Natural-circulation self-cleaning evaporation device

An evaporating device and natural circulation technology, applied in vertical tube evaporators, etc., can solve problems such as ineffectiveness, no evaporators, and weak automatic cleaning of hard dirt, and achieve simple structure, easy operation, and reliable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

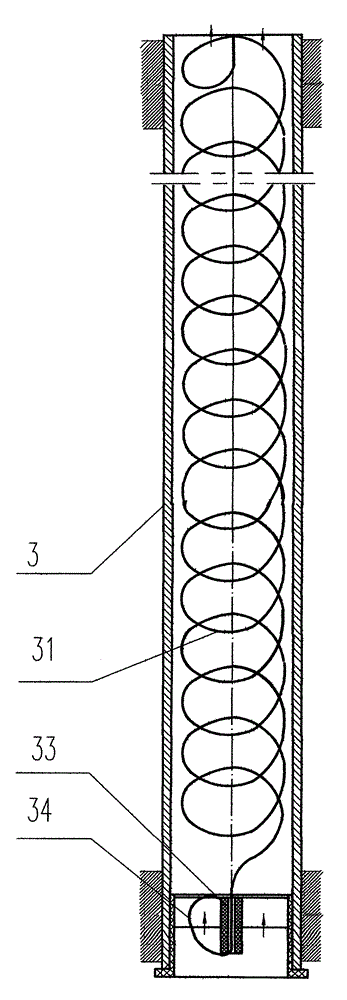

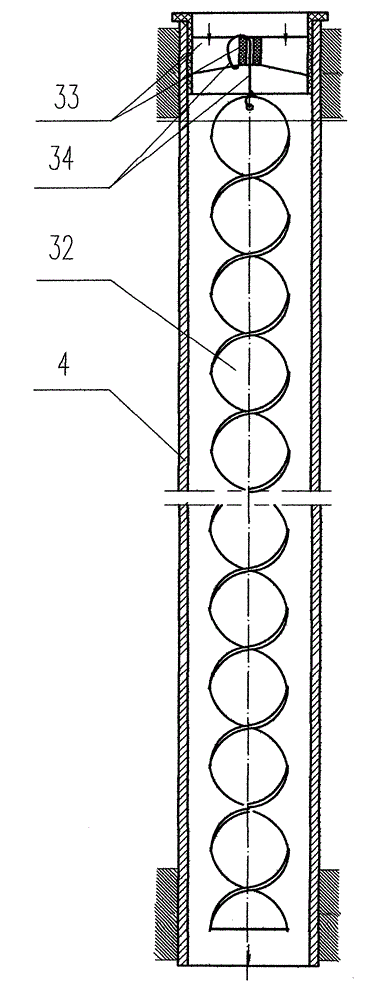

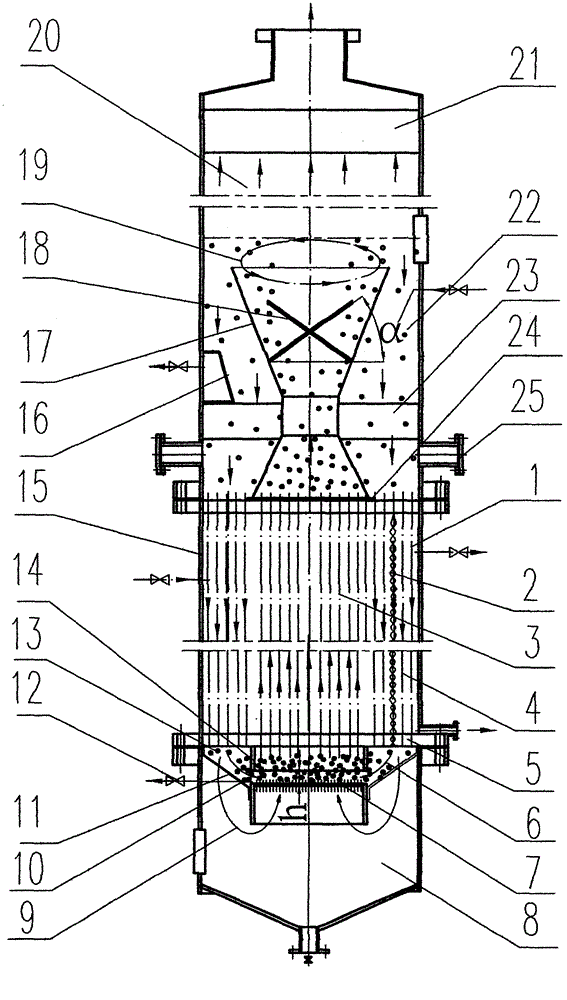

[0014] Attached below figure 1 , figure 2 , image 3 , Figure 4 , the present invention is described in further detail.

[0015] In the figure, 1 heating pipe 2 spiral 3 ascending heating pipe 4 descending heating pipe 5 lower pipe plate 6 circulation main flow 7 sieve plate 8 bottom groove 9 circulation auxiliary flow 10 main circulation channel 11 screen 12 ball release pipe 13 fluidization ball 14 shunt flow Skirt 15 Heating chamber 16 Exit shield 17 Boiling tube 18 Swirling inclined plate 19 Top circulation 20 Evaporation chamber 21 Demister 22 Circulating channel 23 Inclined guide plate 24 Ring gasket 25 Hand hole 26 Load-bearing rib plate 27 Circulating cylinder 28 jet hole 29 air cover 30 air supply pipe 31 steel wire spiral 32 twisted belt spiral 33 nozzle frame 34 spiral fixed steel wire

[0016] A natural circulation self-cleaning evaporation device, the main components are evaporation chamber 20, heating chamber 15, heating pipe 1, spiral 2, diverting skirt 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com