Intense fire gas cooker manufacturing method and product thereof

A manufacturing method and technology for gas stoves, which are used in heating fuels, household stoves/stoves, gaseous heating fuels, etc., can solve problems such as uneven heating, concentrated firepower, and high noise, improve thermal efficiency, and solve problems of excessive firepower concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

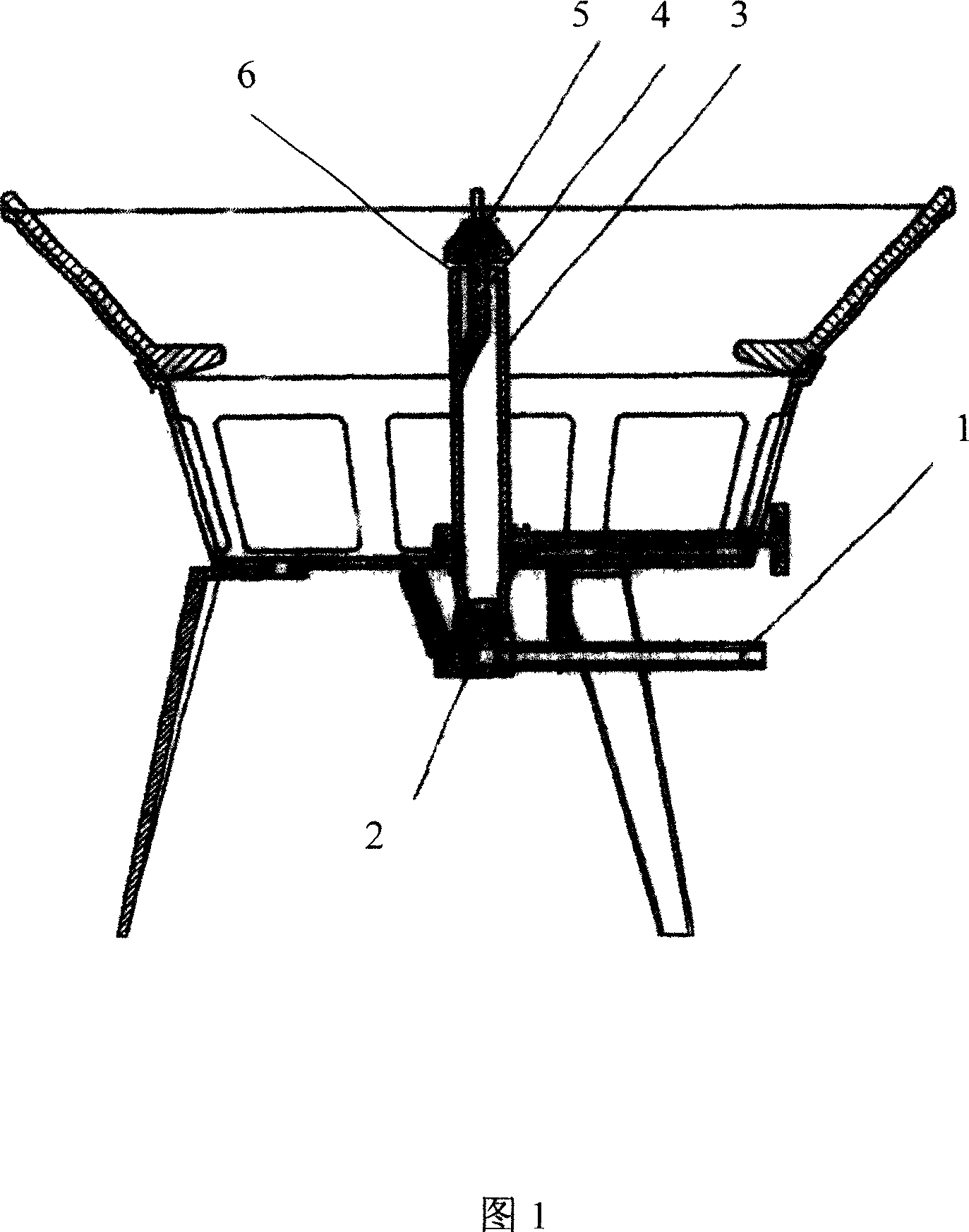

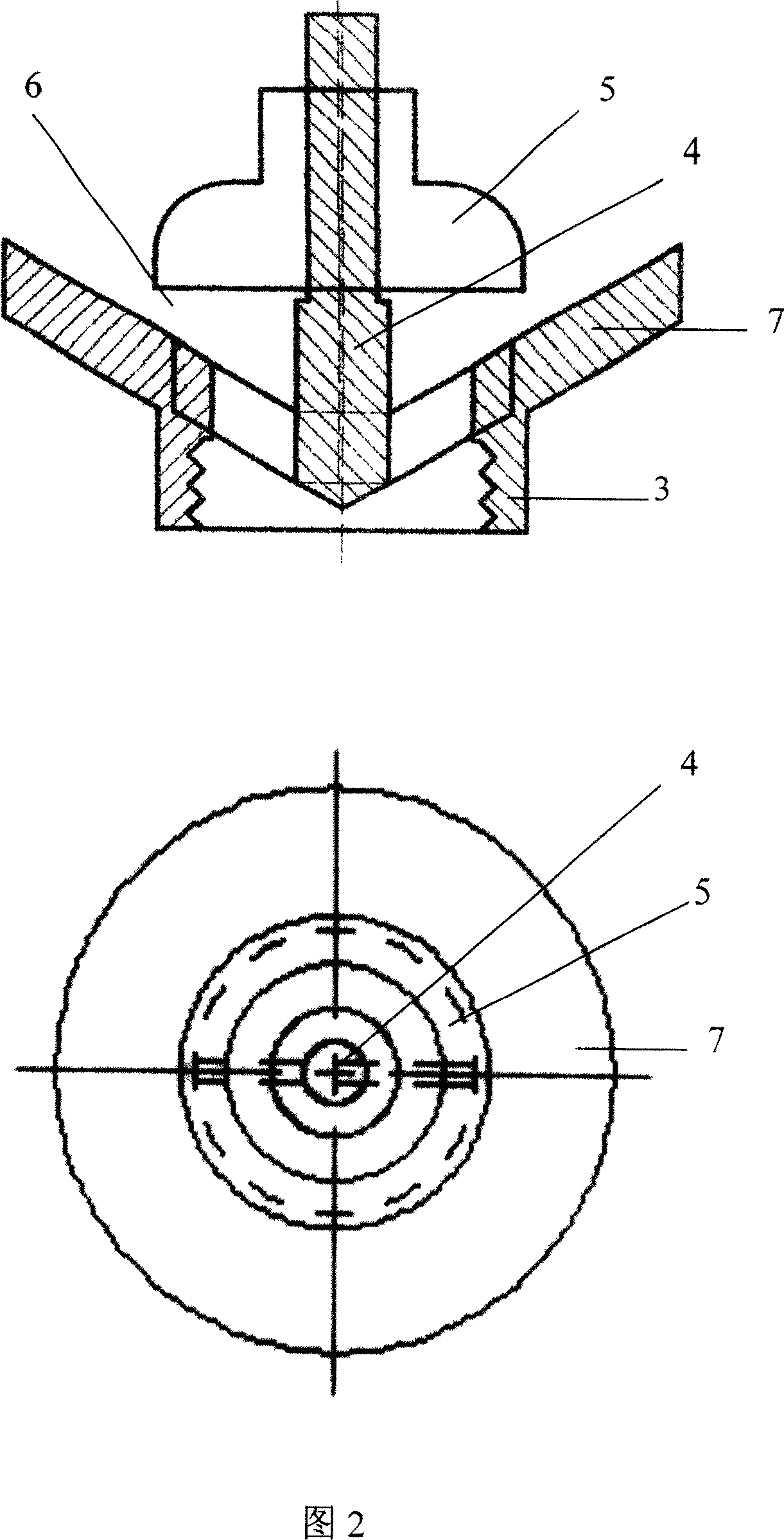

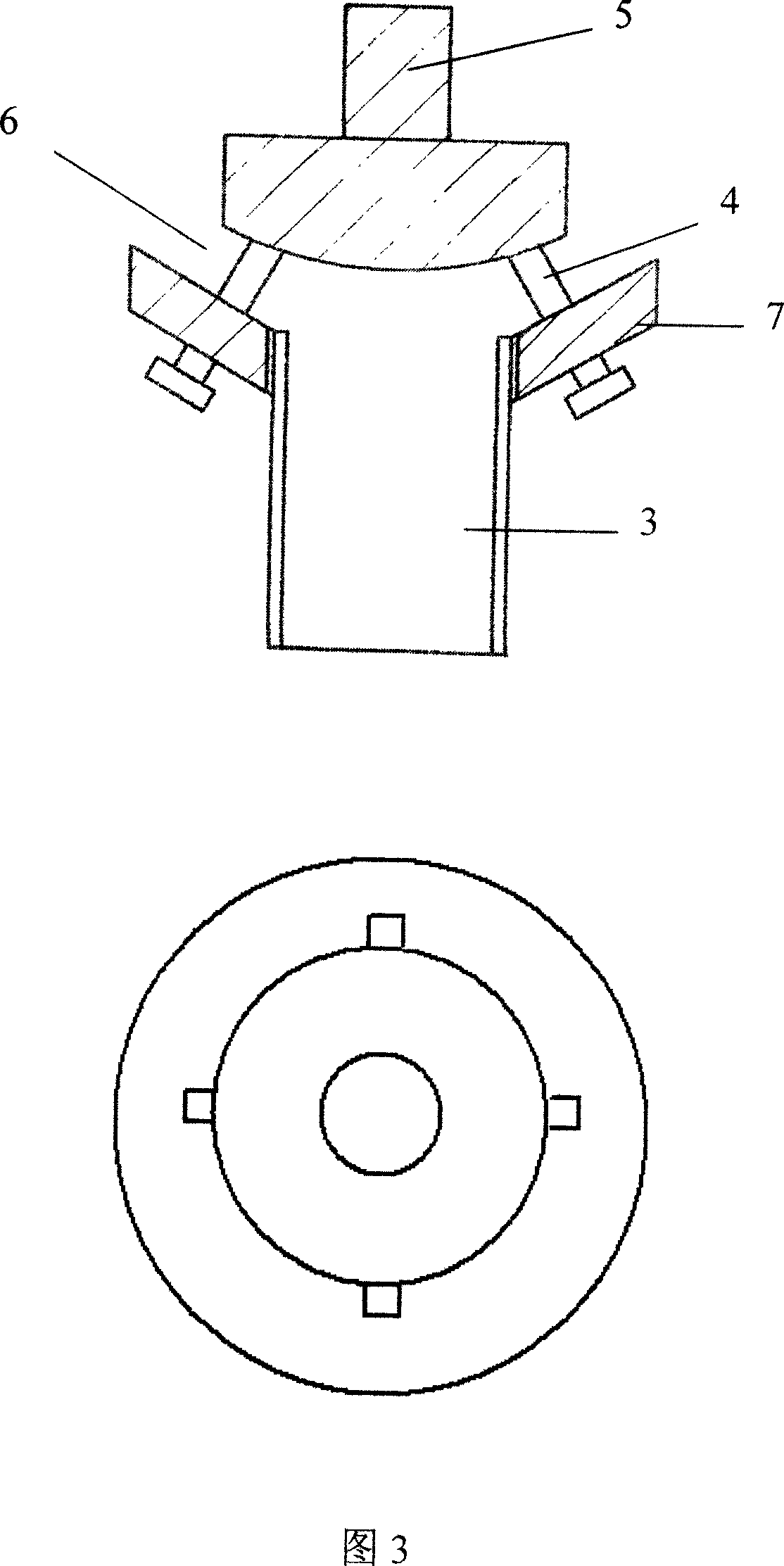

[0028] Fig. 7 is a structural schematic diagram of a specific embodiment of the gas stove of the manufacturing method of the present invention. In the figure: 1 is a combustible gas inlet pipe, 2 is a combustible gas nozzle, 3 is a gas mixing conduit, 4 is a positioning needle for a fire distribution device, and 5 is a fire distribution device. 6 is an air outlet gap, 7 is a fire guide ring, 9 is a propeller-shaped structure wind resistance, 11 is a locking screw, 12 is an air distribution pipe, and 13 is an air inlet. The combustible gas enters the nozzle 2 from the intake pipe 1, and is sprayed into the gas mixing pipe 3 from the nozzle 2. Due to the negative pressure generated by the gas flow, the air enters the gas mixing conduit 3 from the air inlet 13 to mix with the combustible gas, and the mixed gas flows out of the gas mixing conduit 3. Encountered the propeller-shaped air resistance 9 before, under the action of the combustible gas flow, the propeller-shaped wind resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com