Resin liquid-level control for photo-solidification quick formation and resin coating method and apparatus

A resin liquid, light curing technology, applied in the field of rapid prototype manufacturing, can solve the problems of resin coating layer uniformity and layer thickness accuracy, reduce work efficiency, affect workpieces, etc., to overcome the resin coating uniformity and layer thickness. Reduced accuracy, improved work efficiency, overcoming the effects of easily damaged workpieces and uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

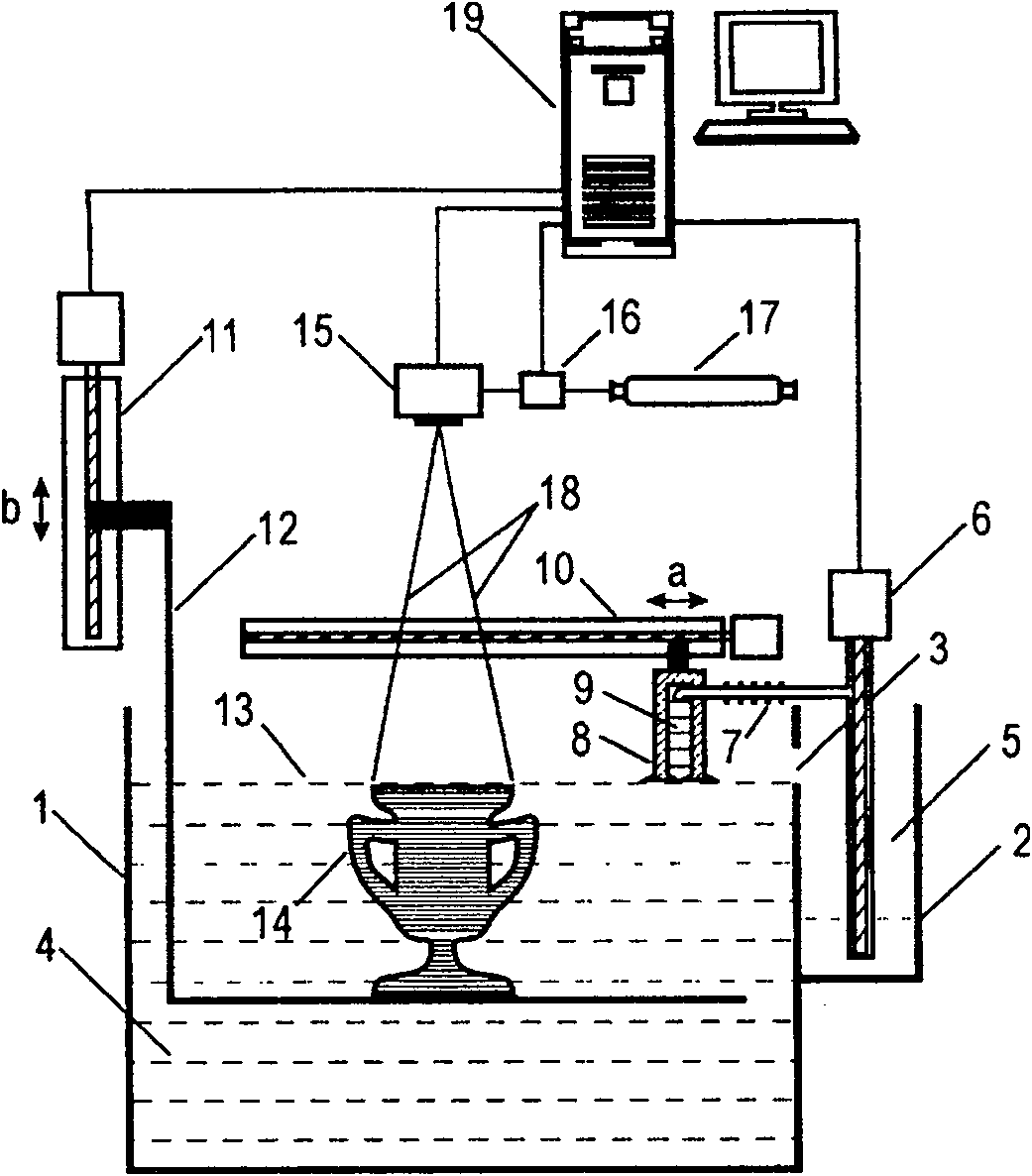

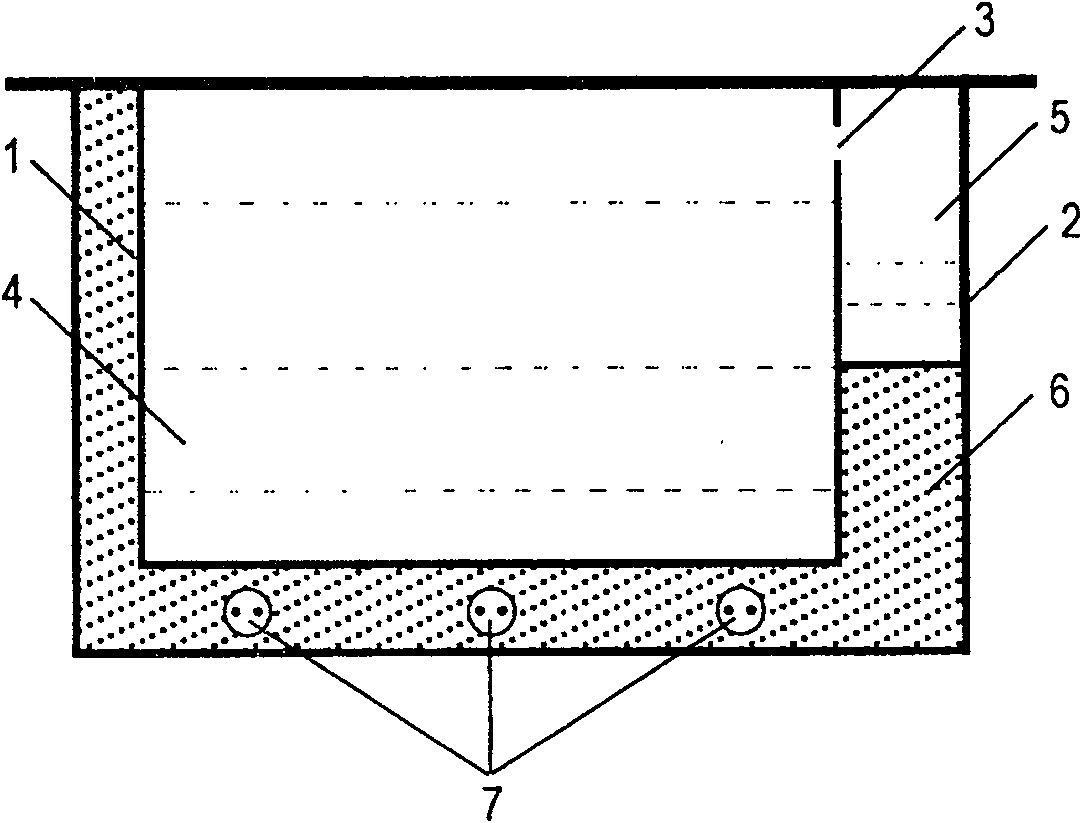

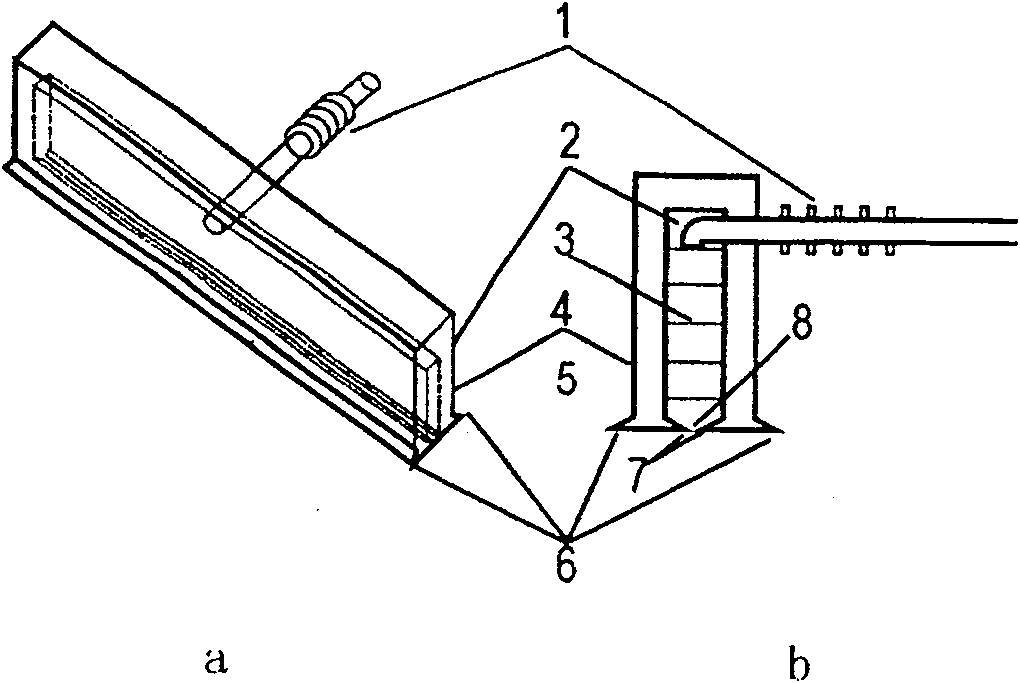

[0022] see figure 1, the present invention includes: a constant temperature control resin tank with a main tank 1, an additional tank 2 and an overflow port 3 structural design, the main tank 1 is used to hold the photosensitive resin 4 required for the molding of the workpiece, and the additional tank 2 is used to hold the photosensitive resin 4 in the workpiece During the molding process, the excess resin 5 flows out through the overflow port 3 due to maintaining the resin liquid level of the main tank; a micropump 6 is connected through a flexible pipe 7 to transport the resin 5 in the attached tank 2 to the cavity of the scraper for storage and storage. Supplemented to the main tank 1, the computer 19 can control the switch and flow of the micropump 6. When the resin liquid level 13 of the main tank is higher than the overflow port 3, the excess resin will flow to the auxiliary tank 2 through the overflow port 3, thereby maintaining The resin liquid level of the main tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com