An upper bearing component and a guide rail system

A kind of rail system, the technology of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand the technical ideas claimed in the present invention more clearly.

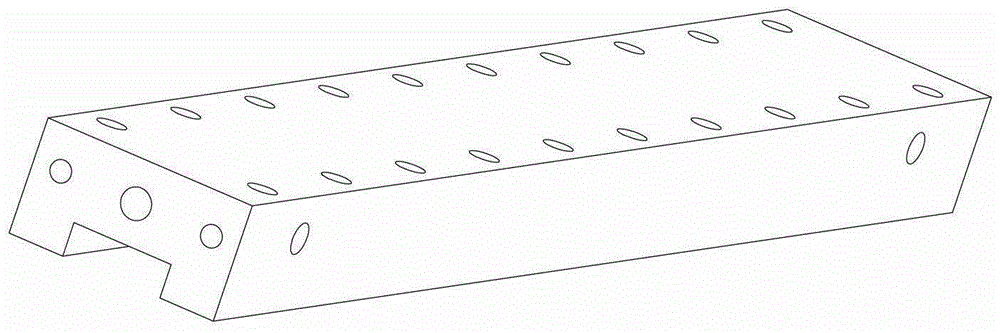

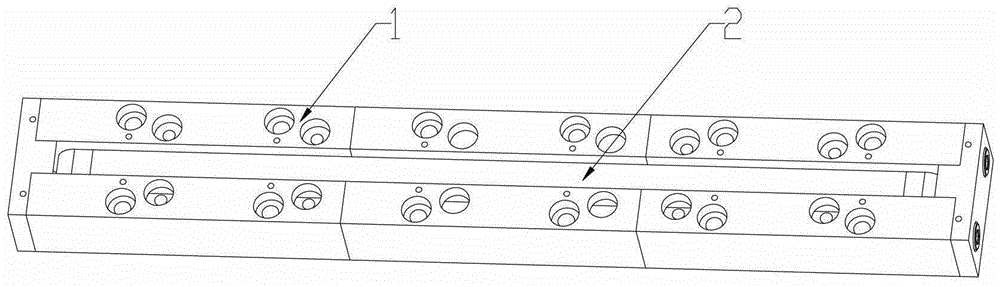

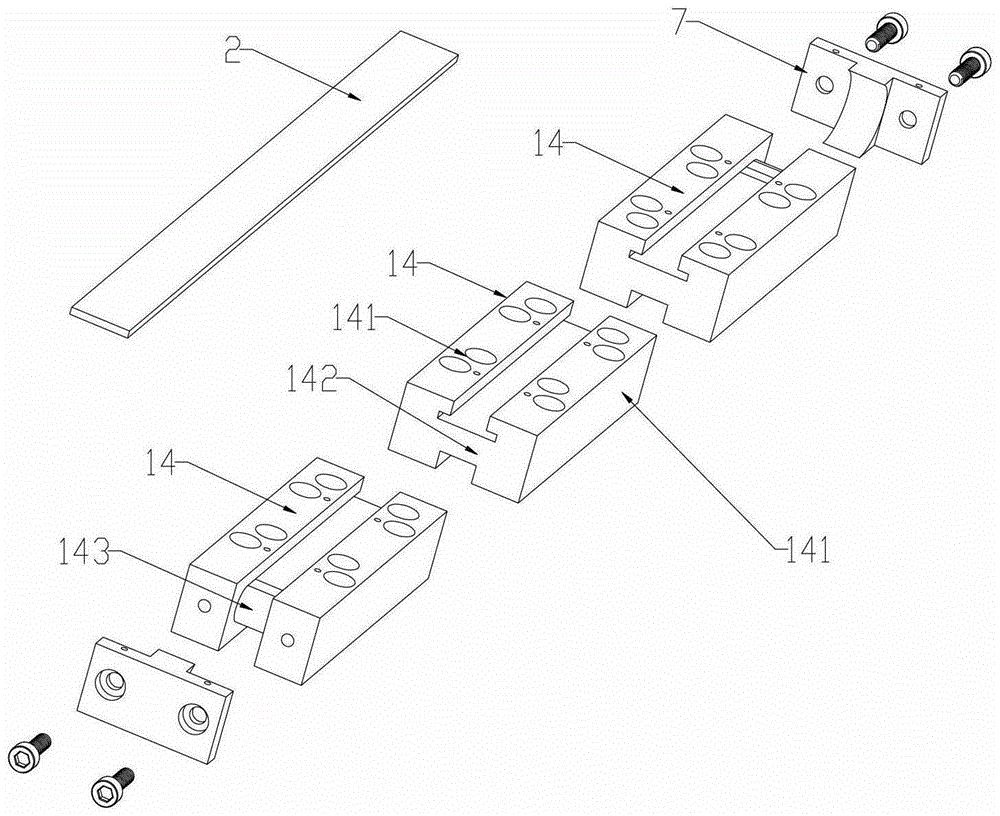

[0030] like figure 2 , 3 , 4 shows an upper bearing assembly of the present invention, comprising an upper bearing substrate 1, a panel 2 fixed on the upper bearing substrate 1 and extending along its length direction. In the present invention, the sliding direction of the upper carrier substrate 1 relative to the lower carrier part is defined as the longitudinal direction of the upper carrier substrate 1 . The outer surface of the panel 2 is a contact surface for contacting the rolling surface of the rolling body 5; the hardness of the panel 2 is greater than or equal to 65HRC. Preferably, the hardness of the panel 2 is 65-85HRC, and the cross section of the panel 2 is rectangular. Wherein, the upper bearing base plate 1 can be made of bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com