Manufacturing method of heat pipe

A manufacturing method and heat pipe technology, applied in the field of heat pipe manufacturing, can solve the problem that the heat pipe cannot adapt to efficient heat dissipation work, etc., and achieve the effects of improving heat conduction efficiency, small flow resistance, and increasing heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

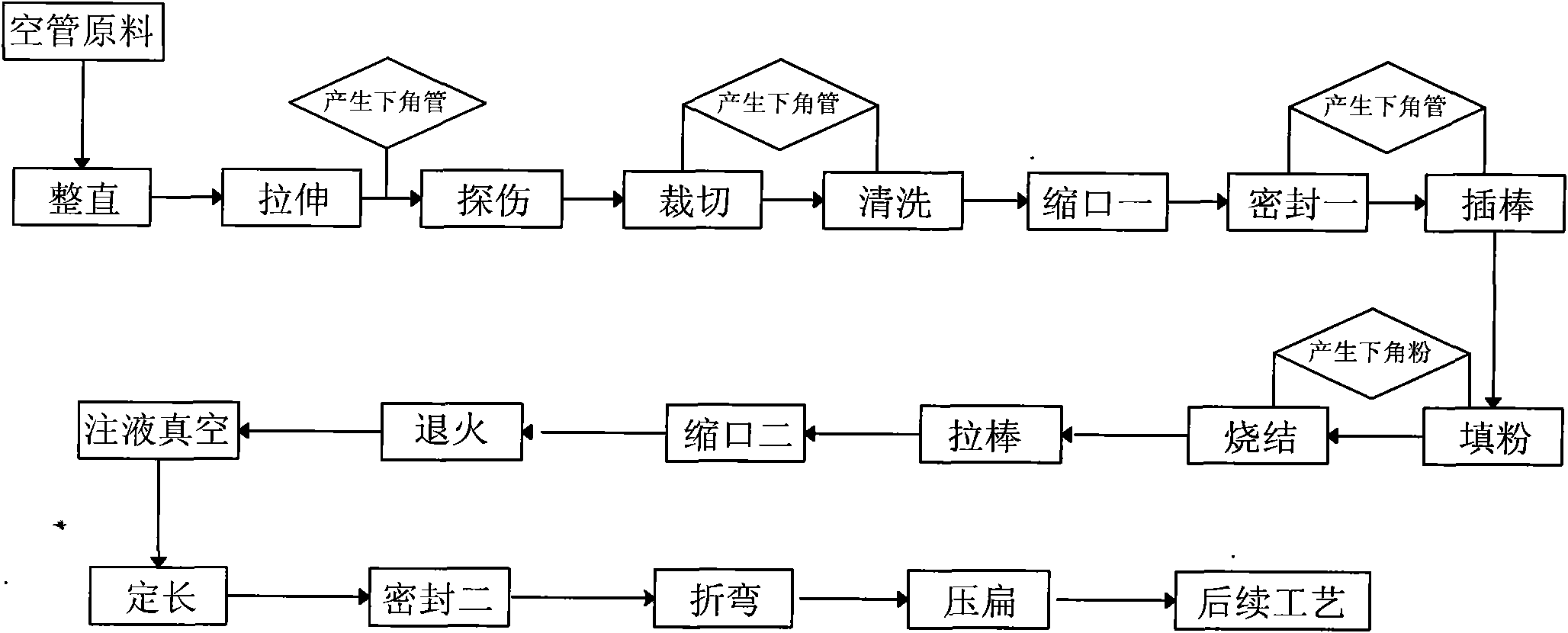

[0032] refer to figure 1 , a method for manufacturing a heat pipe provided by the present invention mainly consists of the following process steps:

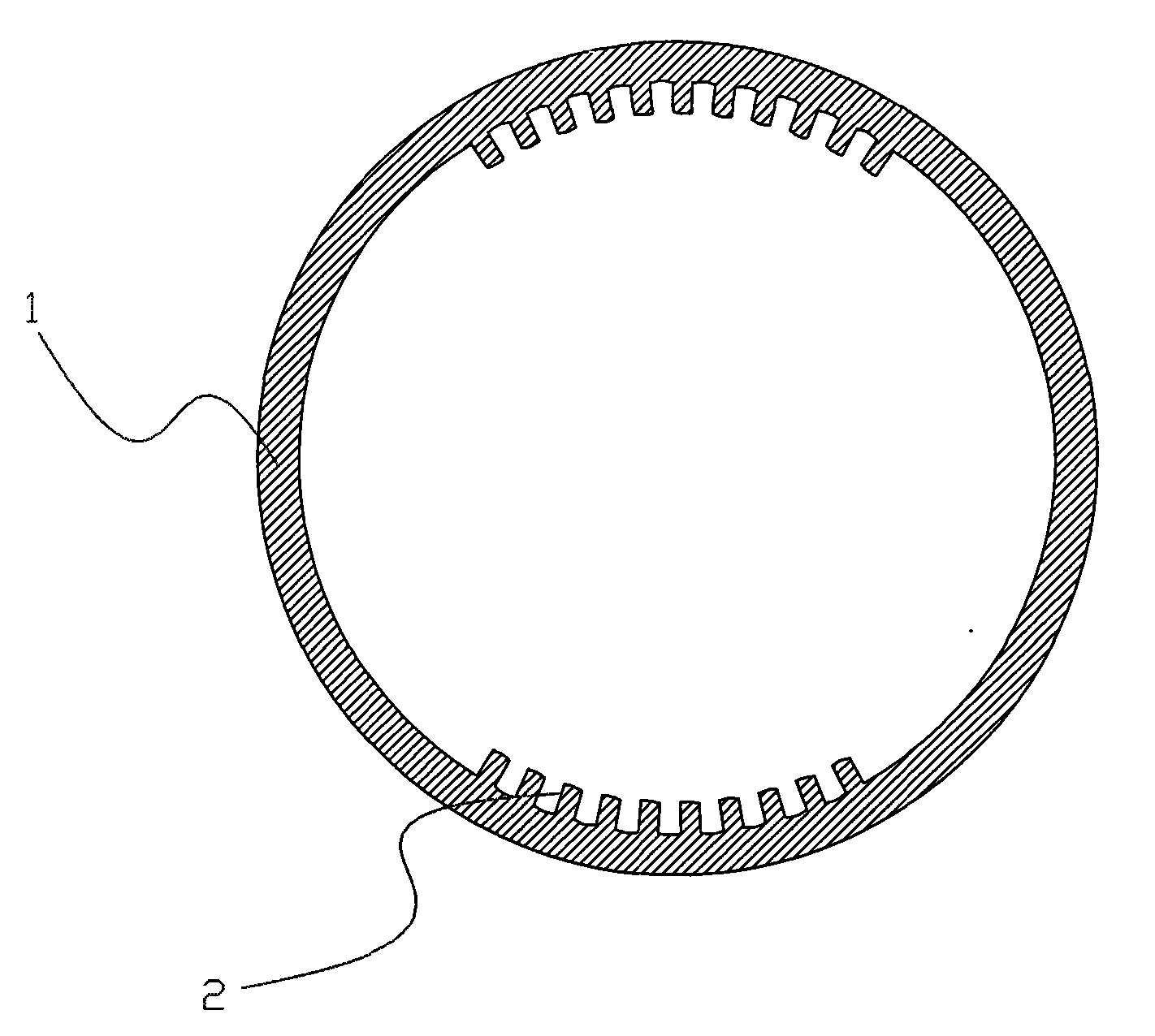

[0033] Step 1, prepare the raw material: prepare a kind of hollow tube raw material with two sets of symmetrical grooves along the axial direction of the inner wall, its structure is as follows figure 2 As shown, on the inner wall of the metal pipe body 1, there are two sets of grooves 2 at symmetrical positions, so that between the two grooves 2 is the smooth inner wall of the metal pipe body 1, and the grooves 2 are along the longitudinal direction of the pipe body 1. It is set and opened longitudinally on the pipe body 1, and its function is to circulate steam;

[0034] Step 2, cutting the empty pipe: cutting the empty pipe to a predetermined length;

[0035] Step 3, necking and sealing 1: shrinking the first end of the cut empty pipe and sealing the necking, preferably, the sealing method is spot welding;

[0036] Step 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com