Hydraulic machine with hydraulic pressurizing mechanism

A hydraulic press and hydraulic technology are applied to hydraulic presses. It can solve the problems of reduced life, low working speed, and increased height of hydraulic cylinders, and achieve the effects of reduced equipment size, simplified hydraulic system, and large mold opening and closing strokes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

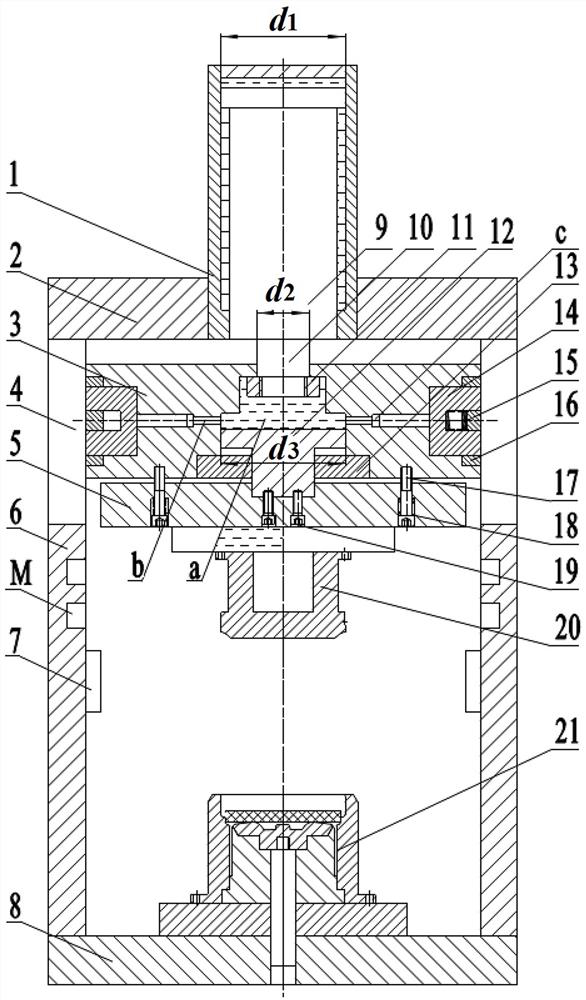

[0032] The specific structure of one of the embodiments of the present invention is described in detail below in conjunction with the accompanying drawings: as figure 1 As shown, a hydraulic press with a hydraulic pressure boosting mechanism includes a main engine and a hydraulic system for controlling the main engine, wherein the main engine includes a main hydraulic cylinder 1, an upper beam 2, a movable beam 3, a lower beam 8, and a column 4, and the movable beam 3 is equipped with a hydraulic booster mechanism, which includes a booster cylinder and a locking mechanism for limiting the position of the booster cylinder body, and also includes a set between the columns 4 on both sides of the hydraulic machine, fixed with the lower beam 8 The connected vertical plate 6 has a pin hole M, which can restrict the movement of the movable crossbeam 3 when used in conjunction with the locking mechanism.

[0033] In this embodiment, a combined hydraulic chamber a is provided inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com