Integration hydrodynamic force transportation and distribution system

A fluid power and fluid technology, which is applied in the field of new energy-related technical equipment, can solve problems such as operation and maintenance, large amount of manual operation, unsuitable intelligence, energy-saving operation, complex composition of fluid transmission and distribution systems, etc., to ensure energy-saving and efficient operation, The effect of shortening the construction period and reducing the lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

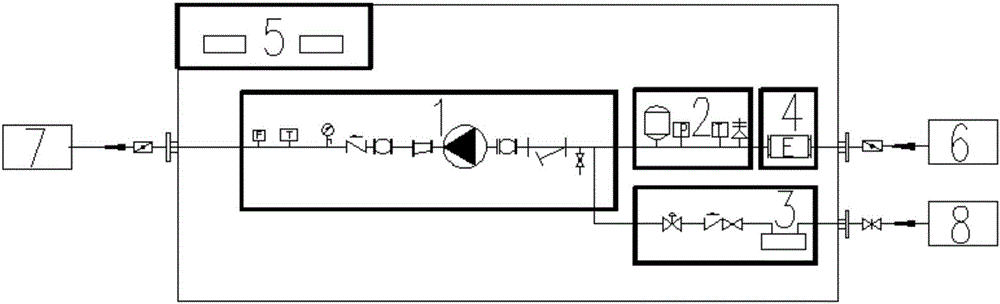

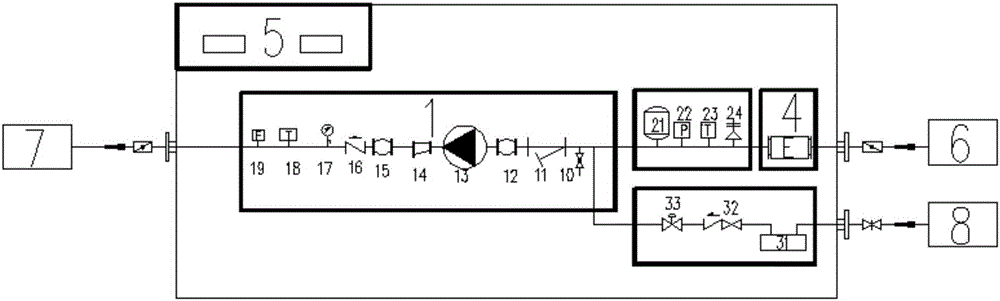

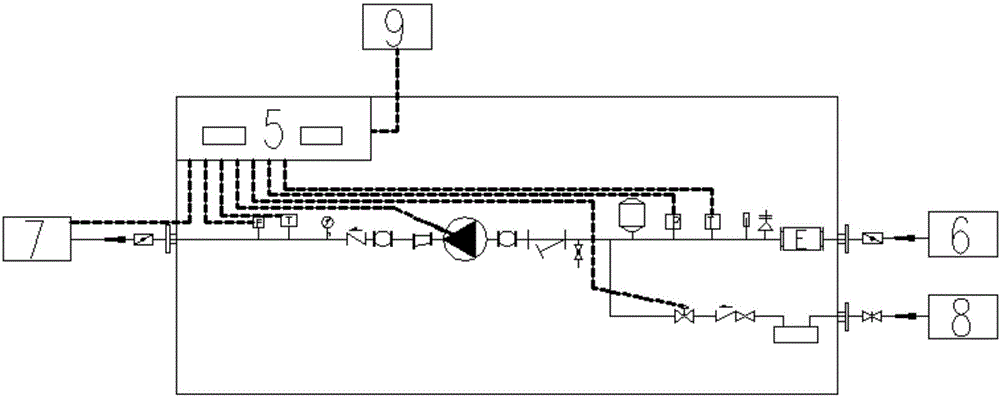

[0037] Embodiment: an integrated fluid power distribution system, such as Figure 1-3 As shown, it includes a cycle power module 1, a constant pressure module 2, a water treatment and replenishment module 3, a scale removal module 4, and a power distribution control and communication module 5.

[0038] The circulating power module 1 has drain valve 10, filter 11, water pump inlet flexible joint 12, circulating water pump 13, water pump outlet reducing diameter 14, outlet flexible joint 15, check valve 16, pressure gauge 17, circulating water temperature Sensor 18 and water flow switch 19.

[0039] The constant pressure module 2 includes a constant pressure tank 21 , a pressure sensor 22 , a constant pressure water temperature sensor 23 and a safety valve 24 connected in sequence.

[0040] The water treatment and replenishment module 3 includes a softening water device 31 , a check valve 32 and an automatic replenishment valve 33 ; the tap water source 8 is softened and enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com