Backlight assembly and liquid crystal display device using the same

A bolt and cooling medium technology, applied in the field of bolts, can solve problems such as temperature reduction, and achieve the effect of eliminating direct influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

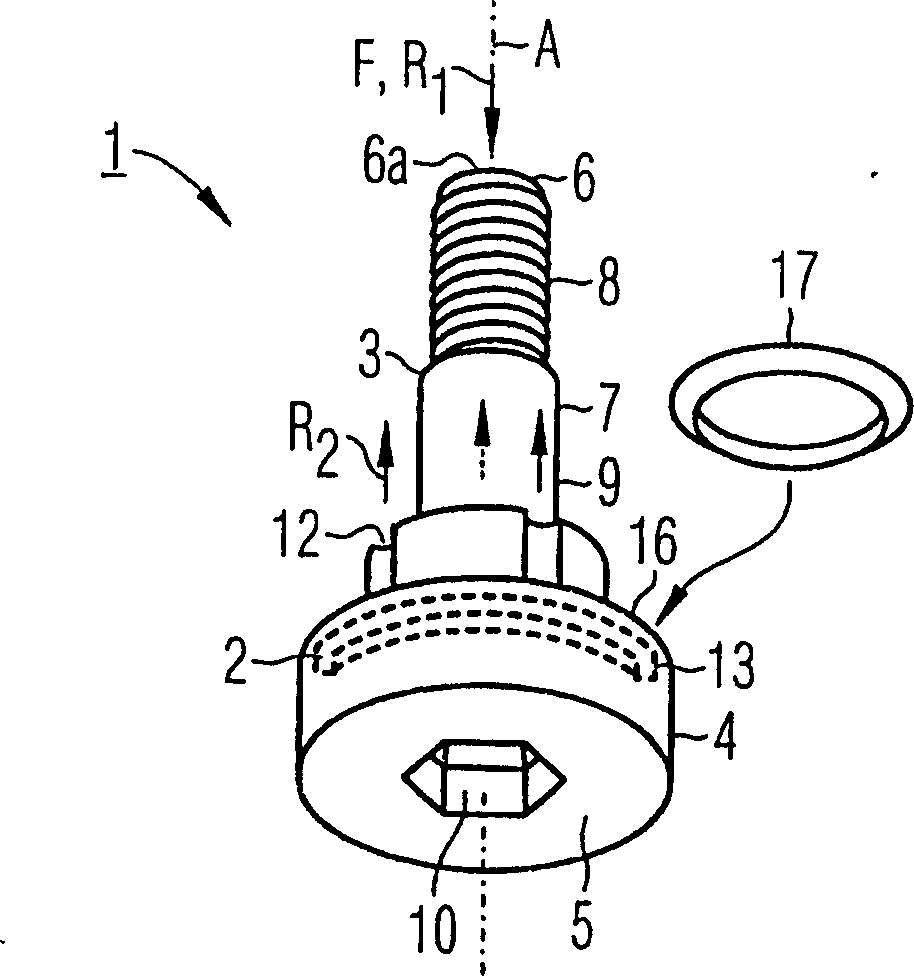

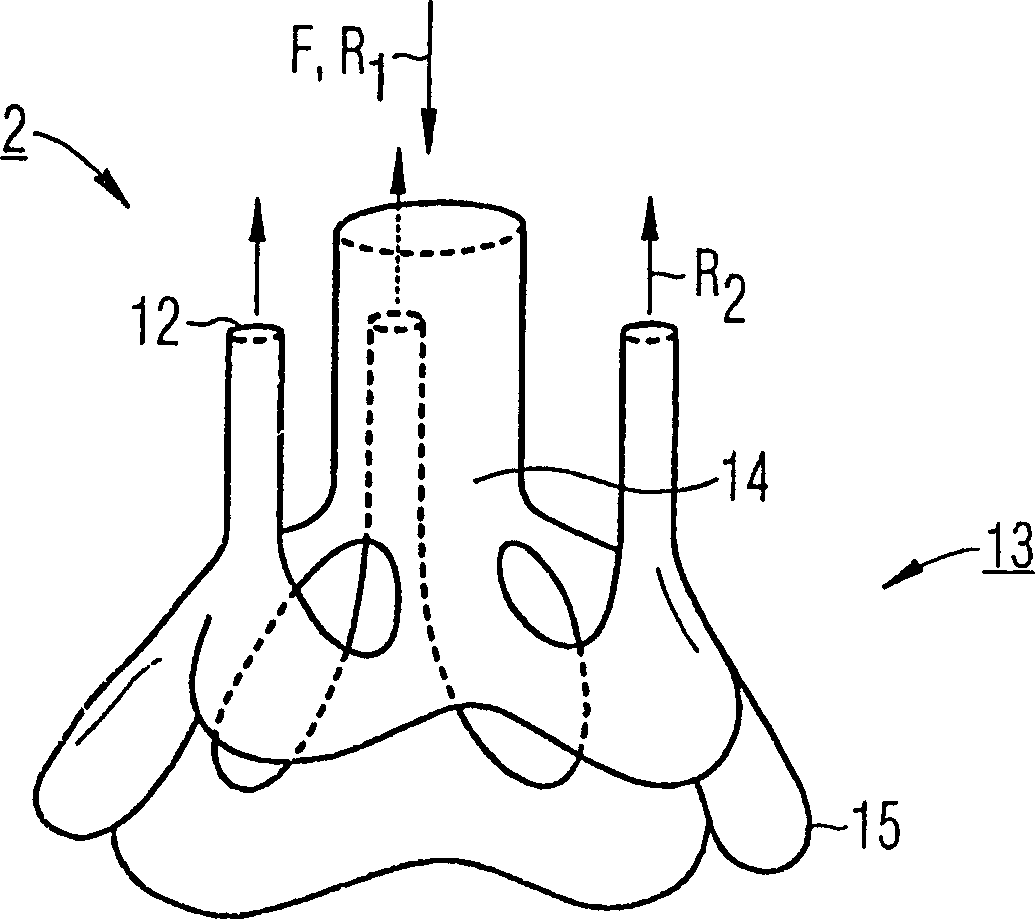

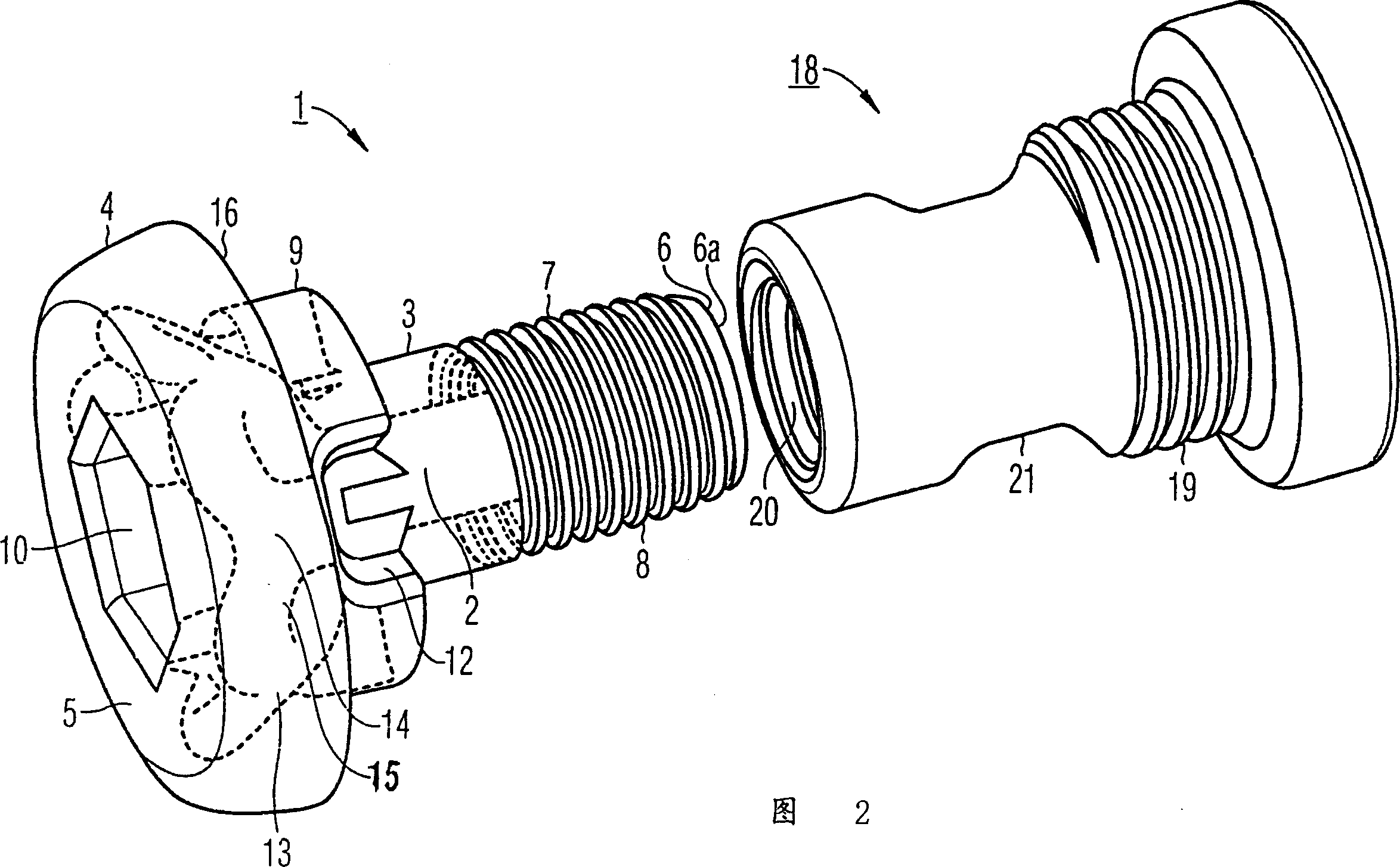

[0017] Figure 1a An internally-coolable screw 1 is shown, the cooling medium channel or cooling channel 2 is cut out in the Figure 1b shown in. The screw 1 has a threaded rod 3 and a nut 4 and extends along an axis or axis of symmetry A from the cover surface 5 of the nut 4 , which is located below in the illustration, to the screw end 6 . The threaded rod 3 has a thread 8 on its outer circumference 7 and a thickened screw flange 9 which delimits the threaded rod 3 in the direction of the nut 4 . The nut 4 has, on its cover surface 5, a hexagonal operating hole 10 for an Allen key.

[0018] The cooling medium or cooling fluid F flows in the axial direction of the screw end 6 in the inflow direction R1 into the inflow opening 6a of the screw 1 and from there from the three cooling medium outflow openings 12 in the outflow direction R2 which is directed opposite to the inflow direction R1 outflow. The cooling channel 2 first extends axially coaxially with the screw 3 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com