Gas stove equipped with anti-dry device

A technology for preventing dry burning and gas stoves, which is applied to burner safety devices, burners, burners, etc., can solve problems such as increased failure points and increased costs, and achieves the effects of reliable work, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

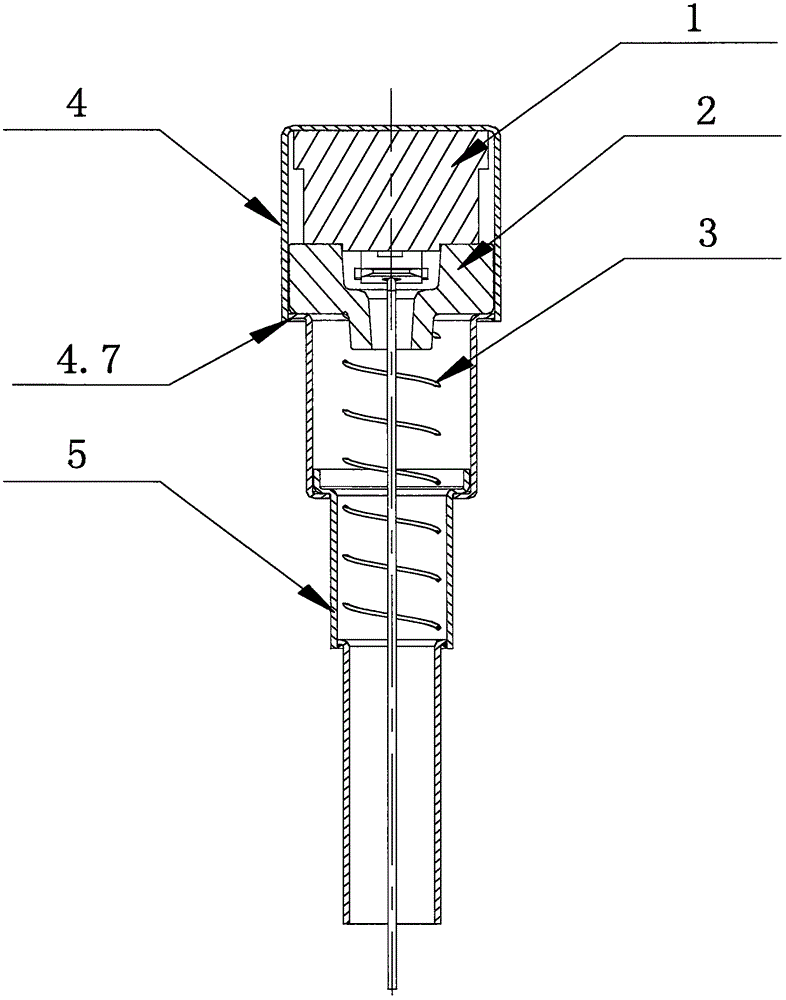

[0026] Such as Figure 1~5 As shown, the specific implementation of the present embodiment is as follows:

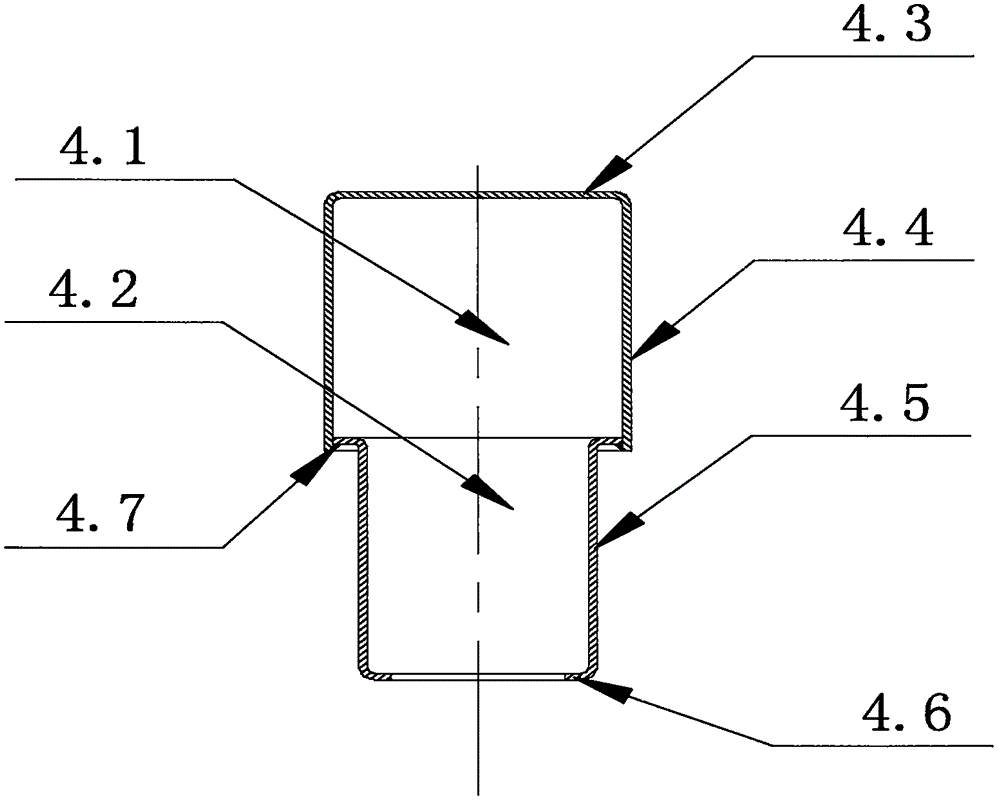

[0027] A gas stove equipped with a dry-burning prevention device is composed of a dry-burning prevention device and a gas stove with a flameout protection device. The dry-burning prevention device is placed at the center of the burner of the gas stove and fixed on the gas stove. The anti-dry device includes a thermostat 1, a thermostat insulating base 2, a spring 3, an anti-dry probe body 4 and an anti-dry probe base 5; the thermostat is a bimetal thermostat, and the thermostat is connected in series Between the induction probe of the gas stove flameout protection device and the gas solenoid valve, the induction probe of the gas stove flameout protection device is matched with the flameout protection device, or a thermocouple, or an ion induction needle.

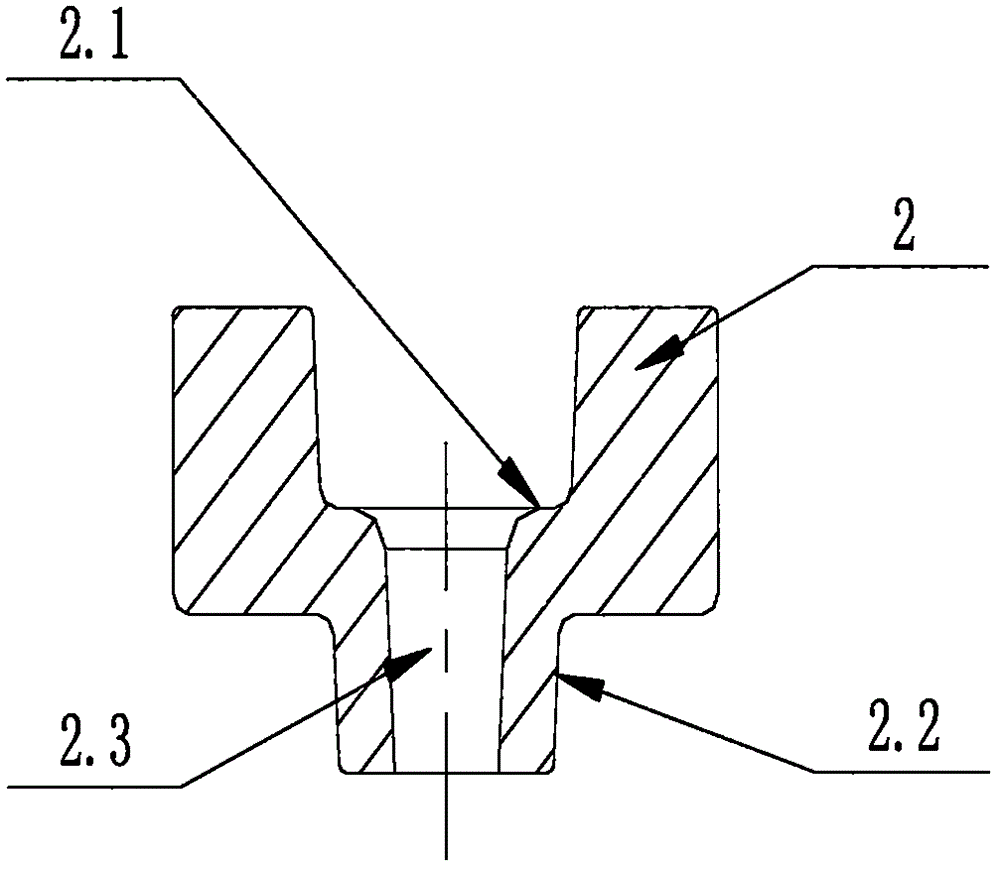

[0028] The insulating base of the thermostat is columnar, with a temperature sensor installation groove 2.1 on the ...

Embodiment 2

[0032] Such as Figure 6 As shown, the only difference between this embodiment and Embodiment 1 is that the top cover of the anti-dry probe body is an independent structure, the upper shell of the probe is integrated with the lower shell of the probe, and the top cover is connected with the upper shell of the probe. The riveting structure 4.8a is used to seal the thermostat and the insulating base of the thermostat in the main body of the anti-dry probe.

[0033] Such as Figure 7 As shown, in this embodiment, the welding structure 4.8 can also be used at the joint between the top cover and the upper shell of the probe.

[0034] In the above-mentioned embodiments, the spring installation cavity on the upper part of the anti-dry probe base and the temperature controller wire protection tube on the lower part can be a welded structure or an integrated structure; the welding structure involved on the anti-dry probe body or The riveting structure is all carried out after the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com