A telescopic lifting beam used for monorail locomotive in coal mine

A monorail crane and telescopic technology, which is applied in the direction of traveling mechanism, load block, load hanging components, etc., to achieve the effect of increasing the guiding length, reducing the amount of expansion and contraction, and the force situation is safe and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

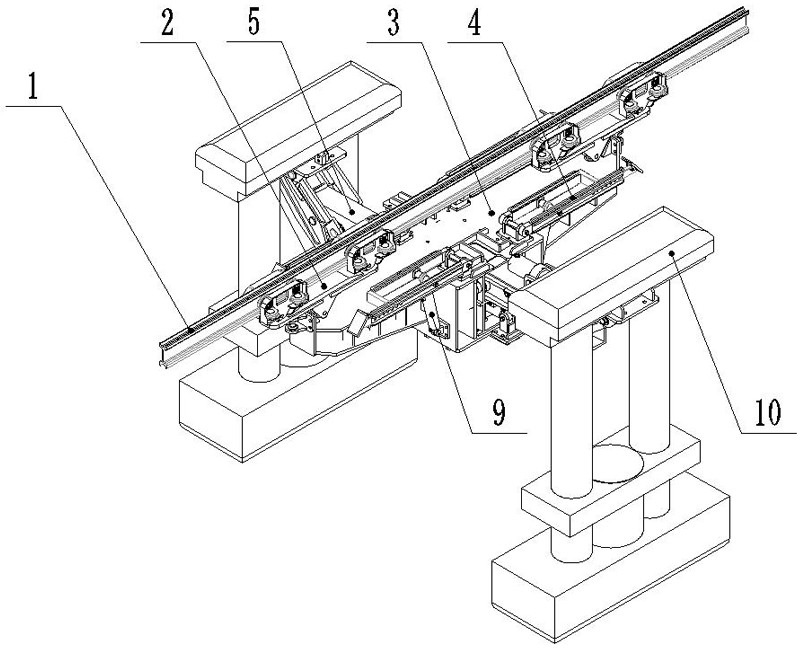

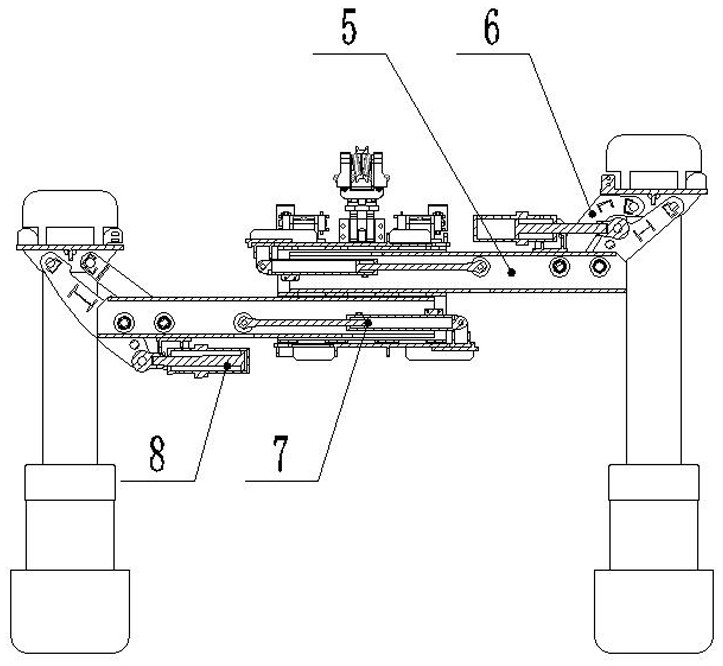

[0030] like figure 1 and figure 2 The shown telescopic hoisting beam for a coal mine monorail crane includes a load-bearing beam 3, a load-bearing trolley 2 and a telescopic arm 5. The load-bearing trolleys 2 are respectively provided above the ends of the load-bearing beam 3, and the load-bearing trolleys 2 and The monorail 1 is matched, and the load-bearing beam 3 is hoisted on the monorail 1 by the carrying trolley 2 and reciprocates along the monorail 1, and is characterized in that:

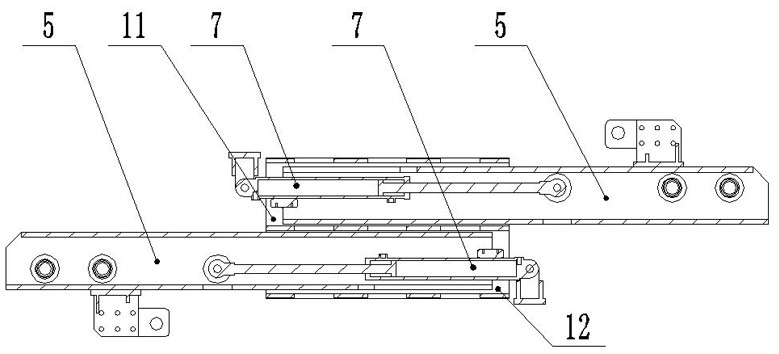

[0031] like image 3 As shown, upper chute 11 and lower chute 12 are respectively set in the middle of the load-bearing beam 3 along the height direction. The upper chute 11 and the lower chute 12 are both set to open on one side, the opening ends of the upper chute 11 and the lower chute 12 are in opposite directions, and the telescopic arms 5 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com