High-gradient internal circulation oil cooling iron remover

An internal circulation and iron remover technology, applied in high gradient magnetic separators, high gradient magnetic separations, open gradient separators, etc., can solve the problems of difficult layout, many oil circuit design bends, etc., to simplify the circulation pipeline , The oil circuit circulation is uniform and reasonable, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, and the following is only illustrated as an example, and those skilled in the art clearly know that as long as the methods and systems consistent with the ideas of the present invention all fall into the present invention; in addition, they should not The protection scope of the present invention is only limited to the following specific structures or components or specific parameters.

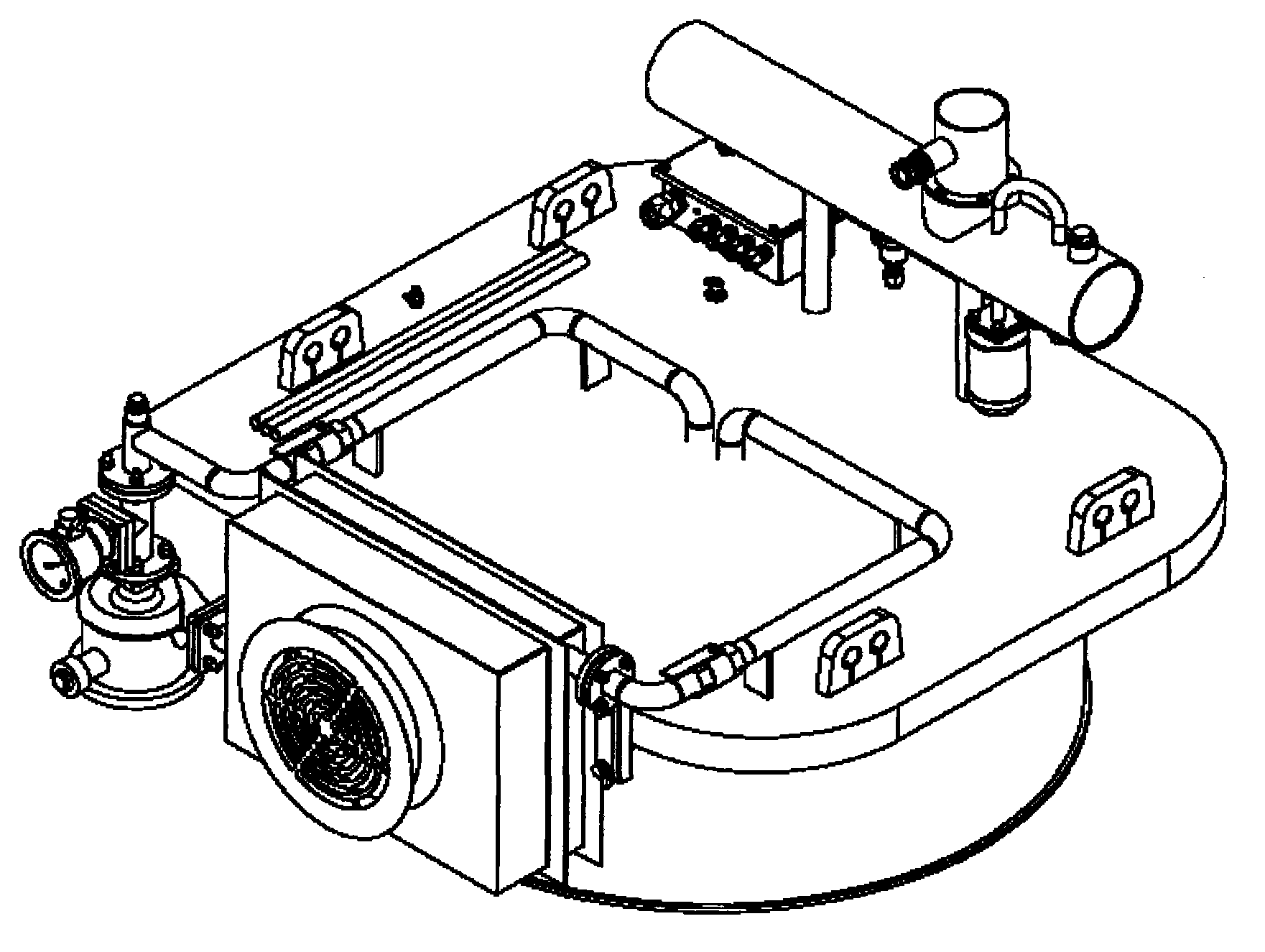

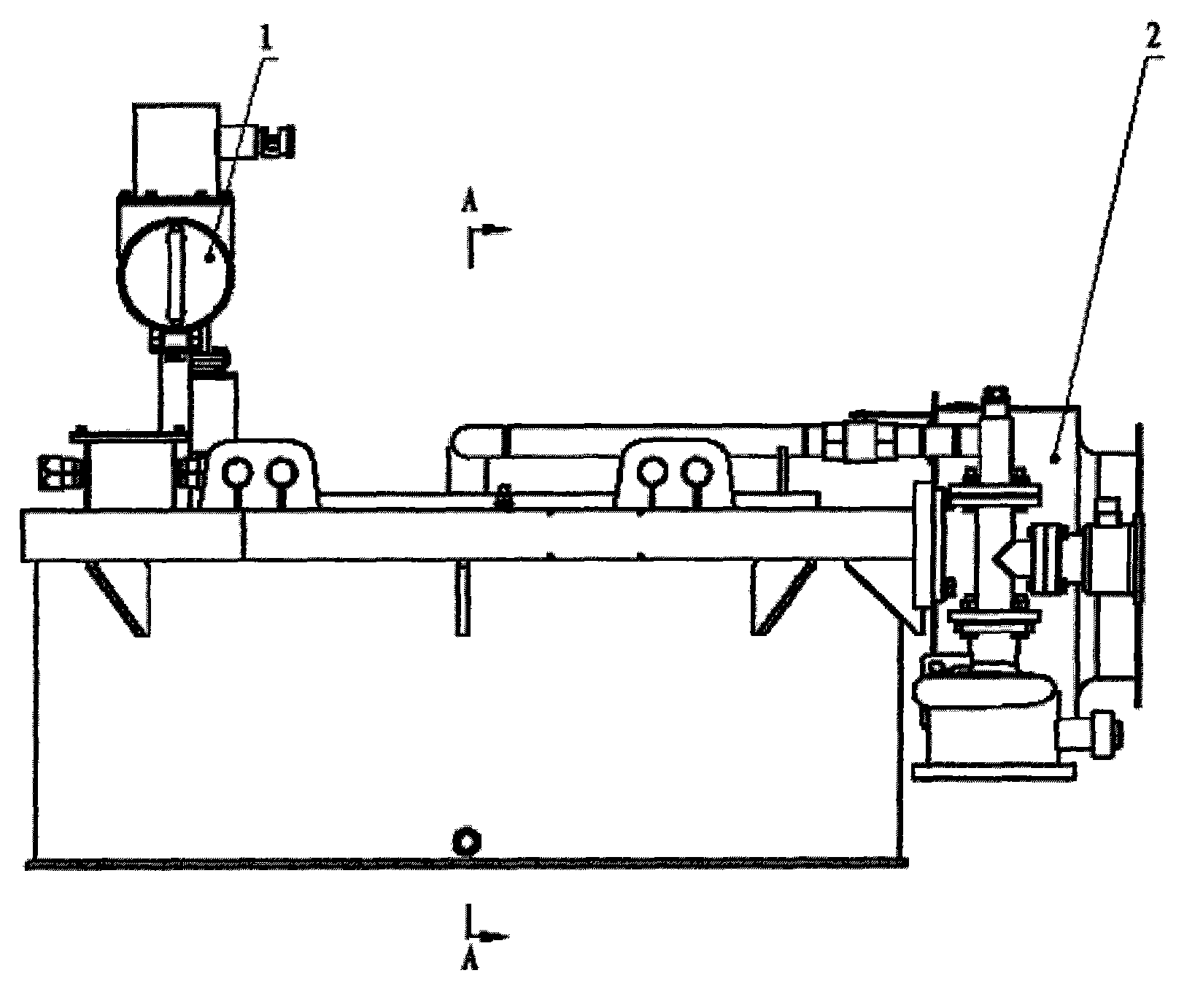

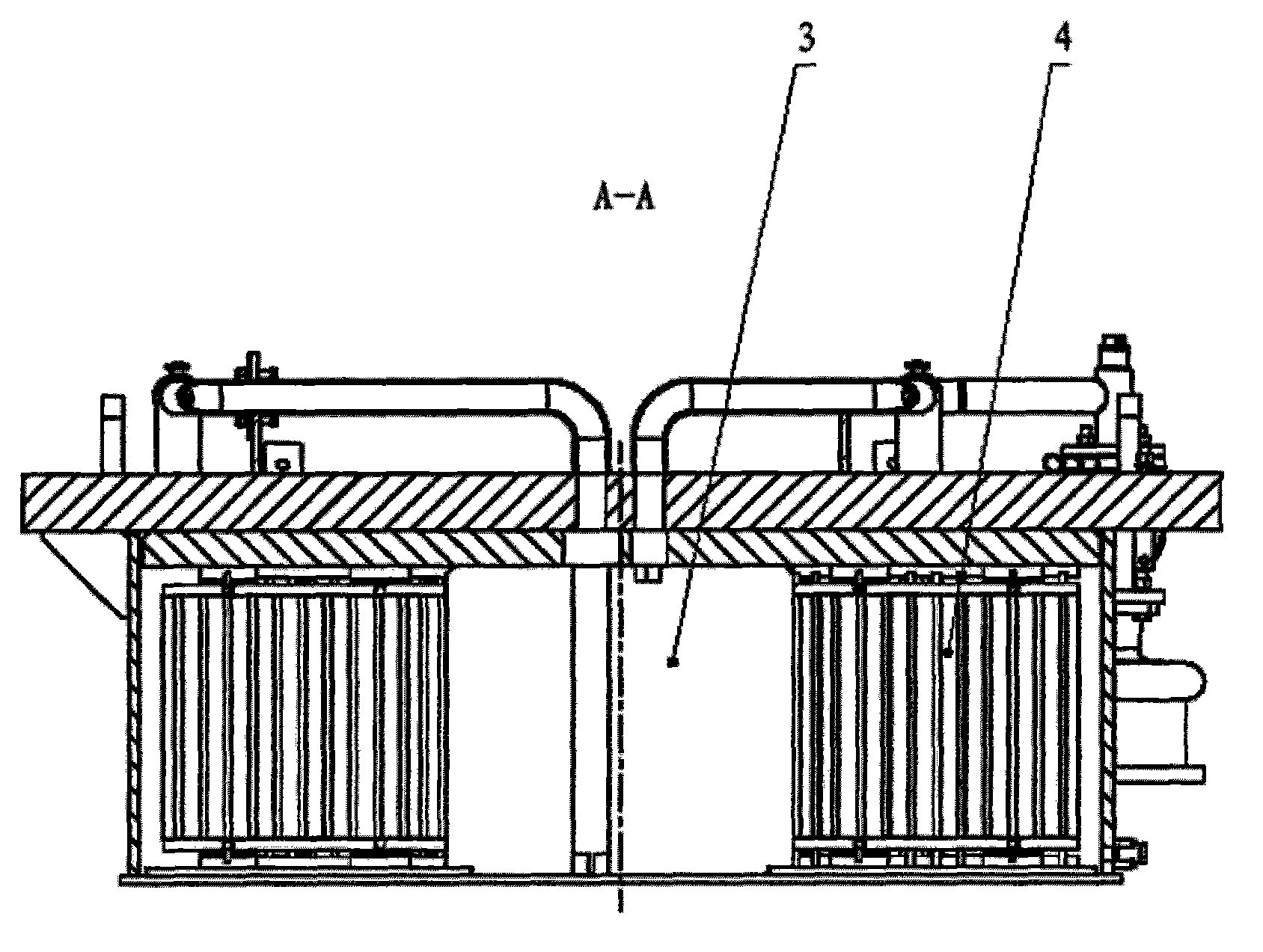

[0030] In the present invention, the core body of the high-gradient internal circulation oil-cooled iron remover is a magnetic system, and the high-gradient internal circulation oil-cooled iron remover can be divided into a magnetic system coil 4, an internal circulation oil circuit system 3, an external cooling system 2, and an oil conservator 1 and other four functional modules. Among them, the magnetic system coil 4 is used to generate excitation to realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com