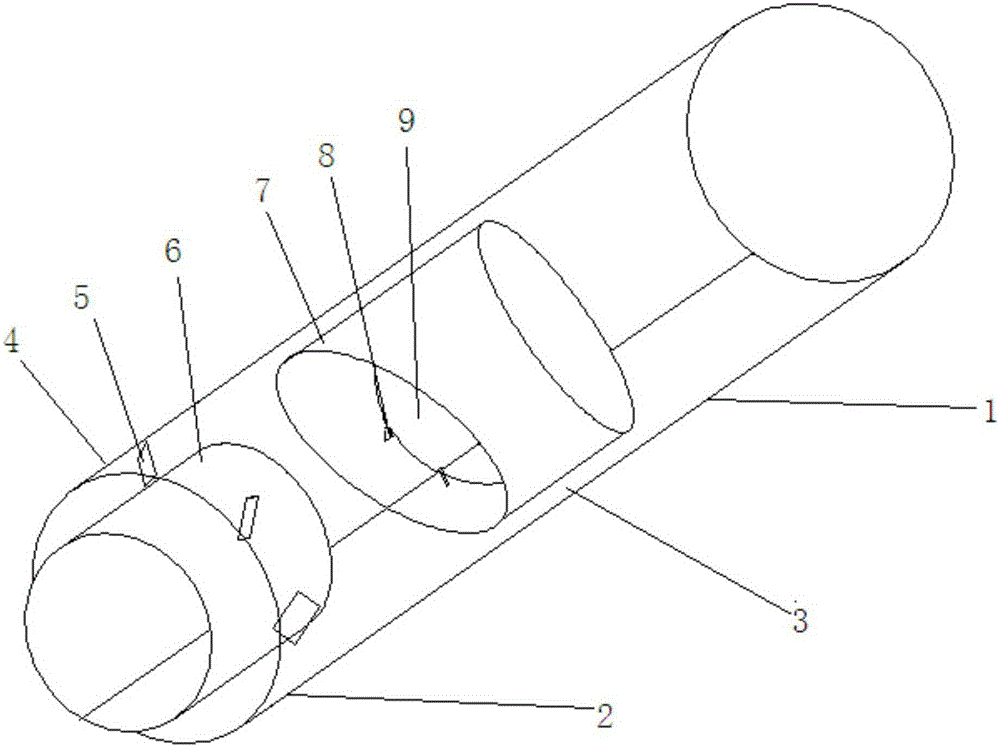

[0032] refer to figure 1 , figure 2 and image 3 , the figure is a specific embodiment of the SCR system urea mixer of the present invention.

[0033] The SCR urea mixer 1 shown in the figure comprises a mixer front part 2 and a mixer rear part 3 .

[0034] Wherein, the front portion 2 of the mixer comprises an annular housing 4, rotating blades 5 and a guide ring 6, the guide ring 6 is placed in the center of the annular housing 4, and the guide ring 6 and the annular housing 4 A number of rotating blades 5 are evenly arranged therebetween, and the two sides of the rotating blades 5 are fixedly connected to the annular casing 4 and the guide ring 6 respectively. The rotating blades 5 form a certain angle with the central axis of the annular housing 4 and are arranged around the central axis in the same rotation direction. The guide ring 6 is trumpet-shaped, and the diameter of the air inlet end is larger than the diameter of the air outlet end.

[0035] The rear part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com