Automatic reciprocating type belt folding machine

A technology of reciprocating belt stacking machine, applied in the field of automatic reciprocating belt stacking machine, can solve the problems such as the deviation of the position of the steel wire rope belt and easy to collapse, so as to improve the work efficiency, prevent bending and breaking under pressure, and waste time. The effect of shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

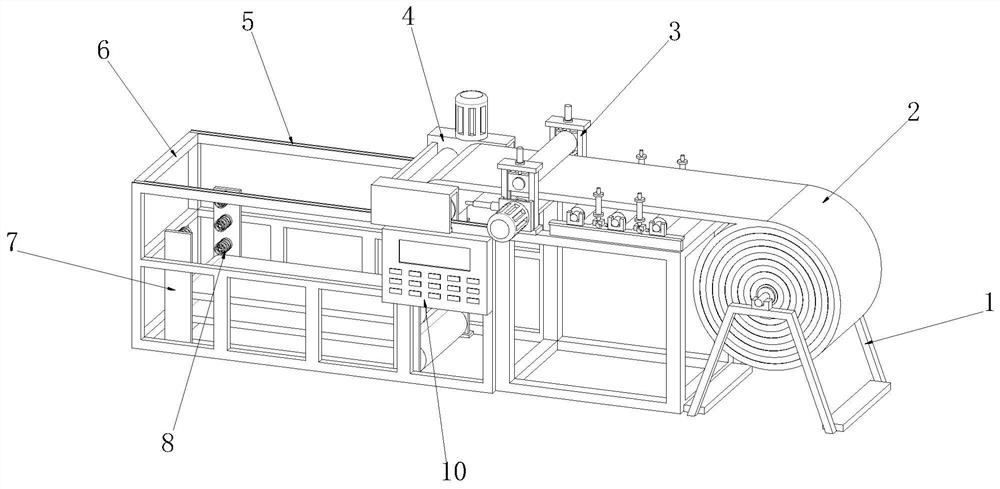

[0038] see Figure 1-4As shown, the automatic reciprocating belt stacking machine includes a discharge rack 1, a belt body 2, a drive frame 3, a swing frame 4, a walking track 5, a support frame 6 and an automatic control box 10, and one side of the upper surface of the support frame 6 is connected with The walking track 5, the side of the upper surface of the support frame 6 close to the walking track 5 is slidably connected with the swing frame 4, the side of the upper surface of the support frame 6 close to the swing frame 4 is connected with the drive frame 3, and the middle position inside the drive frame 3 is slidably connected There is a belt body 2, a discharge rack 1 is provided on one side of the outer wall of the support frame 6, an automatic control box 10 is connected to the front surface of the support frame 6 near the position of the drive frame 3, and a mounting plate 7 is connected to the front and rear sides of the inner wall of the support frame 6 ;

[0039...

Embodiment 2

[0043] The weight of the steel wire rope belt body 2 for mine is relatively heavy, and the weight of each roll of the belt body 2 is more than ten tons. After folding, the folded position has a higher protrusion, and the lower fold is under the gravity of the belt body 2 stacked above. Large deformation occurs, and the force received at the folded position of the bottom belt body 2 is relatively large, and it is easy to bend and break;

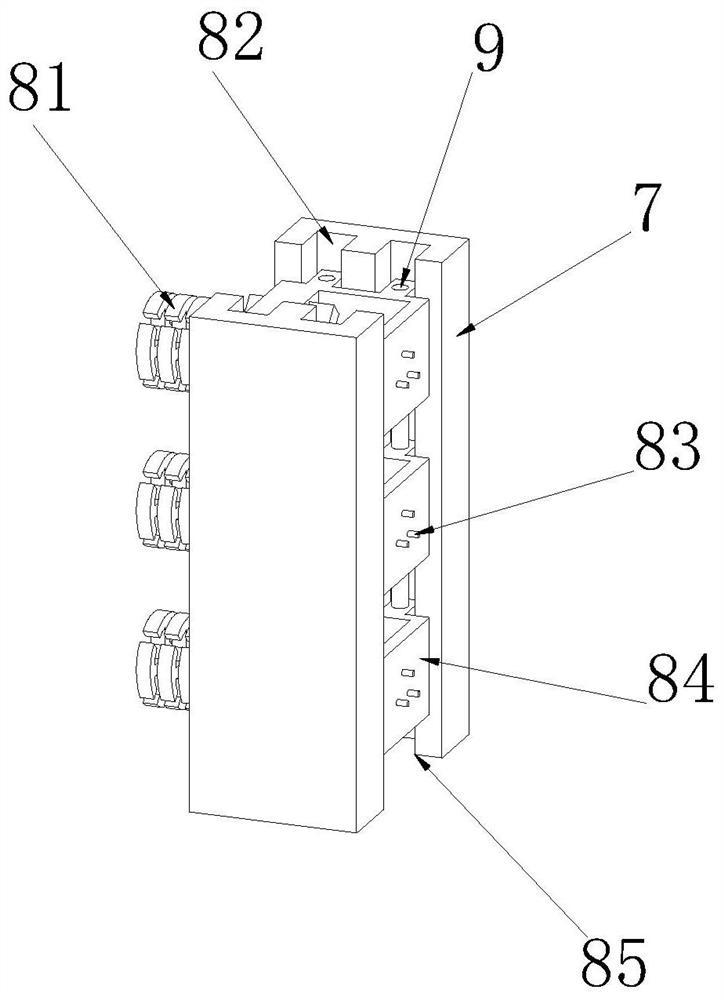

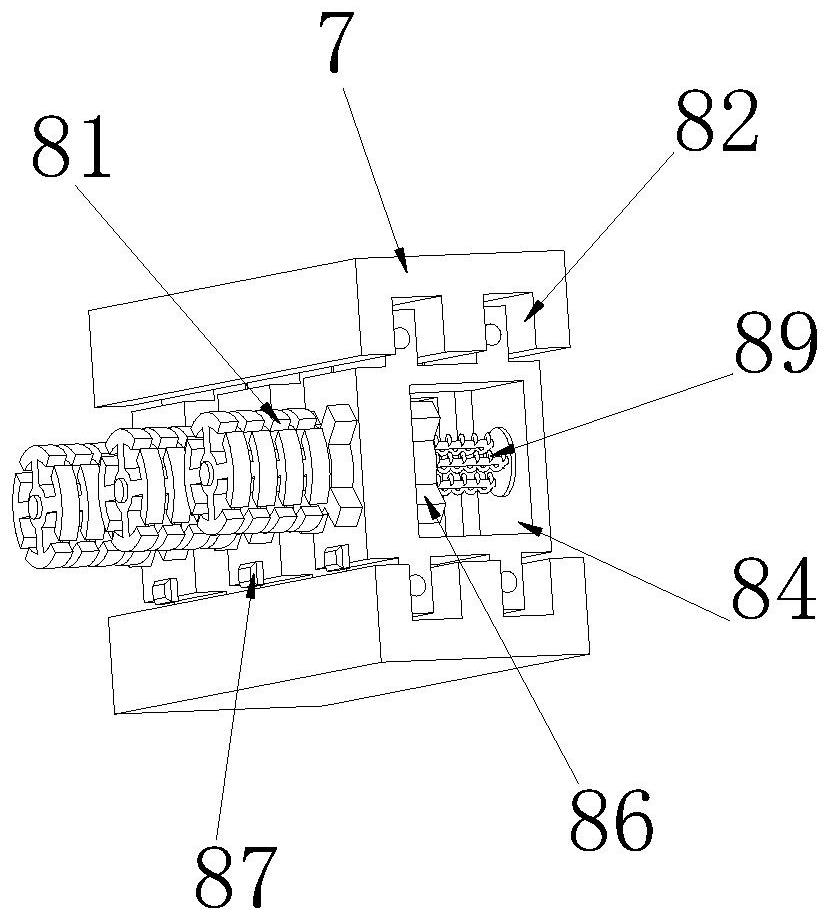

[0044] see Figure 4-6 As shown, the upper surface of the sliding frame 84 is provided with an elastic mechanism 9, the elastic mechanism 9 includes an elastic box 97, and the four directions inside the elastic box 97 are provided with movable chambers, and the outer wall of the elastic box 97 is provided with an adjustment hole corresponding to the position of the movable chamber. 96. The width of the adjustment hole 96 is smaller than the width of the inner space of the movable cavity. The inside of the adjustment hole 96 is slidably connect...

Embodiment 3

[0047] During the reciprocating folding process of the belt body 2, there is no shielding device at the middle position of the stacked belt body 2, which makes the position of the middle position of the belt body 2 prone to shift, and makes the belt body 2 with a higher height after stacking complete. It is prone to collapse due to skew;

[0048] see Figure 7-8 As shown, a limit mechanism 11 is arranged on both sides of the outer wall of the mounting plate 7, and the limit mechanism 11 includes a baffle plate 112, and a through hole 113 is provided on the front surface of the baffle plate 112 corresponding to the position of the auxiliary frame 81, and the size of the through hole 113 is the same as that of the auxiliary frame. The size of the circular structure formed by 81 is the same, so that the auxiliary frame 81 can slide freely in the inside of the through hole 113. There is a chute 114 at the position corresponding to the limit frame 111 on the side, and the limit fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com