Tank-surface-evaporation solar thermal power generation system

A solar thermal power generation and evaporation pond technology, which is applied in the directions of solar thermal power generation, mechanical power generation with solar energy, steam engine installations, etc. Easy to be damaged and other problems, to achieve the effect of saving metal consumables, large evaporation, and fast evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

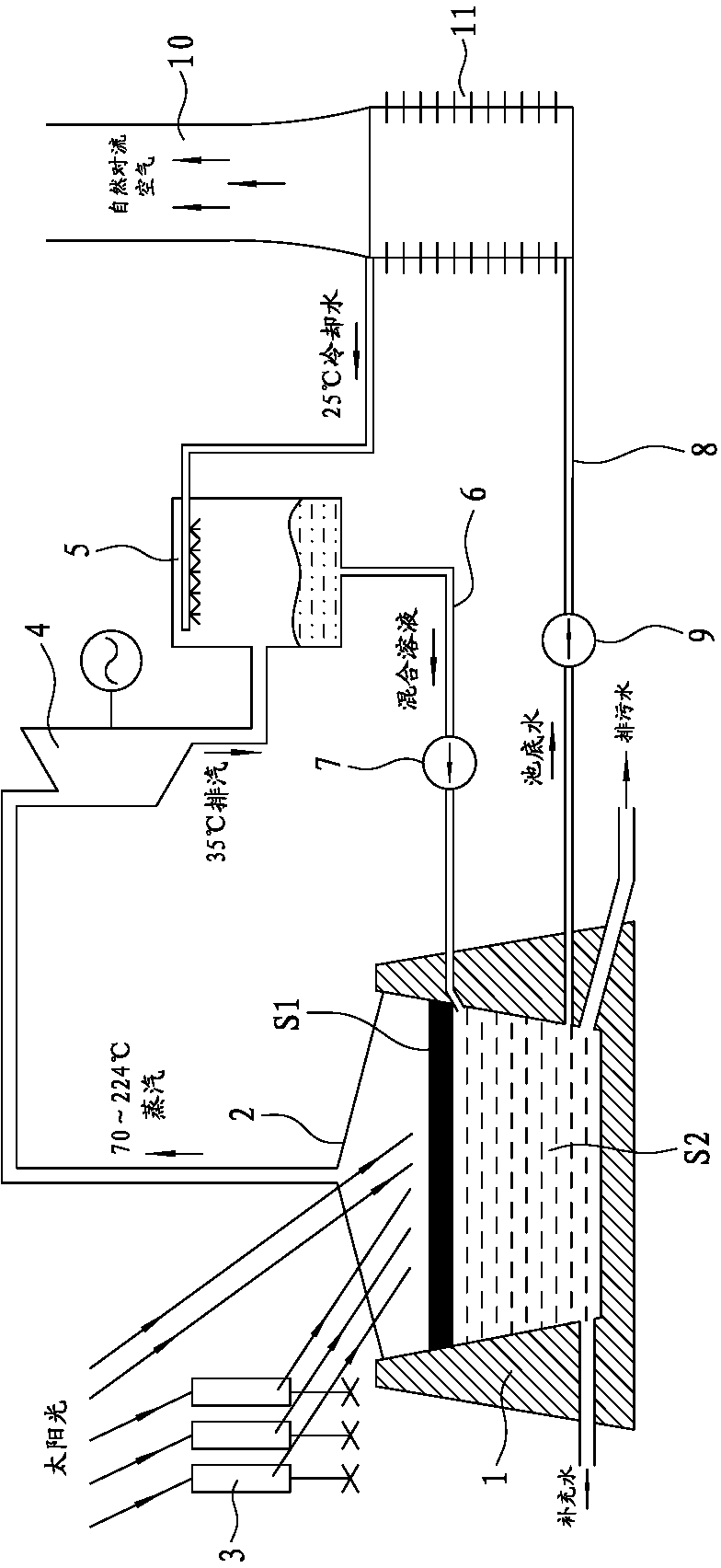

[0014] Such as figure 1 As shown, the present invention is a pool surface evaporation type solar thermal power generation system, which includes an evaporation pool 1, a light-transmitting ceiling 2, a mirror array 3, a turbogenerator set 4, a hybrid condenser 5, and a mixed solution pipeline 6 , Solution pump 7, cooling water pipeline 8, cooling water pump 9, cooling tower 10, air cooler 11.

[0015] The evaporation pool 1 is a natural freshwater lake or an artificial deep water pool added with a low-boiling point refrigerant, and its depth is between 20 and 200m; the liquid in the evaporation pool 1 is divided into upper and lower layers, and the upper layer is a low-boiling point refrigerant with a certain thickness. Layer S1, the lower layer is the freshwater layer S2. The thickness of the low-boiling point working fluid layer S1 is between 0.3 and 2m, and the low-boiling point organic working fluid is selected as a working medium that is insoluble or hardly soluble in wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com