Forming mould for carton extrusion molding

A technology for extrusion forming and forming molds, which is used in papermaking, paper/cardboard containers, container manufacturing machinery, etc., and can solve problems such as single adaptability and no adjustment of equipment/components/components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

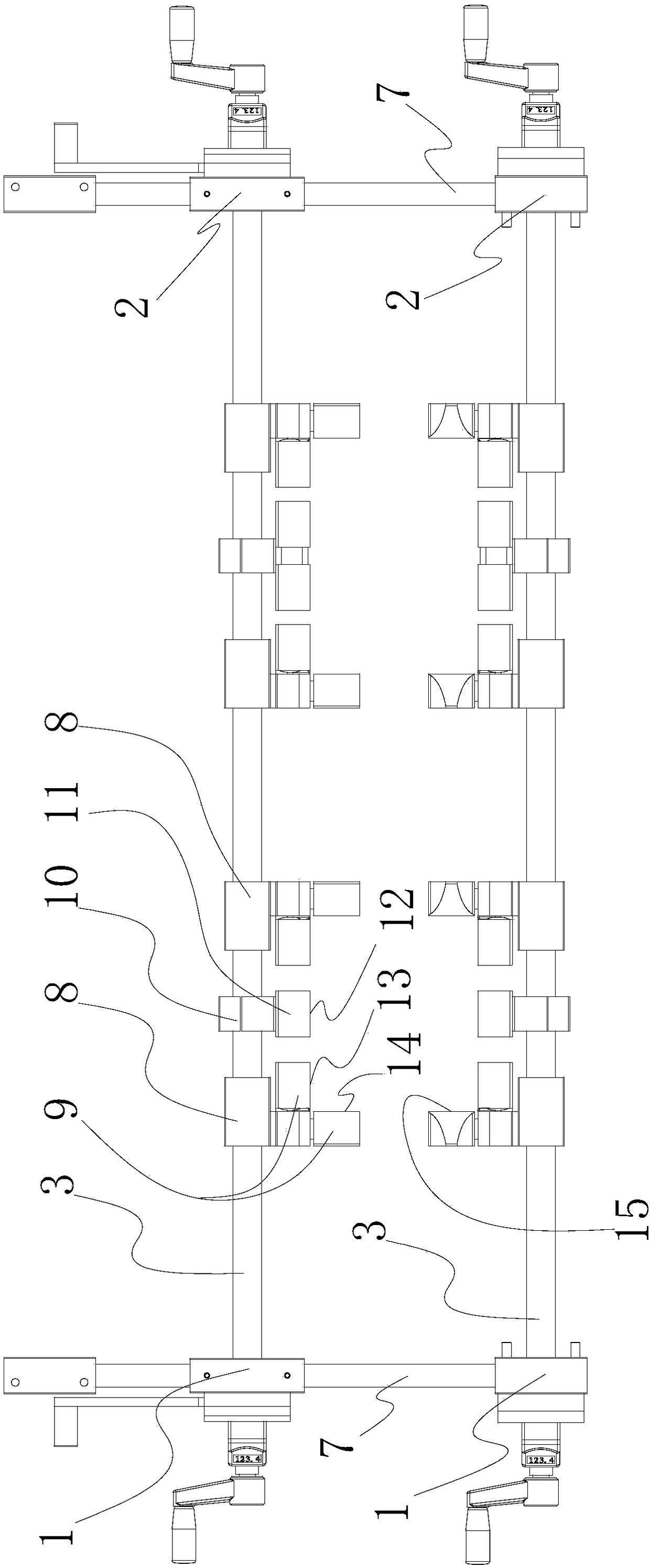

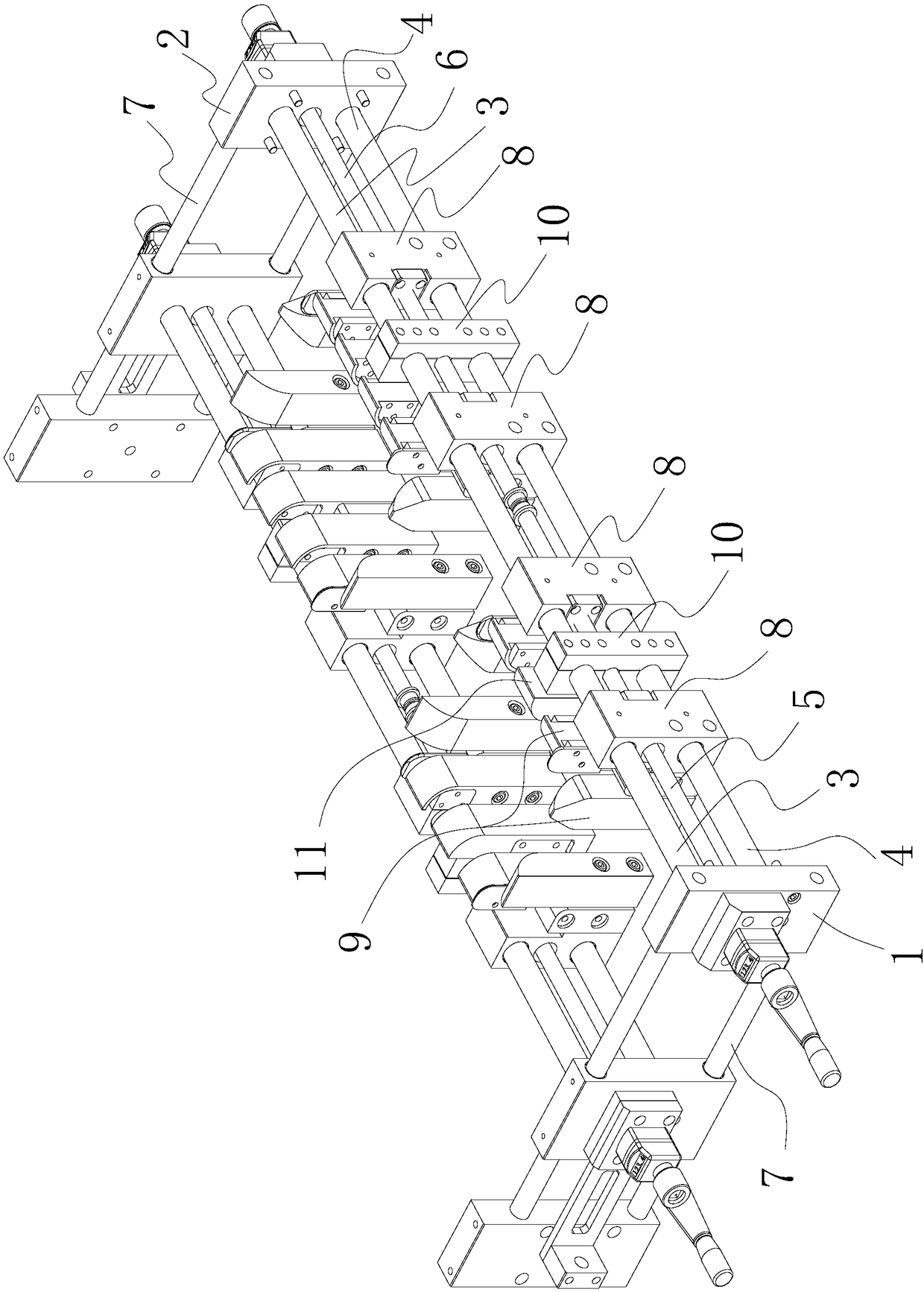

[0021] Such as figure 1 , 2 Shown, the first embodiment of the present invention.

[0022] The forming mold for extrusion forming of the carton is provided with a mounting frame, and two forming parts are mounted on the mounting frame.

[0023] The mount consists of two linear sliding platforms. Each linear slide includes a support block I1, a support block II2, a guide rod I3, a guide rod II4, a screw rod I5, a screw rod II6, a handle I, and a handle II. The support block I1 and the support block II2 are in relative positions, and the guide rod I3 and the guide rod II4 are installed between the support block I1 and the support block II2 to form a frame structure; after installation, the guide rod I3 is parallel to the guide rod II4. The screw rod I5 passes through the support block I1 and is movably connected with the support block I1, the screw rod II6 passes through the support block II2 and is movably connected with the support block II2, and the screw rod I5 and the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com