High-efficiency heat exchange fire grate of heat-conducting oil furnace

A technology of heat-conducting oil furnace and heat-exchanging furnace, which is applied to the grate, heat-storage heater and grate of hollow grate bars, can solve the problems of increased power of circulating pump motor, accelerated shedding speed, low heat-conducting efficiency, etc. The effect of reducing circulation resistance, cost, and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

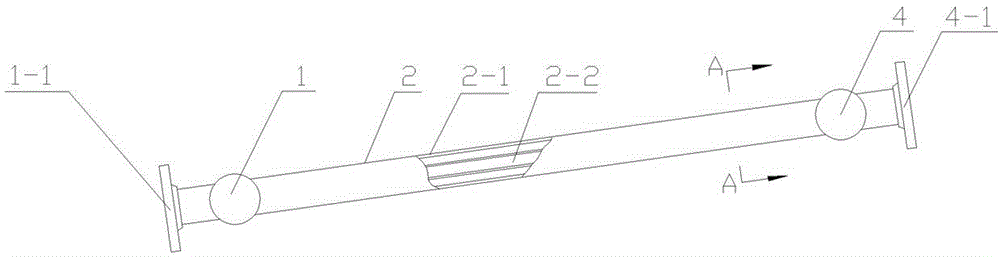

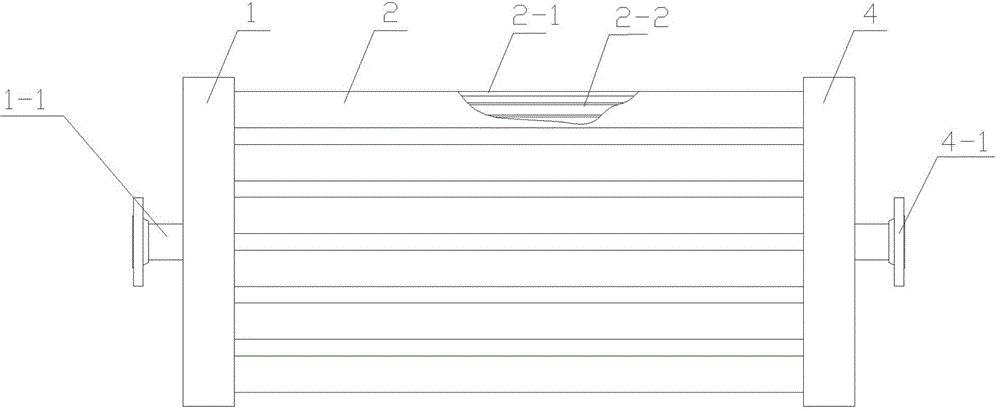

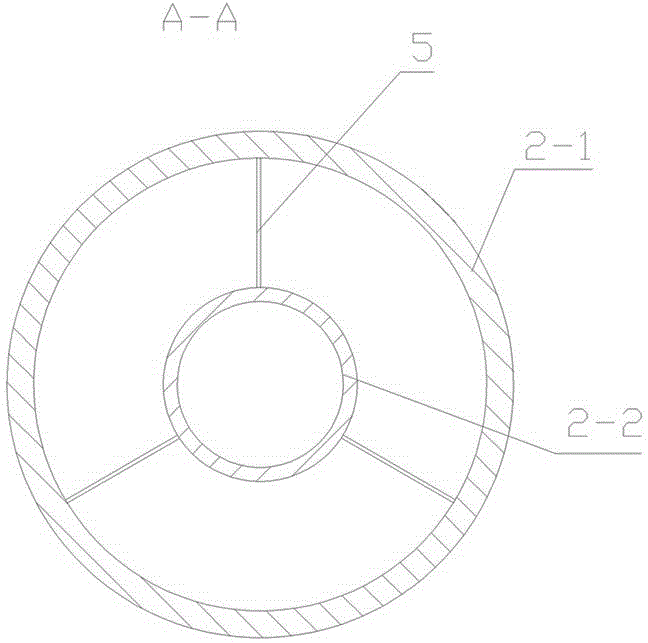

[0015] see Figure 1~Figure 3 , the present invention is used for fire grate for hand-fired coal-fired heat-conducting oil furnace, and its structure includes and connects the heat exchange tube 2 formed between the lower penetrating horizontal tube 1 and the upper penetrating horizontal tube 4 to form a grate shape, and the oil inlet 1- 1. The oil outlets 4-1 are respectively arranged on the lower through-through horizontal tube 1 and the upper through-through horizontal tube 4. The heat exchange tube 2 is a composite sleeve structure, and the inner sleeve 2-2 is a blind tube with one end closed. The terminal support 5 is positioned on the inner wall of the outer casing 2-1. This embodiment adds a blind pipe with one end closed on the basis of the existing heat exchange tube. Since the heat transfer oil in the blind pipe does not affect the circulation of the heat transfer oil in the outer casing 2-1, it is equivalent to reducing the liquid flow of the heat transfer oil. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com