Venturi fertilizer applicator

A fertilizer applicator and Venturi technology, applied in the field of Venturi applicators, can solve the problems of low fertilizer absorption efficiency and small momentum exchange, and achieve high fertilizer absorption efficiency, reduce water loss, and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

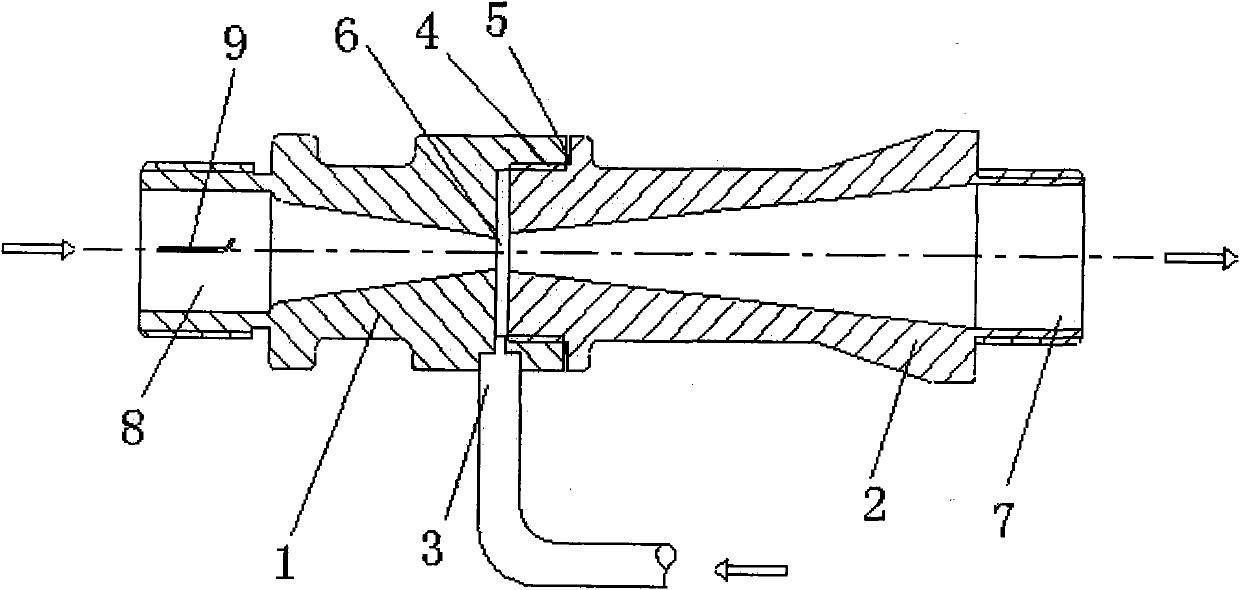

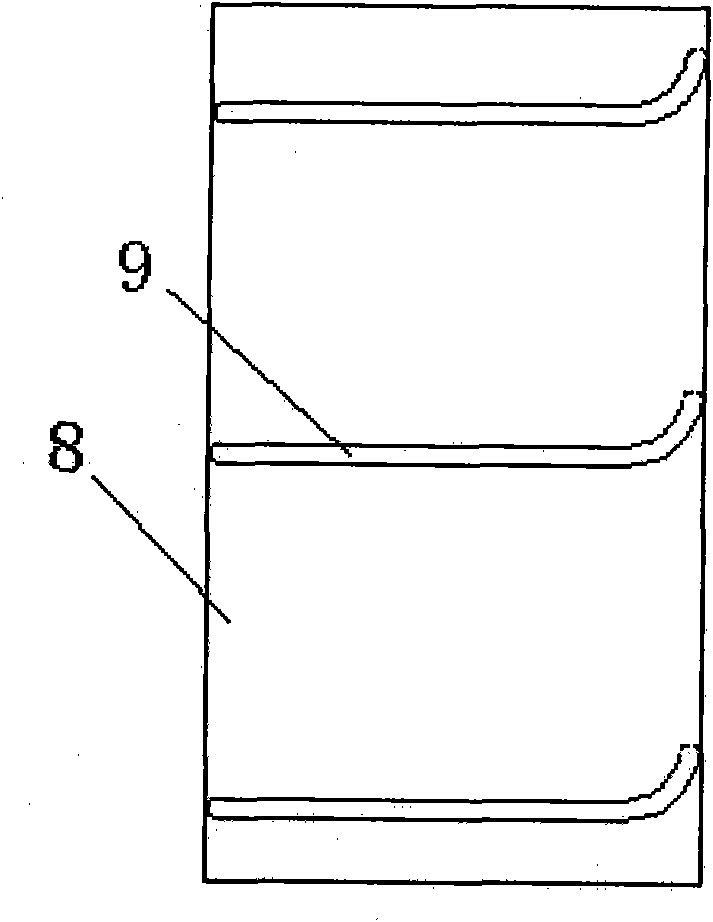

[0014] like figure 1 , figure 2 As shown, the present invention includes a constriction section 1, a diffusion section 2, a suction pipe 3 and the like. The constriction section 1 and the diffusion section 2 are connected by threads 4 and sealed by an "O" type sealing ring 5 . The transition between converging section 1 and diverging section 2 is throat 6 . The suction pipe 3 is sealingly connected at the intersection of the constriction section 1 and the diffusion section 2, and communicates with the throat 6, and the rear part of the diffusion section 2 is an outlet straight pipe section 7. At the front of the contracting section 1 is an inlet straight pipe section 8 , and a group of guide vanes 9 uniformly arranged in the circumferential direction are arranged in the inlet straight pipe section 8 .

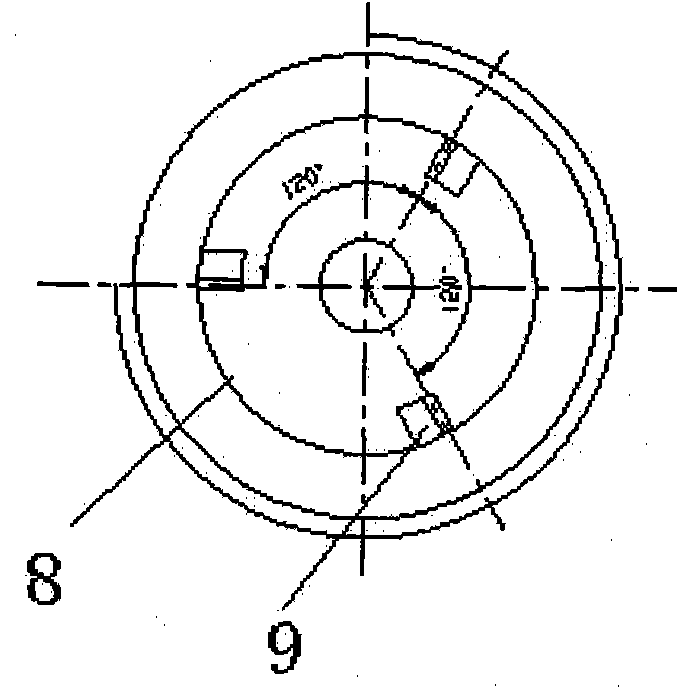

[0015] like image 3 As shown, the guide v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com