Patents

Literature

30results about How to "Little impact on altitude" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Equipment positioning method and system in visible light communication

InactiveCN110554356ALittle impact on altitudeHigh positioning accuracyImage enhancementTelevision system detailsImage resolutionVisible light communication

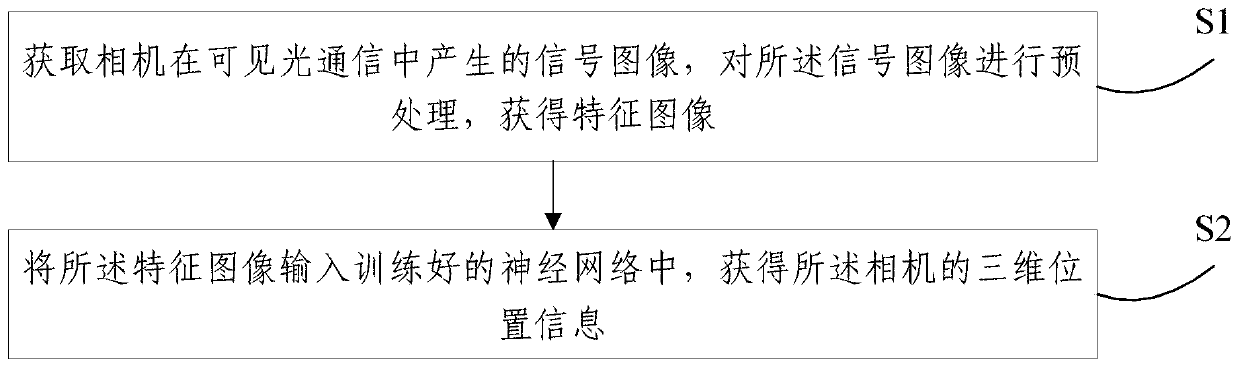

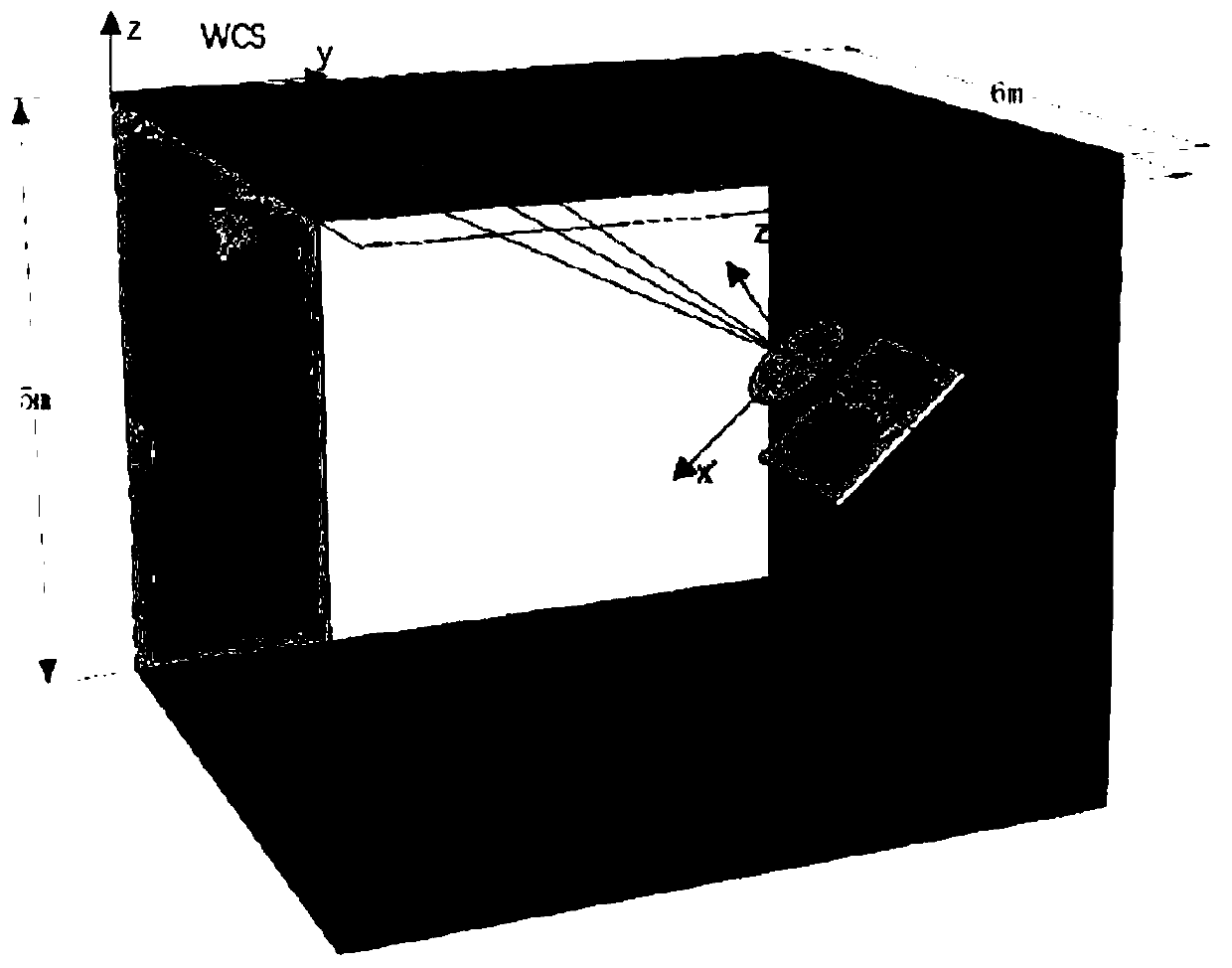

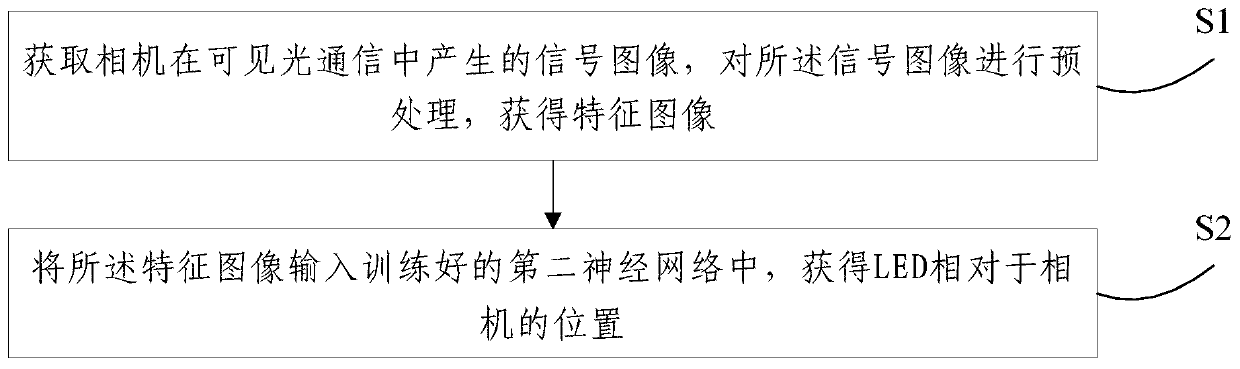

The embodiment of the invention provides equipment positioning method and system in visible light communication, wherein the method comprises the steps: obtaining a signal image generated by a camerain the visible light communication, carrying out the preprocessing of the signal image, and obtaining a feature image; inputting the feature image into a trained neural network to obtain three-dimensional position information of the camera, wherein the three-dimensional position information of the camera comprises, but is not limited to, one or a combination of camera position information and a camera inclination angle. According to the method and the system provided by the embodiment of the invention, the trained neural network is adopted to position the camera in the visible light communication system, and compared with a traditional geometric method, higher positioning precision can be realized under the same resolution, and meanwhile, the influence by the height of the camera is relatively small.

Owner:TSINGHUA UNIV

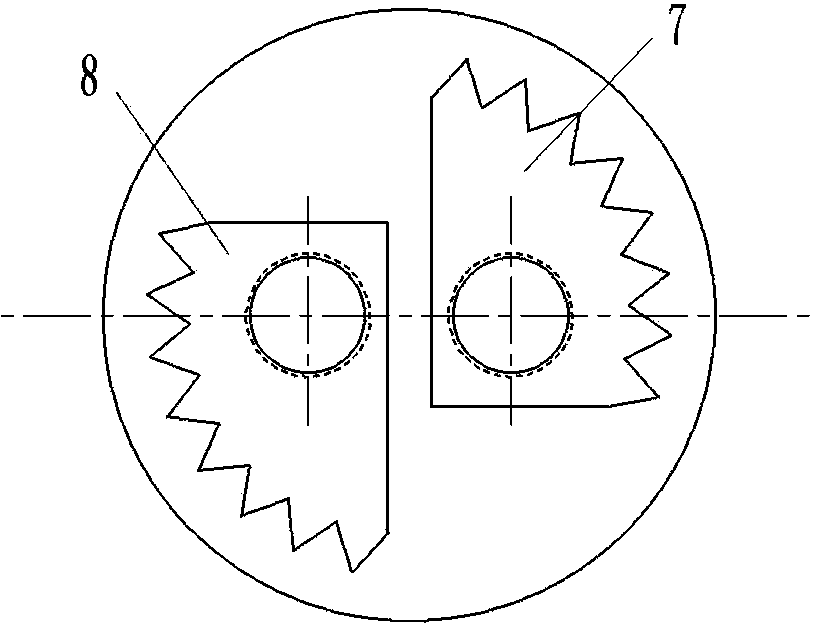

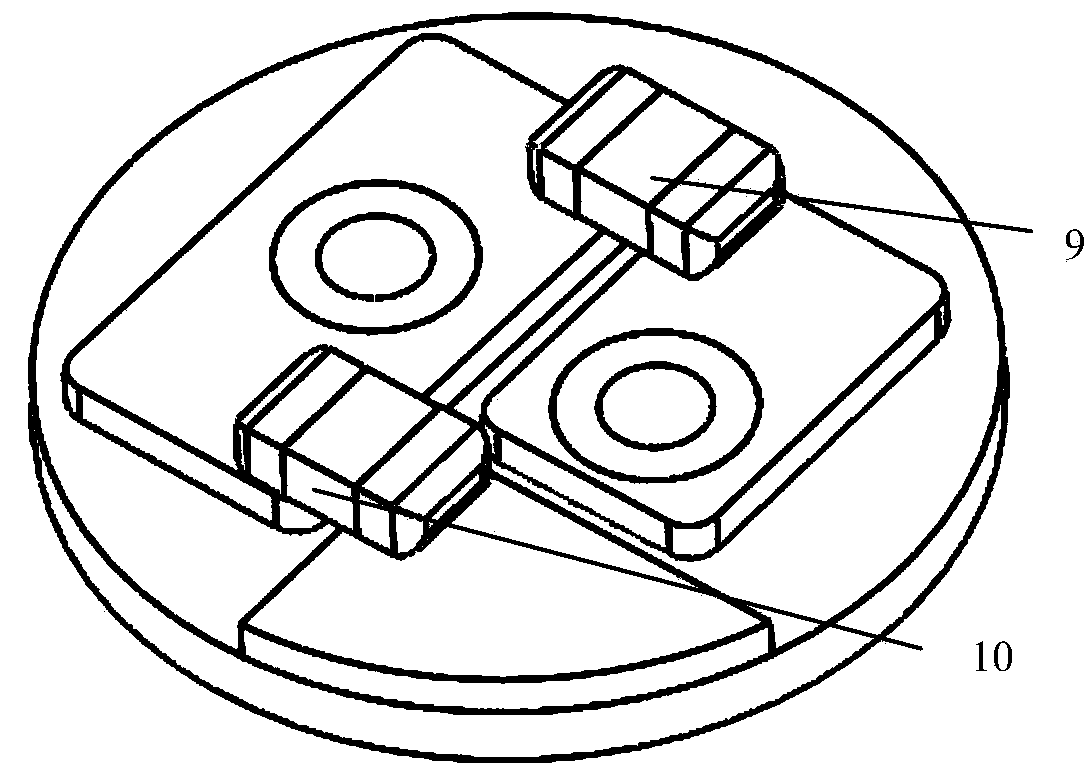

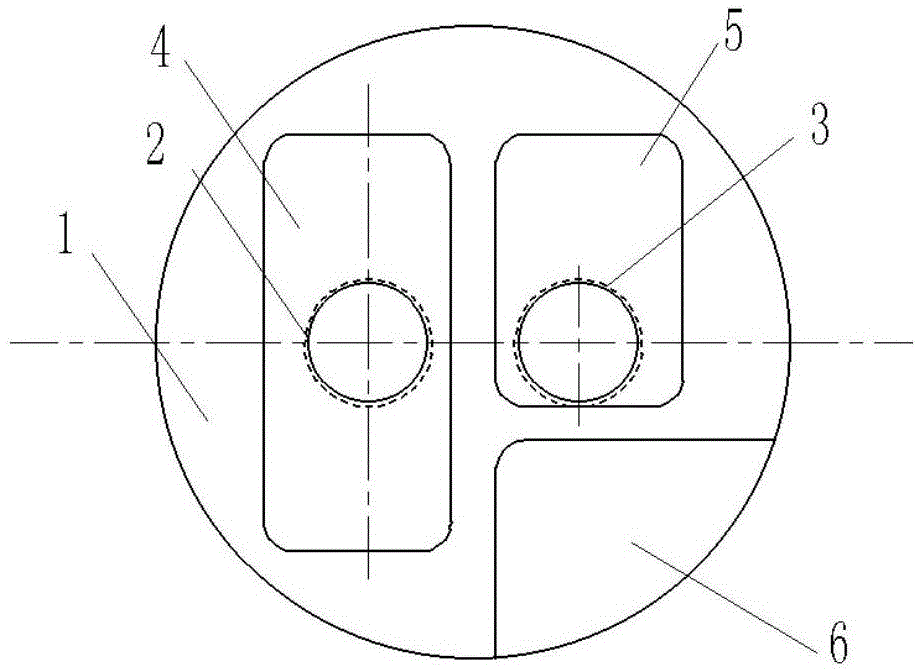

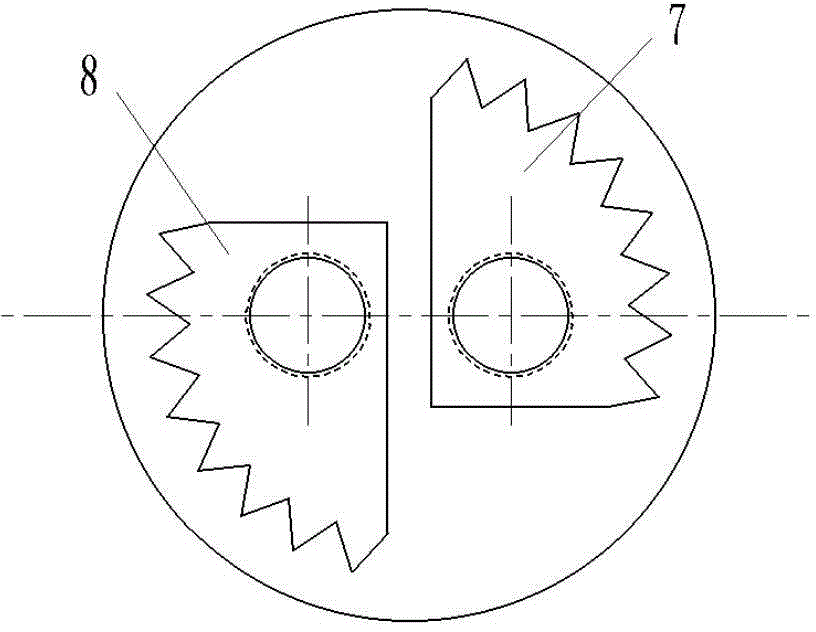

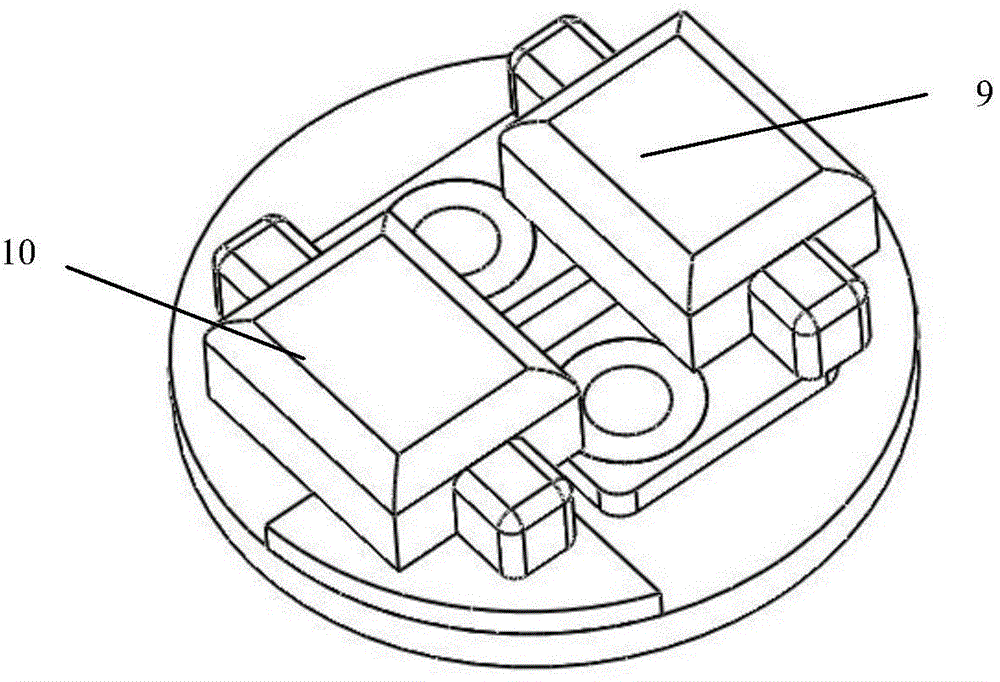

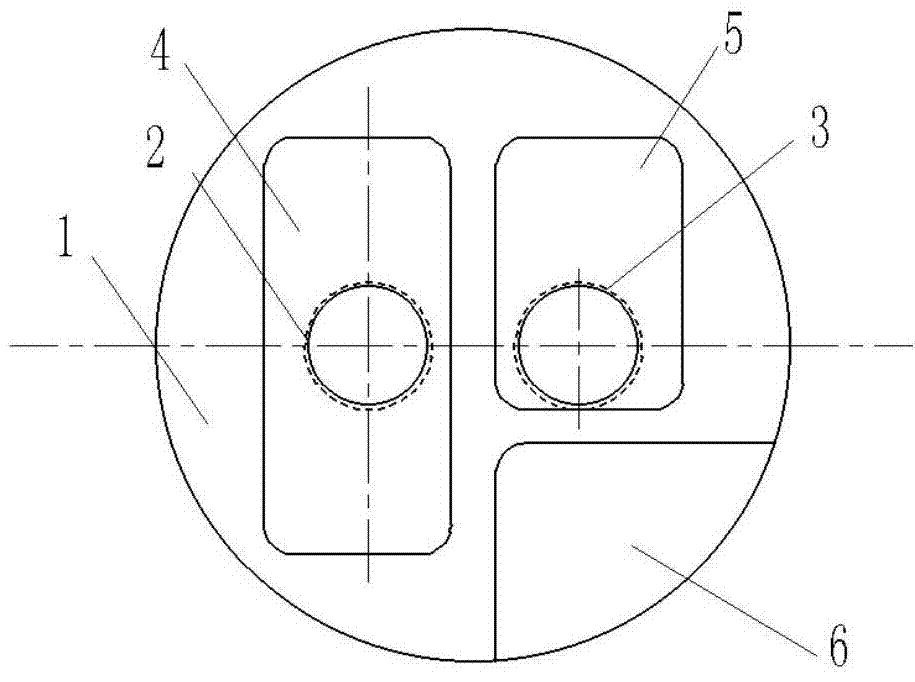

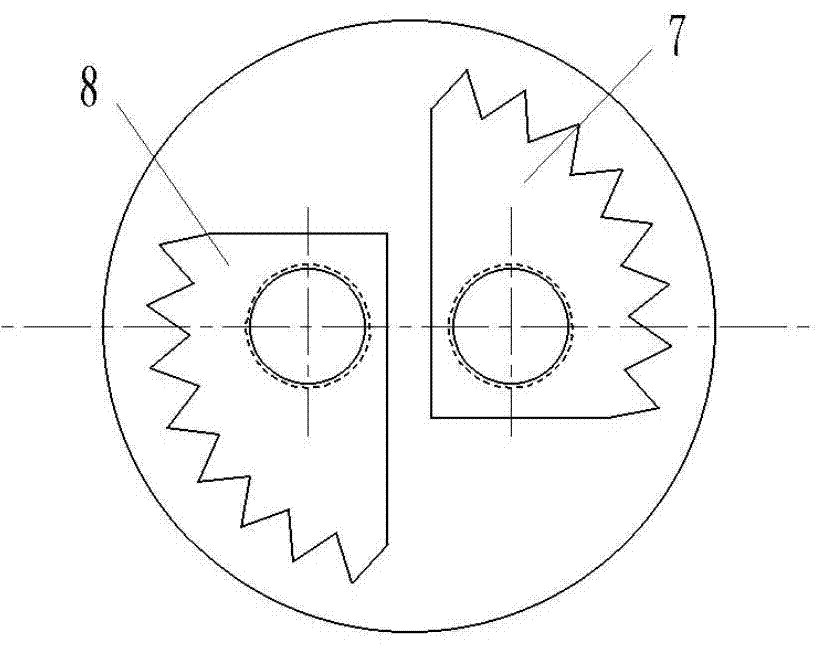

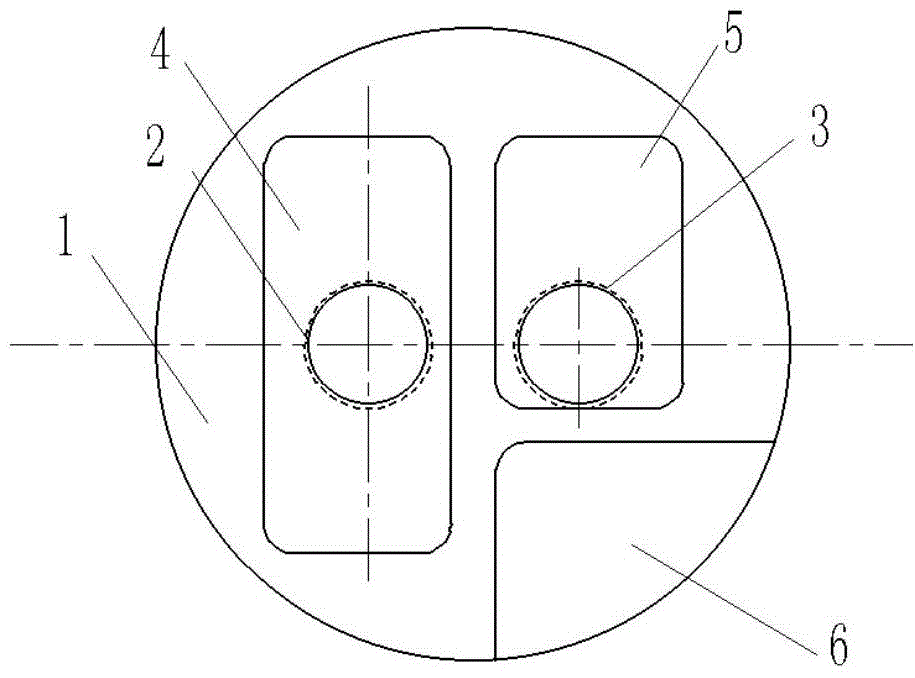

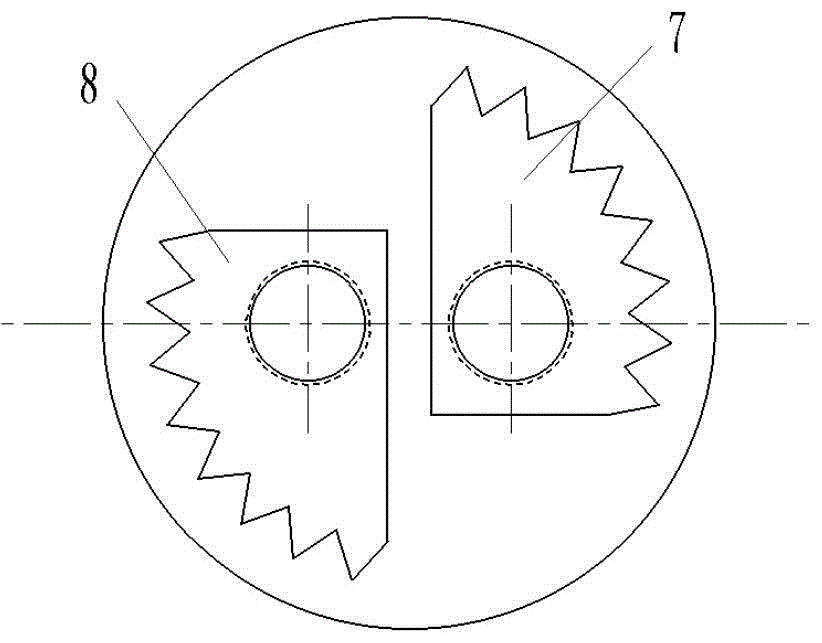

High-effect electrostatic protective component of disk type voltage dependent resistor for bridge-wire electric detonator

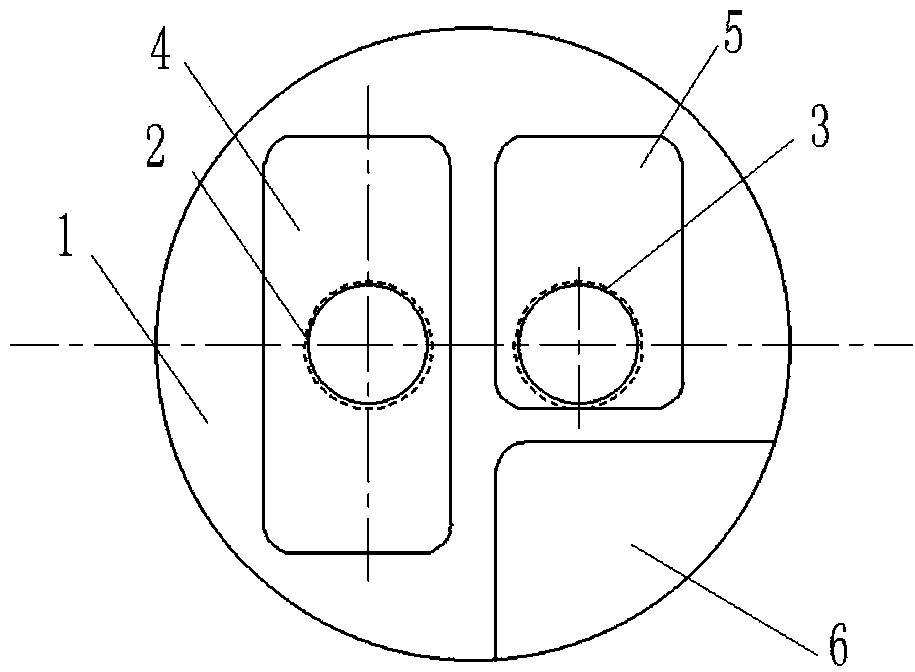

InactiveCN104330001AImprove electrostatic protection abilityLittle impact on altitudeAmmunition fuzesElectrostatic dischargeVaristor

The invention relates to a high-effect electrostatic protective component of a disk type voltage dependent resistor for a bridge-wire electric detonator. The high-effect electrostatic protective component comprises a disk type PCB and two voltage dependent resistor electrostatic protective electronic devices, wherein one voltage dependent resistor is connected with a pin-pin ignition loop in parallel via a circuit board, and the other voltage dependent resistor is connected with a pin-shell ignition loop in parallel via a circuit board; two sawtooth-shaped discharge electrodes are configured at the reverse side of the PCB, and form a pin-shell air gap electrostatic discharge channel together with the inner wall of a metal tube shell; the sawtooth-shaped discharge electrodes and the electrostatic protective devices are connected in parallel to form a double-insurance effect with pin-shell electrostatic protection. The pin-shell protection effect of the electrostatic protective component achieves the human body static electricity resistance above 50kV; the pin-pin protection effect achieves the human body static electricity resistance above 30kV, and can withstand multiple times of impact by electrostatic discharge without any capability change.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Wafer type TVS tube type high-efficiency static protection assembly for ignition wire type electric detonator

InactiveCN104390532AImprove electrostatic protection abilityLittle impact on altitudeAmmunition fuzesDetonatorArchitectural engineering

The invention relates to a wafer type TVS tube type high-efficiency static protection assembly for an ignition wire type electric detonator. The wafer type TVS tube type high-efficiency static protection assembly comprises a wafer-shaped PCB and two TVS tube type static protection electronic devices, wherein one TVS tube is connected in parallel with a leg-leg ignition loop through the circuit board, and the other TVS tube is connected in parallel with a leg-shell ignition loop through the circuit board; two sawtooth-shaped discharge electrodes are arranged on the back surface of the PCB; the sawtooth-shaped discharging electrodes and the inner wall of a metal tube form a leg-shell air gap static discharging channel; the sawtooth-shaped discharge electrodes and the static protection electronic devices are connected in parallel to achieve a dual insurance effect for leg-shell static protection. By the static protection assembly, the leg-shell and leg-leg protection effects can resist static, on a human body, of being more than 50kV, and any change on the performance can be avoided under multiple impacts caused by static discharging.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

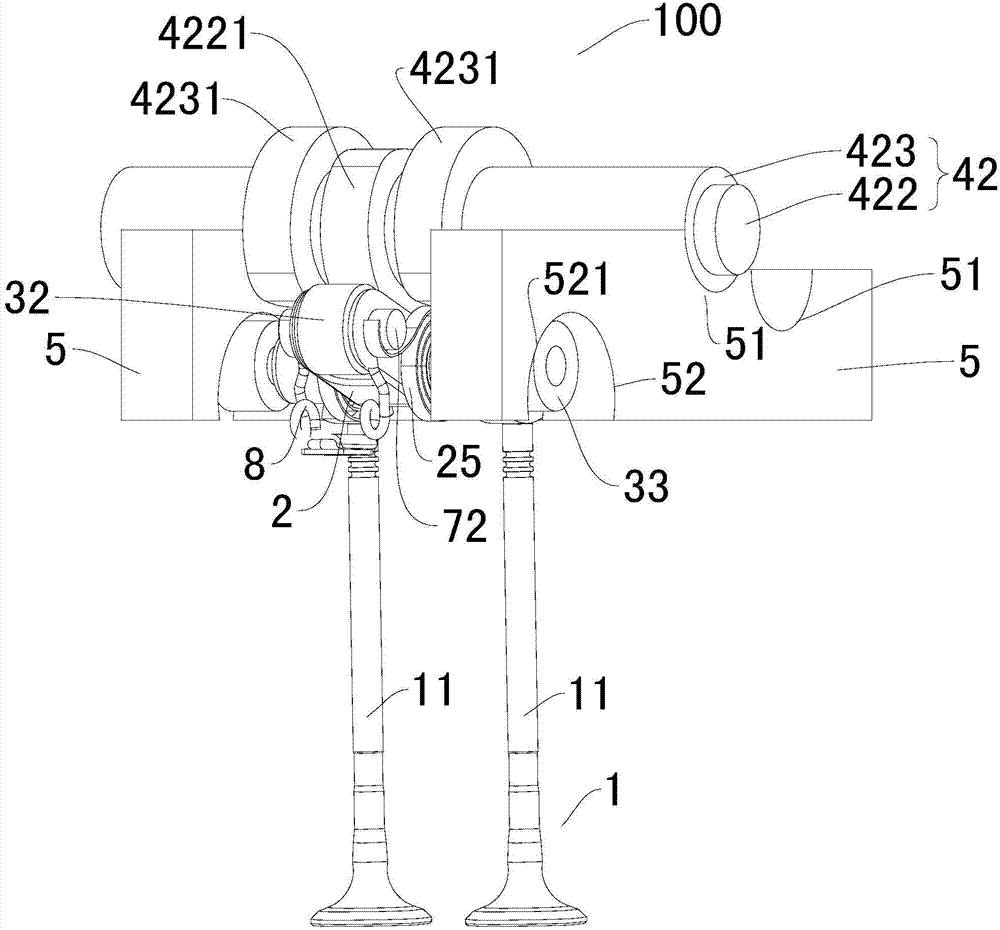

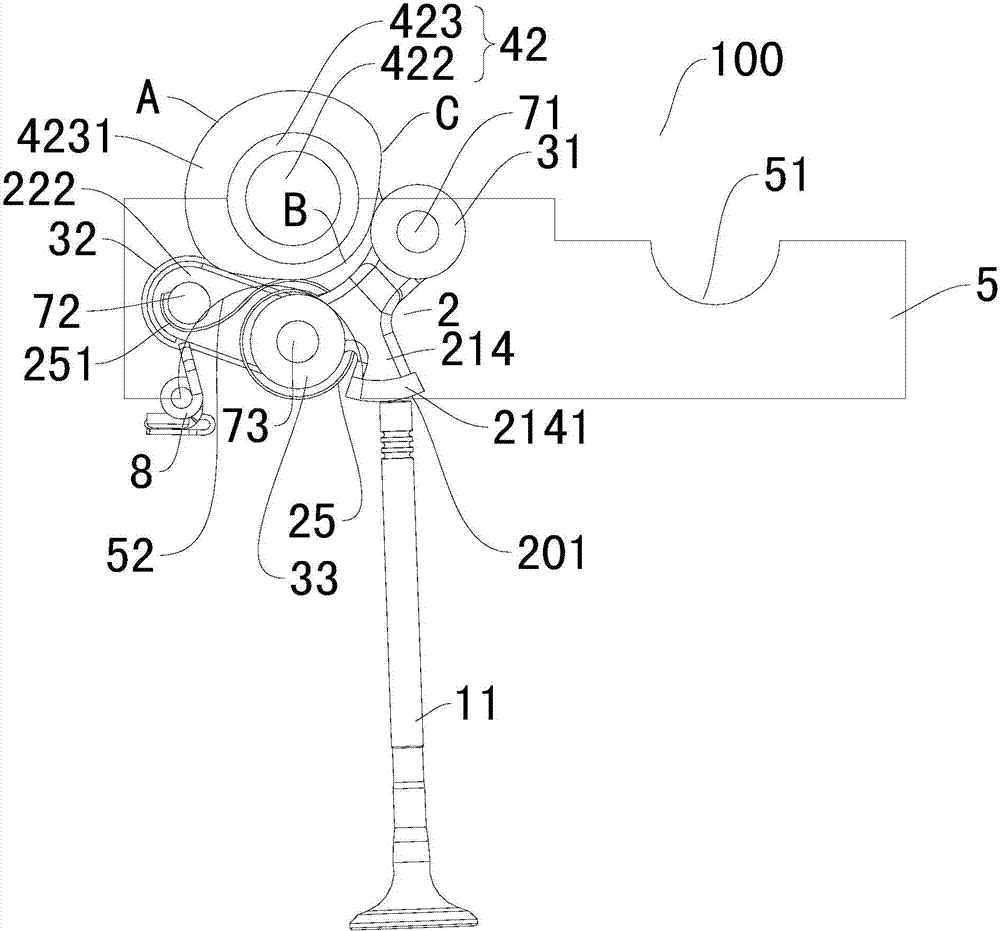

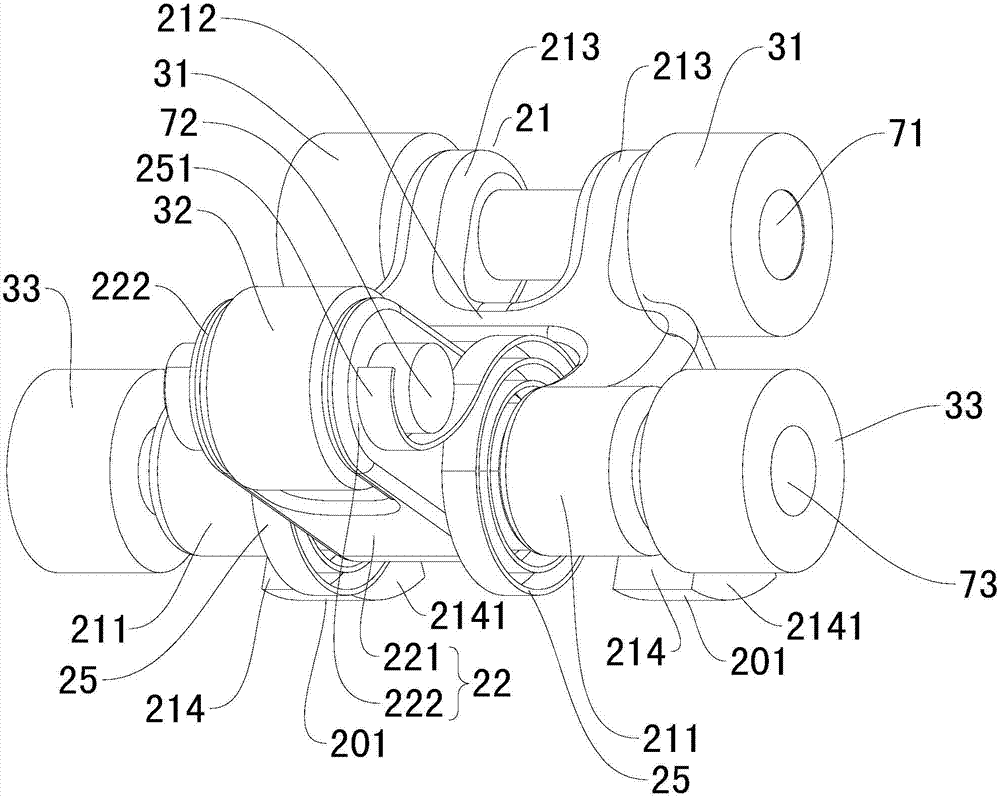

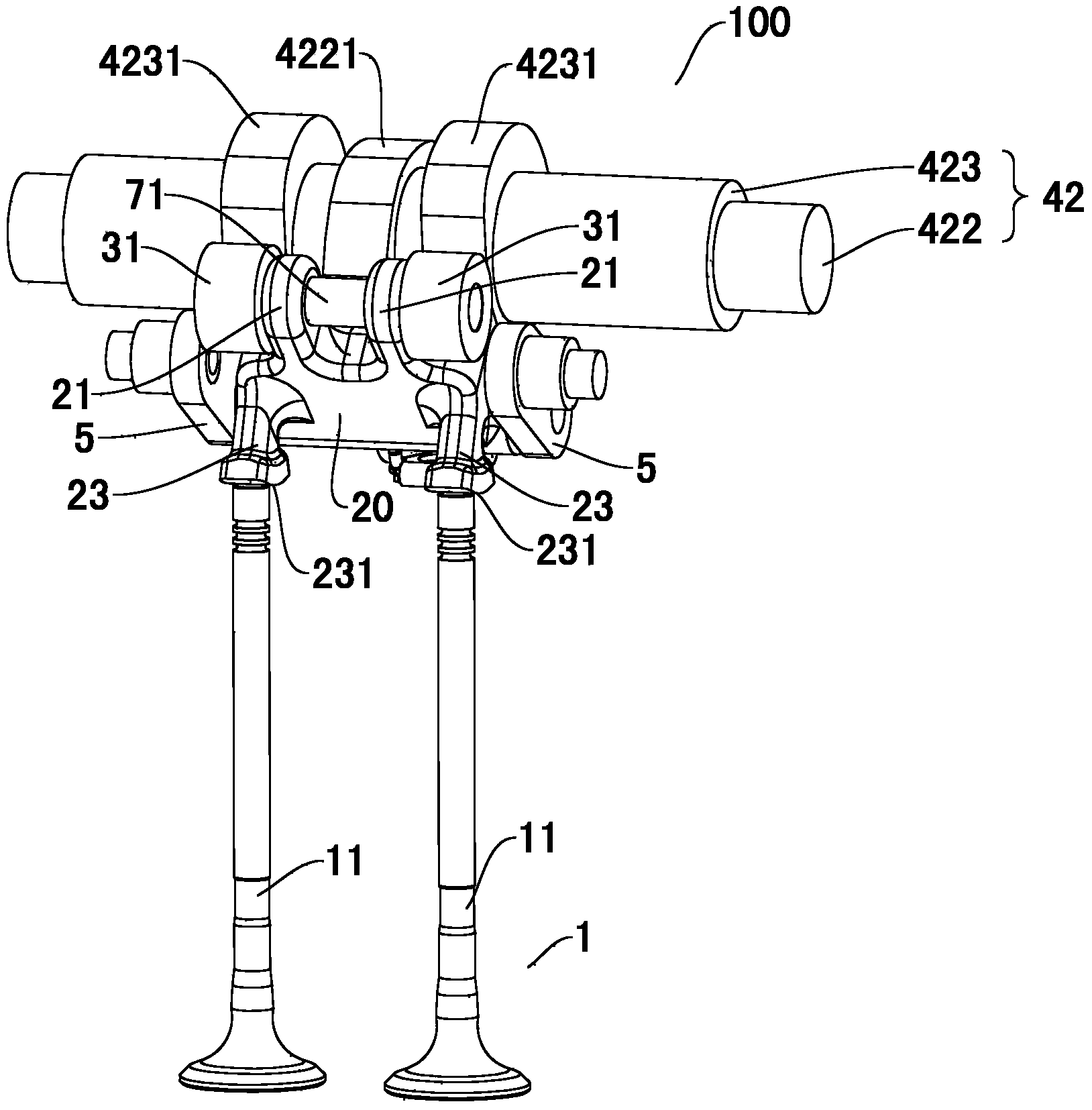

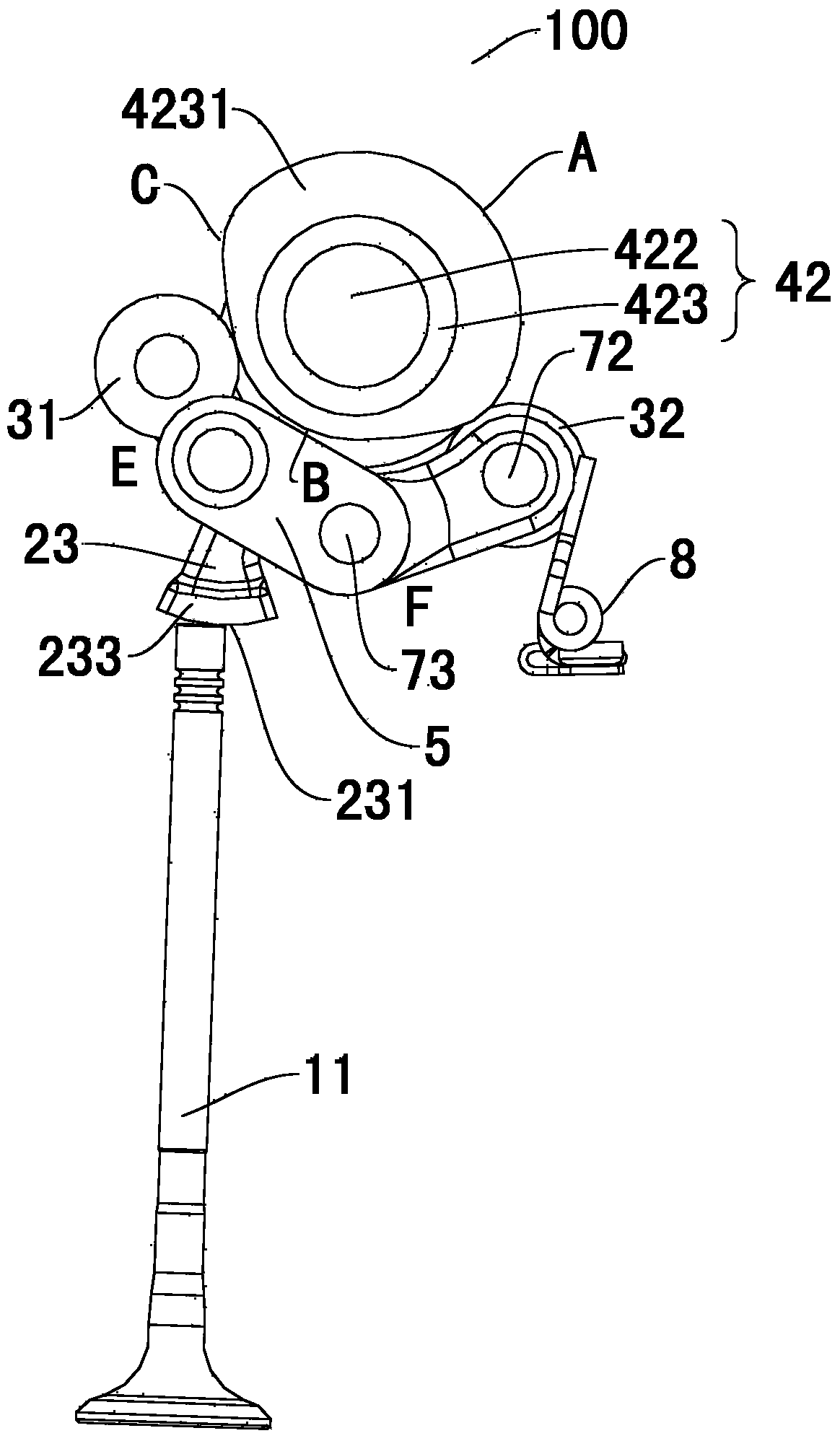

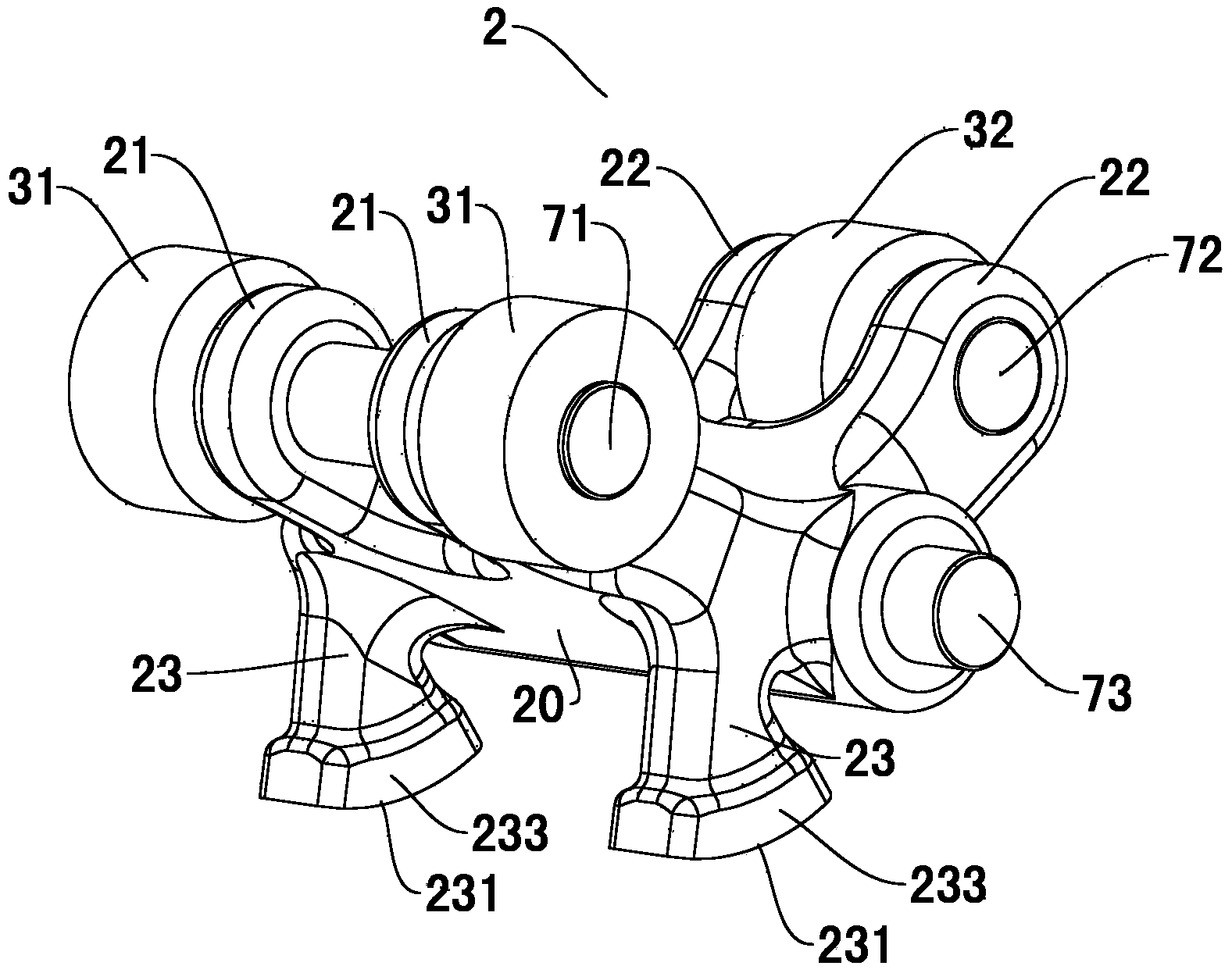

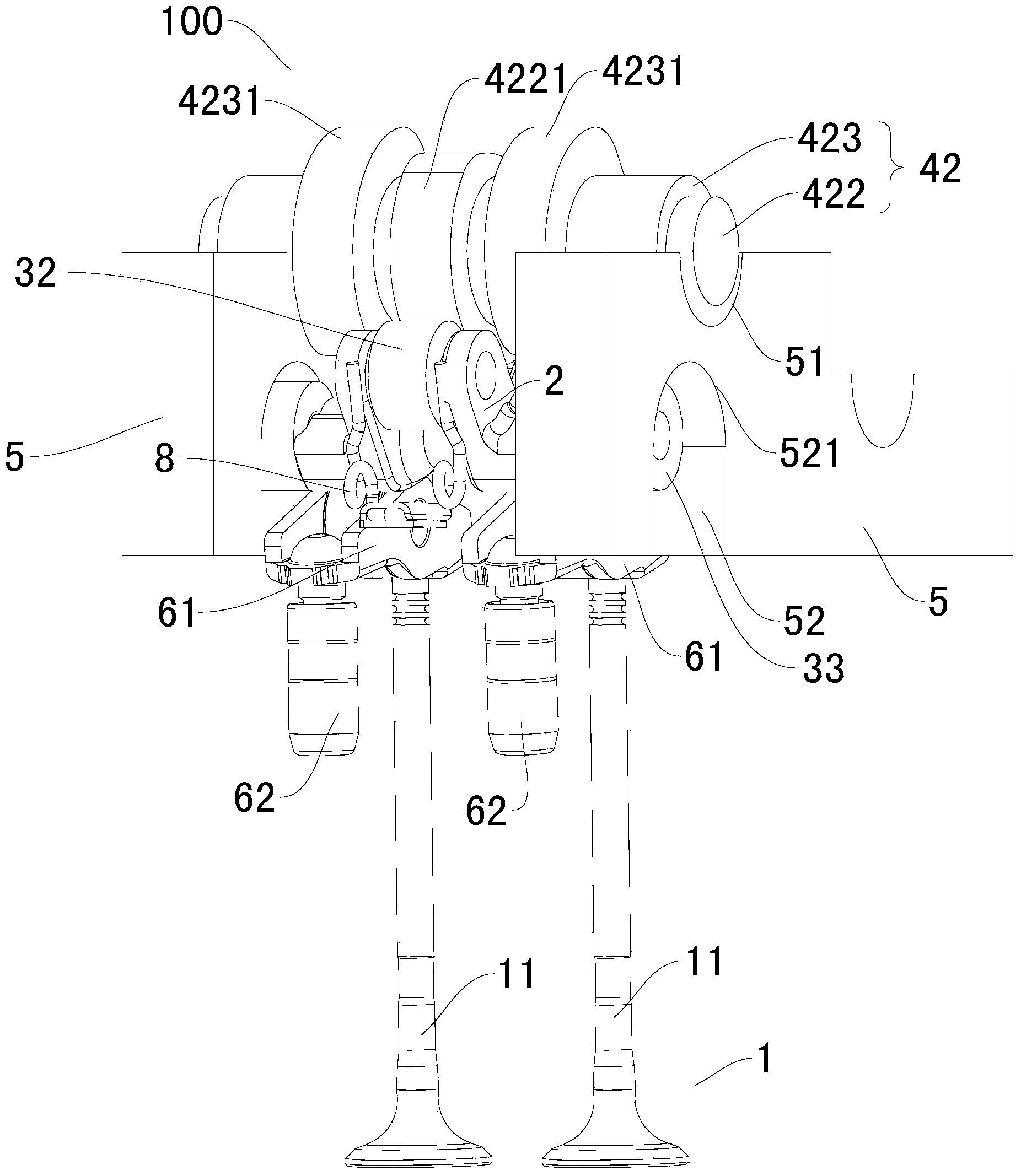

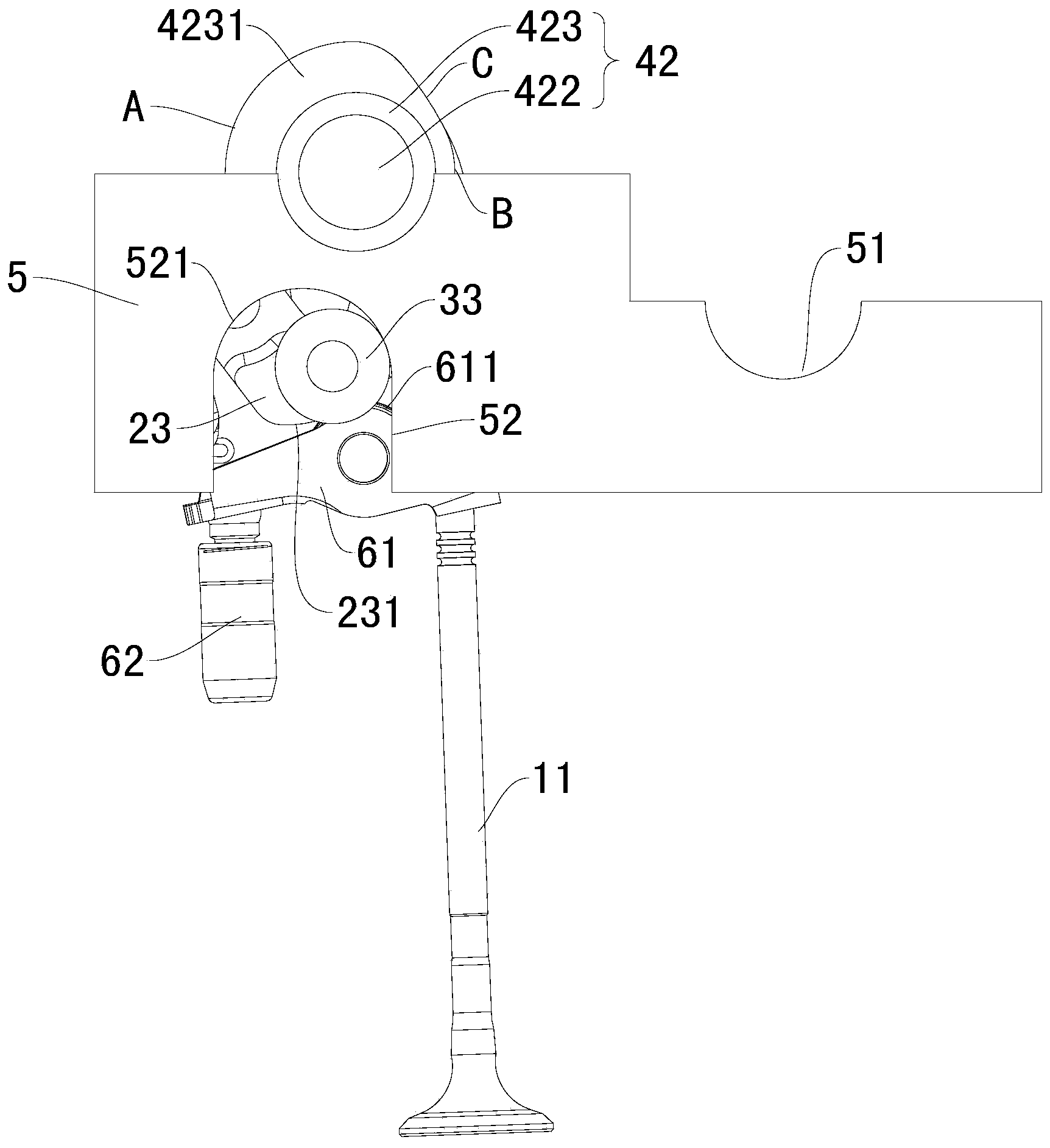

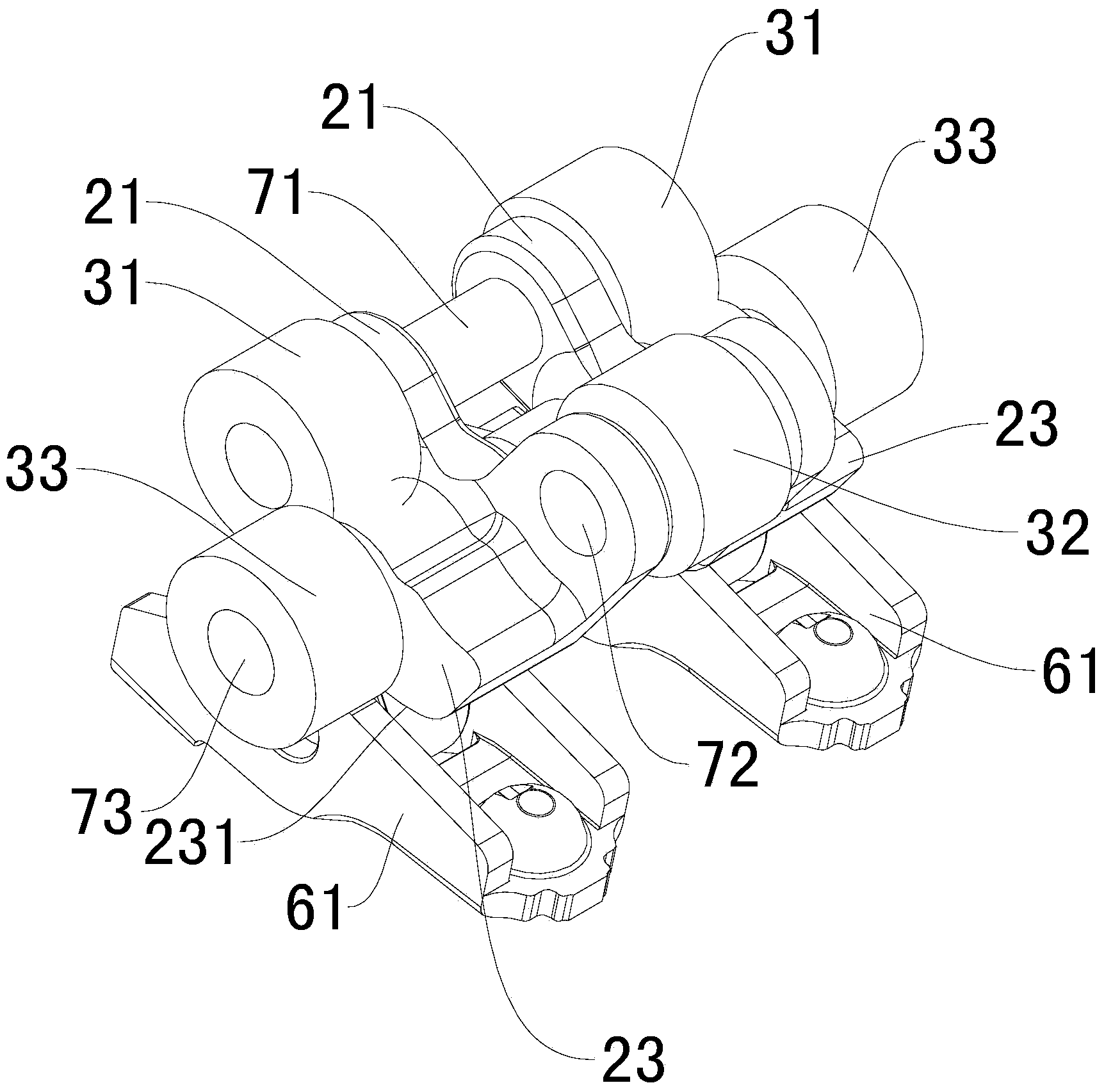

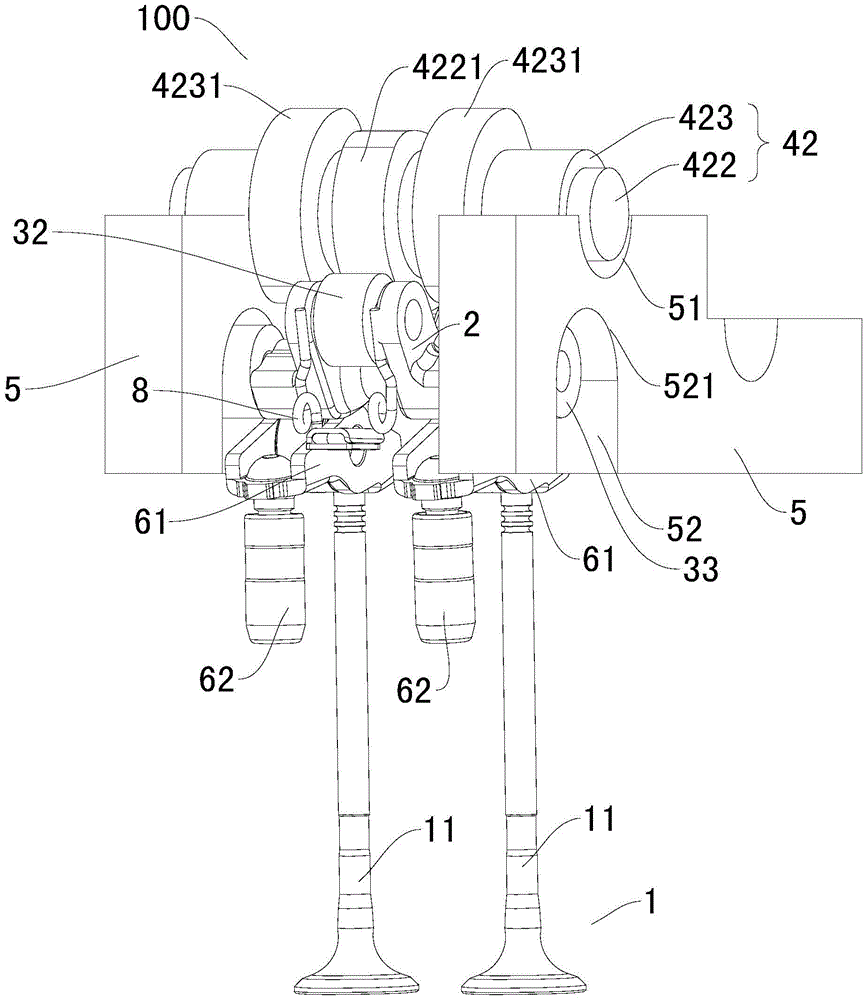

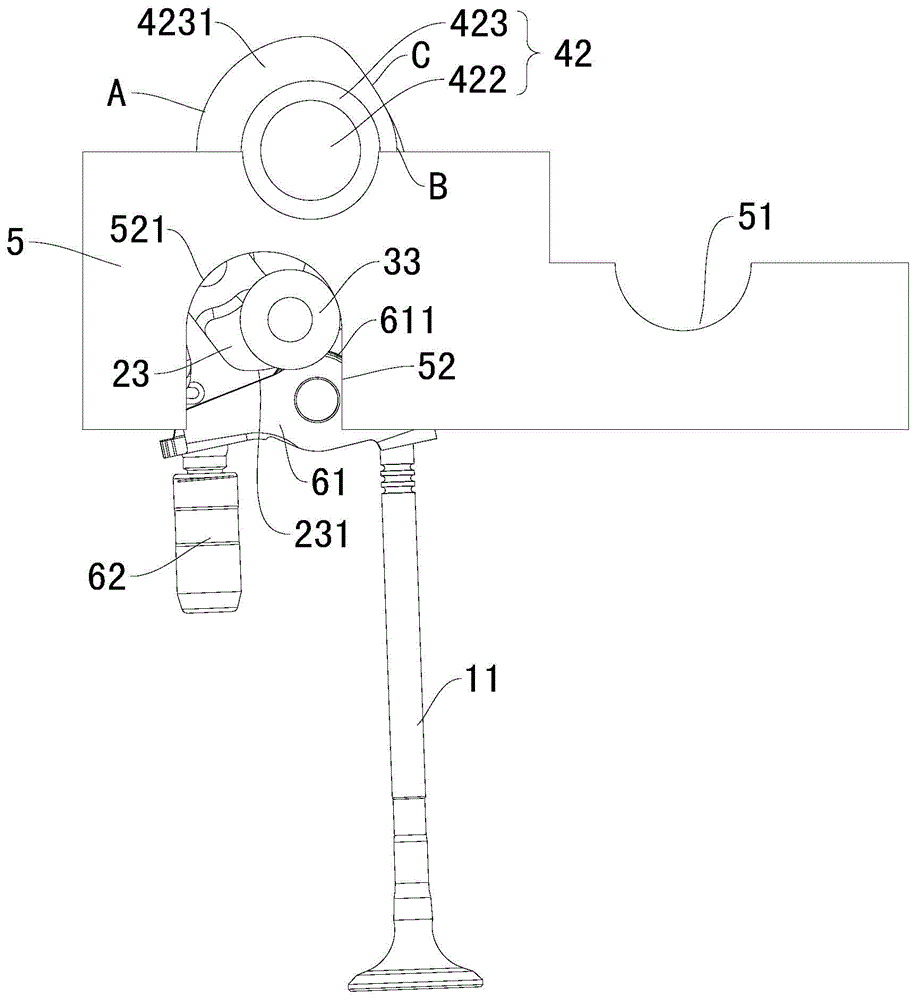

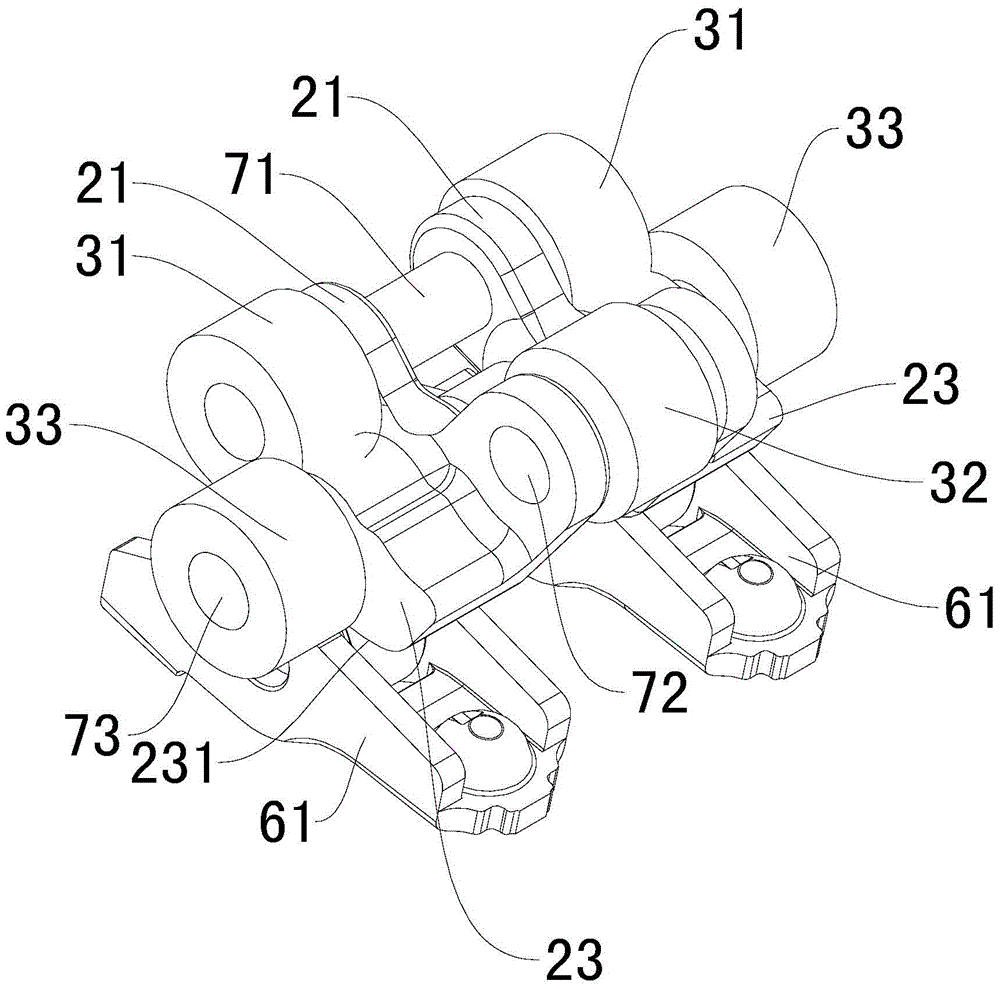

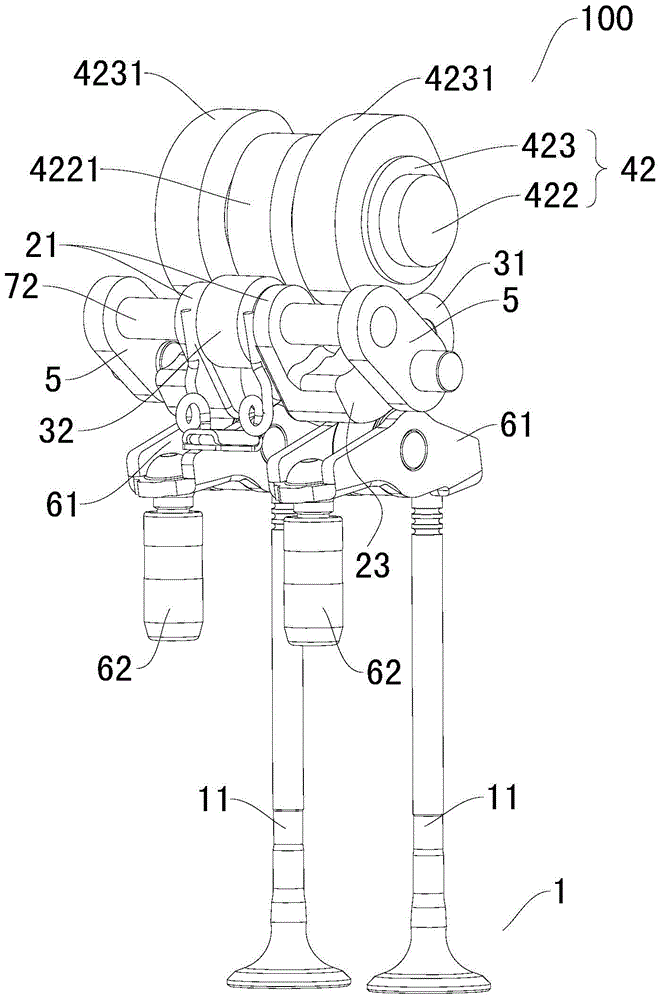

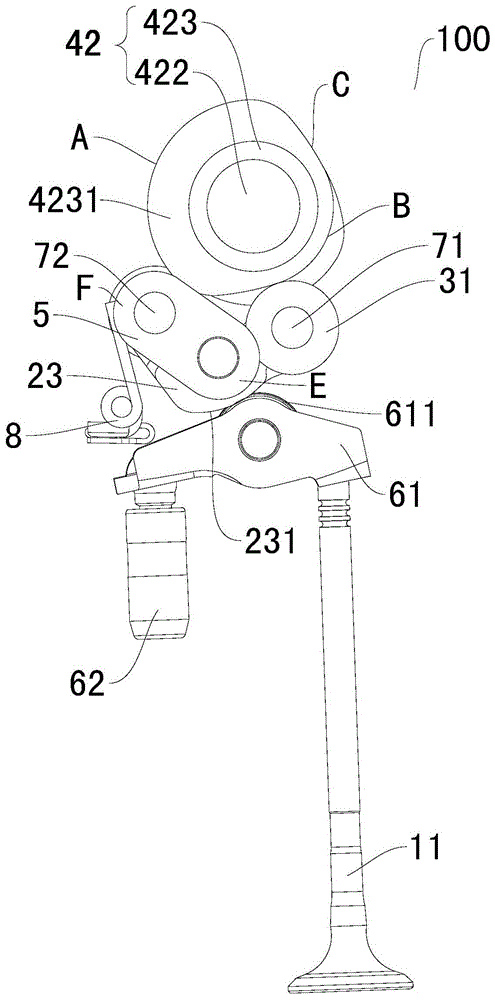

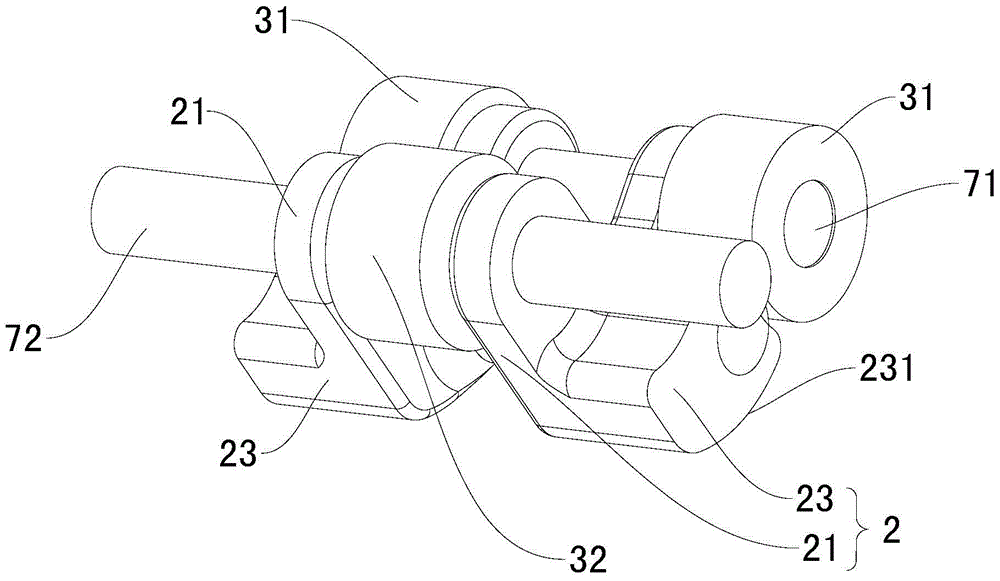

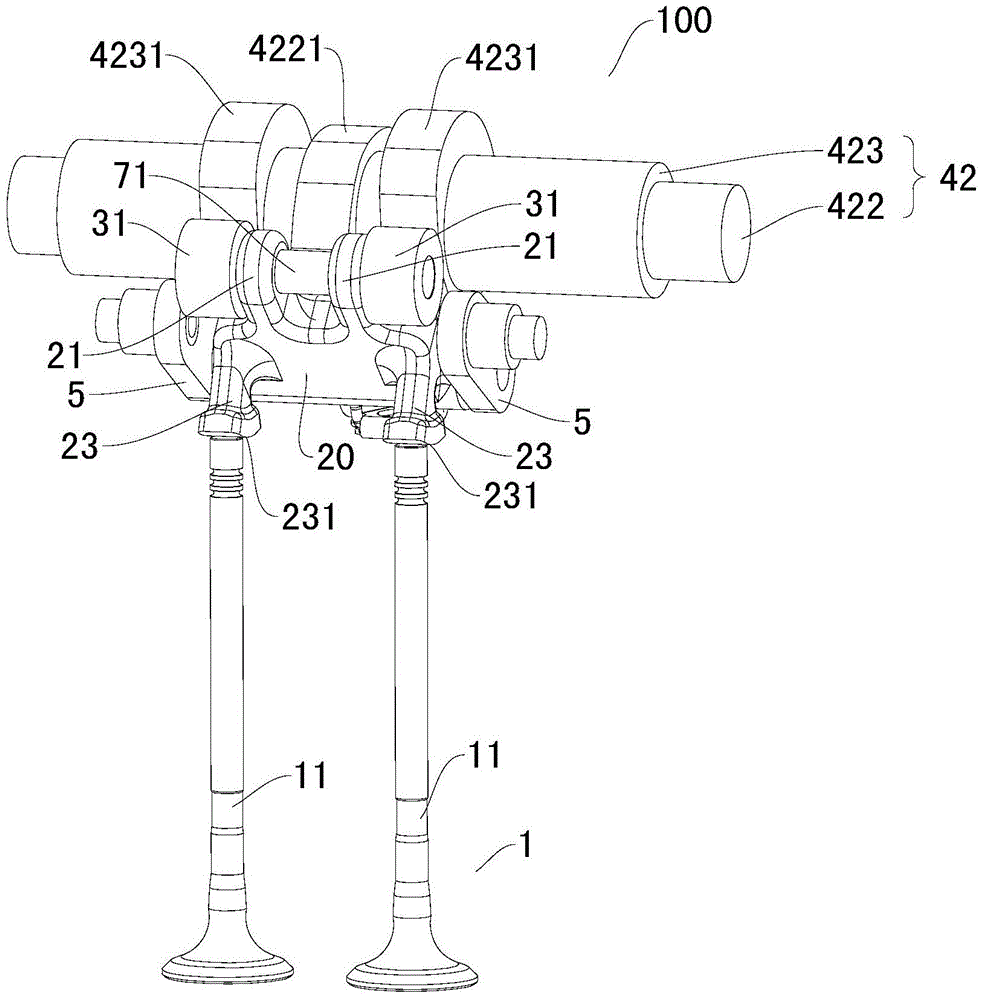

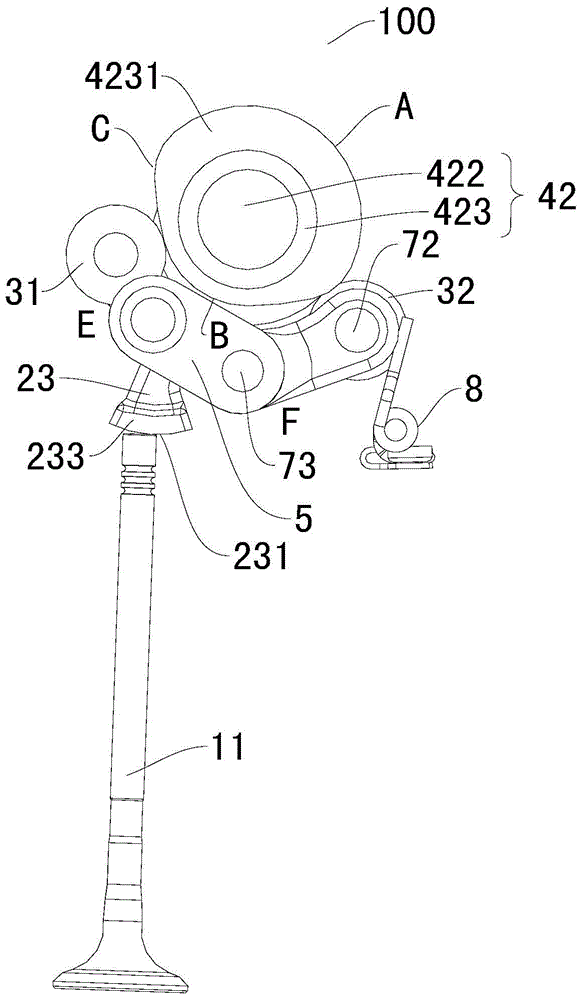

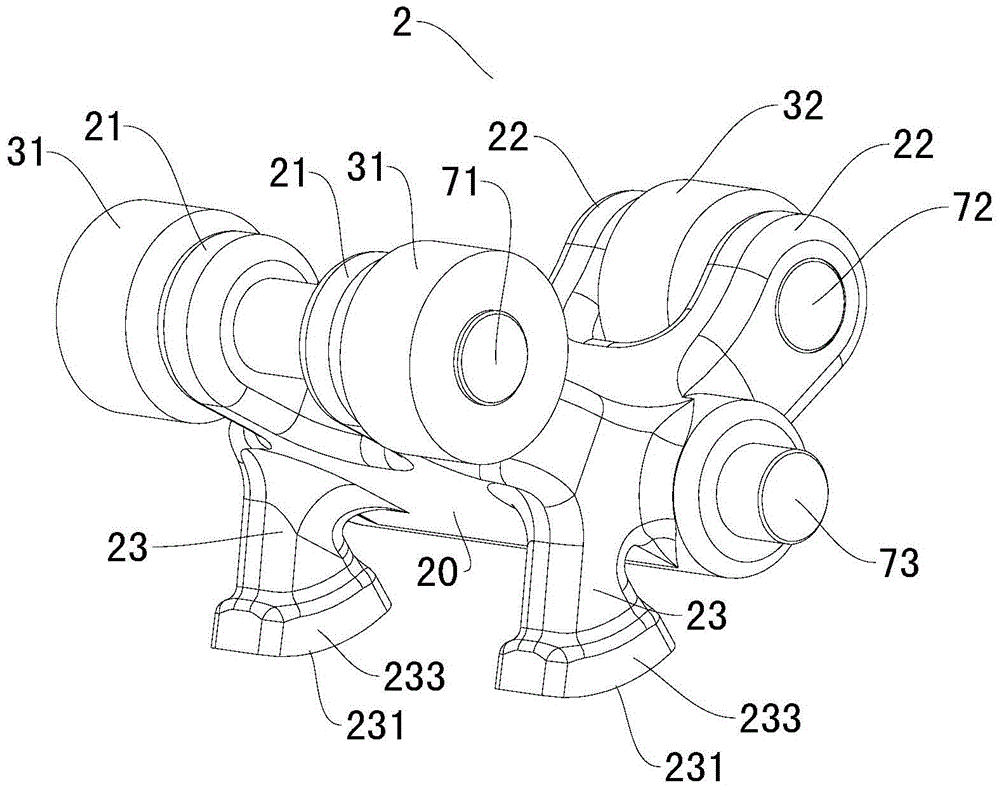

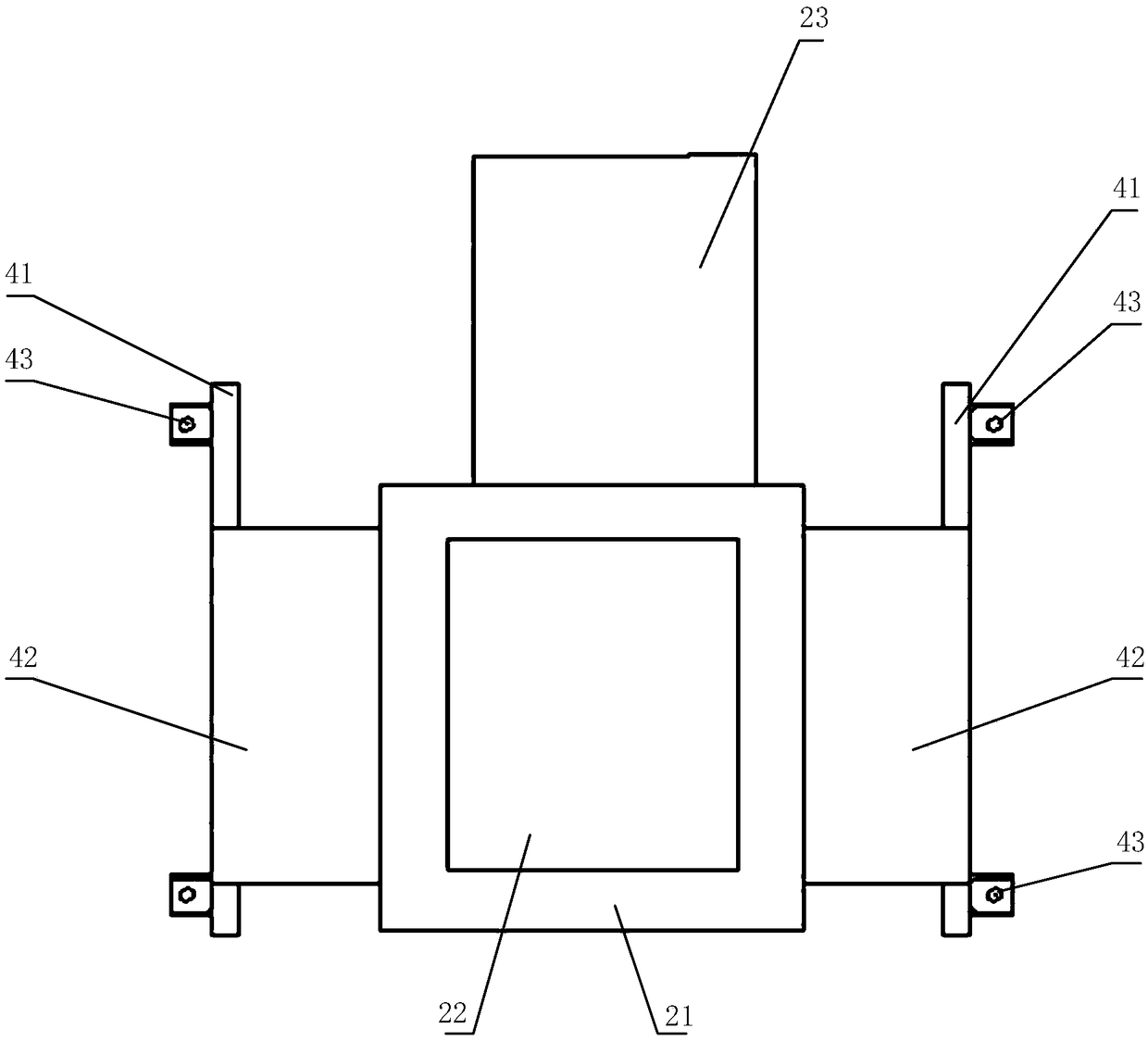

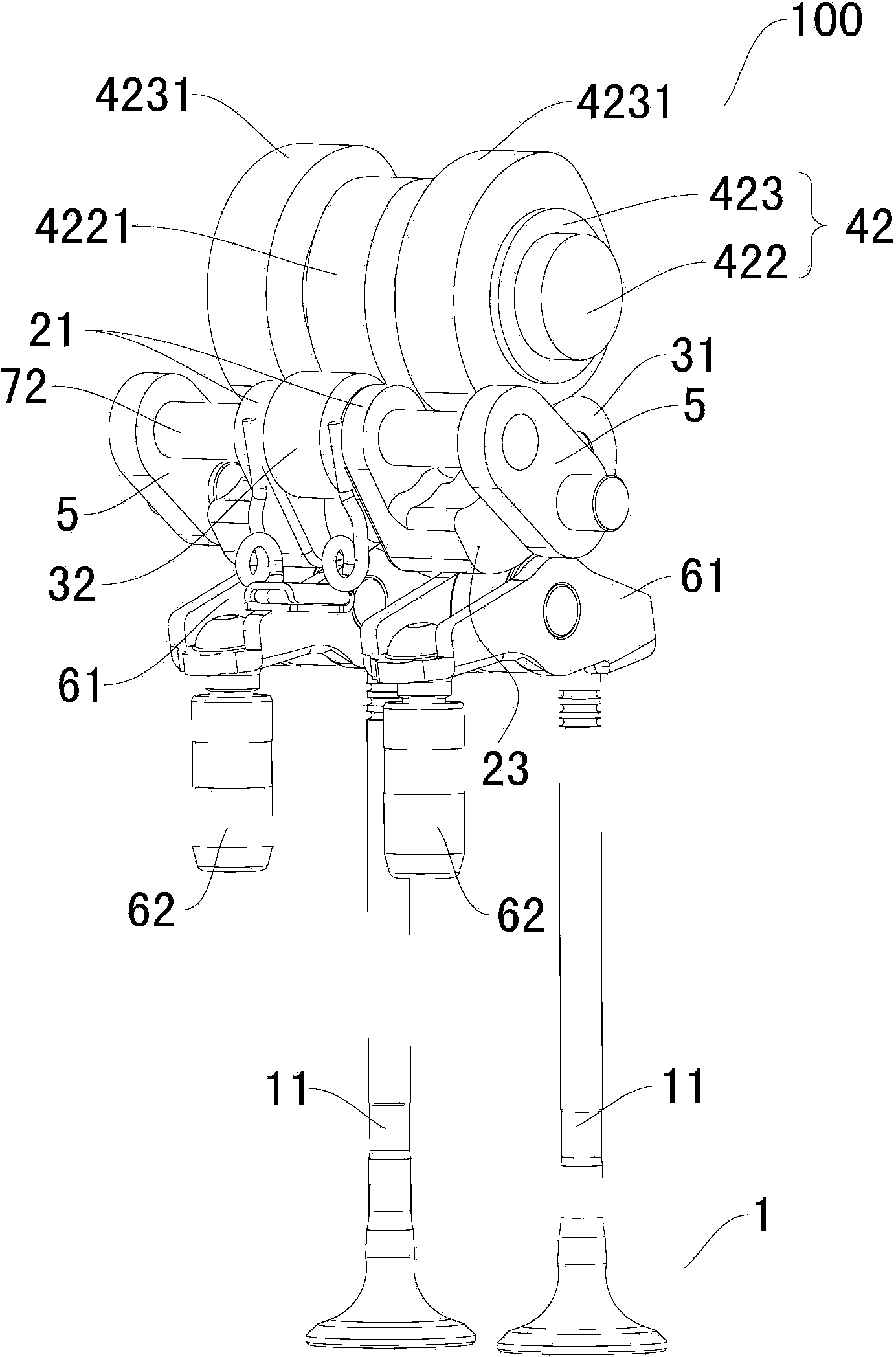

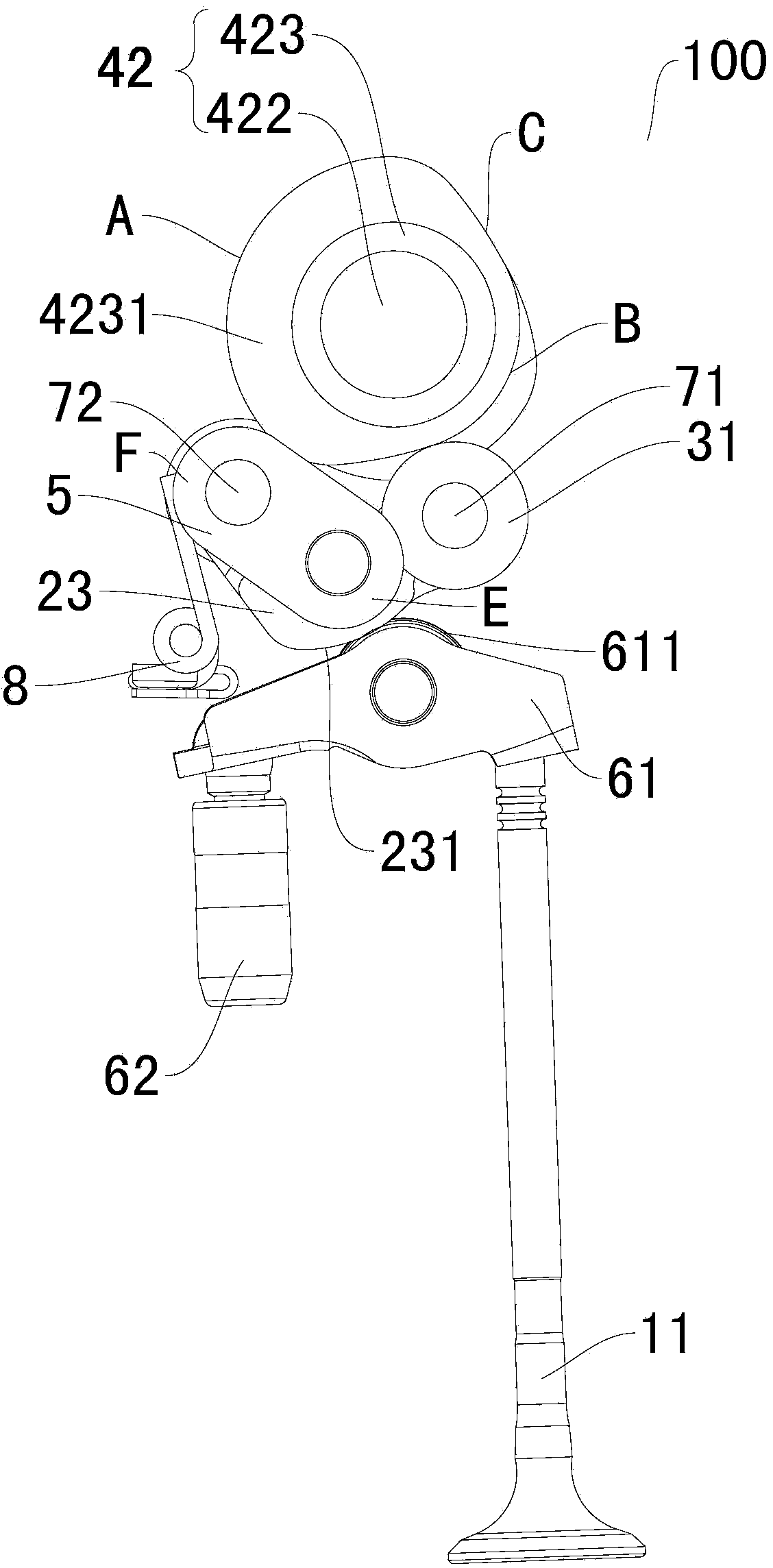

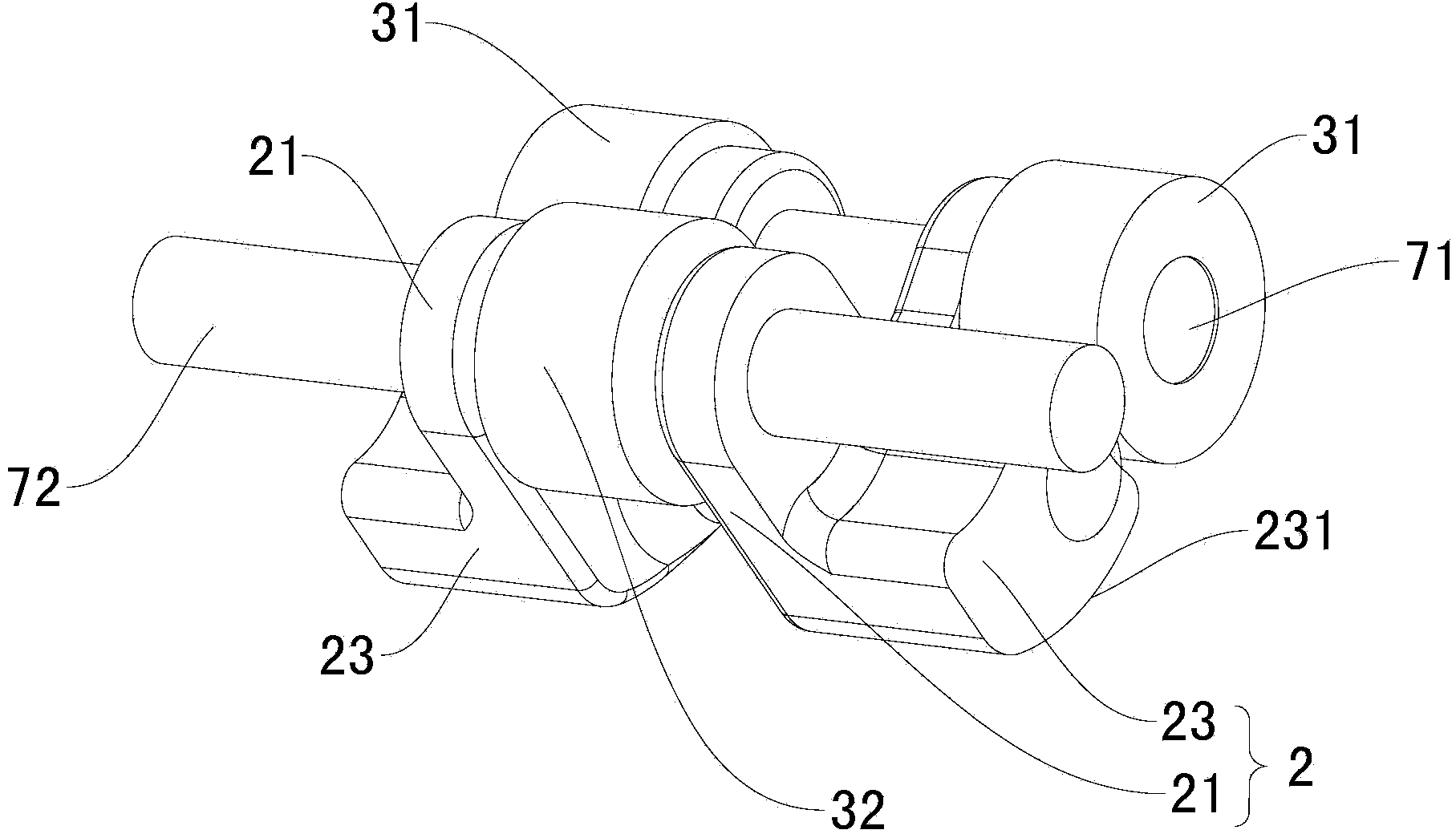

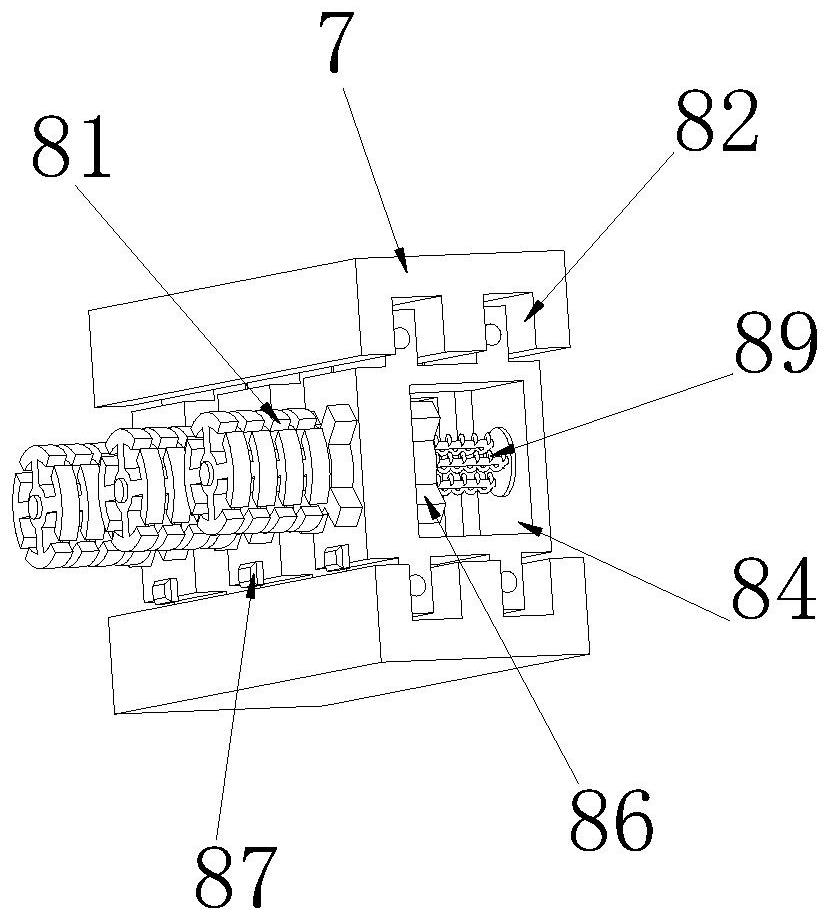

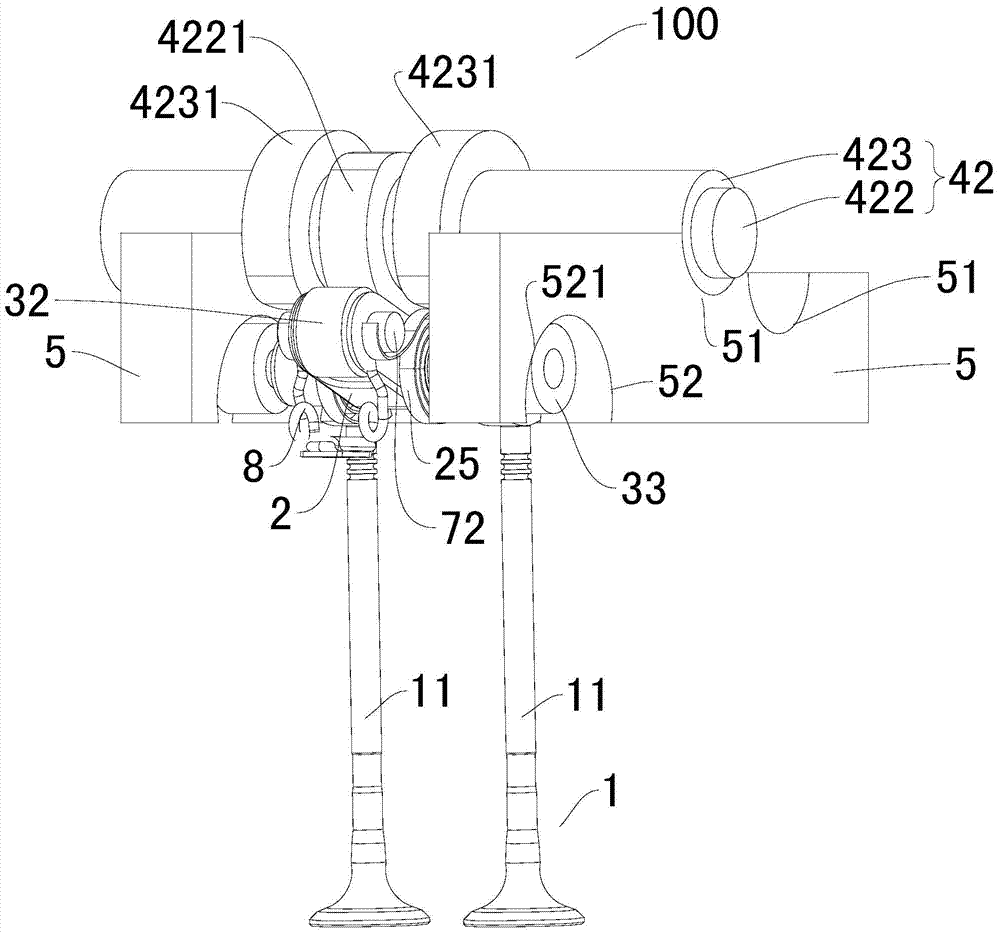

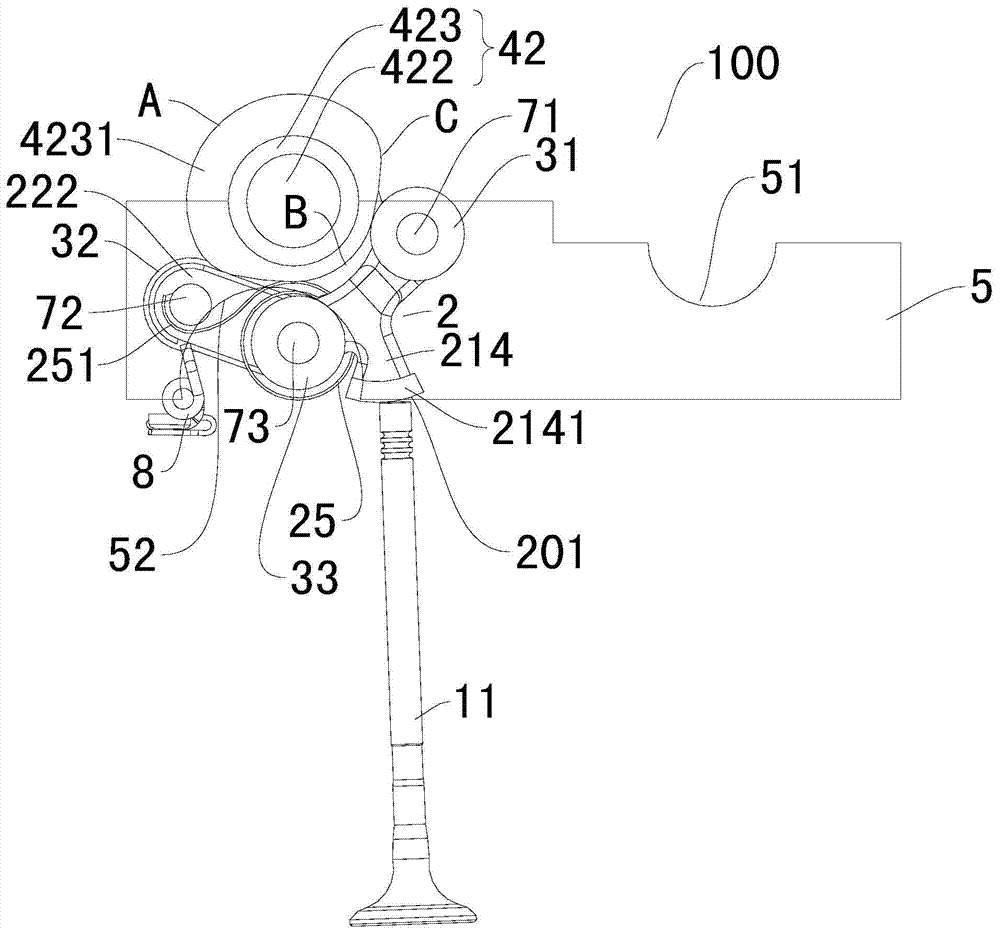

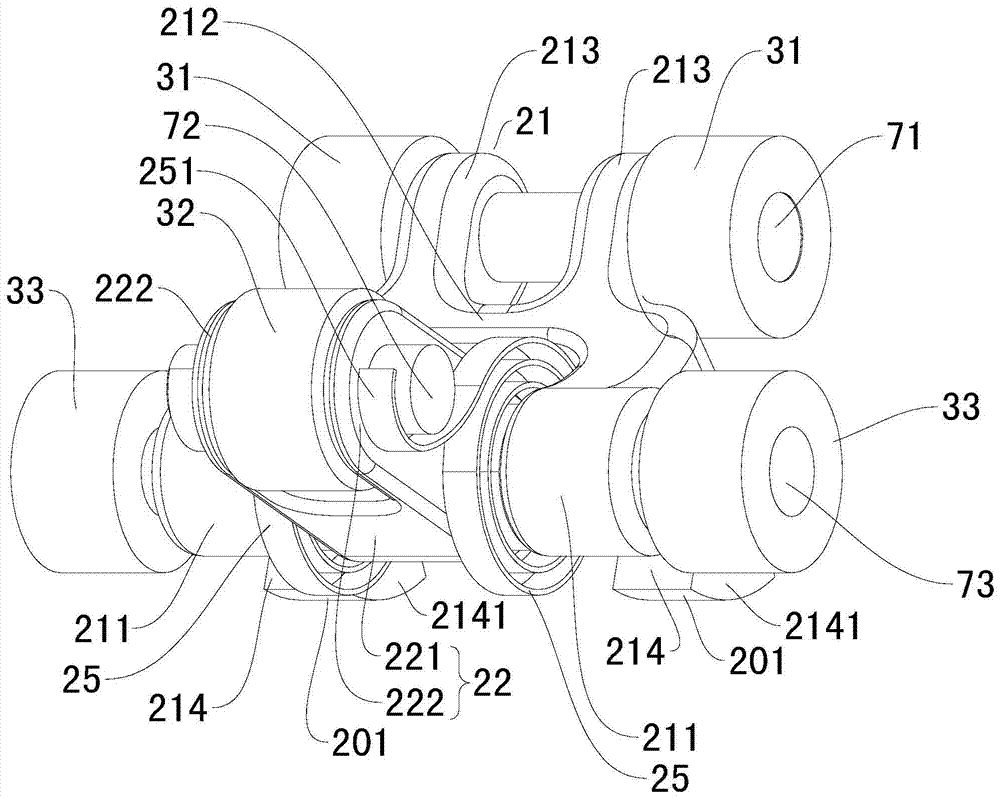

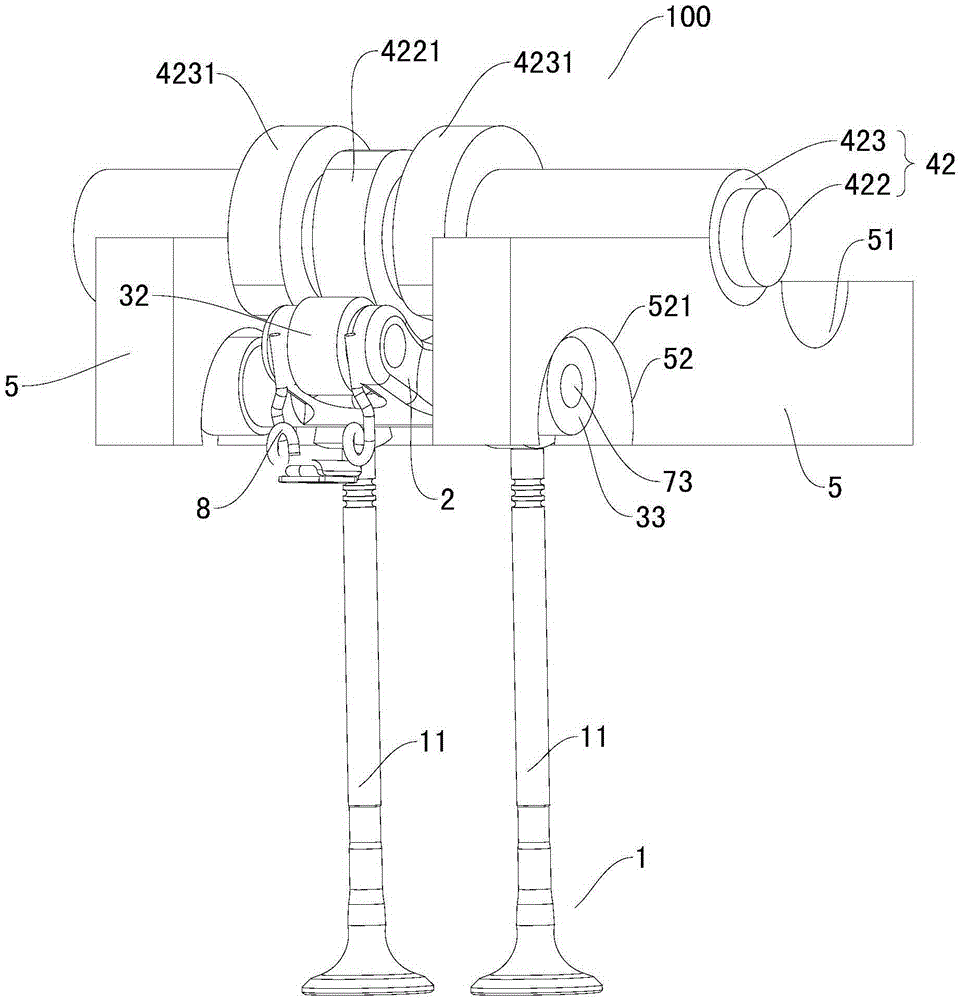

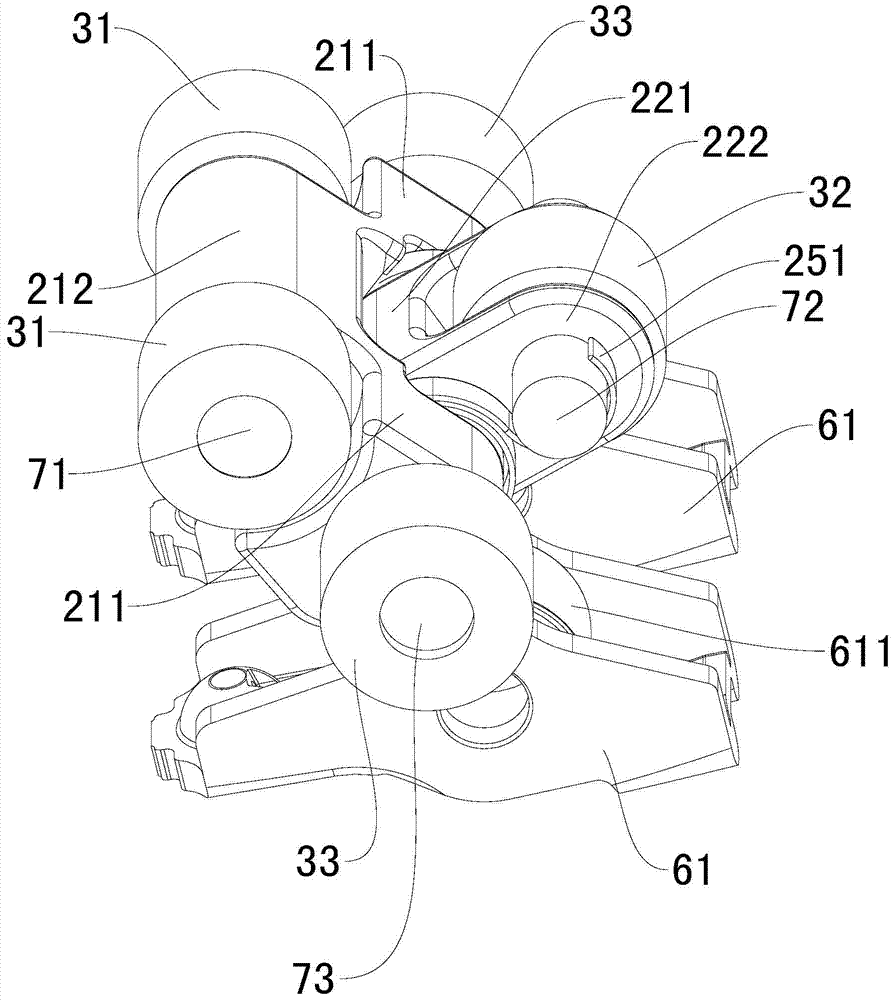

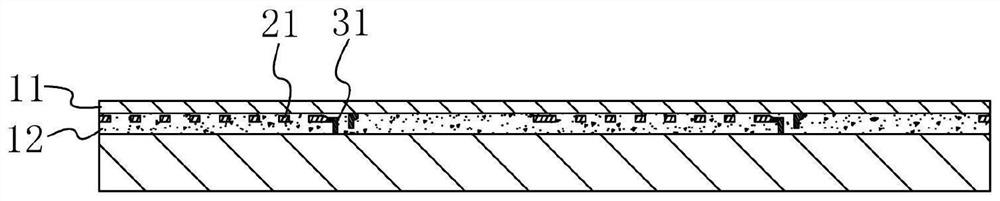

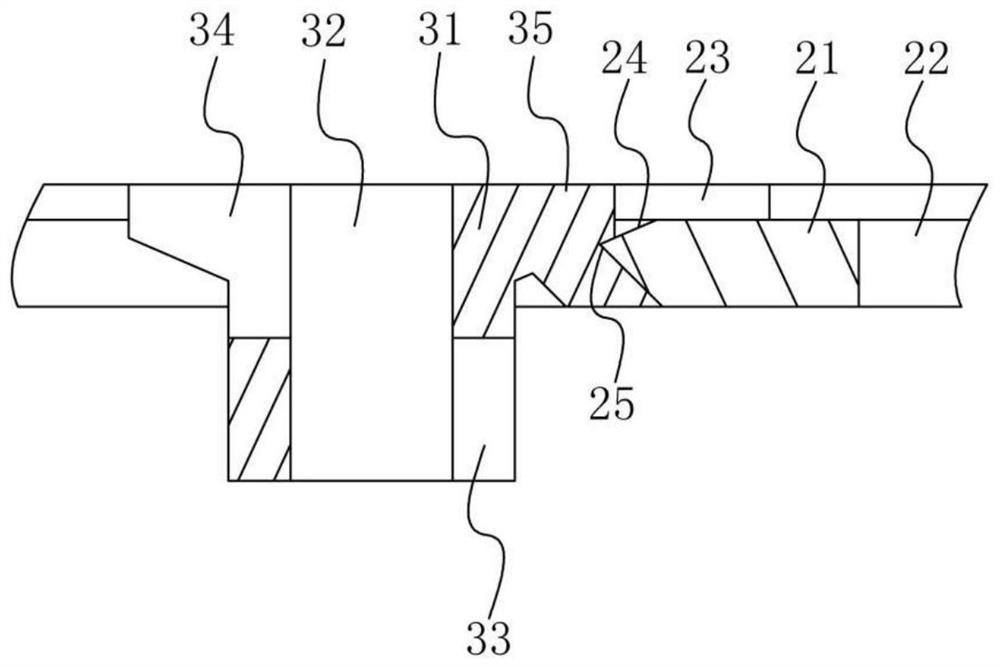

Valve mechanism for engine and vehicle comprising valve mechanism

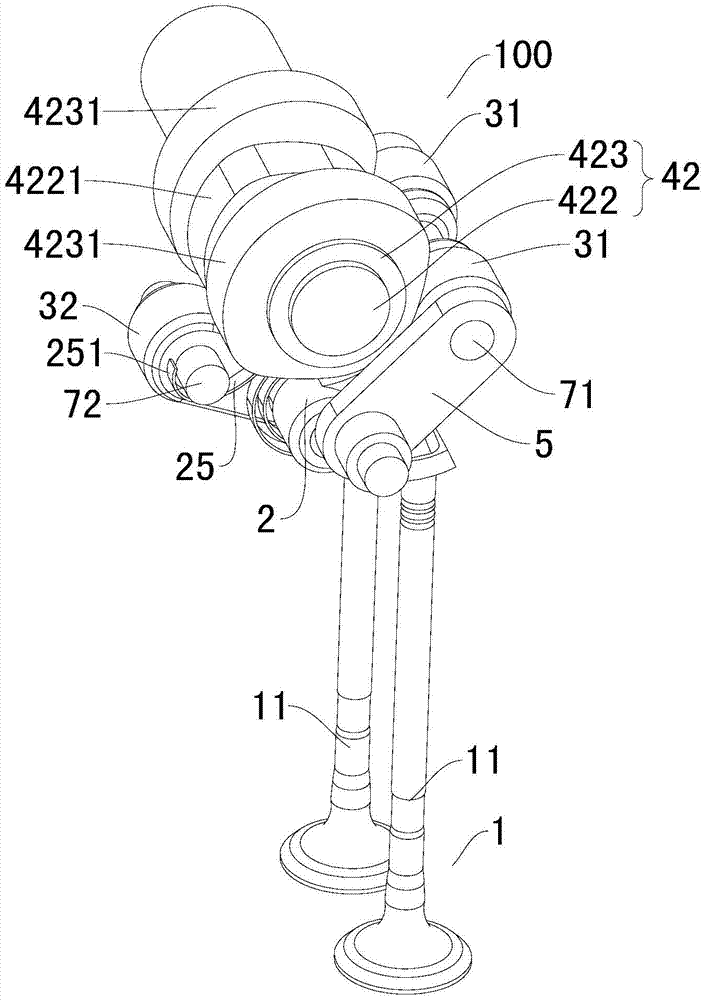

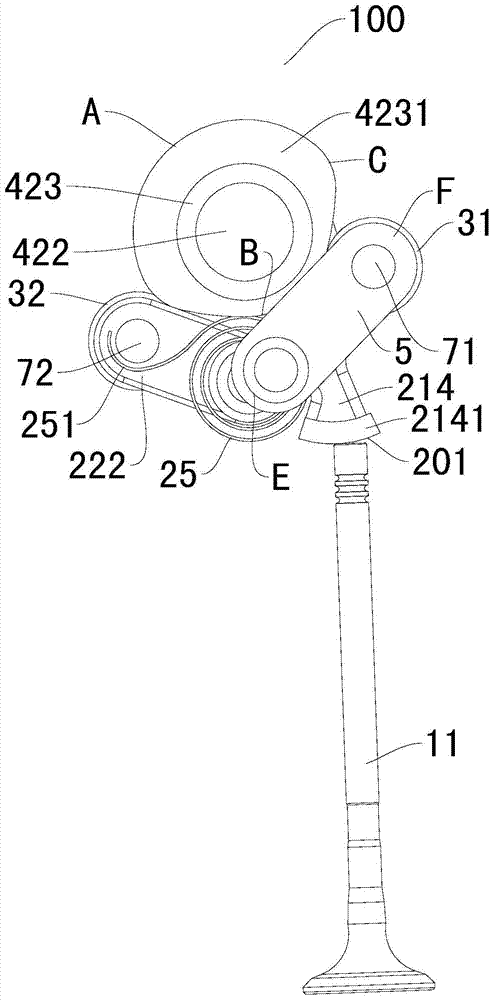

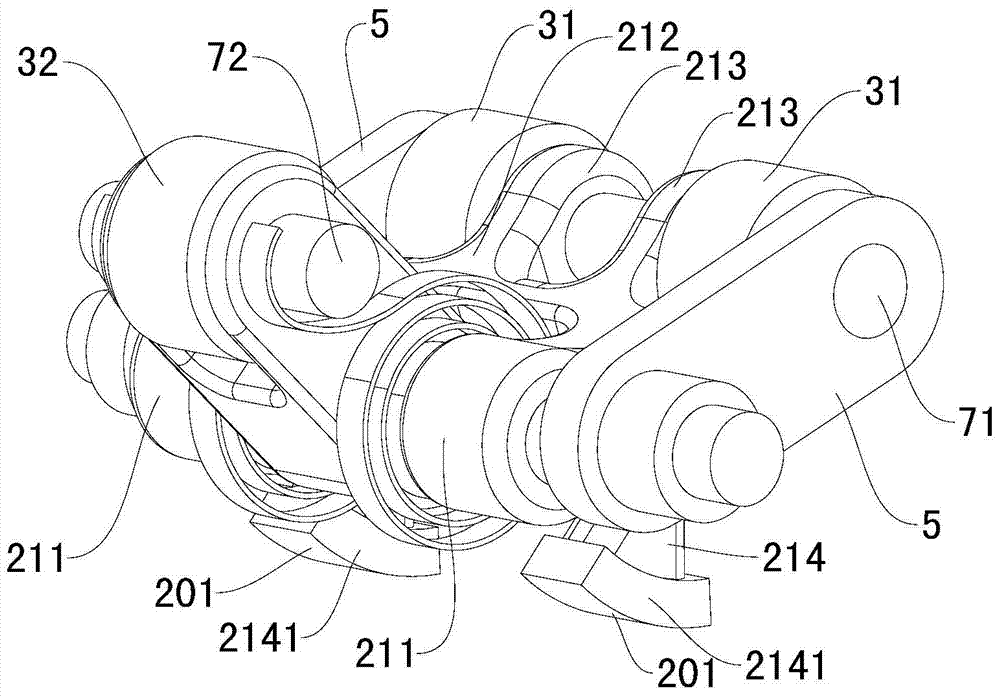

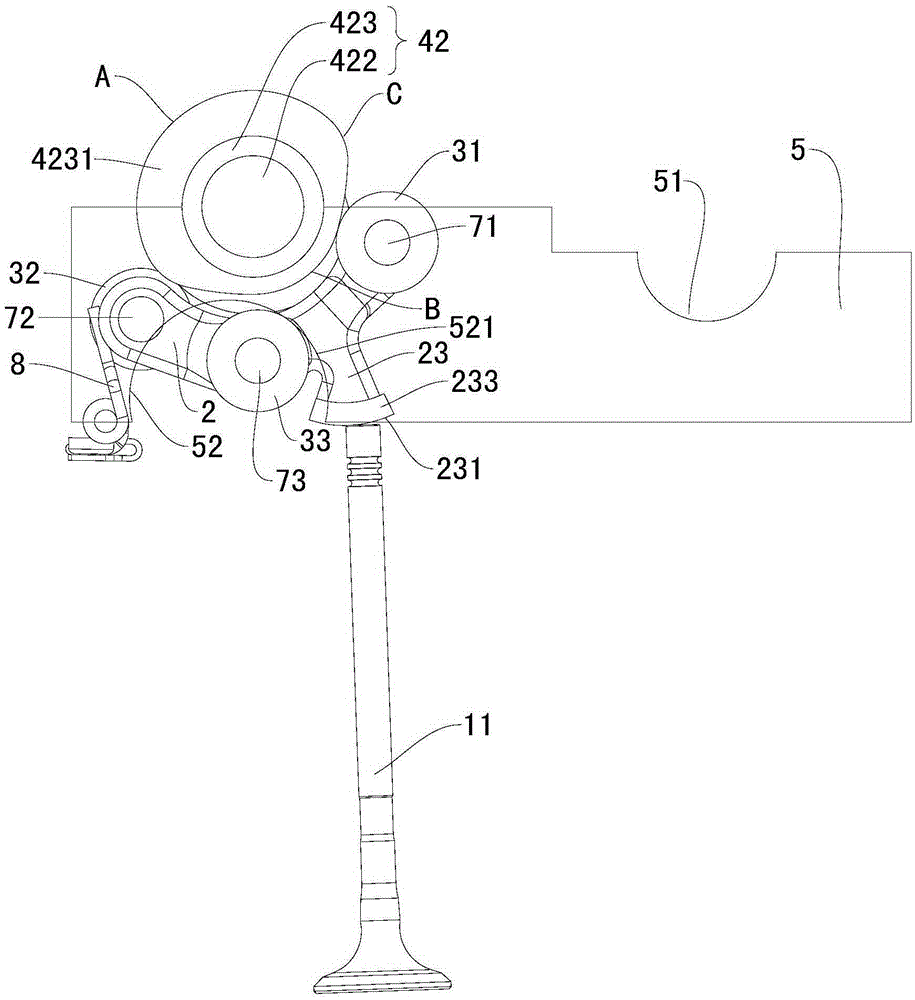

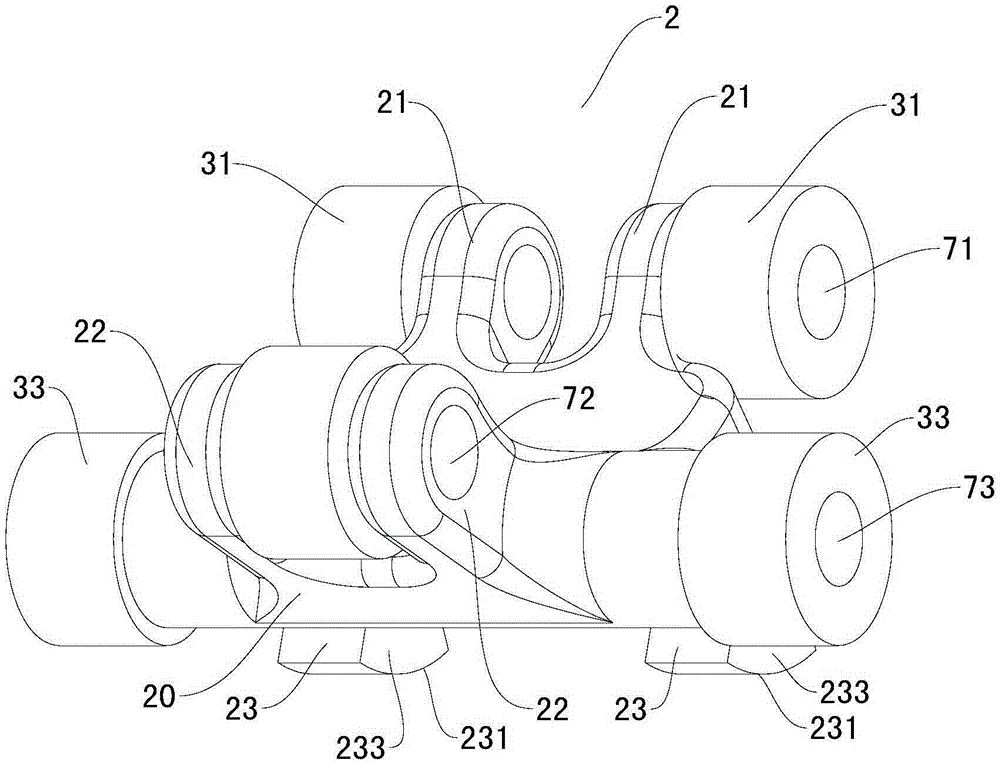

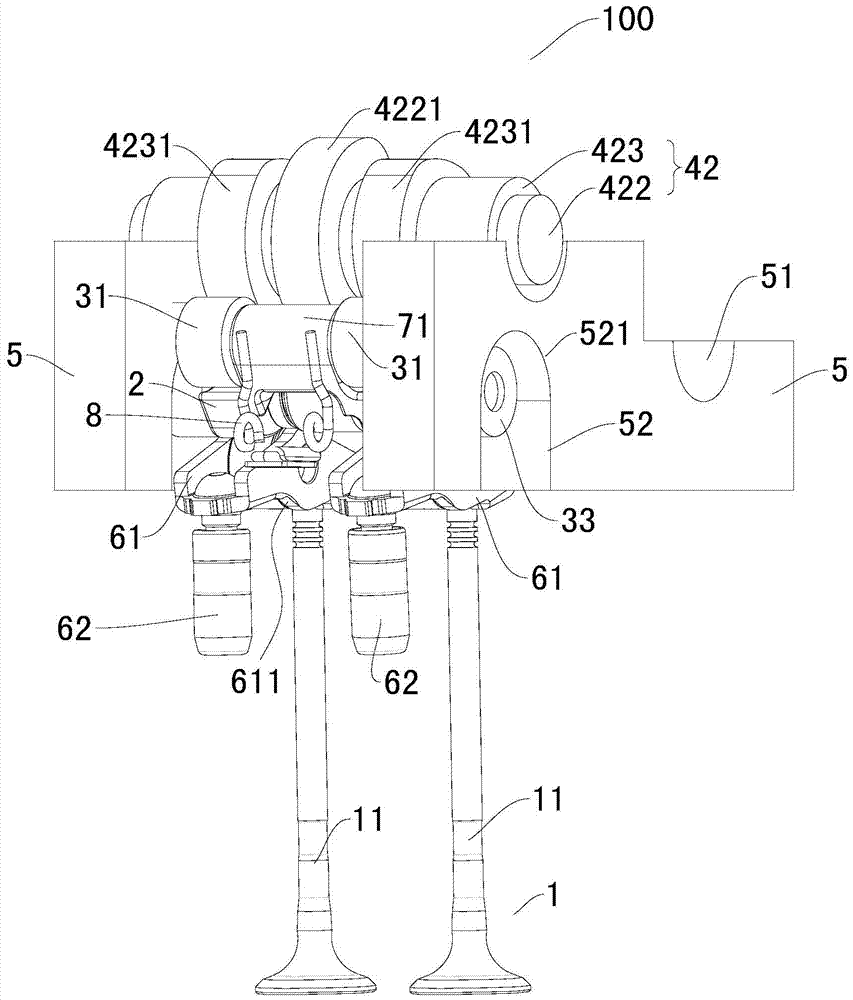

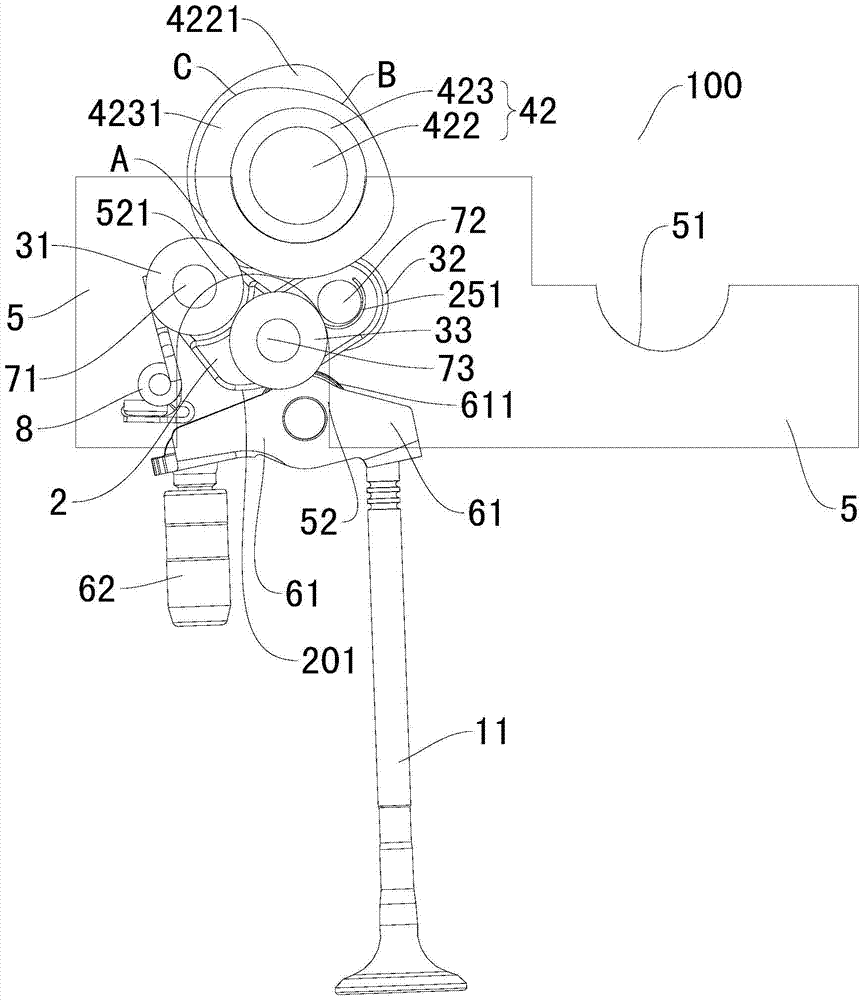

ActiveCN103790669AImprove inflation efficiencyMeet the needs of valve movement rules in different working conditionsValve arrangementsMachines/enginesEngineeringCam

The invention discloses a valve mechanism for an engine and a vehicle comprising the valve mechanism. The valve mechanism comprises a valve mechanism body, a rocker component, a first roller, a second roller, a camshaft, supporting structures, a phase adjusting mechanism, and a third roller or limit pins. The bottom of the rocker component is provided with a drive molded surface which is suitable for directly driving a valve to move. The first roller and the second roller both can be arranged on the rocker component in a pivoting mode. The camshaft comprises an inner shaft and an outer shaft, the inner shaft and the outer shaft are coaxially arranged and provided with an inner shaft cam and an outer shaft cam respectively, and the inner shaft cam and the outer shaft cam can rotate along the corresponding shafts respectively. The outer shaft cam abuts against the first roller, the inner shaft cam abuts against the second roller, the supporting structures are arranged on the two sides of the rocker component and provided with circular arc cambers or sliding grooves, the third roller can be attached to the circular arc cambers in a rolling mode, and the limit pins can be matched in the sliding grooves in a sliding mode. The valve mechanism can achieve secondary opening of the valve, can lengthen the opening lasting time of the valve, and is simple in structure, and low in influence on the height of the engine.

Owner:GREAT WALL MOTOR CO LTD

Valve mechanism for engine and vehicle with same

ActiveCN103758603ALittle impact on altitudeGuaranteed uptimeValve arrangementsMachines/enginesEngineeringCam

The invention discloses a valve mechanism for an engine and a vehicle with the same. The valve mechanism comprises a valve gear, a rocker arm assembly, a first roller, a second roller, a cam shaft, a connecting arm and a phase adjusting mechanism. The bottom of the rocker arm assembly is provided with a driving type face which is directly in contact with the top of a valve of the valve gear to drive the valve to move. The first roller and the second roller can both be arranged on the rocker arm assembly in a pivoted mode. The cam shaft comprises an inner shaft and an outer shaft which are coaxially arranged, the inner shaft and the outer shaft are provided with an inner shaft cam and an outer shaft cam which rotate along corresponding shafts respectively, the outer shaft cam abuts against the first roller, and the inner shaft cam abuts against the second roller. The first end of the connecting arm is connected with the rocker arm in a pivoted mode, and the second end of the connecting arm is arranged on an engine body set of the engine in a pivoted mode. The phase adjusting mechanism is used for adjusting the relative phase of the inner shaft and the outer shaft. The valve mechanism for the engine can achieve secondary opening of the valve, meanwhile, the duration time of opening of the valve can also be prolonged, the structure is simple and compact, and the influence on the height of the engine is small.

Owner:GREAT WALL MOTOR CO LTD

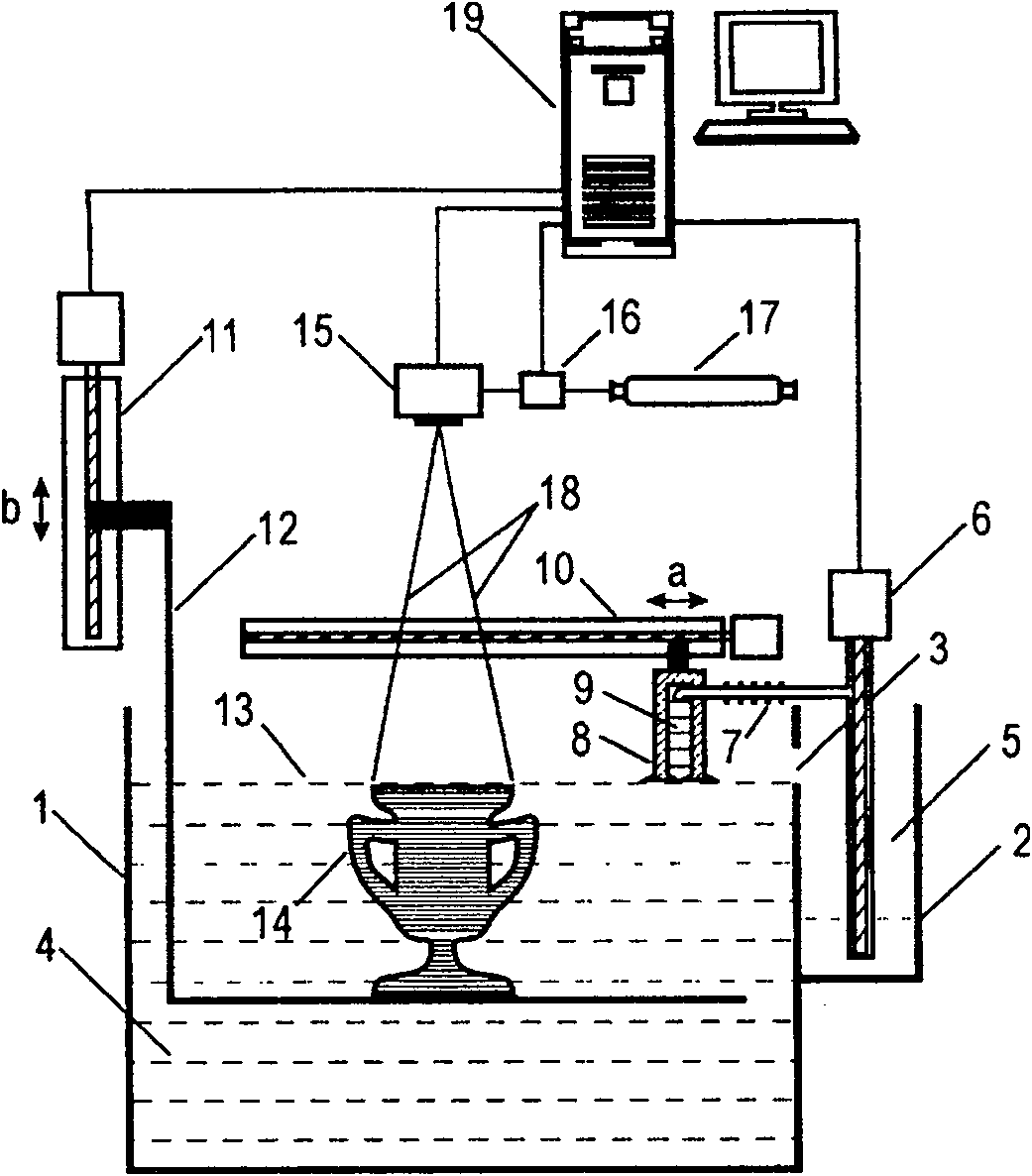

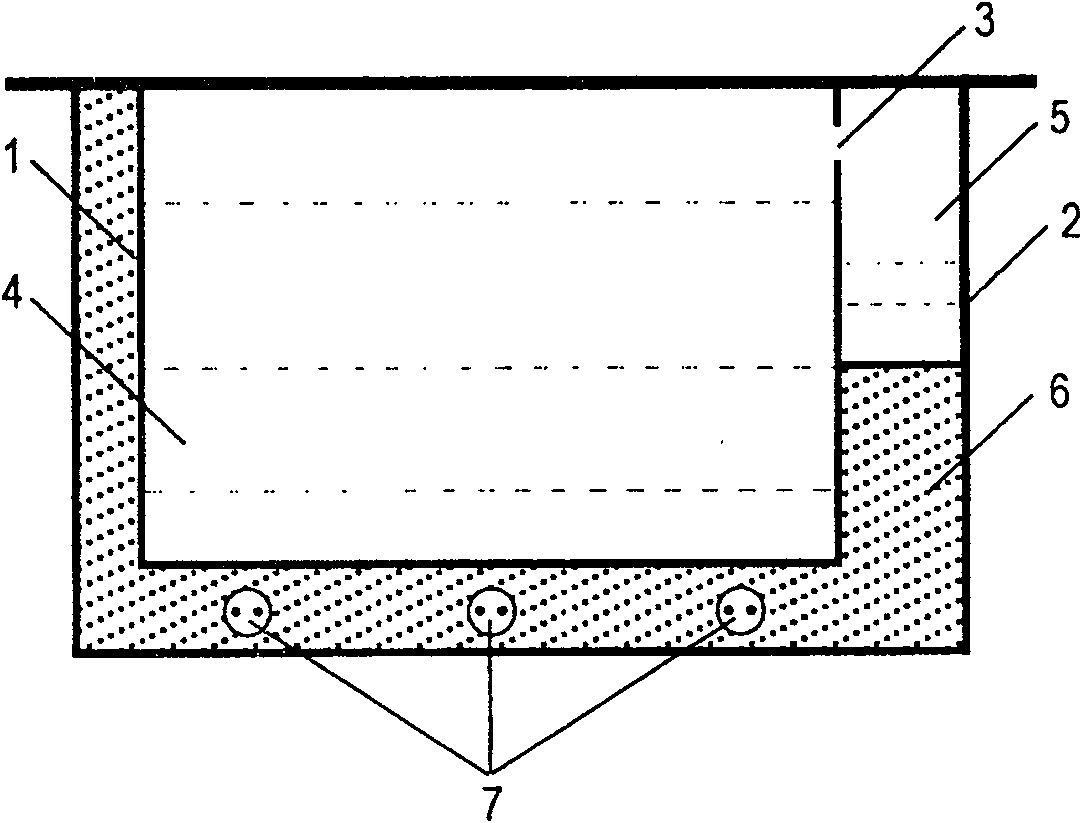

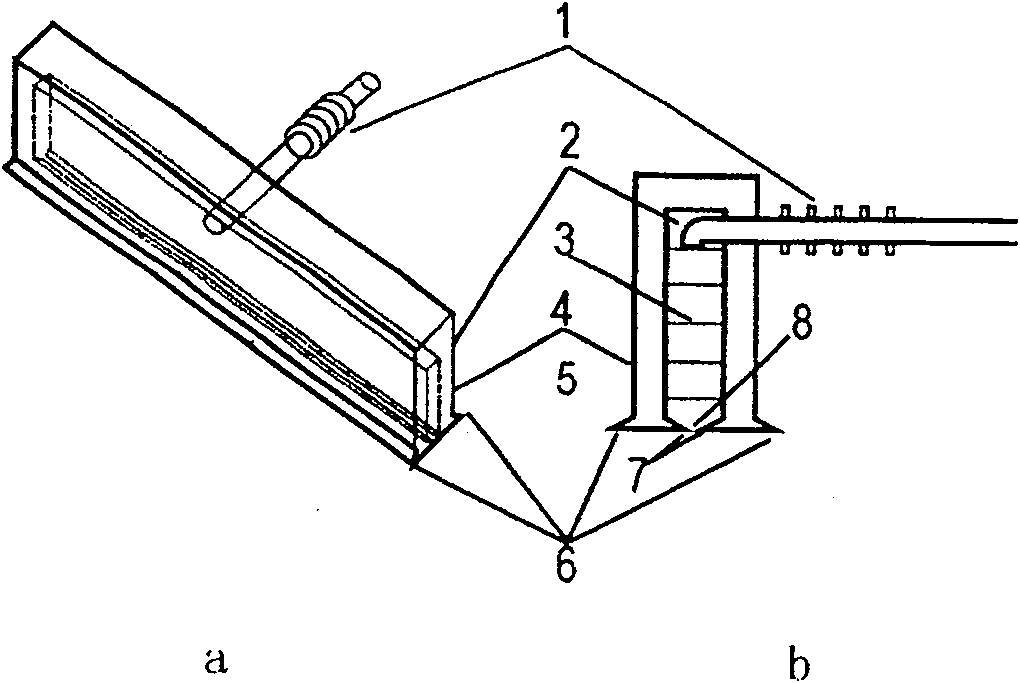

Resin liquid-level control for photo-solidification quick formation and resin coating method and apparatus

Owner:GUANGZHOU ELECTRONICS TECH

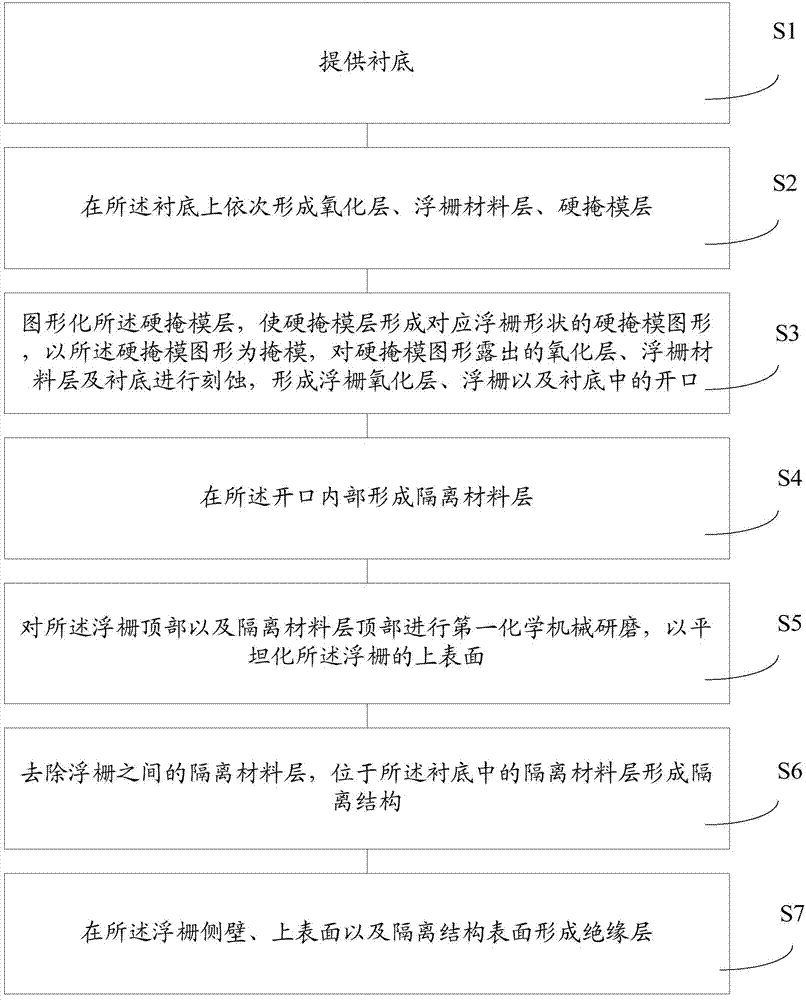

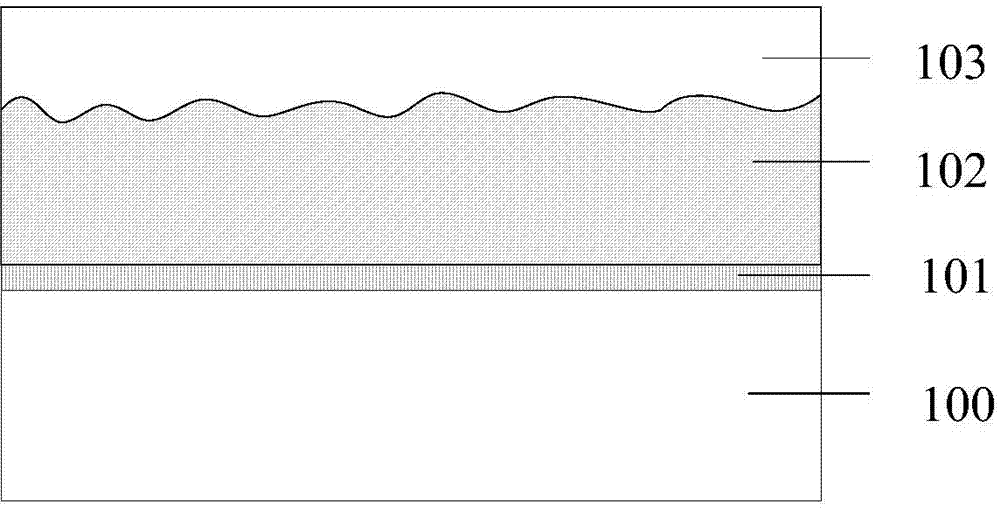

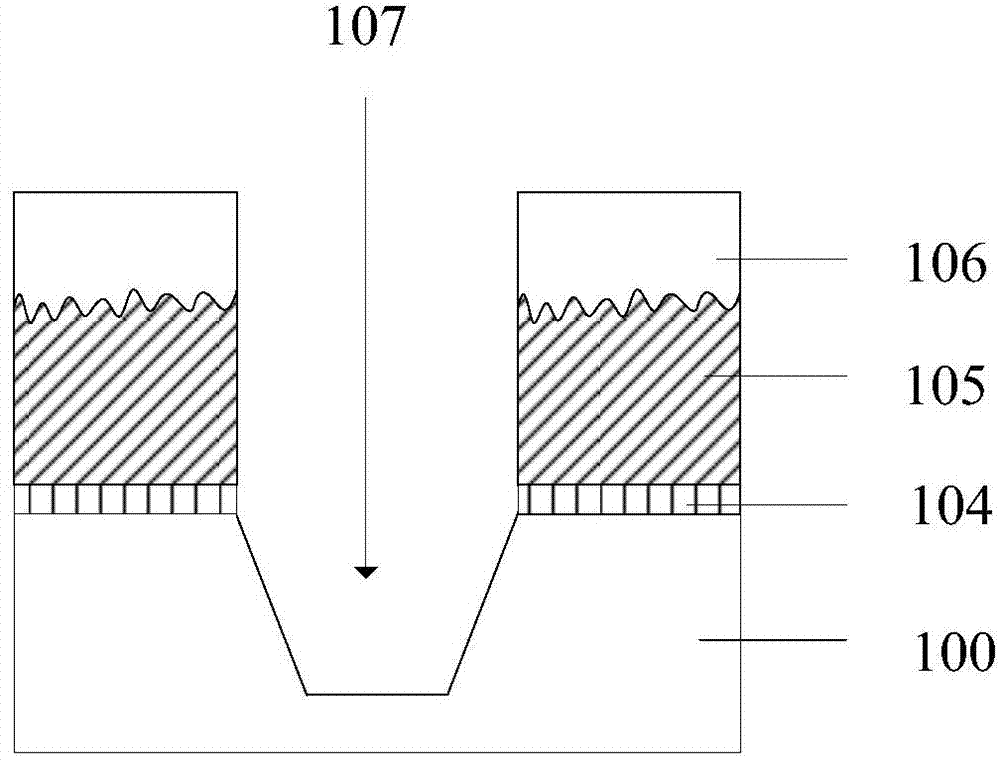

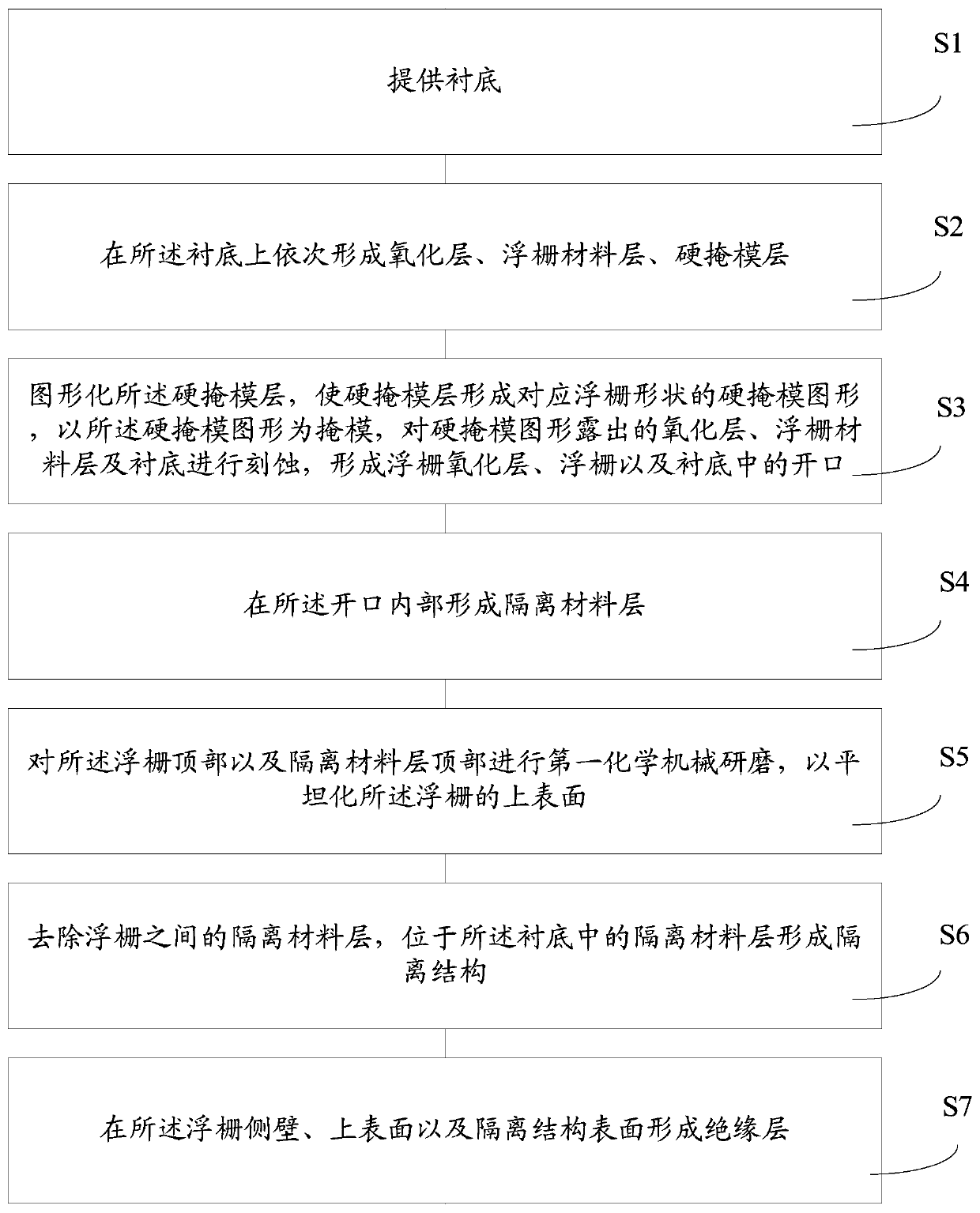

Forming method of storage

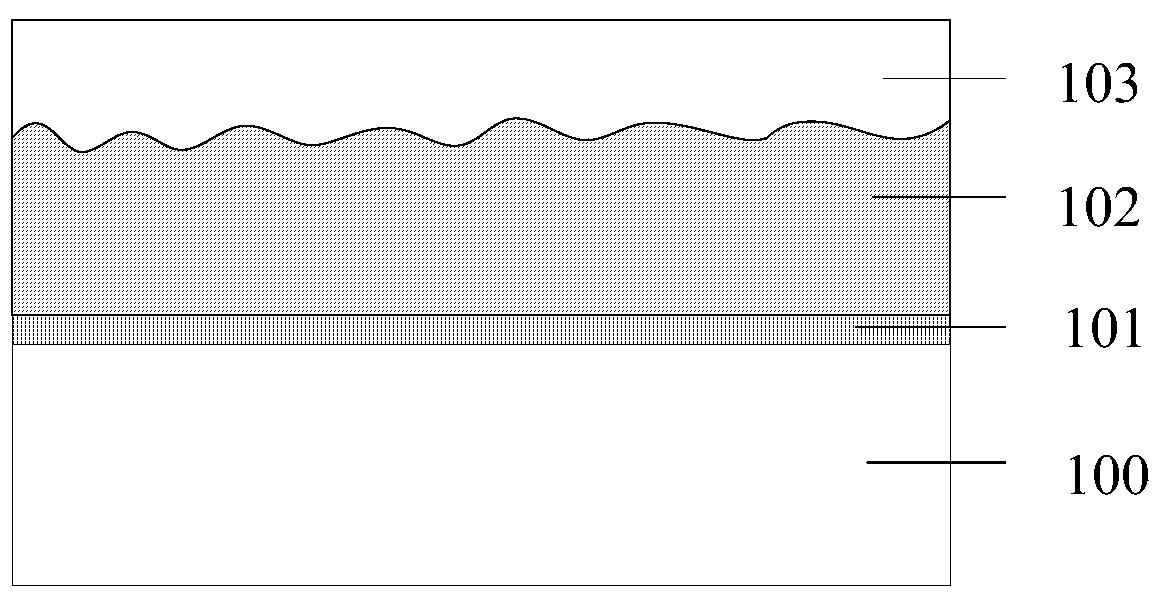

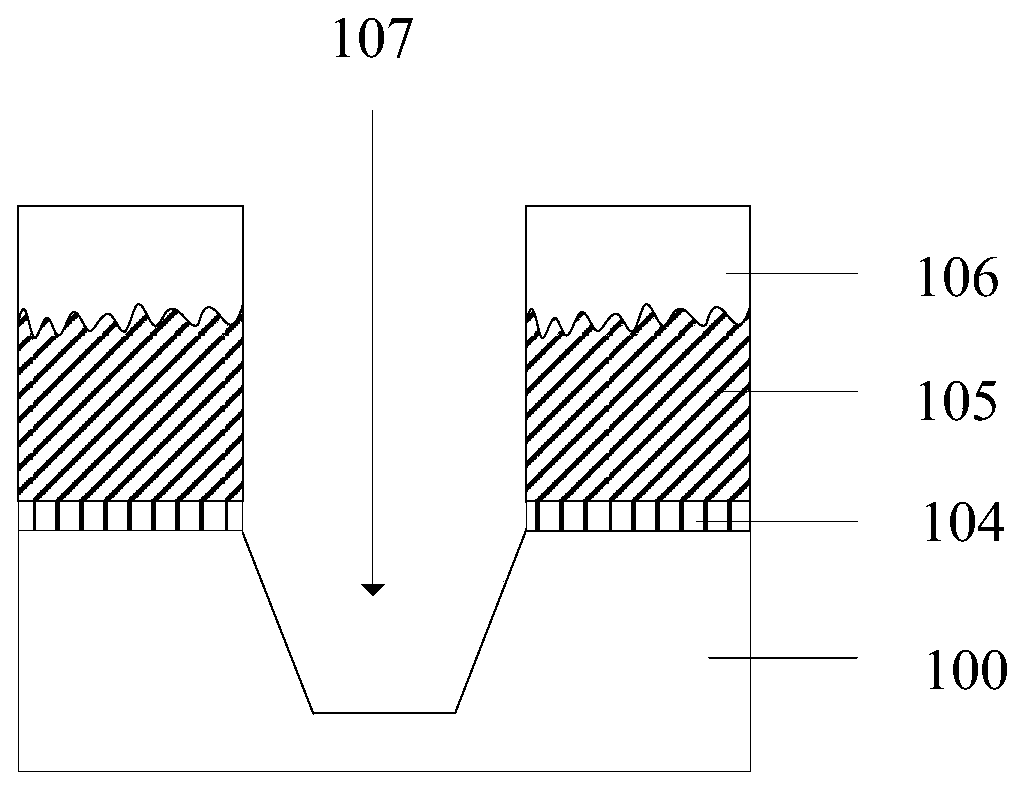

ActiveCN104752362AIncreased ability to hold chargeUniform thicknessSemiconductor/solid-state device manufacturingElectric fieldSurface flatness

The invention provides a forming method of a storage. The forming method includes providing a substrate; forming a floating gate material layer on the substrate; imaging the floating gate material layer and the substrate, and forming floating gates on the substrate and an opening formed in the substrate positioned between the floating gates; forming an isolation material layer in the opening; performing first chemical and mechanical lapping on the tops of the floating gates and the top of the isolation material layer, to planarize the upper surfaces of the floating fates; removing the isolation material layer between the gloating gates, thus allowing the isolation material layer in the substrate to form an isolation structure; forming an insulating layer on the side walls and upper surfaces of the floating gate and the surface of the isolation structure. As the upper surfaces of the floating gates are high in evenness, the insulating layer formed on the upper surfaces of the floating gates are uniform in thickness, sand thereby the local electric field intensity adjacent to the insulating layer is close to the electric field intensity of other areas, and the electric charge maintaining capacity of the floating gates can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Gas distributing mechanism for engine and car with same

ActiveCN103758604ALittle impact on altitudeRealize the second openingValve arrangementsMachines/enginesCamRocker arm

The invention discloses a gas distributing mechanism for an engine and a car with the gas distributing mechanism. The gas distributing mechanism comprises a valve mechanism, a rocker arm assembly, a first roller, a second roller, a cam shaft, a bearing structure, a phase adjusting mechanism, and a third roller or a limiting pin. A driving molded surface is constructed at the bottom of the rocker arm assembly and is suitable for driving a valve to move, the first roller and the second roller can be arranged on the rocker arm assembly in a pivoted mode, the cam shaft comprises an inner shaft and an outer shaft, the inner shaft and the outer shaft are coaxially arranged, an inner shaft cam and an outer shaft cam which rotate along with the corresponding shafts are arranged on the inner shaft and the outer shaft respectively, the outer shaft cam abuts against the first roller, the inner shaft cam abuts against the second roller, the phase adjusting mechanism is used for adjusting the relative phase of the inner shaft and the outer shaft, a circular-arc curved surface or a sliding groove is formed in the bearing structure, the third roller can be tightly attached to the circular-arc curved surface in a rolling mode, and the limiting pin can be arranged in the sliding groove in a sliding and matching mode. The gas distributing mechanism can achieve secondary opening of the valve, the continuous opening time of the valve can be prolonged at the same time, the structure is simple and compact, and the influence on the height of the engine is small.

Owner:GREAT WALL MOTOR CO LTD

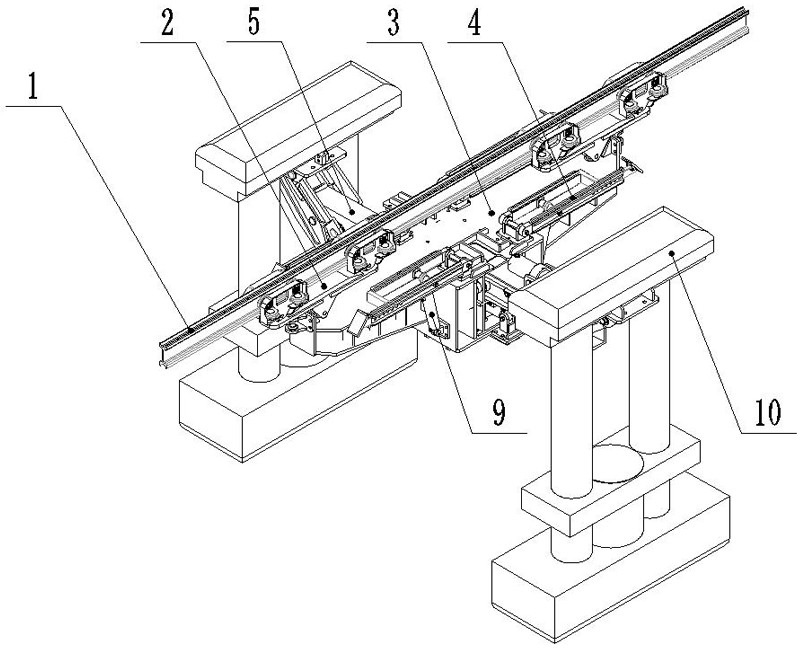

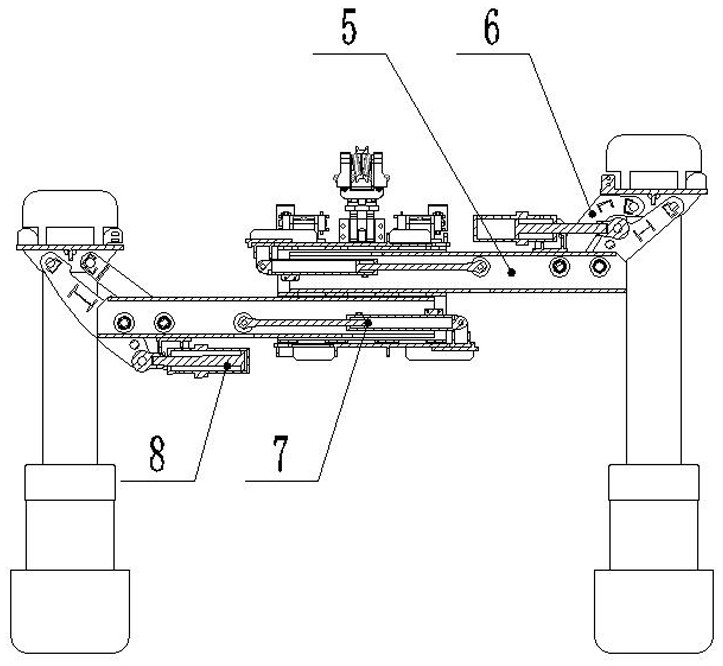

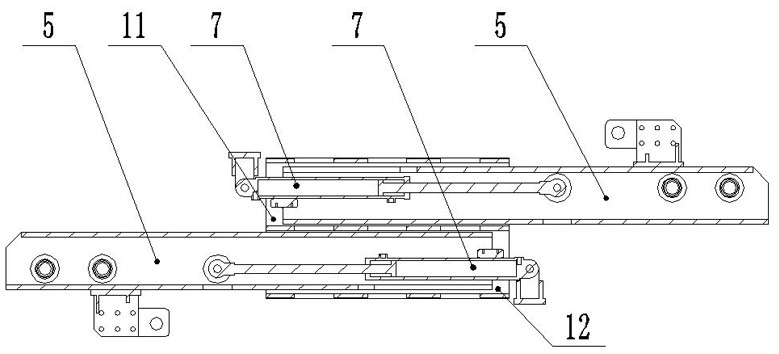

A telescopic lifting beam used for monorail locomotive in coal mine

ActiveCN114348868BIncrease guide lengthStable and safe situationTravelling gearTrolleysMining engineeringWorking environment

A telescopic lifting beam used for a coal mine monorail locomotive belongs to the technical field of coal mine machinery and solves the technical problems of transporting and placing stacked supports. The device includes a load-bearing beam, a load-carrying trolley and a telescopic arm. The direction of the upper chute and the lower chute are set respectively, and the upper chute and the lower chute are set as one-sided openings. The opening ends of the upper chute and the lower chute are in opposite directions. The end of the free end of the telescopic arm is provided with an overturn cylinder along the horizontal direction, and the overturn cylinder drives the overturn mechanism to rotate around the hinge position; Retract; the top support cylinder drives the top support mechanism to rotate around the root. The present invention adopts a unique hoisting method inside the frame of the stacked bracket, fully utilizes the stretching stroke of the stacked bracket itself, and can adapt to the harsh working environment under the mine.

Owner:TAIYUAN KUANGJI ELECTRIC

Method of forming memory

ActiveCN104752362BIncreased ability to hold chargeUniform thicknessSolid-state devicesSemiconductor devicesElectrical field strengthEngineering

The invention provides a method for forming a memory, including providing a substrate; forming a floating gate material layer on the substrate; patterning the floating gate material layer and the substrate, forming a floating gate on the substrate and a floating an opening in the substrate between the gates; forming an isolation material layer inside the opening; performing a first chemical mechanical polishing on the top of the floating gate and the top of the isolation material layer to planarize the upper surface of the floating gate; removing The isolation material layer between the floating gates, the isolation material layer in the substrate forms an isolation structure; an insulating layer is formed on the side wall, upper surface and surface of the isolation structure of the floating gate. Due to the high flatness of the upper surface of the floating gate, the thickness of the insulating layer formed on the upper surface of the floating gate is uniform, so that the local electric field strength near the insulating layer is close to that of other regions, which can improve the ability of the floating gate to hold charges.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Valve train for engine and vehicle with same

ActiveCN103758602BLittle impact on altitudeGuaranteed uptimeValve arrangementsMachines/enginesEngineeringCam

The invention discloses a valve mechanism for an engine and a vehicle with the same. The valve mechanism comprises a vale gear, a rocker arm assembly, a first roller, a second roller, a cam shaft, a connecting arm and a phase adjusting mechanism. The bottom of the rocker arm assembly is provided with a driving type face which is directly in contact with the top of a valve to drive the valve of the valve gear to move. The first roller and the second roller can both be arranged on the rocker arm assembly in a pivoted mode. The cam shaft comprises an inner shaft and an outer shaft which are coaxially arranged, the inner shaft and the outer shaft are provided with an inner shaft cam and an outer shaft cam which can rotate along with corresponding shafts respectively, the outer shaft cam abuts against the first roller, and the inner shaft cam abuts against the second roller. The connecting arm is placed on the two sides of the rocker arm assembly respectively, the first end of the connecting arm is connected with the rocker arm assembly in a pivoted mode, and the second end of the connecting arm is arranged on an engine body set of the engine in a pivoted mode. The phase adjusting mechanism is used for adjusting the relative phase of the inner shaft and the outer shaft. The valve mechanism for the engine can achieve secondary opening of the valve, meanwhile, the duration time of opening of the valve can further be prolonged, the structure is simple and compact, and the influence on the height of the engine is small.

Owner:GREAT WALL MOTOR CO LTD

A high-efficiency electrostatic protection component of disc type tvs tube for bridge wire electric detonator

InactiveCN104390532BImprove electrostatic protection abilityLittle impact on altitudeAmmunition fuzesDetonatorEngineering

The invention relates to a disc-type TVS tube high-efficiency electrostatic protection assembly for a bridge-wire type electric detonator, which comprises a disc-shaped PCB circuit board and two TVS tube electrostatic protection electronic devices. One of the TVS tubes is connected in parallel with the pin-pin firing circuit through the circuit board, and the other TVS tube is connected in parallel with the pin-shell firing circuit through the circuit board. Two zigzag discharge electrodes are arranged on the reverse side of the PCB circuit board, and form the air gap electrostatic discharge channel between the feet and the shell with the inner wall of the metal tube shell. . The electrostatic protection component of the present invention can protect both the foot-shell and the foot-foot to achieve an anti-static effect of more than 50kV on the human body, and can withstand multiple impacts of electrostatic discharge without any performance change.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Valve train for engine and vehicle having same

ActiveCN103758604BLittle impact on altitudeRealize the second openingValve arrangementsMachines/enginesEngineeringCam

The invention discloses a gas distributing mechanism for an engine and a car with the gas distributing mechanism. The gas distributing mechanism comprises a valve mechanism, a rocker arm assembly, a first roller, a second roller, a cam shaft, a bearing structure, a phase adjusting mechanism, and a third roller or a limiting pin. A driving molded surface is constructed at the bottom of the rocker arm assembly and is suitable for driving a valve to move, the first roller and the second roller can be arranged on the rocker arm assembly in a pivoted mode, the cam shaft comprises an inner shaft and an outer shaft, the inner shaft and the outer shaft are coaxially arranged, an inner shaft cam and an outer shaft cam which rotate along with the corresponding shafts are arranged on the inner shaft and the outer shaft respectively, the outer shaft cam abuts against the first roller, the inner shaft cam abuts against the second roller, the phase adjusting mechanism is used for adjusting the relative phase of the inner shaft and the outer shaft, a circular-arc curved surface or a sliding groove is formed in the bearing structure, the third roller can be tightly attached to the circular-arc curved surface in a rolling mode, and the limiting pin can be arranged in the sliding groove in a sliding and matching mode. The gas distributing mechanism can achieve secondary opening of the valve, the continuous opening time of the valve can be prolonged at the same time, the structure is simple and compact, and the influence on the height of the engine is small.

Owner:GREAT WALL MOTOR CO LTD

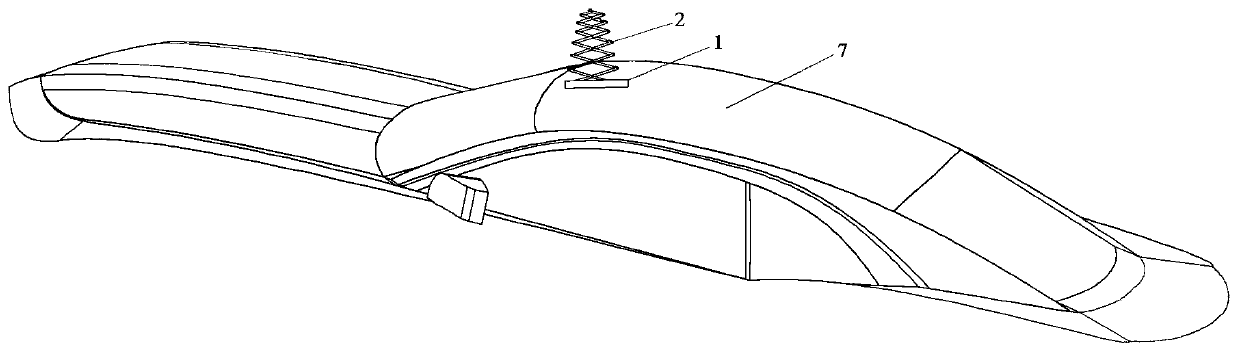

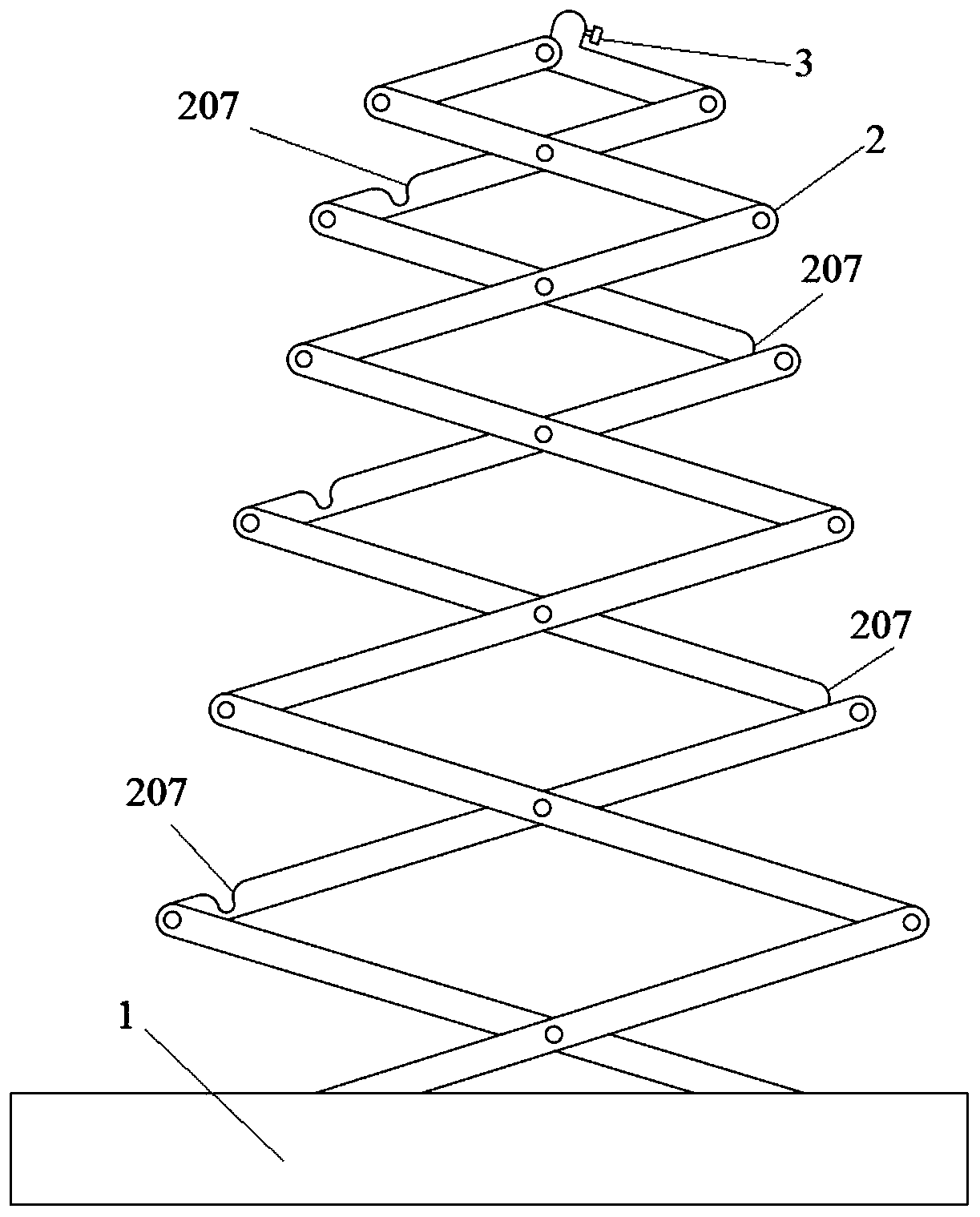

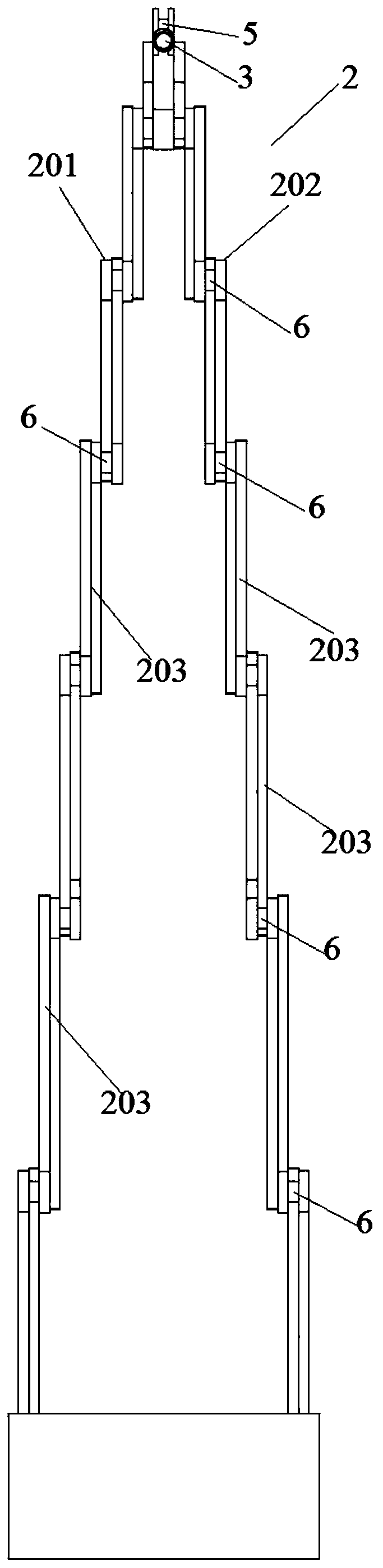

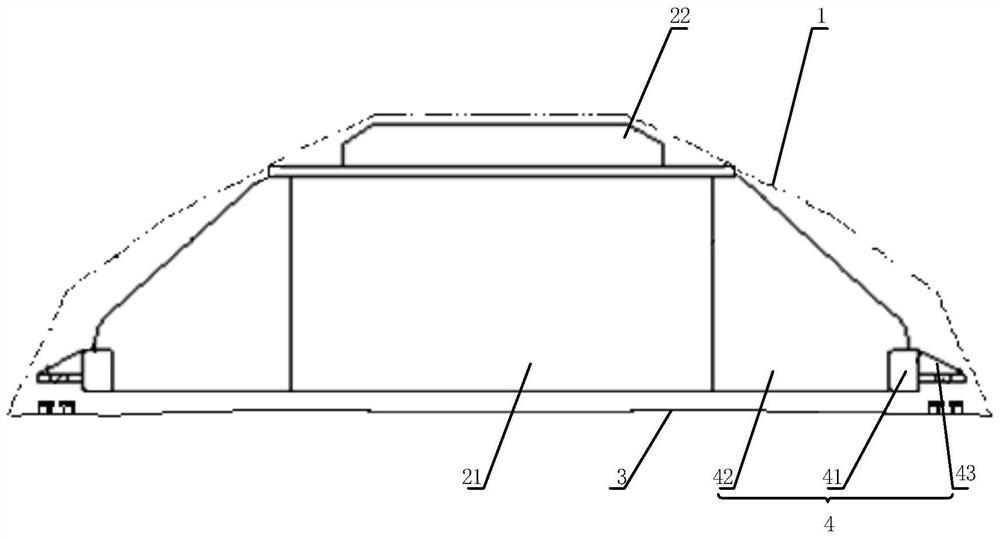

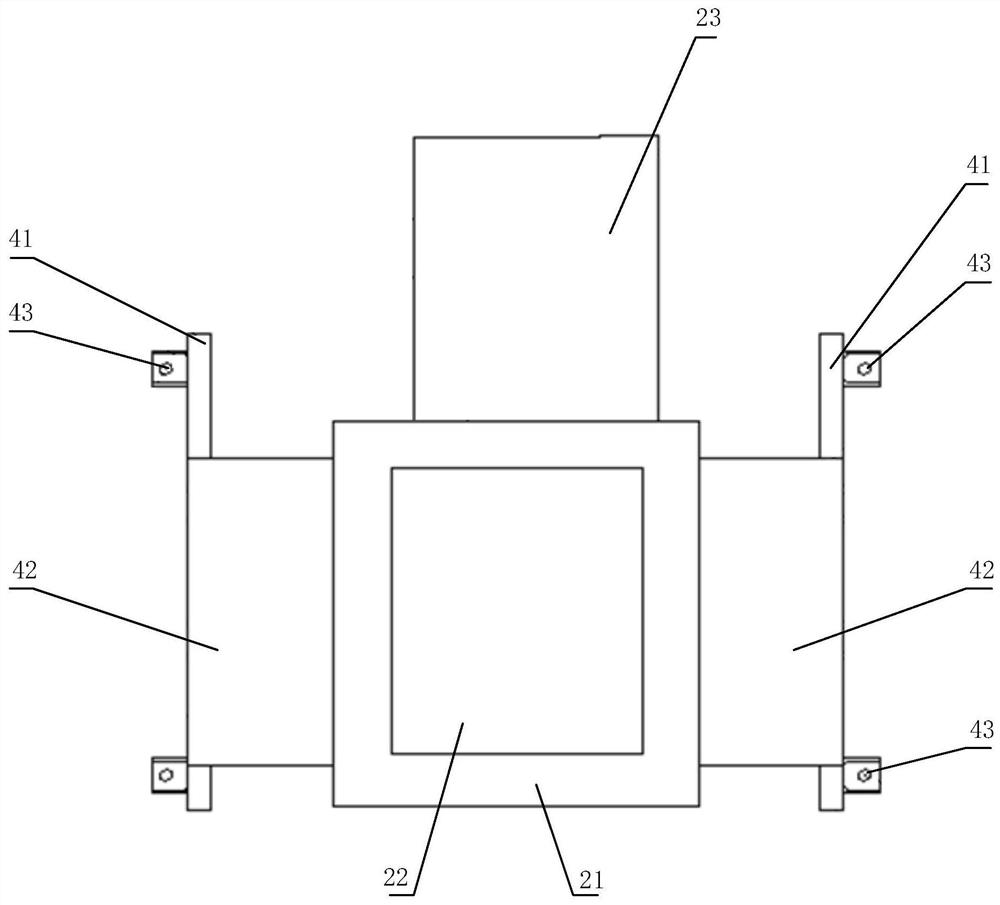

Lifting camera assembly for safe driving of vehicle

InactiveCN111469775AWide field of visionExtended reaction timeVehicle componentsElectric machineryStructural engineering

The invention discloses a lifting camera assembly for safe driving of a vehicle, and relates to the technical field of safe driving of vehicles. The lifting camera assembly comprises a box body and alifting frame, wherein a motor is fixed on the inner side of the box body; a threaded column is fixed on the motor; a T-shaped column is fixed on the box body; the lifting frame comprises a hinge frame A and a hinge frame B; the hinge frame A and the hinge frame B are formed by hinging connecting rods with different lengths end to end; a connecting hole is formed in the connecting rod; the hinge frame A is hinged with the hinge frame B; the bottom of the hinge frame A is hinged with the T-shaped column; a connecting shaft is arranged between the two hinge frames B in a rotationally matched manner; a moving block is arranged between the two connecting shafts in a rotationally matched manner; the moving block is in threaded connection with the threaded column; and a micro camera is arrangedon the lifting frame. Under the action of the box body, the lifting frame, the motor and the micro camera, the property loss of people is greatly reduced, the accident damage degree can be greatly reduced through the increased reaction time, and the death rate in an accident is also greatly reduced to a certain extent.

Owner:合肥森印科技有限公司

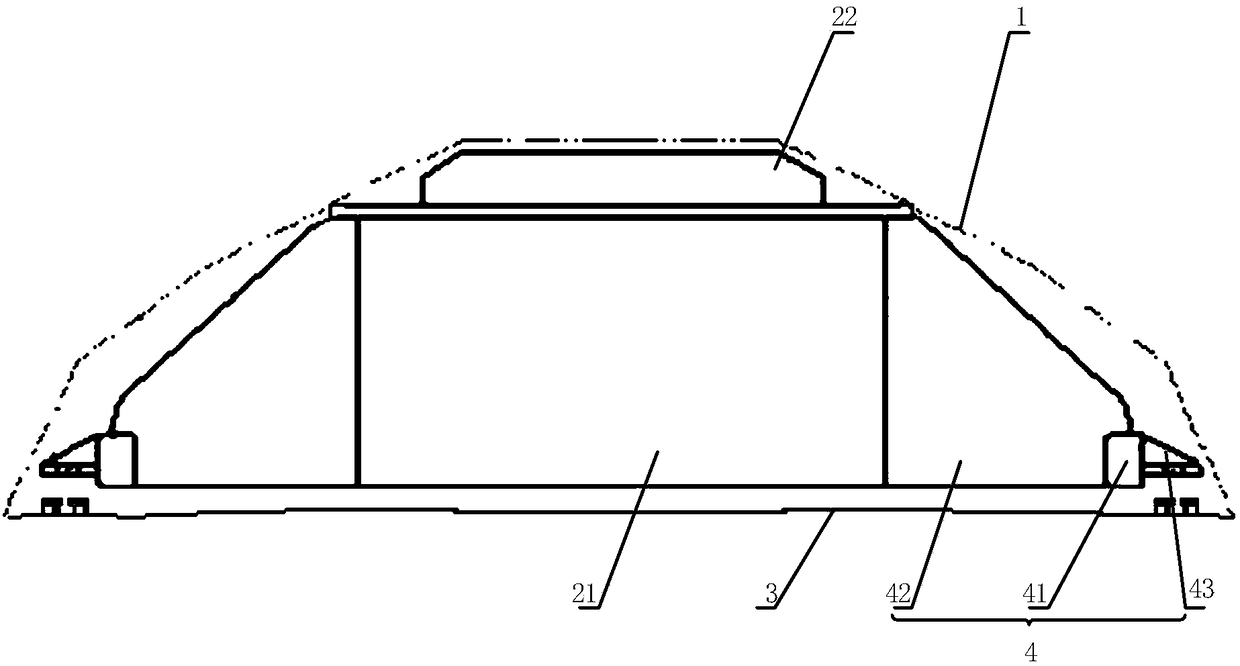

a rail vehicle

ActiveCN109036783BLow failure rateHigh working reliabilityTransformers/reacts mounting/support/suspensionTransformers/inductances coolingTraction transformerControl theory

The invention discloses a rail transit vehicle, which comprises a car body and a traction transformer. The traction transformer is fixed on the top of the car body, and the outer contour of the traction transformer is located in the contour line of the roof protruding away from the bottom surface of the car body. The traction transformer Installed on the top of the car body, and at the same time ensure that the outer contour of the traction transformer is within the contour line of the roof, it is not only beneficial to a certain extent to prevent the traction transformer from being damaged by pollution, blockage and scratches, so as to improve the use by reducing the failure rate service life, to improve the reliability of rail transit vehicles; and it is beneficial to reduce the height of the bottom surface of the vehicle body from the ground, avoiding the addition of a higher platform, and weakening the influence of the height of the platform, which is conducive to improving its adaptability. Therefore, the rail transit vehicle provided by the present invention is conducive to improving its working reliability and adaptability.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

A high-efficiency electrostatic protection component of a disc varistor for a bridge wire type electric detonator

InactiveCN104330001BImprove electrostatic protection abilityLittle impact on altitudeAmmunition fuzesDetonatorElectrical resistance and conductance

The invention relates to a high-effect electrostatic protective component of a disk type voltage dependent resistor for a bridge-wire electric detonator. The high-effect electrostatic protective component comprises a disk type PCB and two voltage dependent resistor electrostatic protective electronic devices, wherein one voltage dependent resistor is connected with a pin-pin ignition loop in parallel via a circuit board, and the other voltage dependent resistor is connected with a pin-shell ignition loop in parallel via a circuit board; two sawtooth-shaped discharge electrodes are configured at the reverse side of the PCB, and form a pin-shell air gap electrostatic discharge channel together with the inner wall of a metal tube shell; the sawtooth-shaped discharge electrodes and the electrostatic protective devices are connected in parallel to form a double-insurance effect with pin-shell electrostatic protection. The pin-shell protection effect of the electrostatic protective component achieves the human body static electricity resistance above 50kV; the pin-pin protection effect achieves the human body static electricity resistance above 30kV, and can withstand multiple times of impact by electrostatic discharge without any capability change.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Valve train for engine and vehicle having same

ActiveCN103775159BLittle impact on altitudeGuaranteed uptimeValve arrangementsMachines/enginesRelative phaseEngineering

The invention discloses an air distribution mechanism for an engine and a vehicle with the same. The distribution mechanism comprises an air valve mechanism, a rocker arm assembly, a camshaft, a first roller, a second roller, a connecting arm and a phase adjusting mechanism, wherein the bottom of the rocker arm assembly is provided with a driving molded surface which is suitable for driving an air valve of the air valve mechanism to move along the direction which is parallel to the central line of the air valve; the first roller and the second roller are respectively arranged on the rocker arm assembly in a pivoting manner; the camshaft comprises an inner shaft and an outer shaft, which are coaxial with each other, the inner shaft and the outer shaft are respectively provided with an inner shaft cam and an outer shaft cam, which can rotate along with the corresponding shaft, the outer shaft cam pushes against the first roller, and the inner shaft cam pushes against the second roller; a first end of the connecting arm is connected with the rocker arm assembly in a pivoting manner, and a second end of the connecting arm is arranged on to a body group of the engine in a pivoting manner; the phase adjusting mechanism is used for adjusting the relative phase of the inner shaft and the outer shaft. By adopting the air distribution mechanism, the secondary opening of the air valve can be realized; meanwhile, the opening duration of the air valve can be prolonged; moreover, the structure is simple and compact, and the influence on the height of the engine is small.

Owner:GREAT WALL MOTOR CO LTD

Valve train for engine and vehicle having same

ActiveCN103758603BLittle impact on altitudeGuaranteed uptimeValve arrangementsMachines/enginesEngineeringCam

The invention discloses a valve mechanism for an engine and a vehicle with the same. The valve mechanism comprises a valve gear, a rocker arm assembly, a first roller, a second roller, a cam shaft, a connecting arm and a phase adjusting mechanism. The bottom of the rocker arm assembly is provided with a driving type face which is directly in contact with the top of a valve of the valve gear to drive the valve to move. The first roller and the second roller can both be arranged on the rocker arm assembly in a pivoted mode. The cam shaft comprises an inner shaft and an outer shaft which are coaxially arranged, the inner shaft and the outer shaft are provided with an inner shaft cam and an outer shaft cam which rotate along corresponding shafts respectively, the outer shaft cam abuts against the first roller, and the inner shaft cam abuts against the second roller. The first end of the connecting arm is connected with the rocker arm in a pivoted mode, and the second end of the connecting arm is arranged on an engine body set of the engine in a pivoted mode. The phase adjusting mechanism is used for adjusting the relative phase of the inner shaft and the outer shaft. The valve mechanism for the engine can achieve secondary opening of the valve, meanwhile, the duration time of opening of the valve can also be prolonged, the structure is simple and compact, and the influence on the height of the engine is small.

Owner:GREAT WALL MOTOR CO LTD

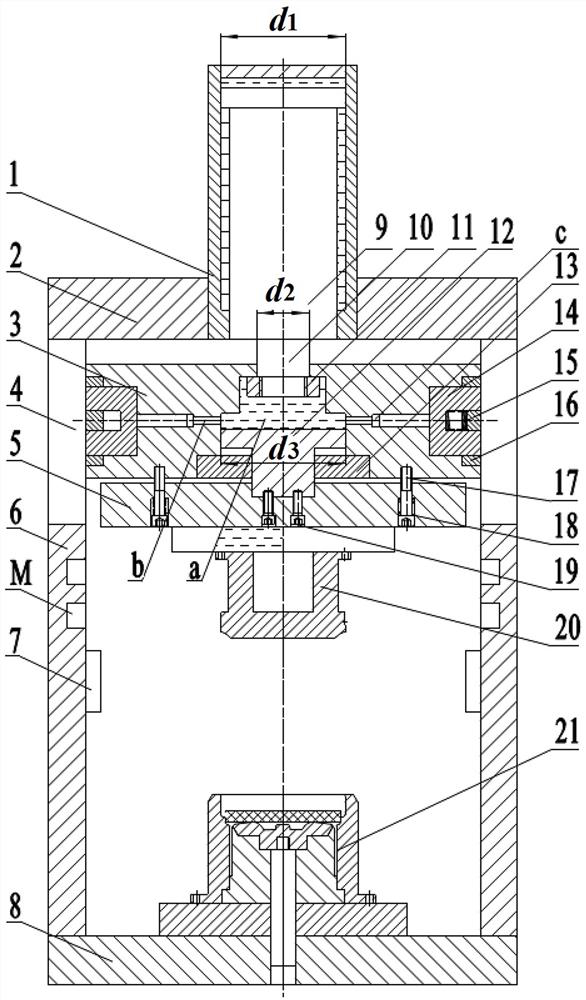

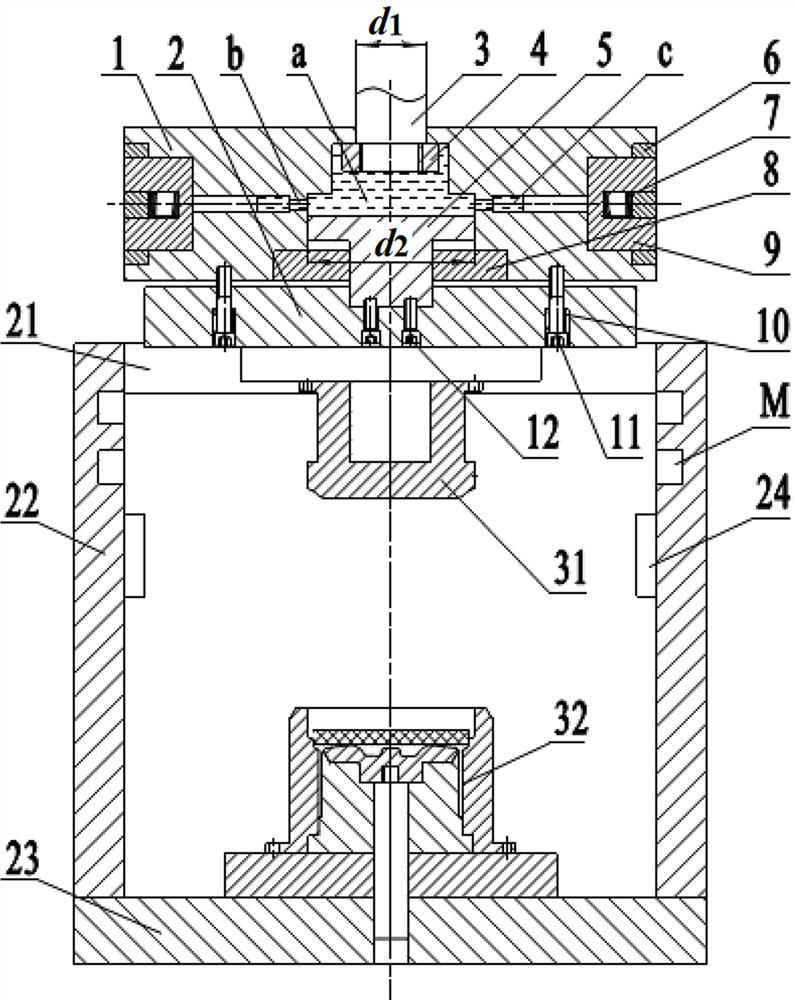

Hydraulic machine with hydraulic pressurizing mechanism

PendingCN113202831AMeet the needs of formingQuick opening and closing strokeMetal-working apparatusFluid-pressure convertersHydraulic cylinderWorking pressure

A hydraulic machine with a hydraulic pressurizing mechanism comprises a main hydraulic cylinder, a pressurizing cylinder and a locking mechanism used for limiting the position of a cylinder body of the pressurizing cylinder, and the main hydraulic cylinder provides a power source; the pressurizing cylinder is driven by power of the main hydraulic cylinder, after the main hydraulic cylinder drives the pressurizing cylinder to move by a certain stroke, the locking mechanism restrains and fixes the position of a cylinder body of the pressurizing cylinder, the power end of the main hydraulic cylinder provides power for the pressurizing cylinder, pressure is transmitted through a pressure transmitting medium in the pressurizing cylinder, power output of the pressurizing cylinder is achieved, and the hydraulic machine generates pressurizing action. By optimizing the structural composition of the pressurizing mechanism, the hydraulic machine can generate large working pressure and has a large rapid mold opening and closing stroke so as to meet the requirement for extrusion forming of large metal parts.

Owner:HENAN UNIV OF SCI & TECH

A hydraulic pressure booster

ActiveCN113210555BPressure magnificationHigh work pressureForging/hammering/pressing machinesForging press drivesEngineeringPiston

A hydraulic pressurizing mechanism, the pressurizing mechanism comprises a pressurizing plate and a lateral locking mechanism for locking the position of the pressurizing plate, the pressurizing plate has a combined hydraulic chamber, and the combined hydraulic chamber is in the combined hydraulic chamber From top to bottom in the vertical direction, there are a small-diameter pressure chamber and a large-diameter pressurization chamber in sequence. and has a protruding end, the protruding end is used for connecting with the movable beam of the press; the pressurizing chamber is slidably fitted with a pressurizing piston, and the lower end of the pressurizing piston passes through the pressurizing plate and is connected to the pressing piece. In this scheme, without changing the overall structure of the press, the pressurizing mechanism can be directly matched to the press, which can amplify the pressure of the equipment and greatly increase the forming force. Large metal parts are formed on smaller hydraulic presses.

Owner:HENAN UNIV OF SCI & TECH

A rail transit vehicle

ActiveCN109036783AReduce pollutionReduce cloggingTransformers/reacts mounting/support/suspensionTransformers/inductances coolingFailure rateTraction transformer

A rail transit vehicle including car body and traction transformer, the traction transformer is fixed on the top of the vehicle body and the outer contour of the traction transformer is located in theroof contour line protruding in a direction away from the bottom surface of the vehicle body, Setting the traction transformer at the top of the car body and ensuring that the outer contour of the traction transformer is located in the contour line of the car roof is not only beneficial to avoiding the damage of pollution, blockage and scratch of the traction transformer to a certain extent, butalso prolongs the service life by reducing the failure rate and improves the working reliability of the rail transit vehicles. But also helps to reduce the height of the bottom surface of the car bodyfrom the ground, avoid adding a higher platform, and weaken the influence of the platform height, so as to improve its adaptability. Therefore, the rail transit vehicle provided by the invention is conducive to improving its working reliability and adaptability.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

Air distribution mechanism for engine and vehicle with same

ActiveCN103775159ALittle impact on altitudeGuaranteed uptimeValve arrangementsMachines/enginesRelative phaseEngineering

The invention discloses an air distribution mechanism for an engine and a vehicle with the same. The distribution mechanism comprises an air valve mechanism, a rocker arm assembly, a camshaft, a first roller, a second roller, a connecting arm and a phase adjusting mechanism, wherein the bottom of the rocker arm assembly is provided with a driving molded surface which is suitable for driving an air valve of the air valve mechanism to move along the direction which is parallel to the central line of the air valve; the first roller and the second roller are respectively arranged on the rocker arm assembly in a pivoting manner; the camshaft comprises an inner shaft and an outer shaft, which are coaxial with each other, the inner shaft and the outer shaft are respectively provided with an inner shaft cam and an outer shaft cam, which can rotate along with the corresponding shaft, the outer shaft cam pushes against the first roller, and the inner shaft cam pushes against the second roller; a first end of the connecting arm is connected with the rocker arm assembly in a pivoting manner, and a second end of the connecting arm is arranged on to a body group of the engine in a pivoting manner; the phase adjusting mechanism is used for adjusting the relative phase of the inner shaft and the outer shaft. By adopting the air distribution mechanism, the secondary opening of the air valve can be realized; meanwhile, the opening duration of the air valve can be prolonged; moreover, the structure is simple and compact, and the influence on the height of the engine is small.

Owner:GREAT WALL MOTOR CO LTD

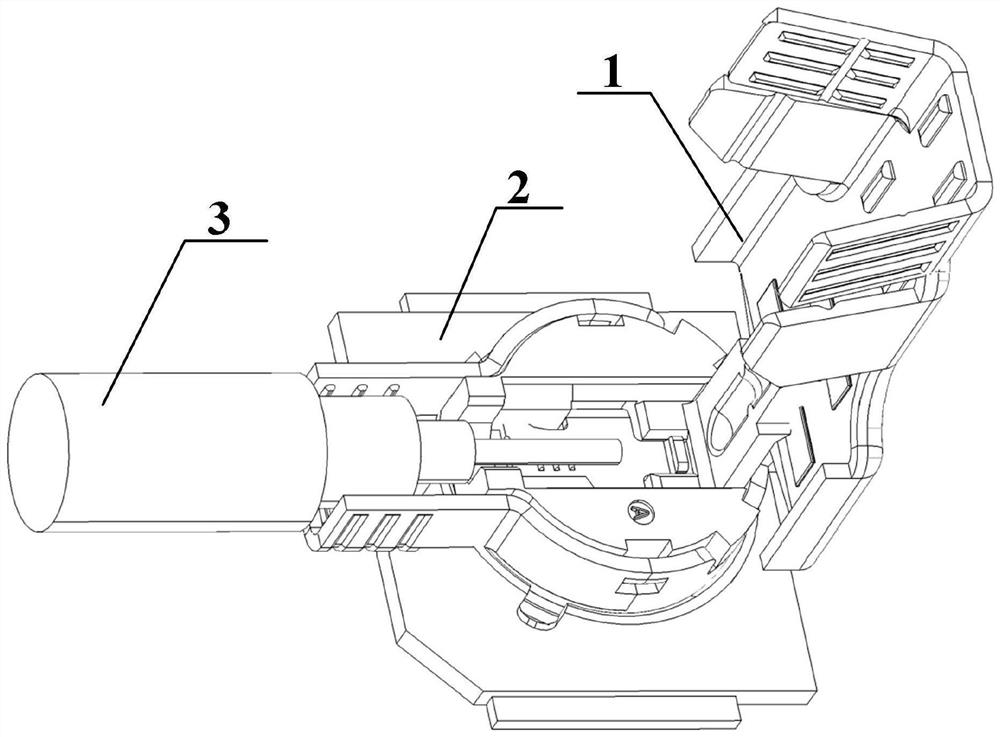

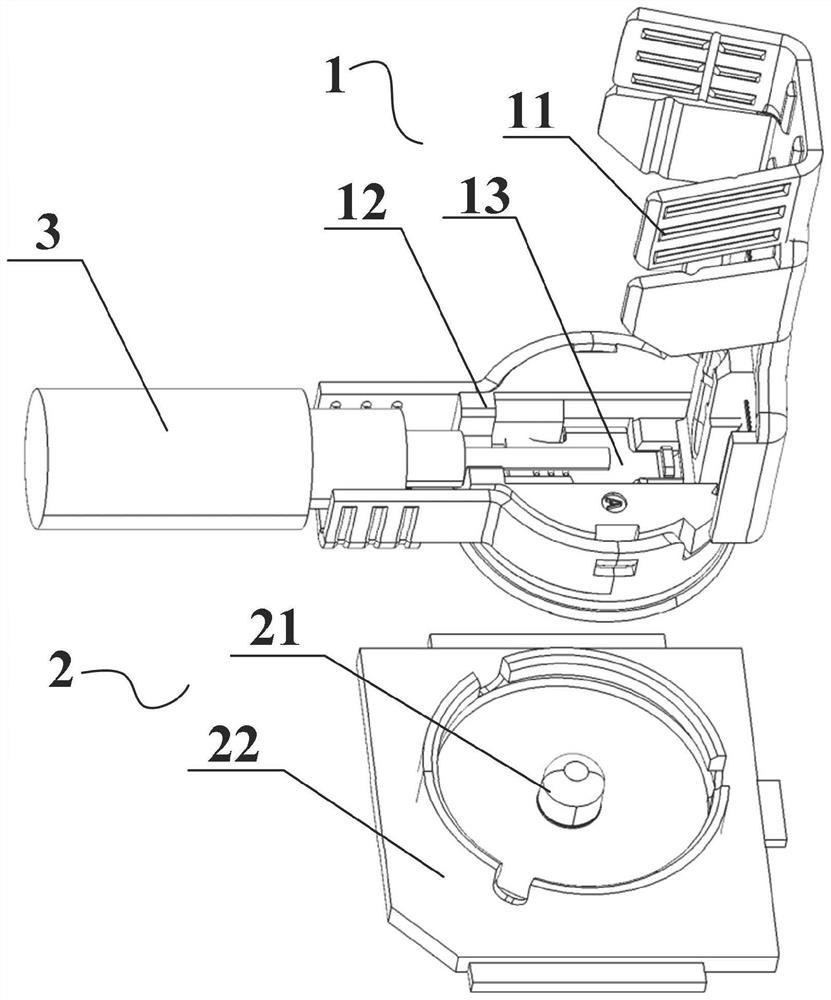

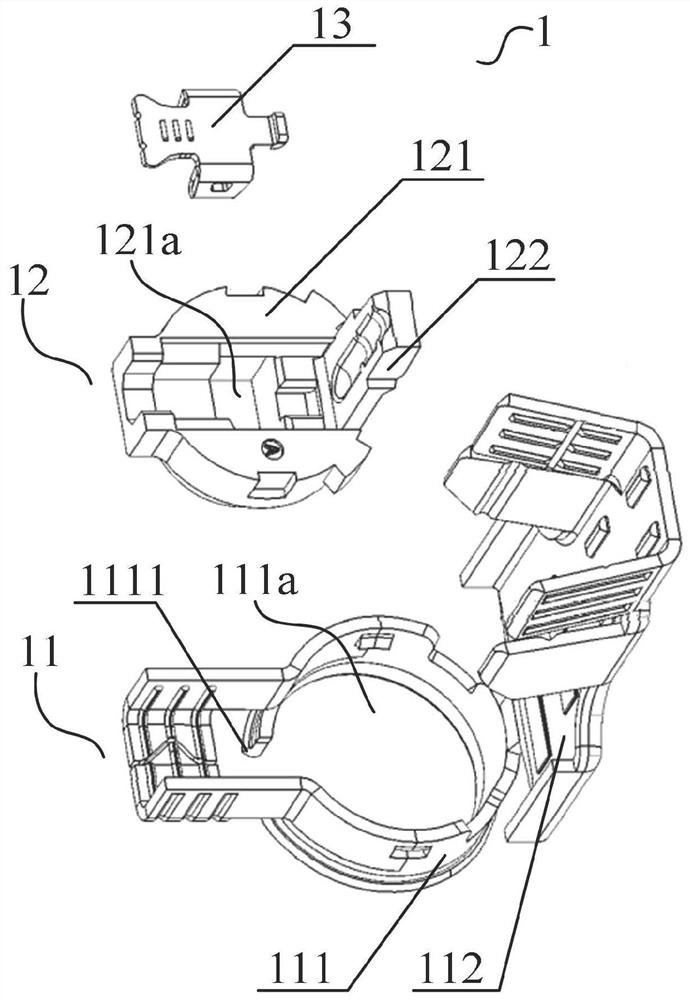

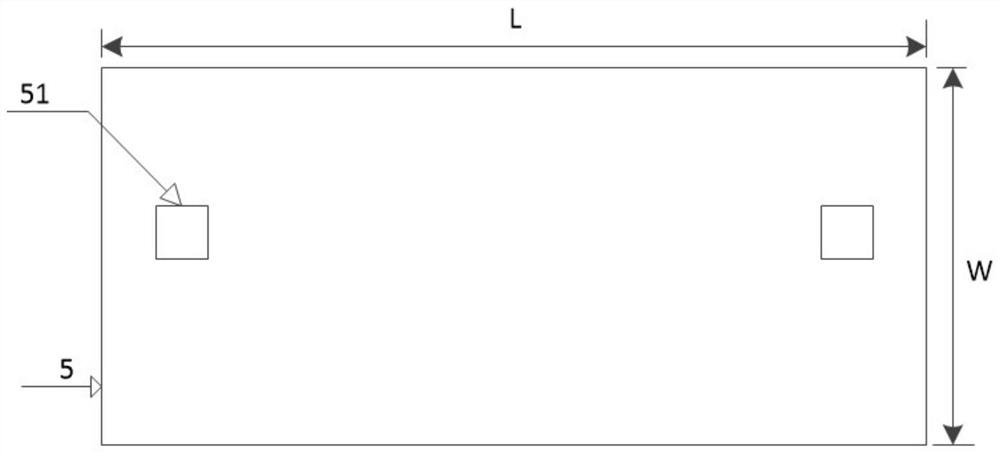

Wire end connecting terminal and coaxial cable connector

ActiveCN113285314AImprove reliabilityIncrease the lengthCoupling contact membersTwo-part coupling devicesCoaxial cableAcute angle

The invention discloses a wire end connecting terminal and a coaxial cable connector. The wire end connecting terminal comprises a terminal main body which is provided with a top surface used for being electrically connected with a cable and two contact arms respectively formed by bending and extending the two sides of the terminal main body and used for being electrically connected with the plate end connecting terminals. One contact arm comprises a first force arm part which is formed by bending and extending from two sides of the terminal main body towards a direction far away from the top surface, and a second force arm part which is formed by bending and extending from the bottom edge of the first force arm part towards the other contact arm; the included angle between the first force arm part and the second force arm part is an acute angle. According to the equipment disclosed by the invention, the length of the force arm can be increased under the condition that the overall height of the wire end connecting terminal is not changed, so that the embedding force when the wire end connecting terminal is embedded with the plate end connecting terminal is increased, and the reliability of the wire end connecting terminal is improved.

Owner:KUNSHAN JIAHUA ELECTRONICS

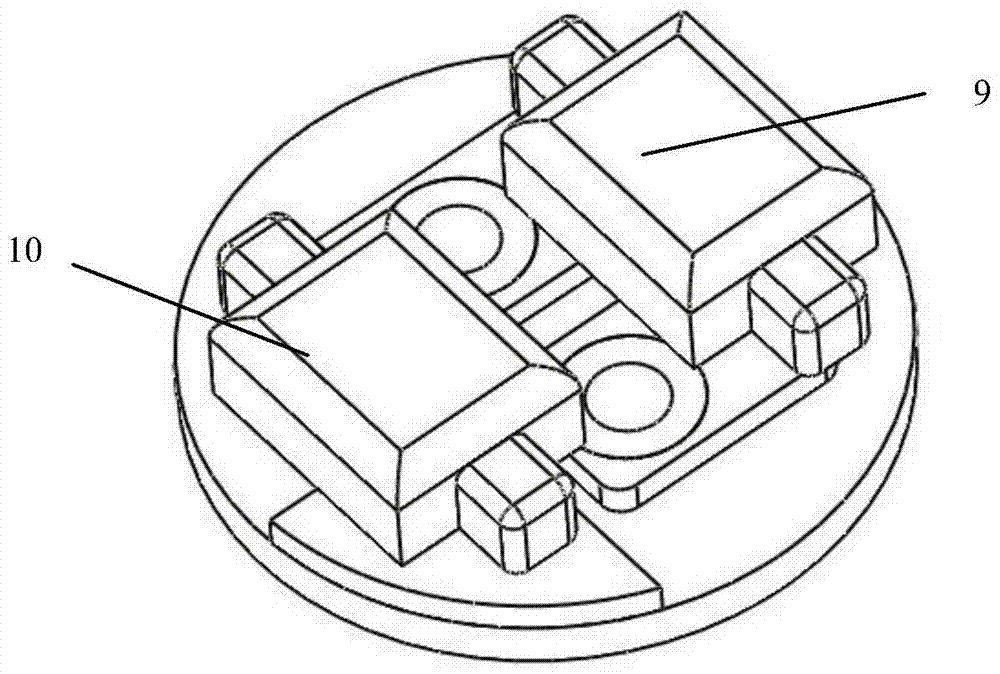

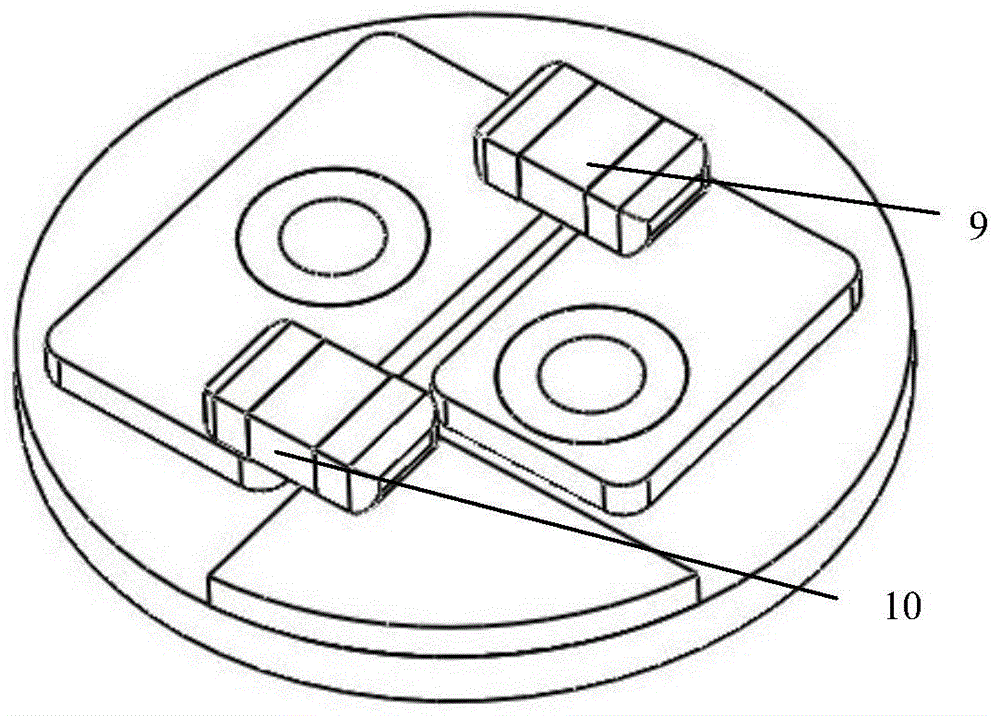

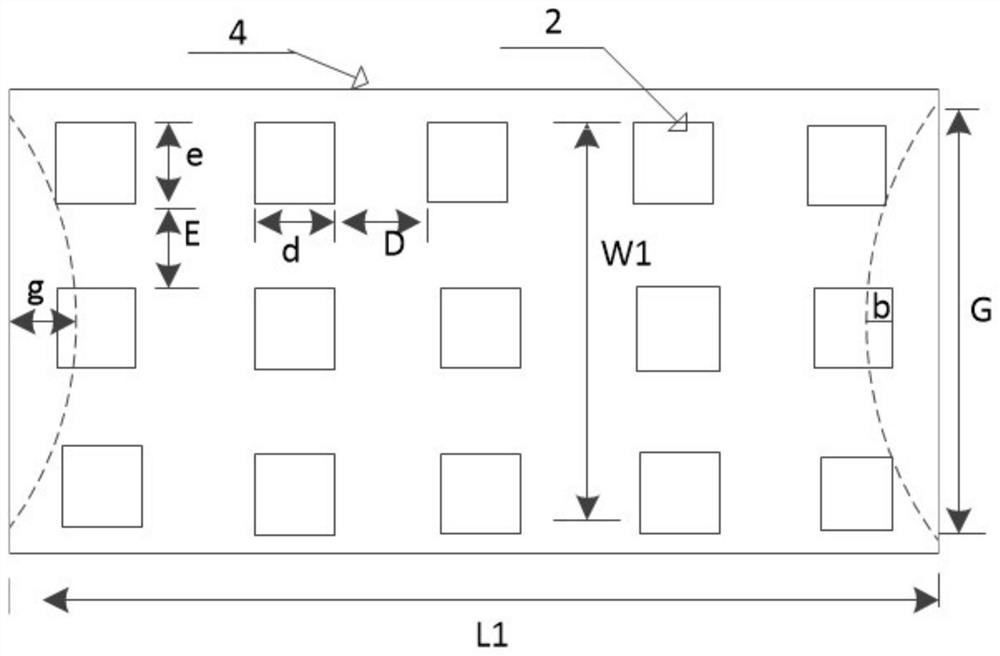

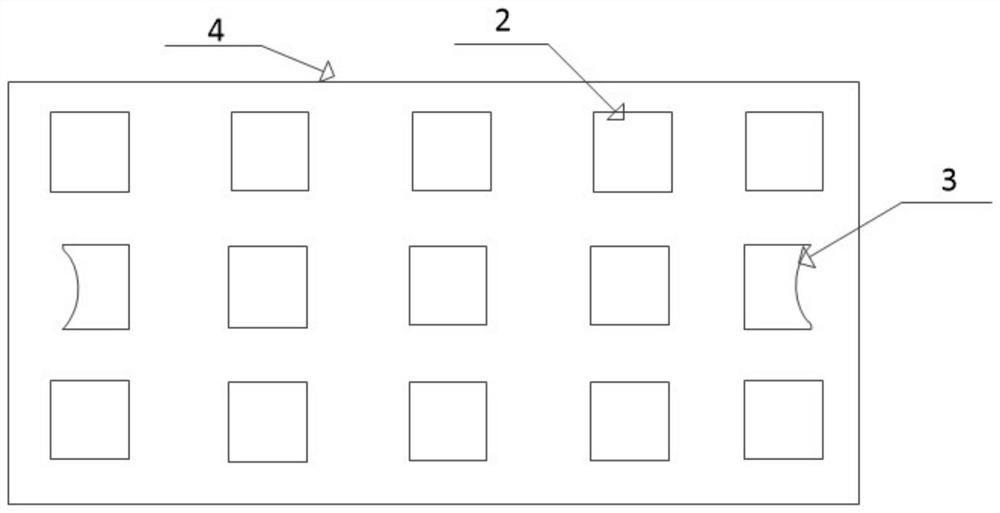

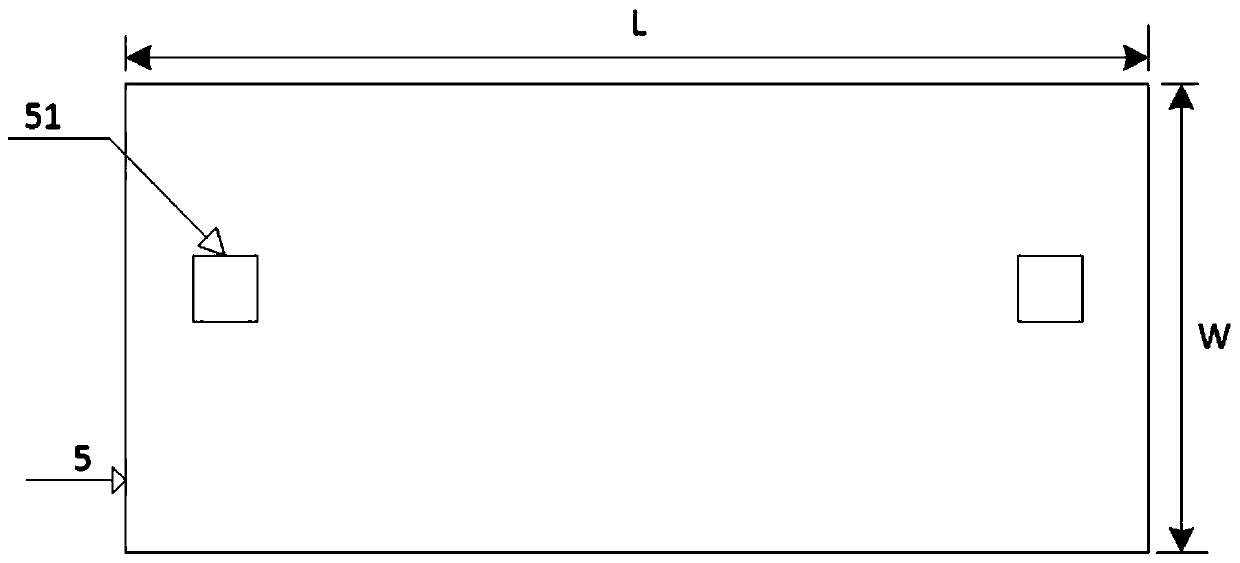

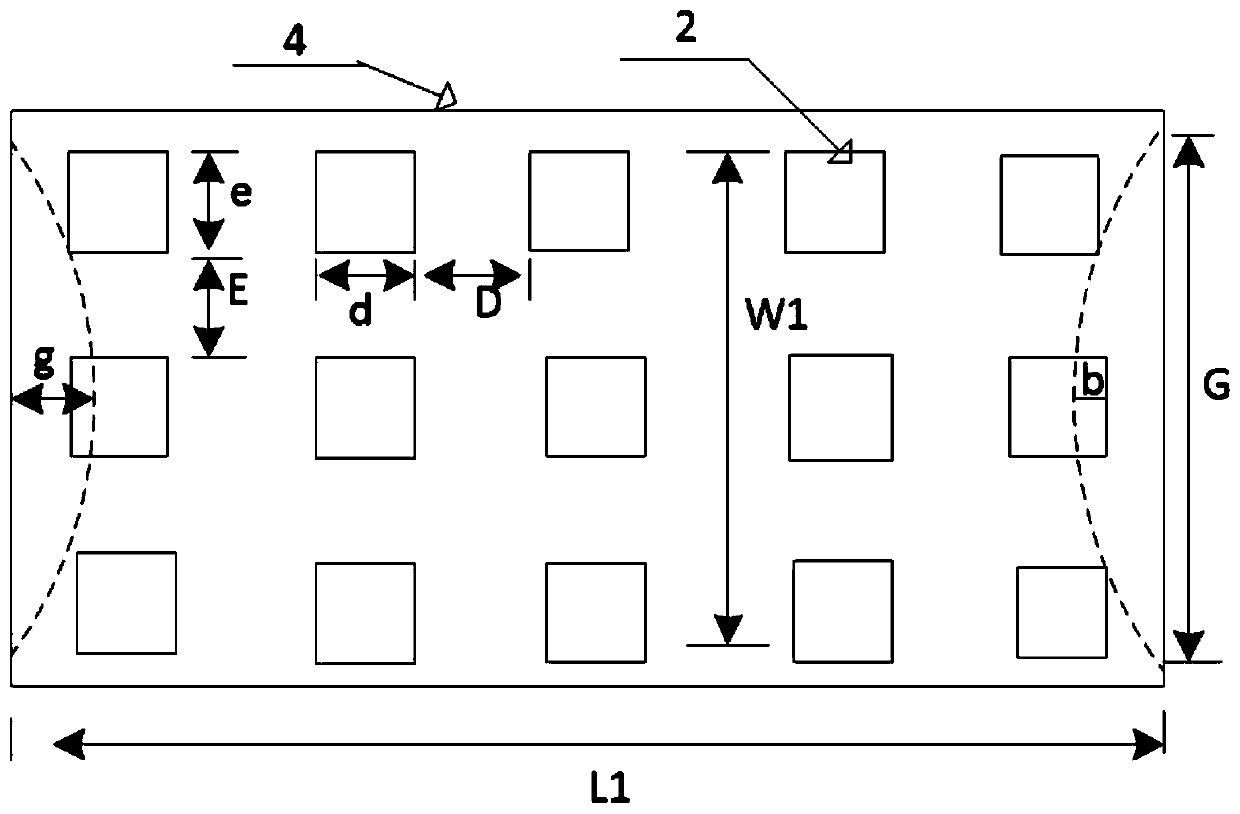

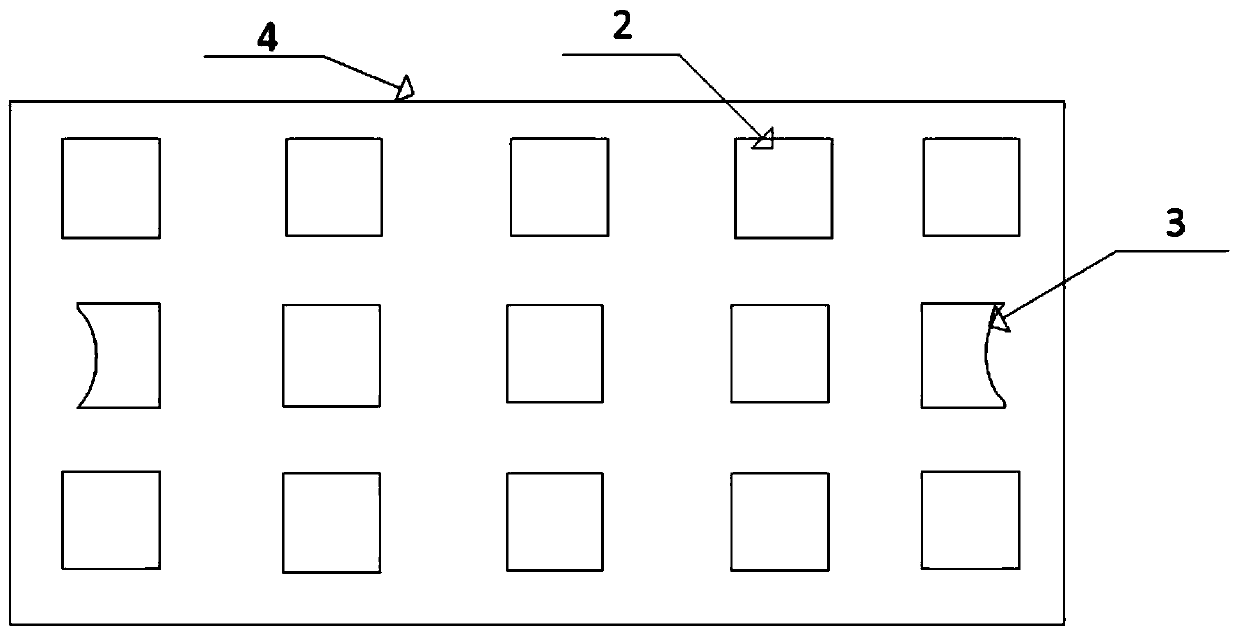

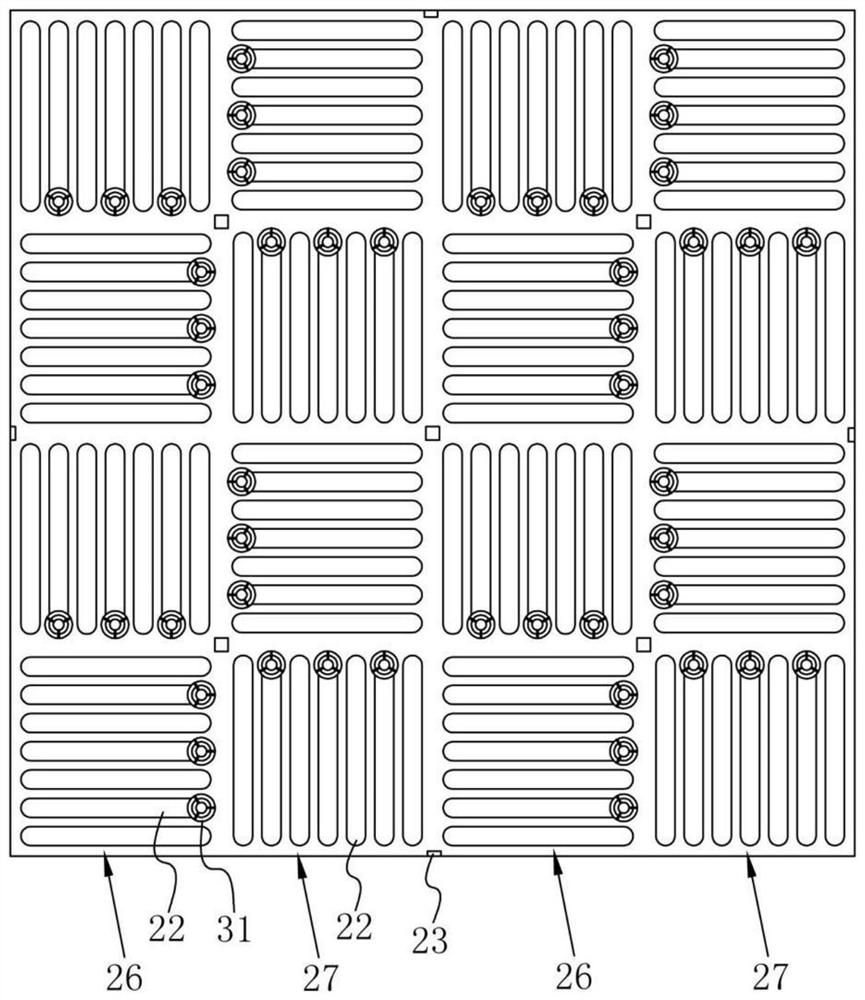

A dipping head for coating conductive adhesive

InactiveCN110252581BReduce the difficulty of design and processingThe dipping glue production process is simpleLiquid surface applicatorsCoatingsElectrically conductive adhesiveMaterials science

The invention discloses a glue dipping head for conductive glue coating. The glue dipping head comprises a connecting shaft, a rotating body, a glue dipping head base, glue dipping salient points and glue dipping shrinkage salient points, wherein the rotating body is fixedly arranged on the connecting shaft; the glue dipping head base is arranged at the bottom of the connecting shaft; the glue dipping salient points and the glue dipping shrinkage salient points are arranged on the glue dipping head base in matrix arrangement; and the glue dipping shrinkage salient points are positioned on the outermost side of the glue dipping head base. The glue dipping head has the advantages that the space layout of the glue dipping salient points is optimized, and the size and structure of the glue dipping salient points of a bonding pad of a chip are optimally designed, so that the ideal condition that effective overflow of the conductive glue on non-bonding pad parts of the chip and proper overflow of the conductive glue on the bonding pad parts of the chip is achieved; and according to the glue dipping head, the production efficiency and the quality of the conductive glue coating are improved, the viscosity change of the conductive glue and the height of the conductive glue in a glue dipping disc are less affected, and the glue dipping head is beneficial to large-scale production.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

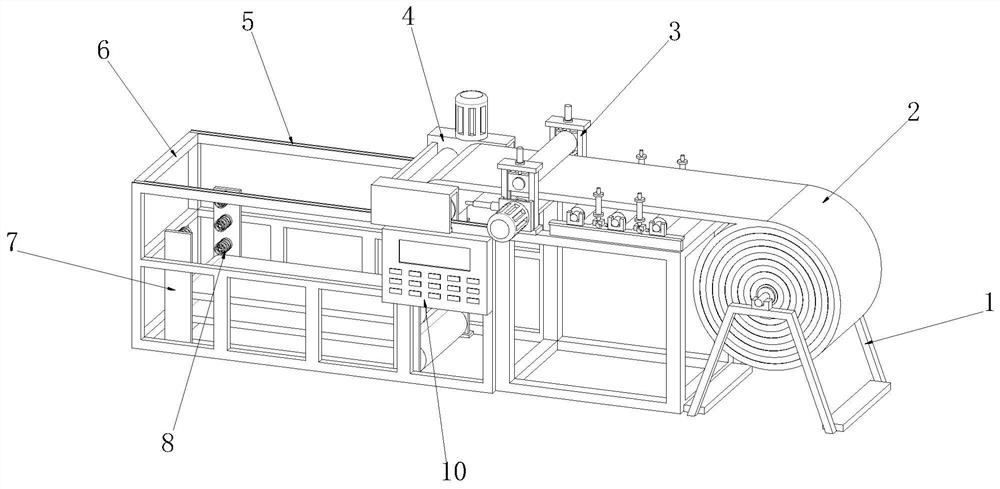

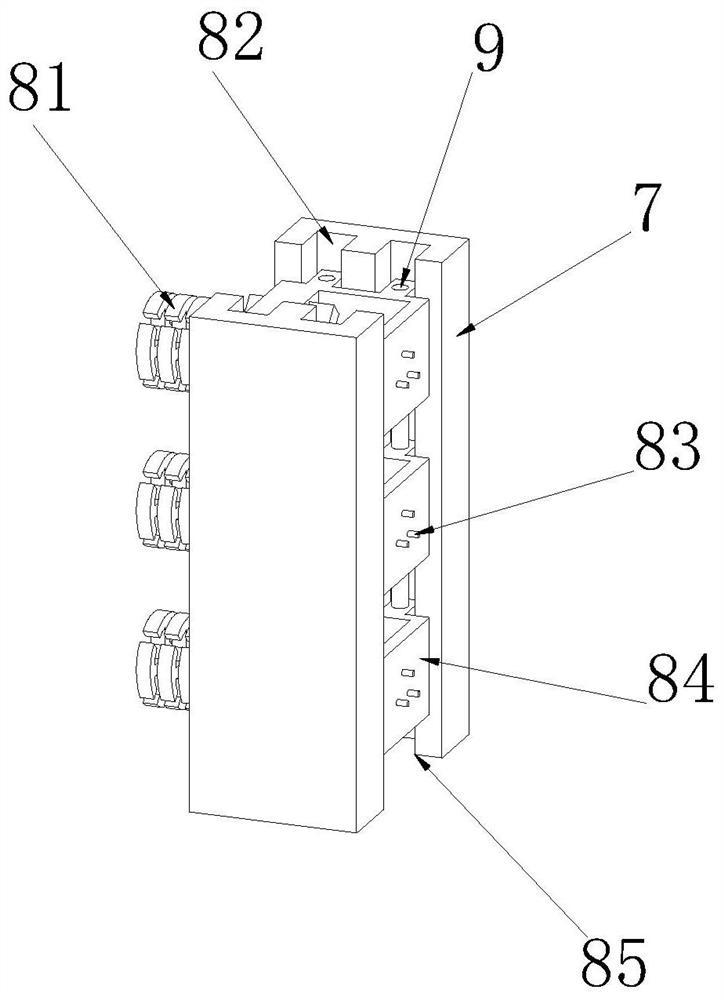

Automatic reciprocating type belt folding machine

InactiveCN113844944AReduce movement distanceShorten the timeFolding thin materialsBraced frameAutomatic control

The invention relates to a steel wire rope belt folding technology, and particularly relates to an automatic reciprocating type belt folding machine which is used for solving the problems that in the reciprocating folding process of a steel wire rope belt, the work efficiency is affected due to long moving distance, and collapse is caused by bending breakage and position deviation at the folding position due to the pressure effect. The automatic reciprocating type belt folding machine comprises a discharging frame, a belt body, a driving frame, a supporting frame and an automatic control box, a walking rail is connected to one side of the upper surface of the supporting frame, and a swing frame is slidably connected to one side, close to the walking rail, of the upper surface of the supporting frame. According to the automatic reciprocating type belt folding machine, the moving distance of the swing frame is shortened by limiting the position movement of the steel wire rope belt through an auxiliary frame, the work efficiency of the belt folding machine is improved, the folding position of the steel wire rope belt is supported by the auxiliary frame under the supporting of an elastic cushion, the folding position of the steel wire rope belt is prevented from being bent and broken, and the steel wire rope belt is blocked by a baffle so that the collapse caused by position deviation is prevented.

Owner:安徽格锐鑫智能装备有限公司

Valve train for engine and vehicle having same

ActiveCN103790669BImprove inflation efficiencyMeet the needs of valve movement rules in different working conditionsValve arrangementsMachines/enginesEngineeringCam

The invention discloses a valve mechanism for an engine and a vehicle comprising the valve mechanism. The valve mechanism comprises a valve mechanism body, a rocker component, a first roller, a second roller, a camshaft, supporting structures, a phase adjusting mechanism, and a third roller or limit pins. The bottom of the rocker component is provided with a drive molded surface which is suitable for directly driving a valve to move. The first roller and the second roller both can be arranged on the rocker component in a pivoting mode. The camshaft comprises an inner shaft and an outer shaft, the inner shaft and the outer shaft are coaxially arranged and provided with an inner shaft cam and an outer shaft cam respectively, and the inner shaft cam and the outer shaft cam can rotate along the corresponding shafts respectively. The outer shaft cam abuts against the first roller, the inner shaft cam abuts against the second roller, the supporting structures are arranged on the two sides of the rocker component and provided with circular arc cambers or sliding grooves, the third roller can be attached to the circular arc cambers in a rolling mode, and the limit pins can be matched in the sliding grooves in a sliding mode. The valve mechanism can achieve secondary opening of the valve, can lengthen the opening lasting time of the valve, and is simple in structure, and low in influence on the height of the engine.

Owner:GREAT WALL MOTOR CO LTD

Glue dipping head for conductive glue coating

InactiveCN110252581AReduce the difficulty of design and processingThe dipping glue production process is simpleLiquid surface applicatorsCoatingsEngineeringViscosity

The invention discloses a glue dipping head for conductive glue coating. The glue dipping head comprises a connecting shaft, a rotating body, a glue dipping head base, glue dipping salient points and glue dipping shrinkage salient points, wherein the rotating body is fixedly arranged on the connecting shaft; the glue dipping head base is arranged at the bottom of the connecting shaft; the glue dipping salient points and the glue dipping shrinkage salient points are arranged on the glue dipping head base in matrix arrangement; and the glue dipping shrinkage salient points are positioned on the outermost side of the glue dipping head base. The glue dipping head has the advantages that the space layout of the glue dipping salient points is optimized, and the size and structure of the glue dipping salient points of a bonding pad of a chip are optimally designed, so that the ideal condition that effective overflow of the conductive glue on non-bonding pad parts of the chip and proper overflow of the conductive glue on the bonding pad parts of the chip is achieved; and according to the glue dipping head, the production efficiency and the quality of the conductive glue coating are improved, the viscosity change of the conductive glue and the height of the conductive glue in a glue dipping disc are less affected, and the glue dipping head is beneficial to large-scale production.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

Valve train for engine and vehicle with same

ActiveCN103758605BLittle impact on altitudeGuaranteed uptimeValve arrangementsMachines/enginesMechanical engineering

The invention discloses a gas distributing mechanism for an engine and a car with the gas distributing mechanism. The gas distributing mechanism comprises a valve mechanism, a rocker arm assembly, a first roller, a second roller, a cam shaft, a bearing structure, a phase adjusting mechanism, and a third roller or a limiting pin. A driving molded surface which is constructed at the bottom of the rocker arm assembly directly drives a valve to move, the first roller and the second roller can be arranged on the rocker arm assembly in a pivoted mode, the cam shaft comprises an inner shaft and an outer shaft, the inner shaft and the outer shaft are coaxially arranged, an inner shaft cam and an outer shaft cam which rotate along with the corresponding shafts are arranged on the inner shaft and the outer shaft respectively, the outer shaft cam abuts against the first roller, the inner shaft cam abuts against the second roller, the phase adjusting mechanism is used for adjusting the relative phase of the inner shaft and the outer shaft, a circular-arc curved surface or a sliding groove is formed in the bearing structure, the third roller can be tightly attached to the circular-arc curved surface in a rolling mode, and the limiting pin can be arranged in the sliding groove in a sliding and matching mode. The gas distributing mechanism can achieve secondary opening of the valve, the continuous opening time of the valve can be prolonged at the same time, the structure is simple and compact, and the influence on the height of the engine is small.

Owner:GREAT WALL MOTOR CO LTD

Valve train for engine and vehicle having same

ActiveCN103775153BImprove inflation efficiencyMeet the needs of valve movement rules in different working conditionsValve arrangementsMachines/enginesCamRocker arm

The invention discloses a gas distribution mechanism for an engine and a vehicle with the same. The gas distribution mechanism includes: a valve train; a rocker arm assembly with a drive profile adapted to drive the movement of the valve at the bottom; first and second rollers that are pivotally arranged on the rocker arm assembly; including a coaxial arrangement The camshafts of the inner shaft and the outer shaft have an inner shaft cam and an outer shaft cam that rotates with the corresponding shaft respectively, the outer shaft cam abuts against the first roller, and the inner shaft cam abuts against the second roller ; The support structure arranged on both sides of the rocker arm assembly; the phase adjustment mechanism; the gas distribution mechanism also includes a third roller or a limit pin, and the support structure is also configured with an arc surface or a sliding groove, and the third roller can roll Closely attached to the arc surface, the limit pin is slidably fitted in the slide groove. The valve mechanism of the present invention can realize the secondary opening of the valve, and at the same time can prolong the opening duration of the valve, has a simple and compact structure, and has little influence on the height of the engine.

Owner:GREAT WALL MOTOR CO LTD

Ceramic sheet paving structure and paving method for covering old bricks with ceramic sheets

PendingCN114150839AGuaranteed reliabilityEasy to useBuilding repairsAdhesivesMetal meshCeramic tiles

The invention discloses a ceramic sheet paving structure. The ceramic sheet paving structure comprises a ceramic sheet, an adhesive layer, a metal mesh plate and a shaping piece, the invention further discloses a paving method for covering the old bricks with the ceramic thin plates. The paving method comprises the following steps: coating an adhesive; paving a metal net plate; a shaping piece is arranged; paving a ceramic thin plate; adjusting the ceramic thin plate; adsorbing the metal net plate; and solidifying the adhesive. The ceramic thin plate paving device has the beneficial effects that the reliability after paving can be effectively guaranteed while paving of ceramic thin plates is achieved, the effect of being convenient to use is achieved, the advantage of being low in noise is achieved, and the influence on the surrounding environment in the paving process is reduced. According to the ceramic sheet paving structure, the problem that tiles are inconvenient to lay again on the ground on which the tiles are laid in the secondary decoration process is solved, the problem that the ceramic sheets are easy to break after secondary decoration paving due to the fact that the thickness of the ceramic sheets is too low is also solved, and the stability of the ceramic sheets during paving and after paving is ensured; and the flatness of the paved ground can be further improved.

Owner:GUANGDONG NEWPEARL CERAMIC GRP CO LTD +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com