Ceramic sheet paving structure and paving method for covering old bricks with ceramic sheets

A ceramic sheet and paving technology, applied in building construction, building maintenance, floor and other directions, can solve the problems of people's life and work impact, high labor cost, large demolition of ceramic tiles, etc., to achieve good application and promotion prospects, convenient Replacement and installation, the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

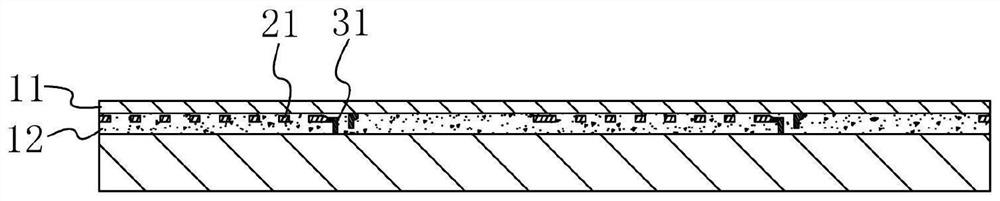

[0040] refer to figure 1 and figure 2 , a ceramic sheet pavement structure, including a ceramic sheet 11, an adhesive layer 12, a metal mesh plate 21 and a molded part 31. The adhesive layer 12 is located under the ceramic thin plate 11 and fixedly connected with the ceramic thin plate 11 , the metal mesh plate 21 is disposed in the adhesive layer 12 , and the thickness of the metal mesh plate 21 is smaller than that of the adhesive layer 12 .

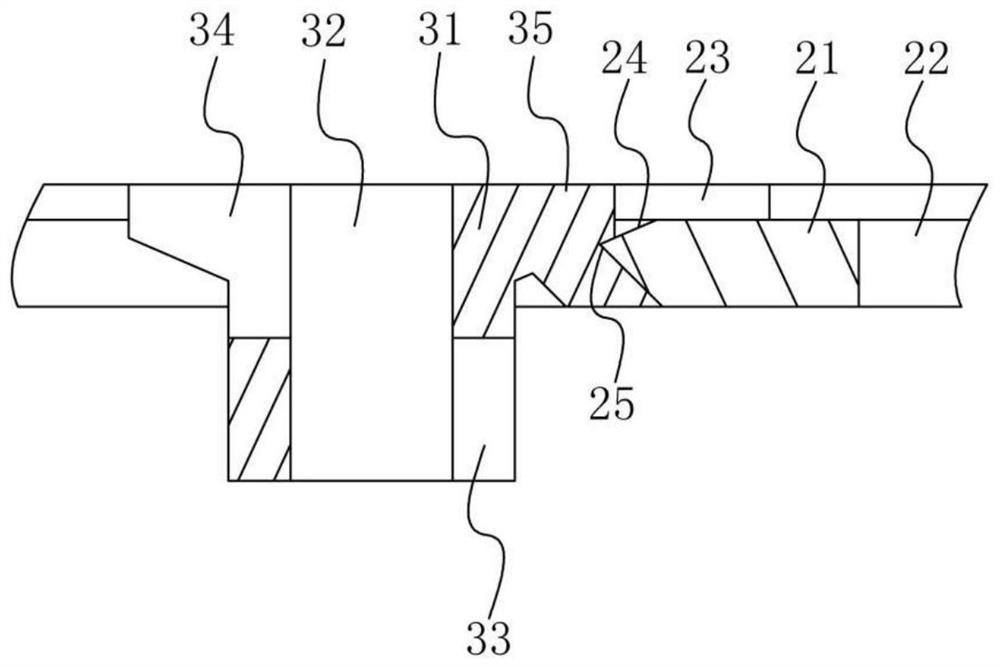

[0041] The shaping part 31 is arranged in the through groove 22, the shaping part 31 is provided with a through hole 32 arranged vertically, and the lower end of the shaping part 31 is provided with 3 lower communicating ports 33 extending along the horizontal direction, and 3 lower communicating ports 33 With the through hole 32 as the center, the circumference is evenly distributed, and the two ends of the lower communication port 33 are respectively connected to the through hole 32 and the outer wall of the plastic part 31. The up...

Embodiment 2

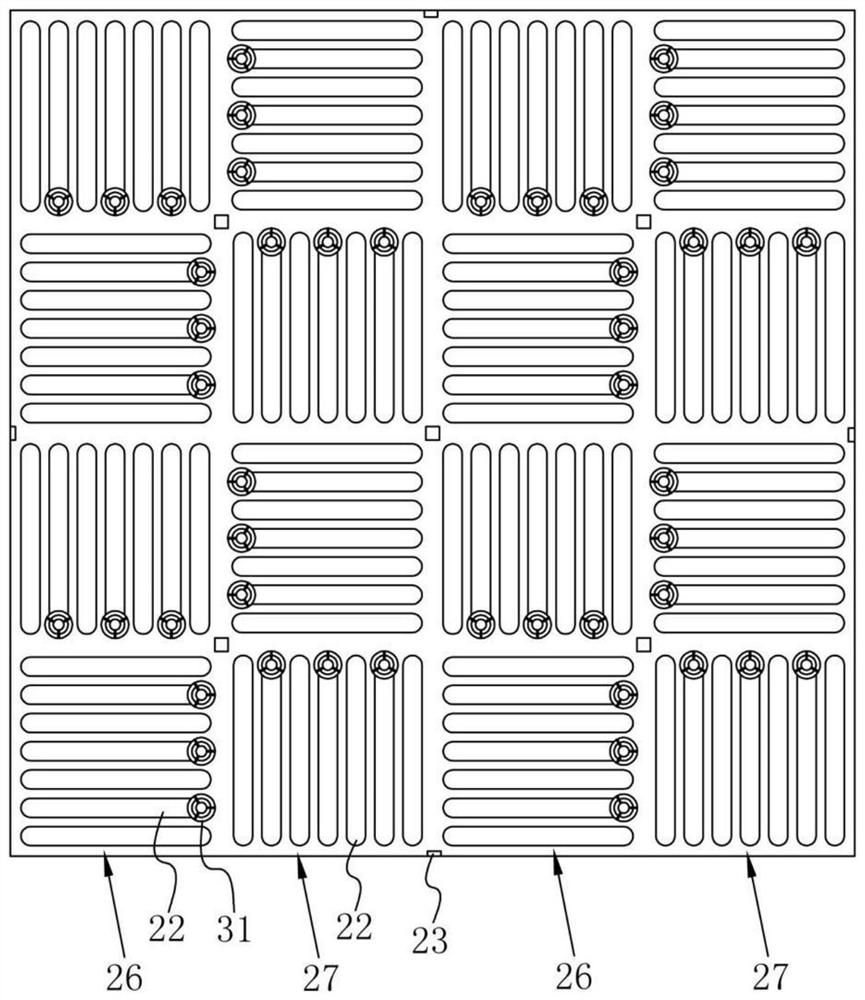

[0075] A ceramic sheet pavement structure, the difference from Example 1 is that both the ceramic sheet and the metal mesh are square, the side length of the ceramic sheet is 30 cm, and the side length of the metal mesh is 90 cm. 9 ceramic sheets.

[0076] This embodiment has the following advantages: 9 ceramic thin plates can be arranged on one metal mesh plate to facilitate paving and disassembly.

Embodiment 3

[0078] A ceramic sheet pavement structure, the difference from Example 1 is that both the ceramic sheet and the metal mesh are square, the side length of the ceramic sheet is 60 cm, the side length of the metal mesh is 120 cm, and the metal mesh is provided with 4 ceramic sheets.

[0079] This embodiment has the following advantages: 4 ceramic thin plates can be arranged on one metal mesh plate to facilitate paving and disassembly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com