High-load vertical ultradeep bioreactor

A bioreactor, high-load technology, applied in the direction of sustainable biological treatment, aerobic process treatment, etc., can solve problems such as poor degassing effect of carbon dioxide, increased difficulty in pipe network transformation, backflow of liquid in wells, etc., to reduce engineering investment and operating costs, low operating and maintenance costs, and reduced circulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

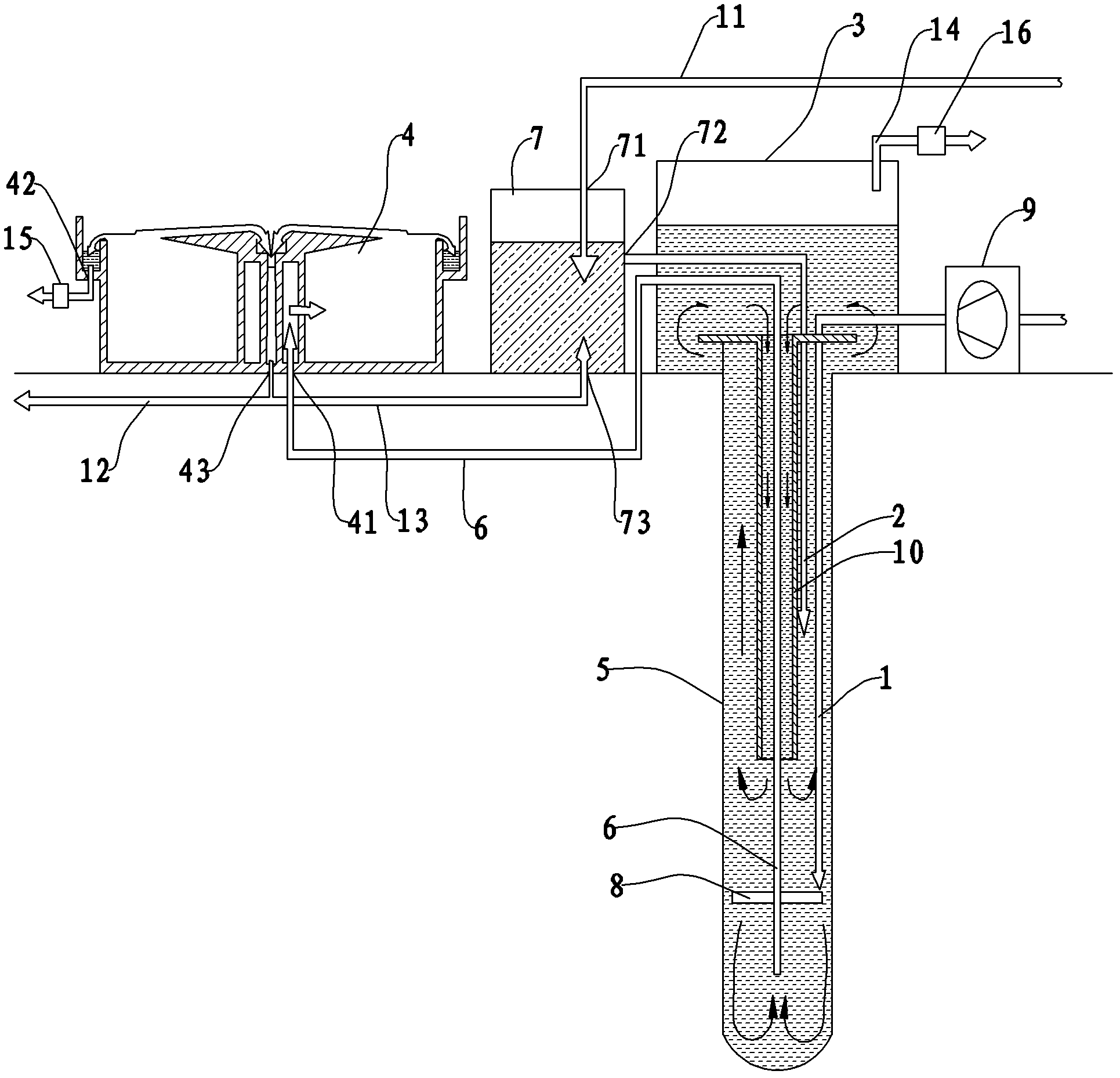

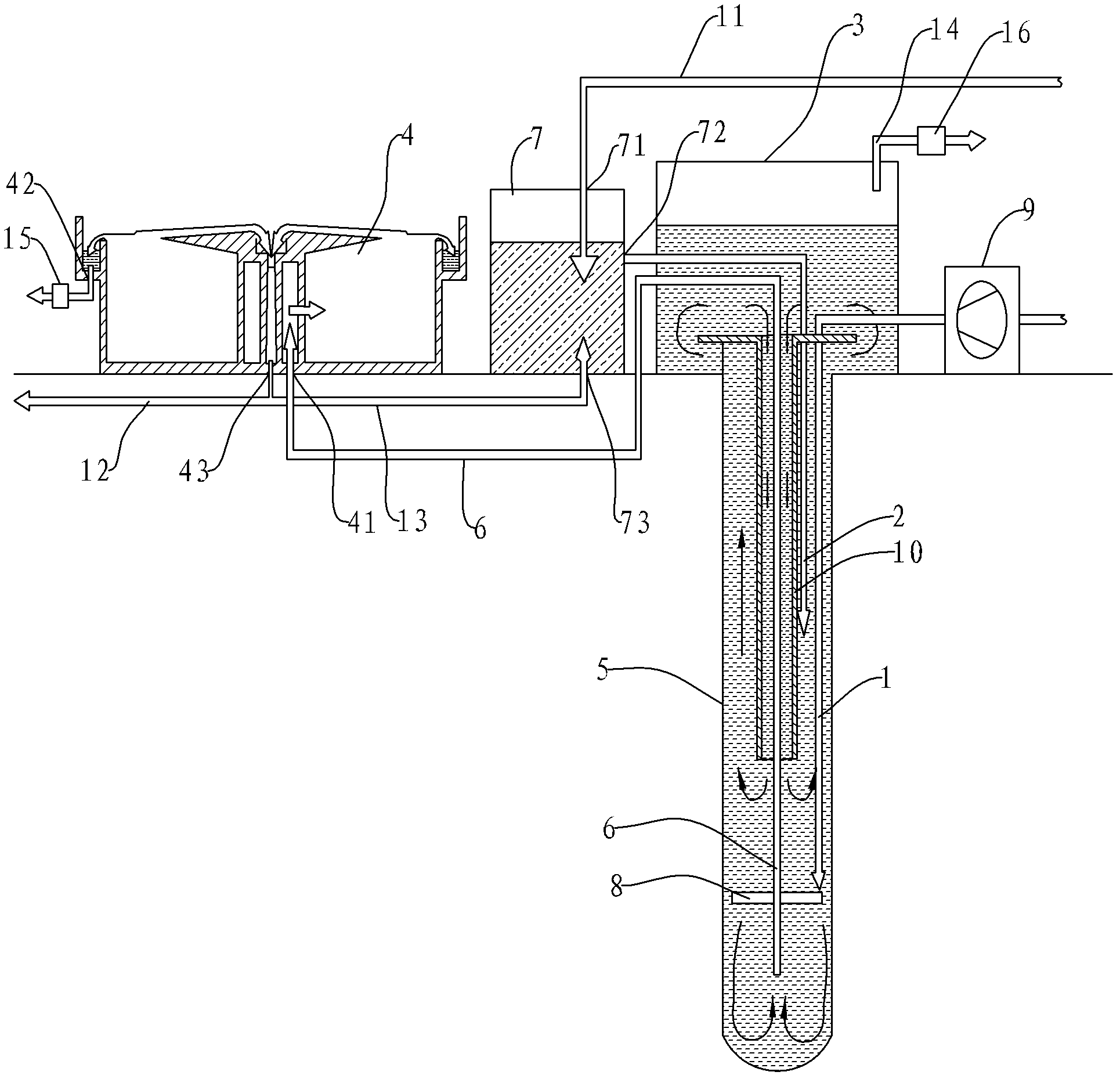

[0041] Such as figure 1 As shown, the high-load vertical ultra-deep bioreactor mainly includes a reactor body 5 , a head box 3 , a denitrification zone 7 , and a buoyancy purifier 4 .

[0042] The reactor main body 5 is made of leak-proof steel. The reactor main body 5 is provided with an aeration device 8 , a water inlet pipe 2 , an air supply pipe 1 , and a water outlet pipe 6 . The air inlet of the air supply pipe 1 is connected to an air compressor 9 .

[0043] The water outlet of the water inlet pipe 2 is located in the middle of the reactor body 5 in the axial direction; the air outlet of the air supply pipe 1 is lower than the water outlet of the water inlet pipe 2; the water inlet of the water outlet pipe 6 is located at the inner bottom of the reactor body 5 and is located The bottom of the device 8; in this way, it is beneficial to the further mixing of the incoming water and the air, and at the same time prevents the short flow of the outgoing water.

[0044] An in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com