Patents

Literature

31results about How to "Realize the second opening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

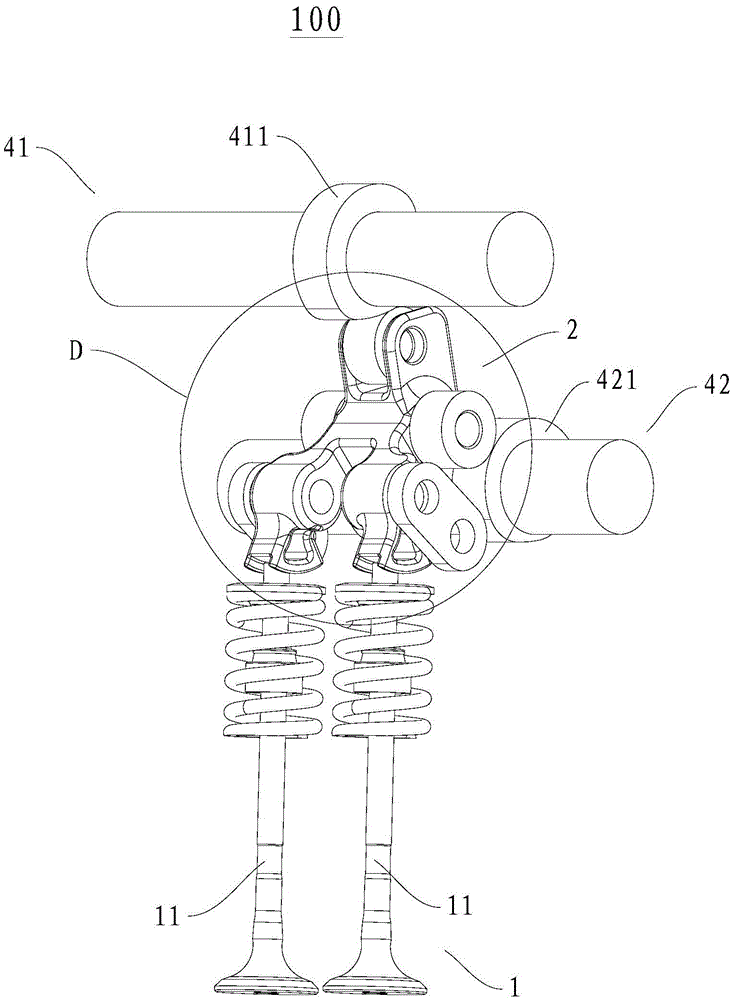

Air distribution mechanism for engine and vehicle comprising same

ActiveCN103758601ARealize the second openingExtension of timeValve arrangementsMachines/enginesRelative phaseEngineering

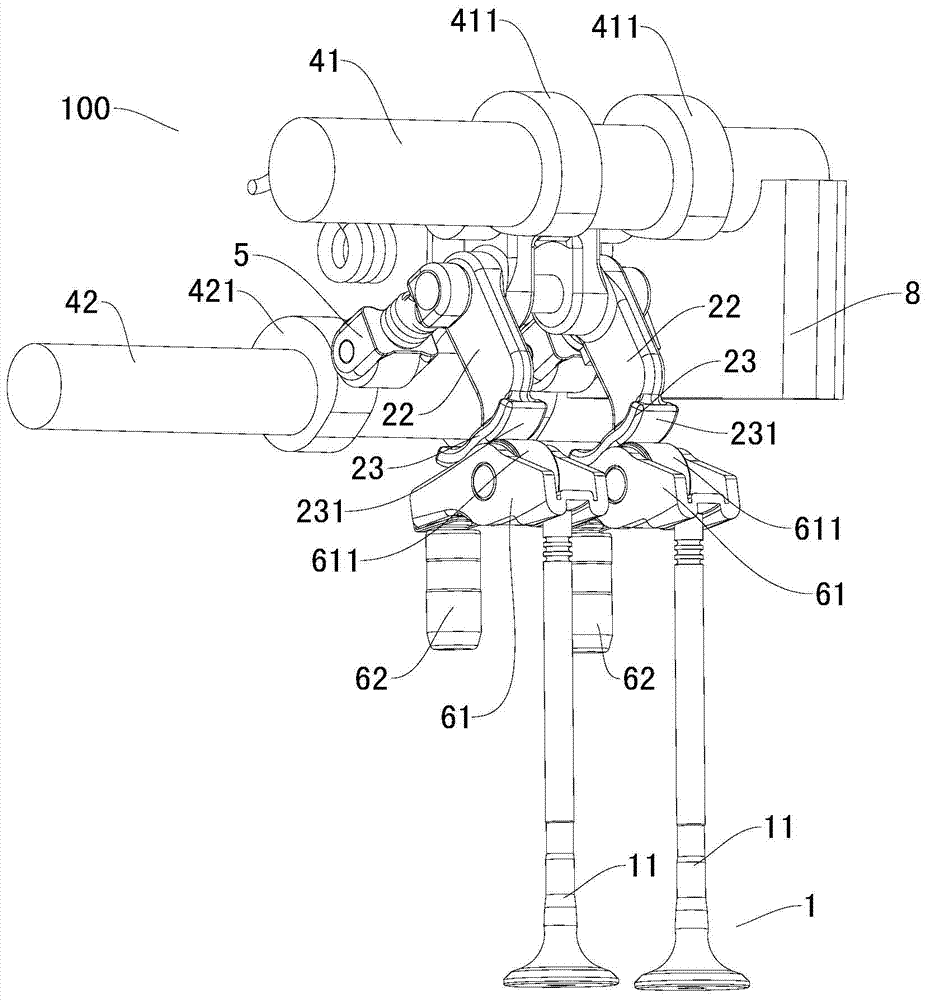

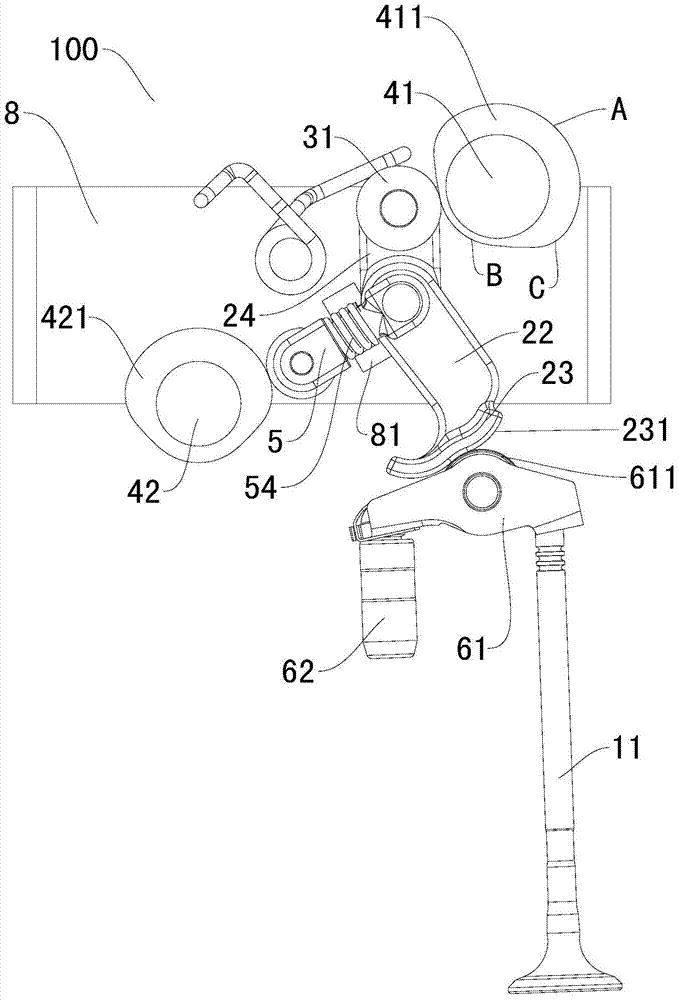

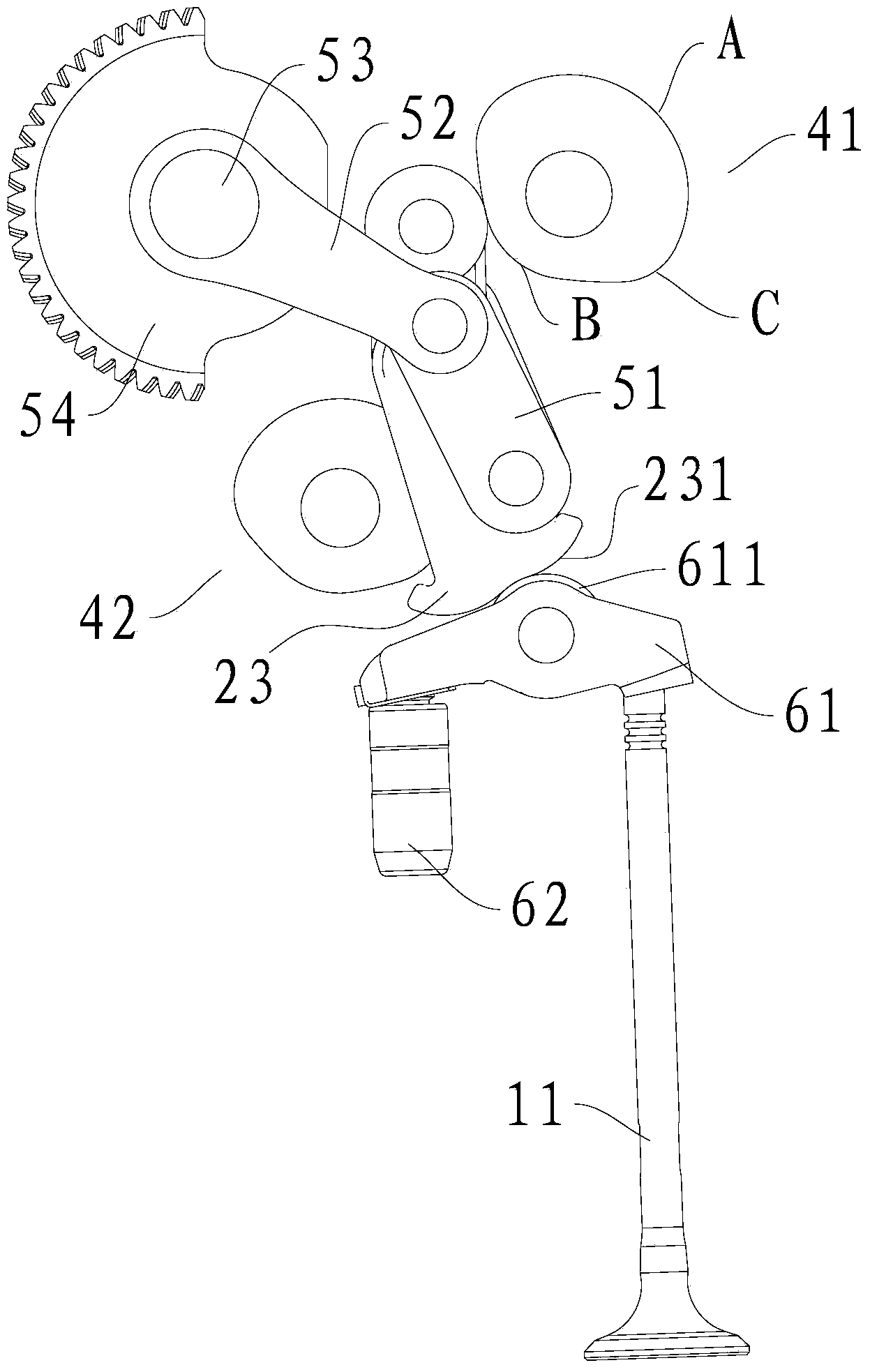

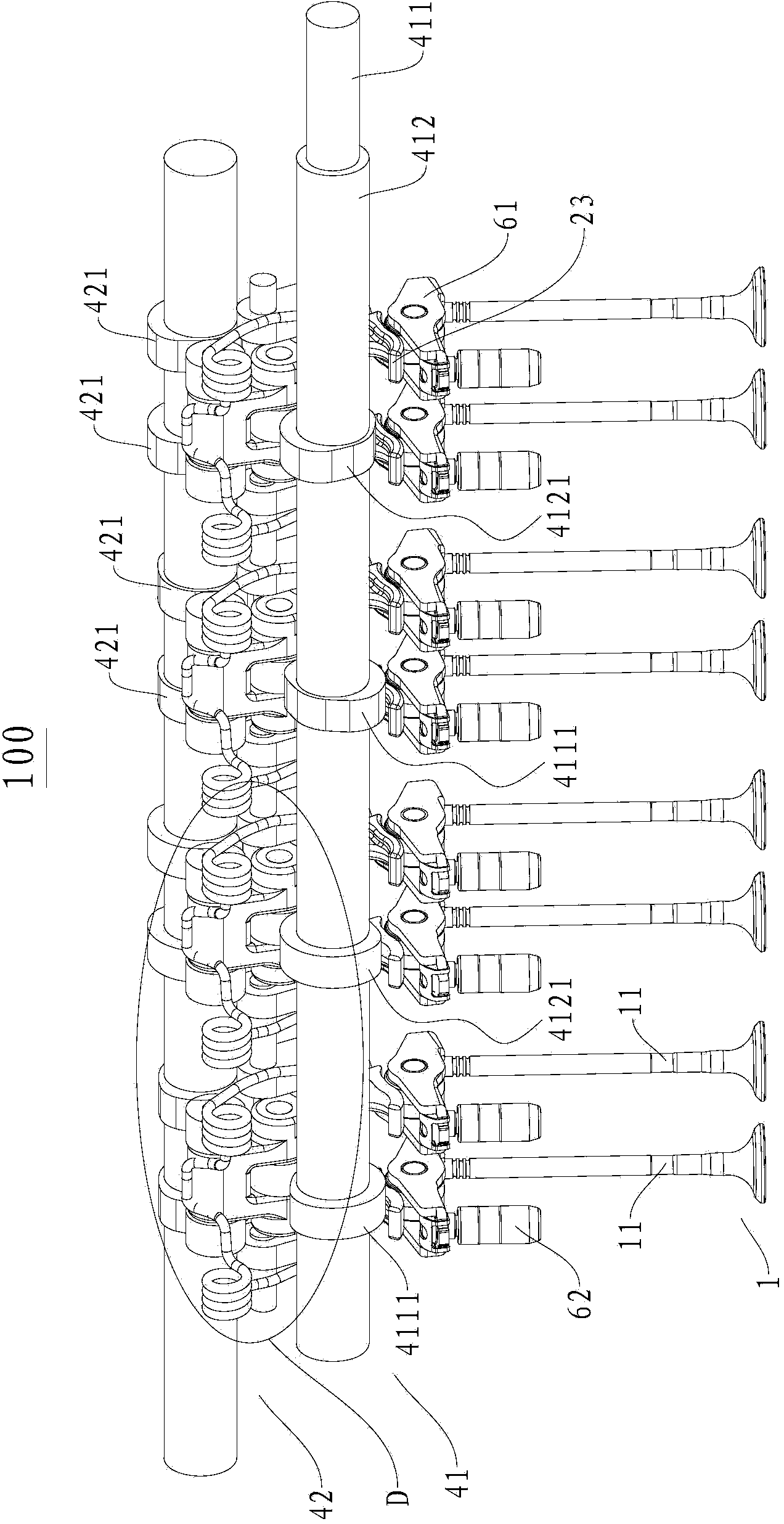

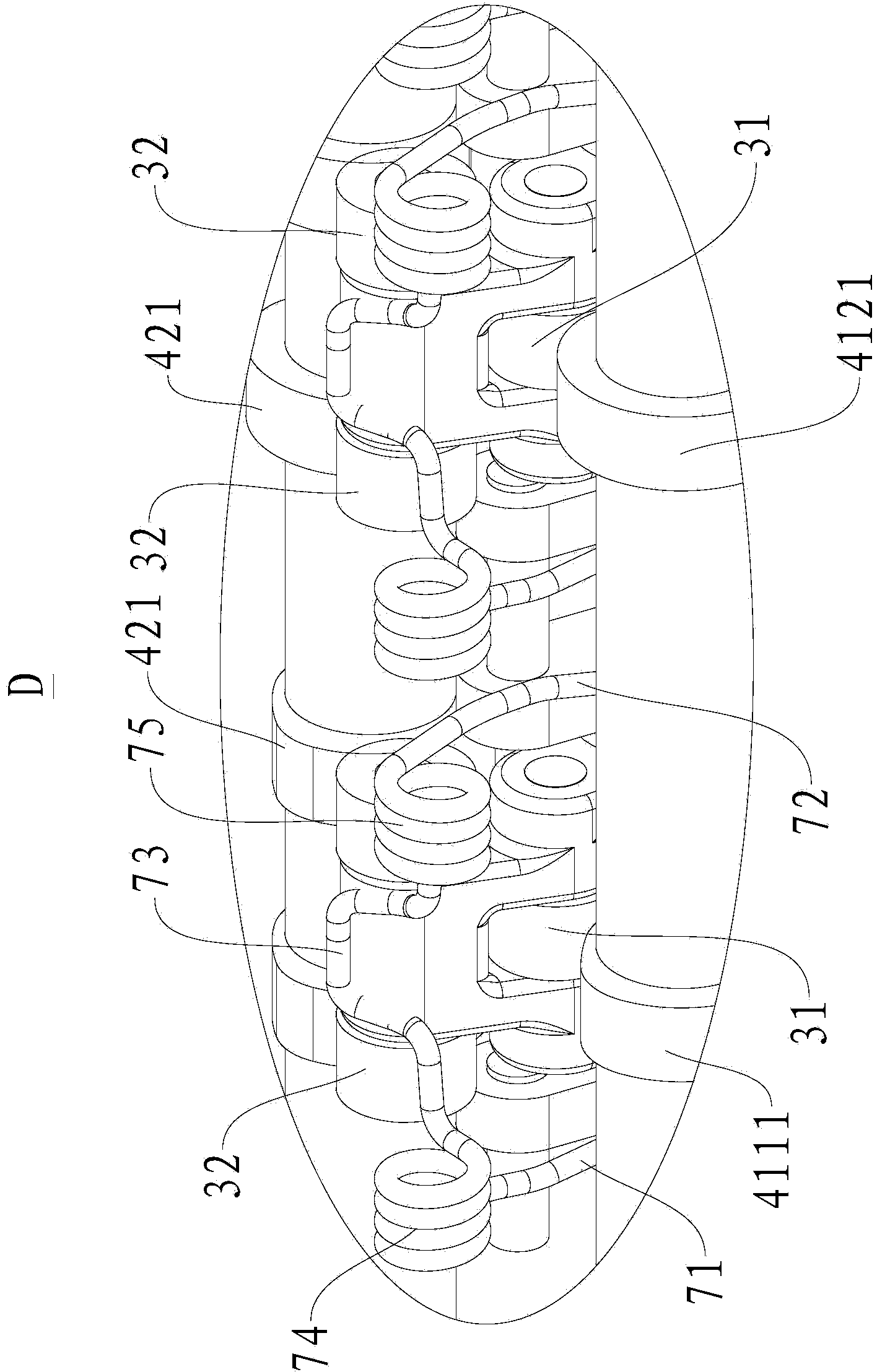

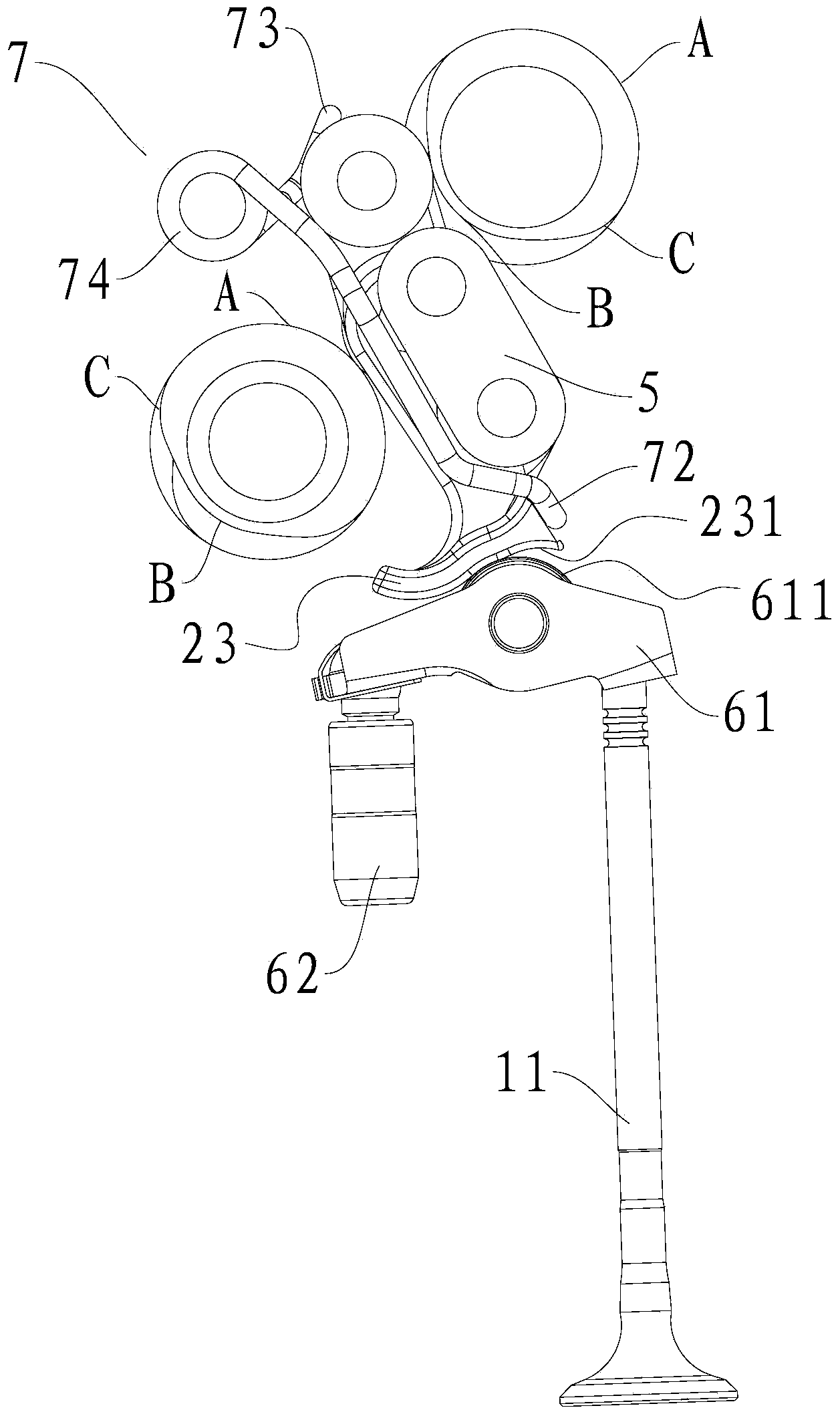

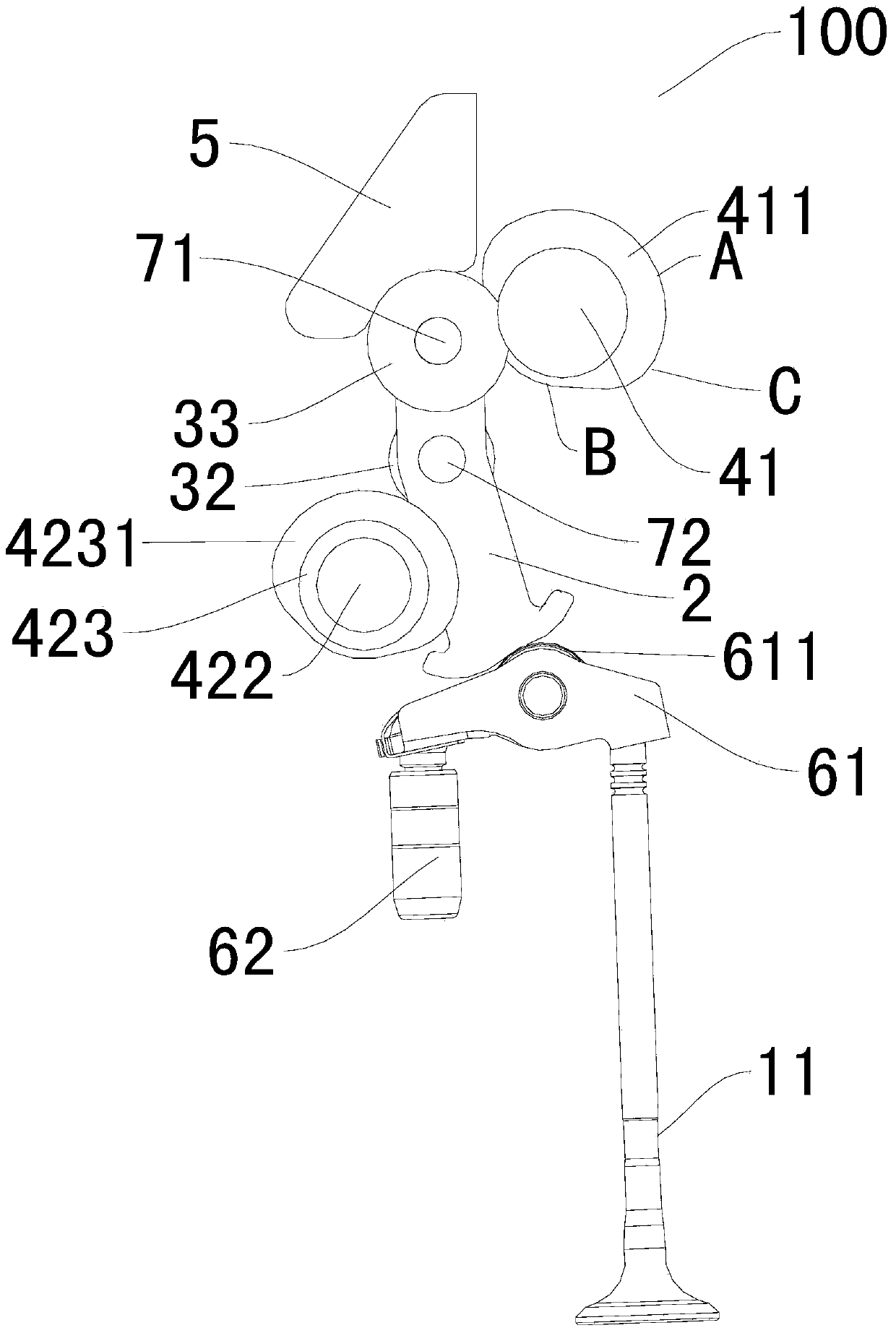

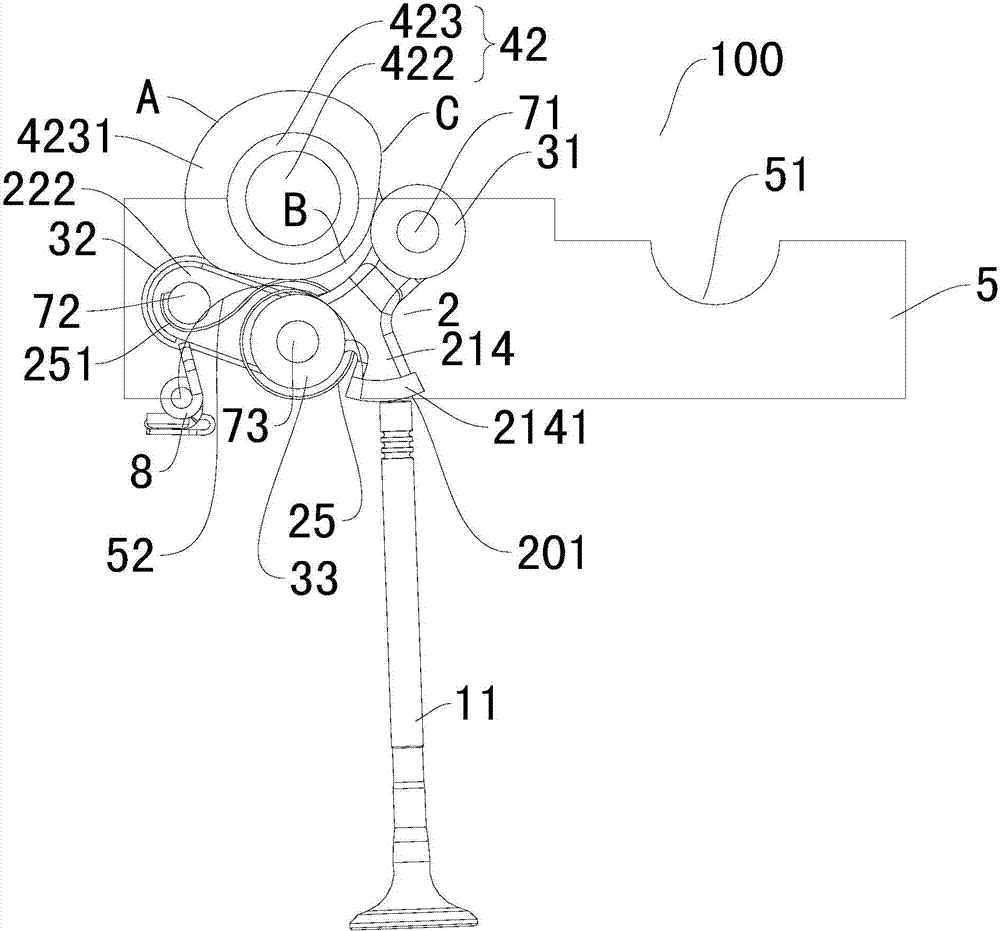

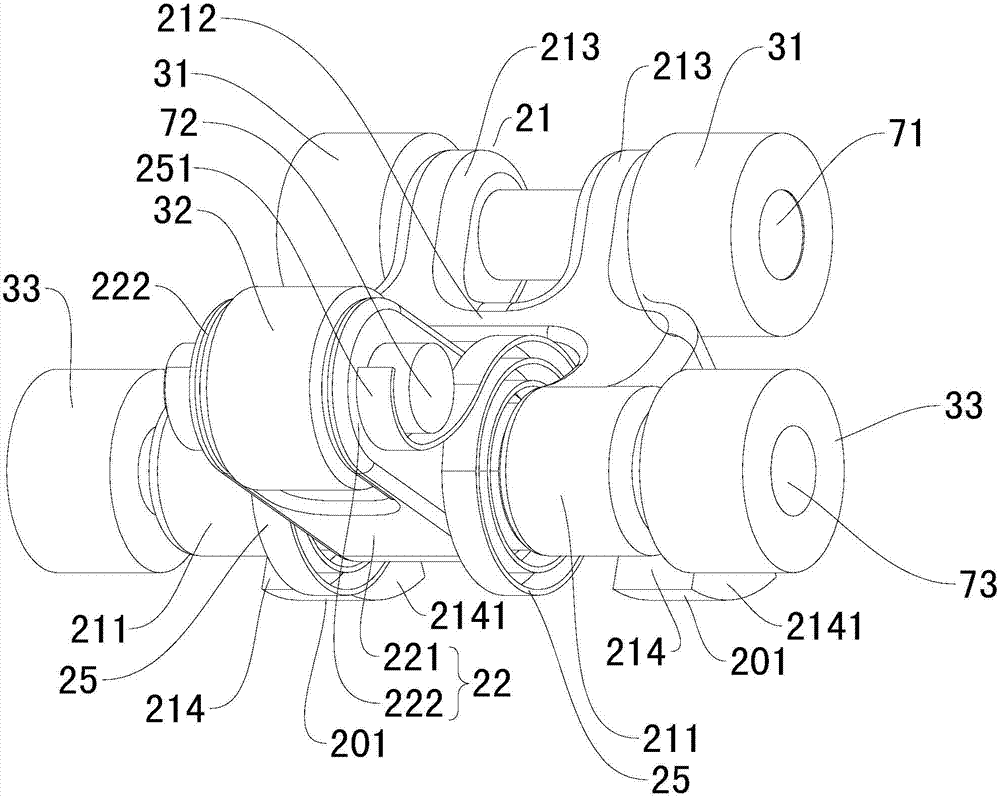

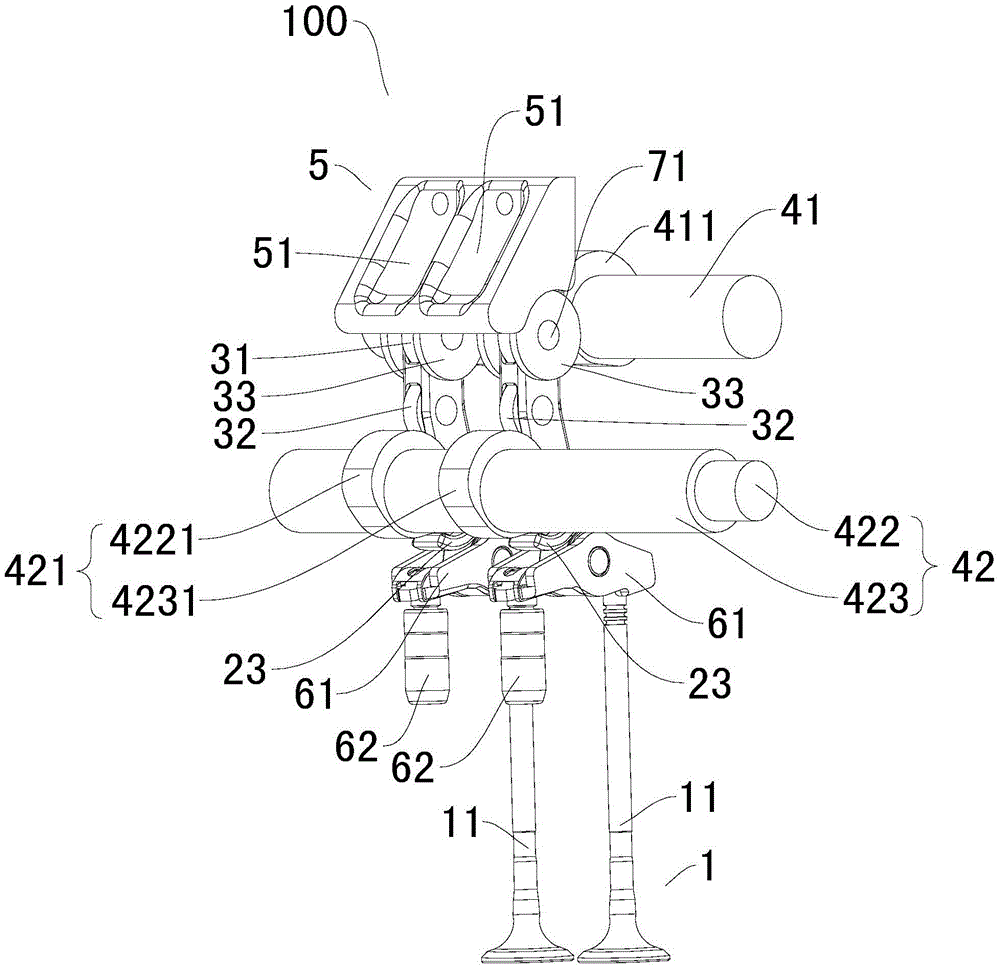

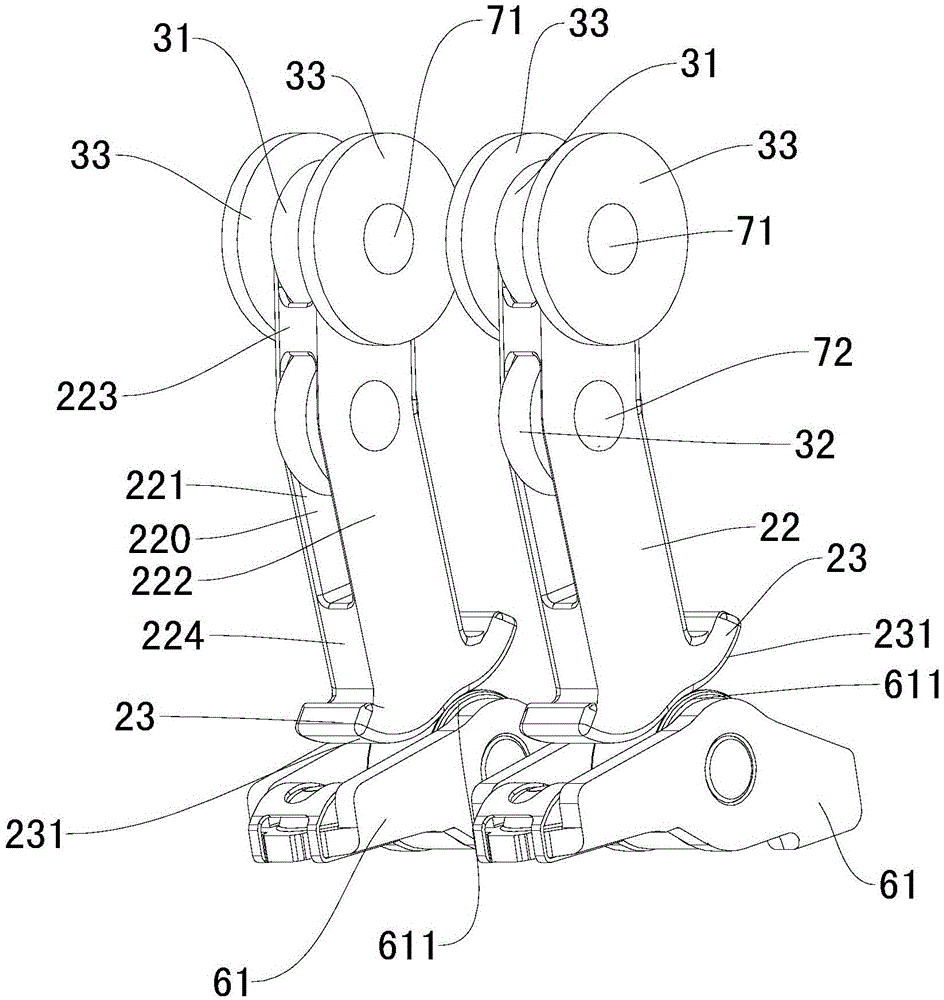

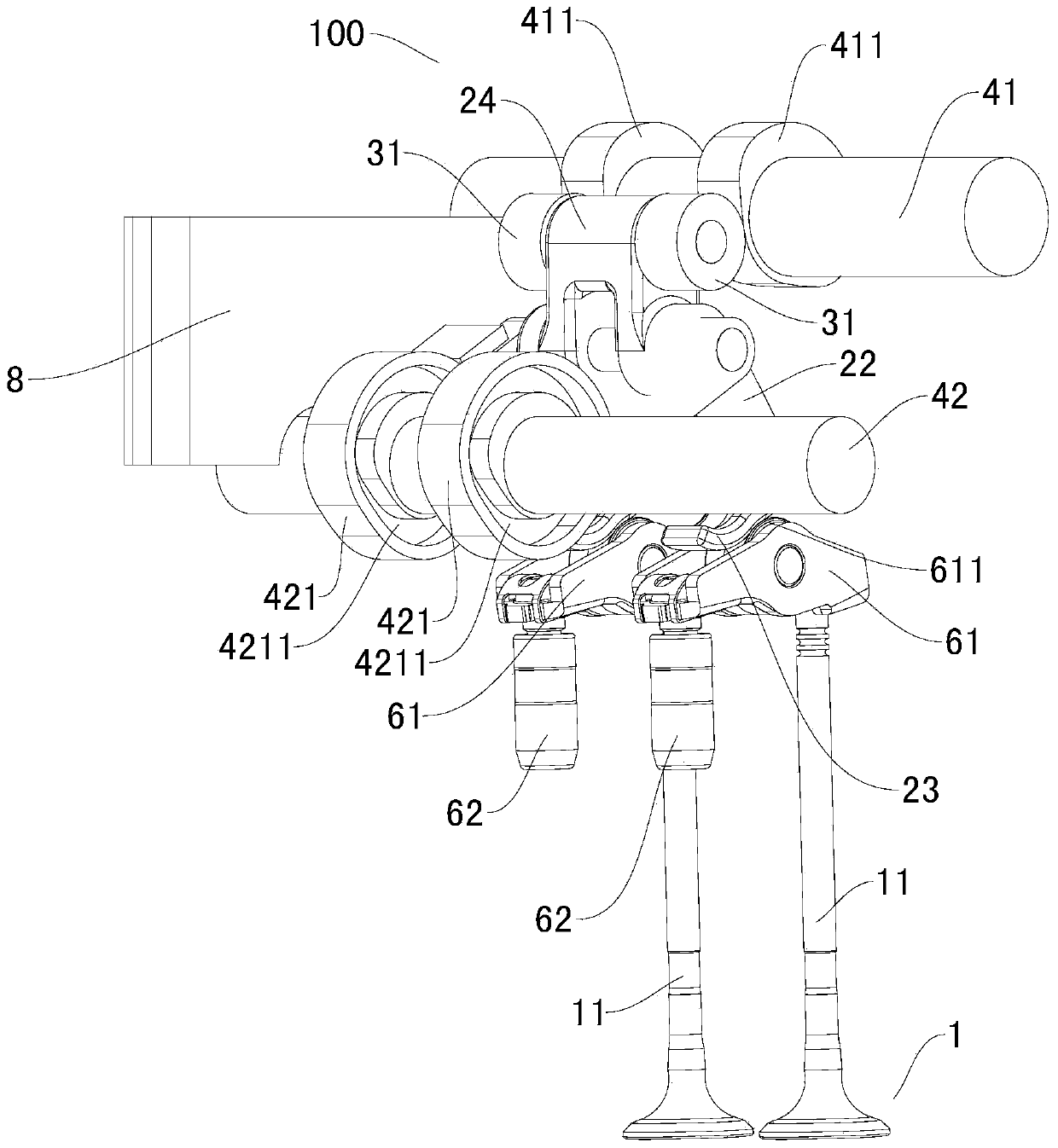

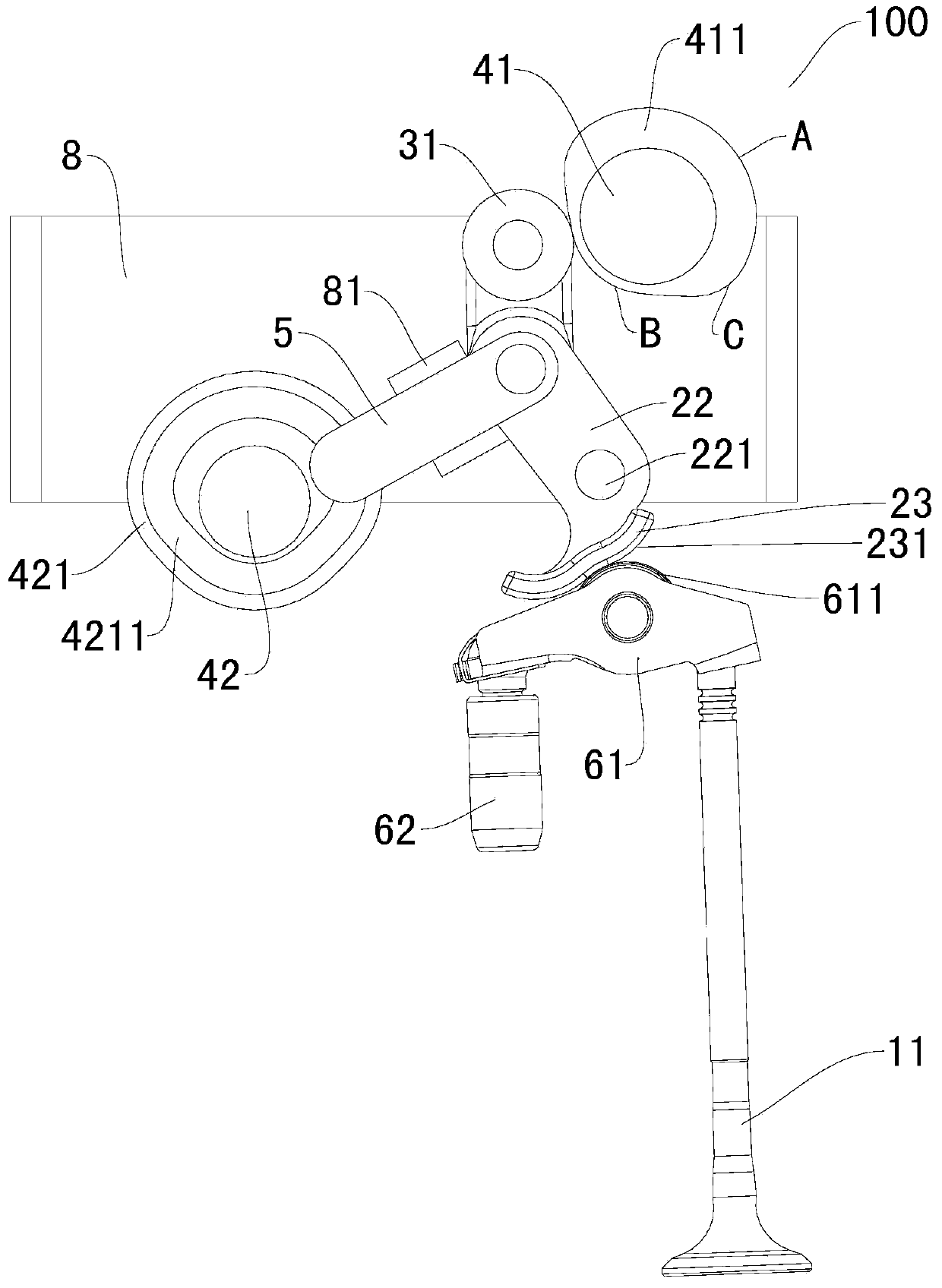

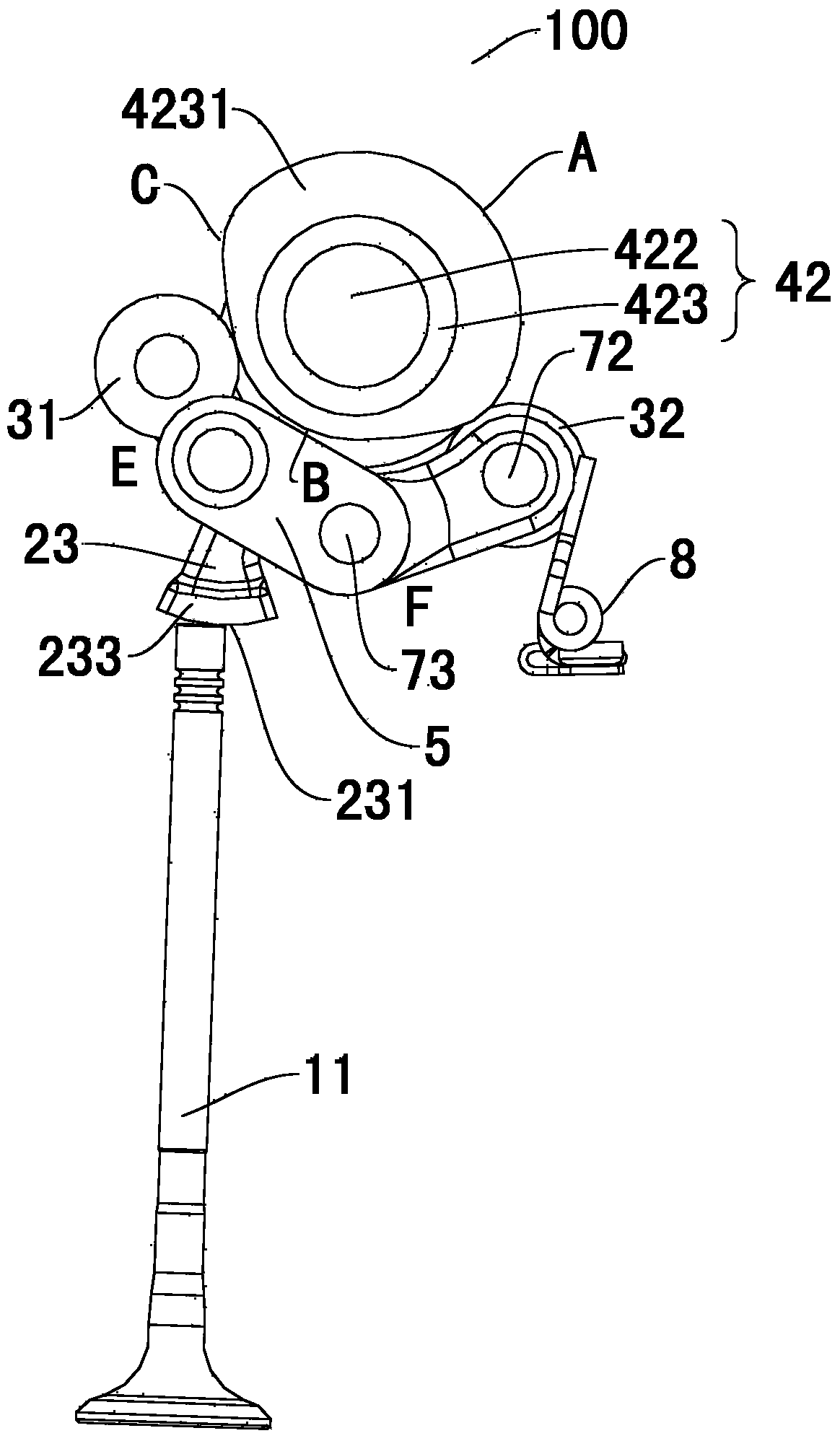

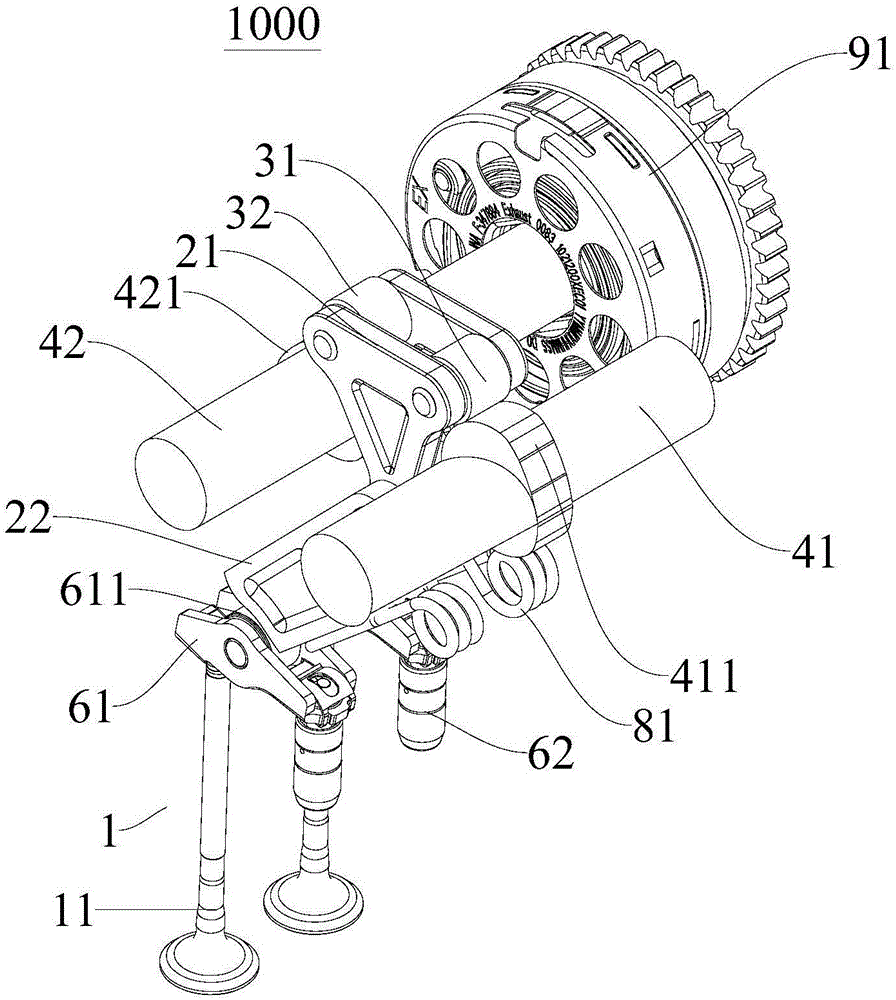

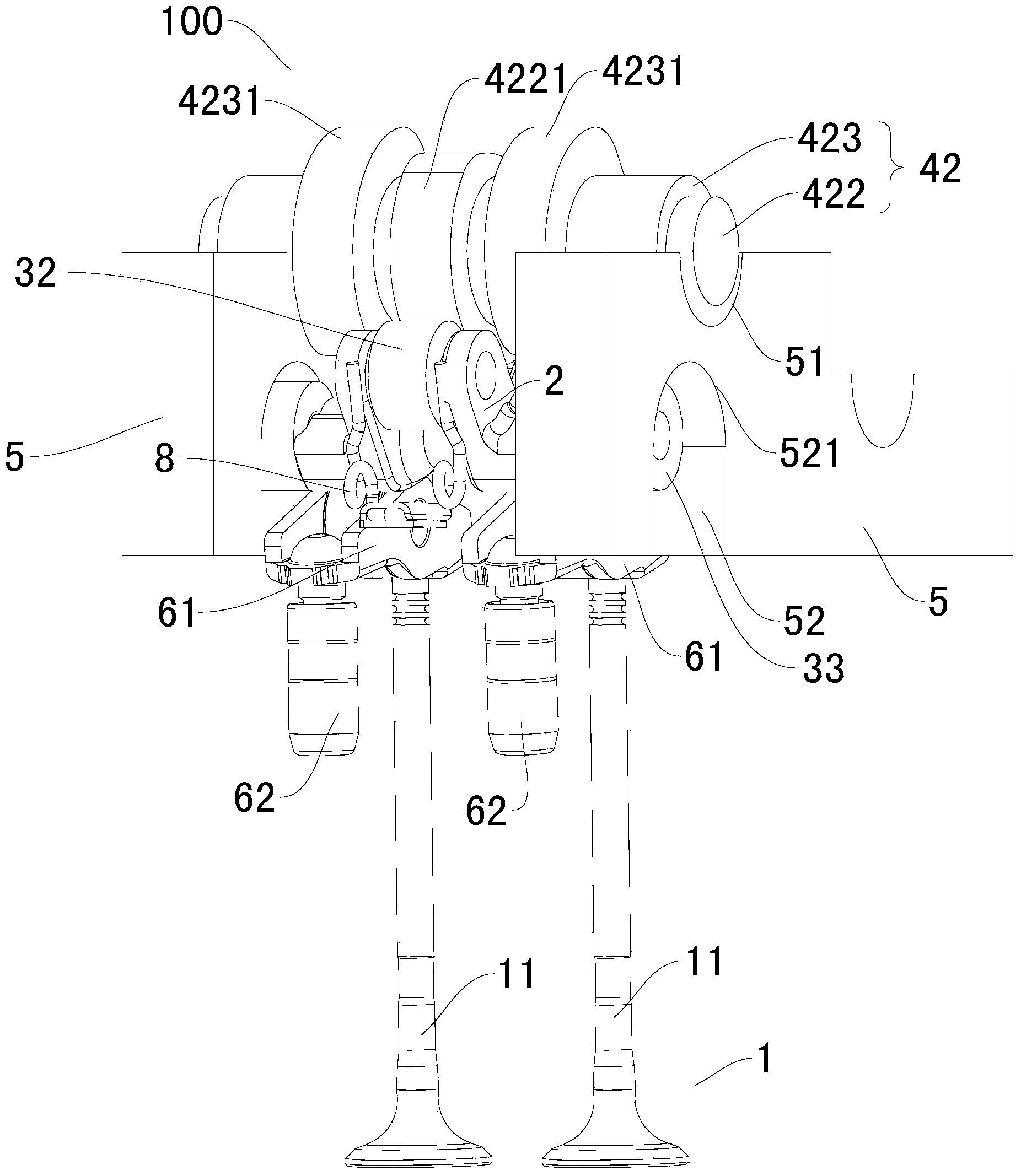

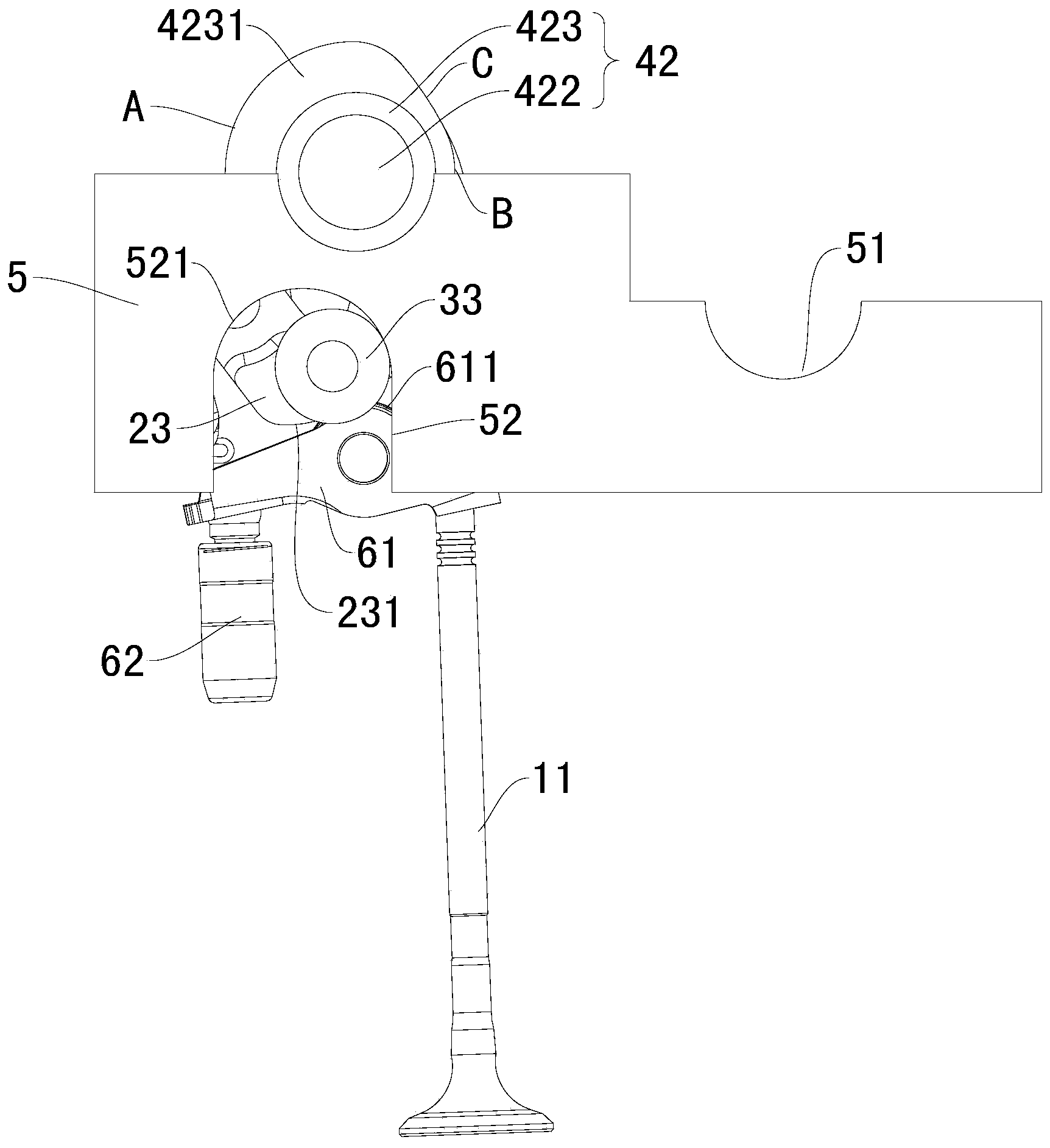

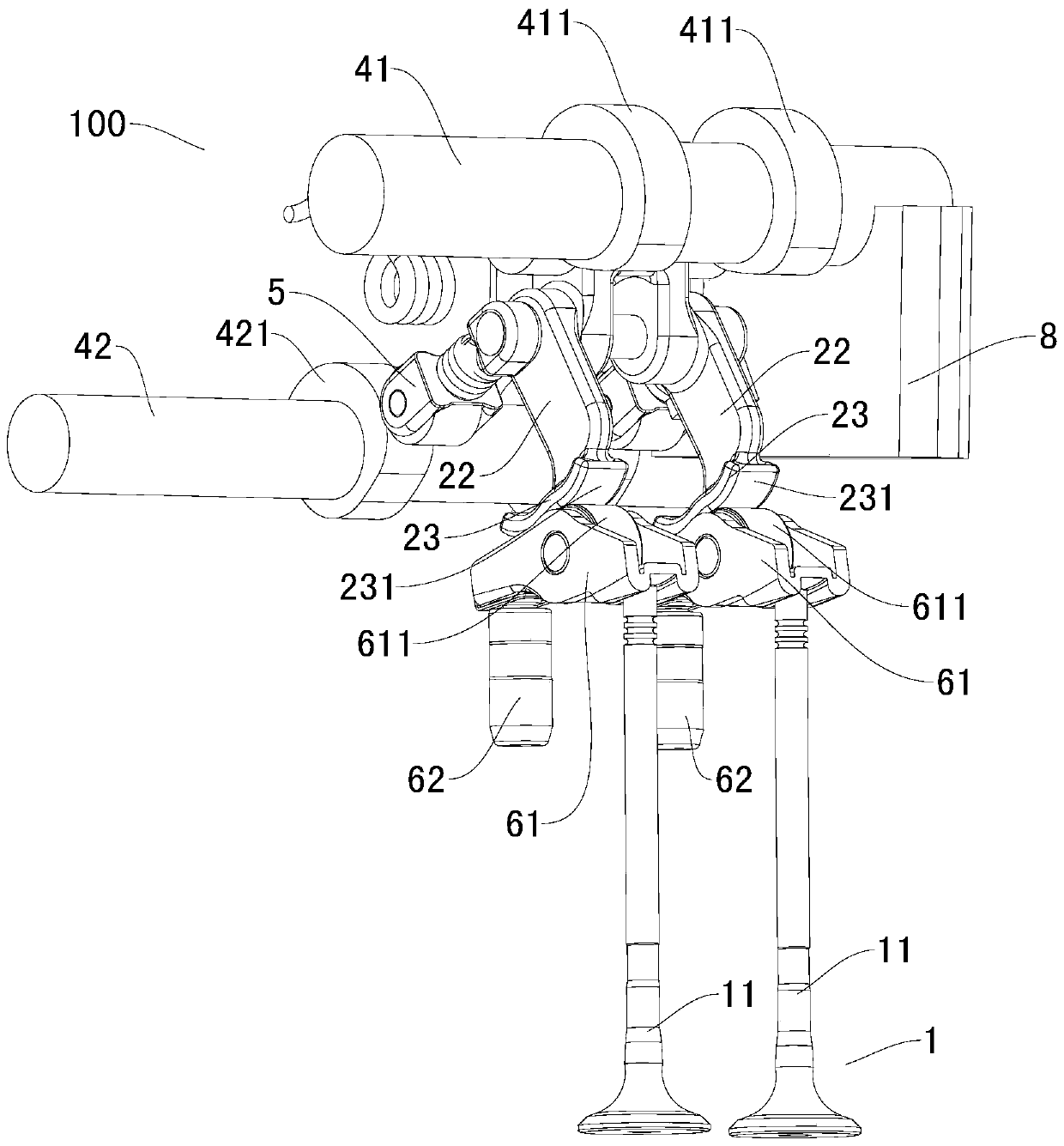

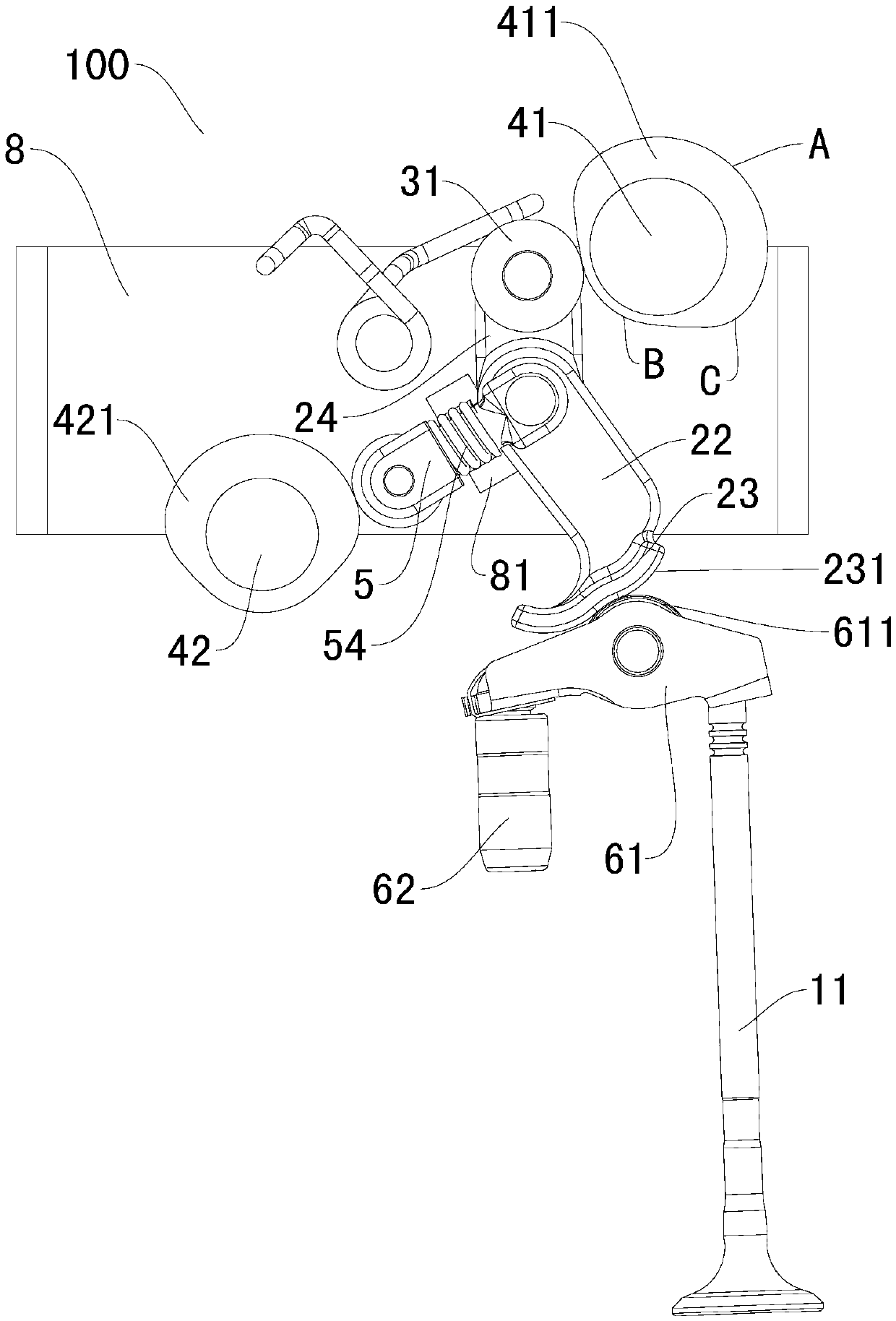

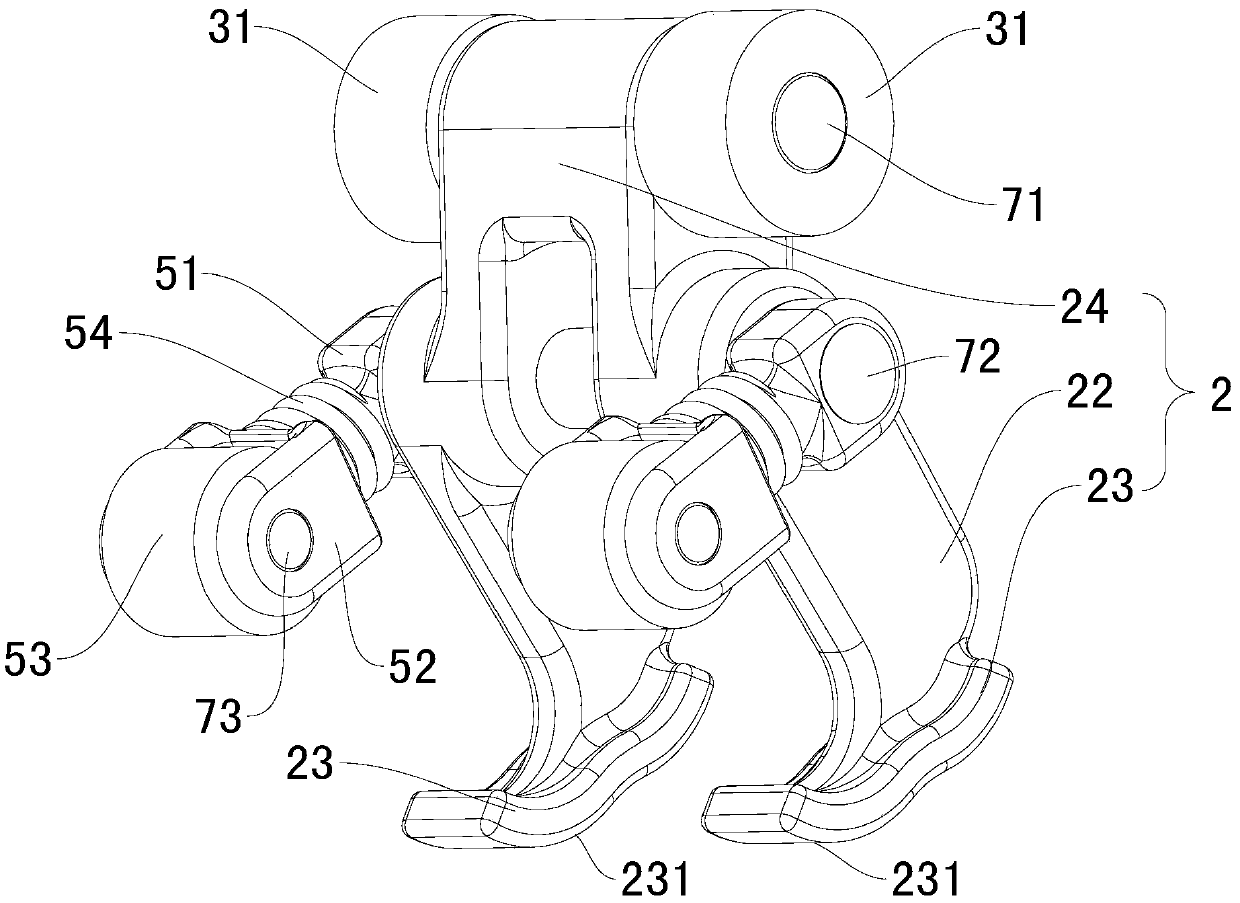

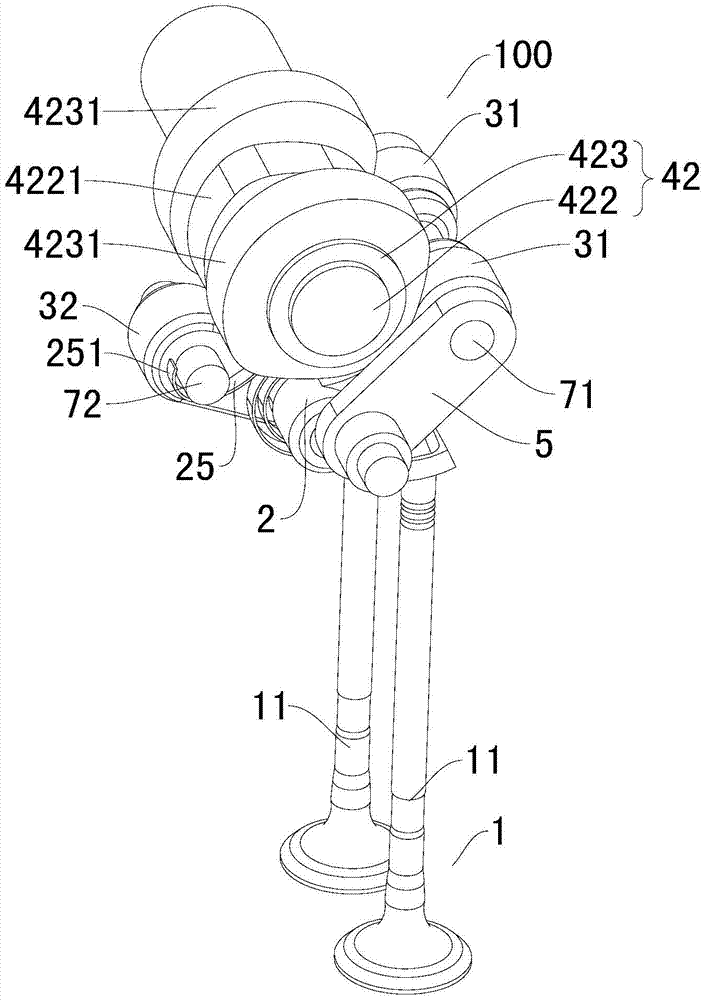

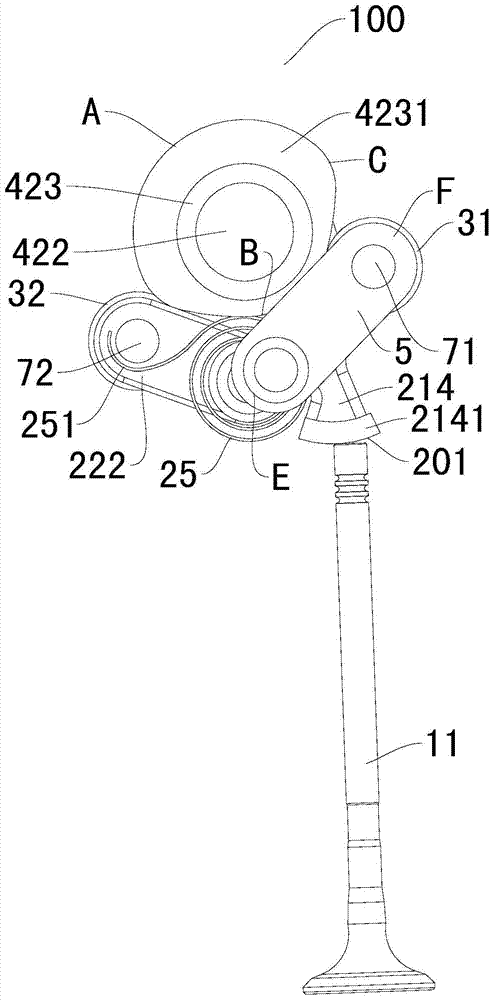

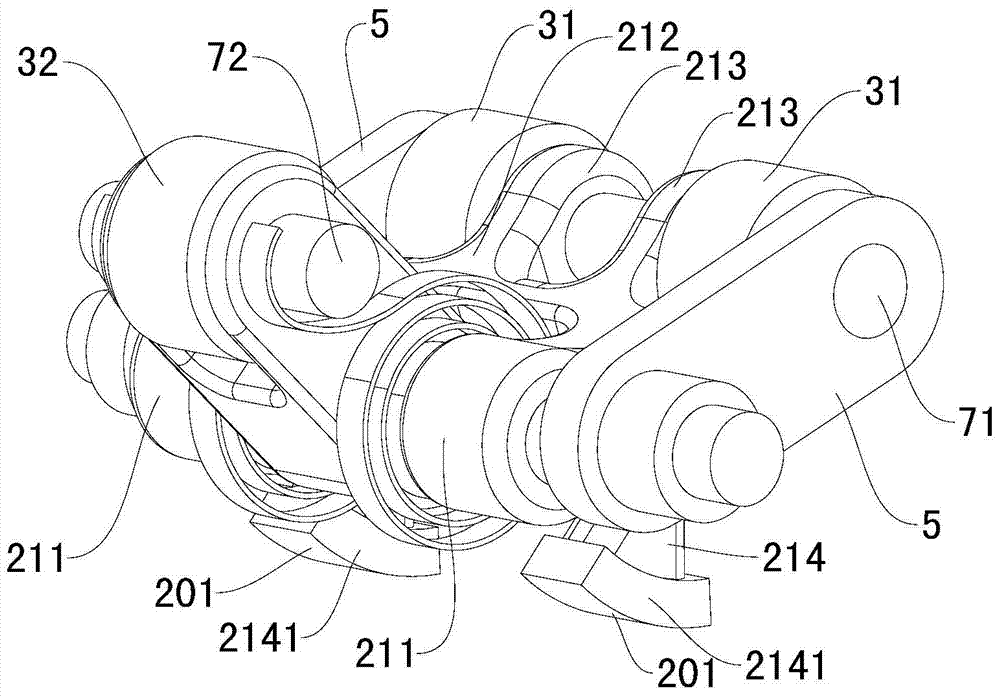

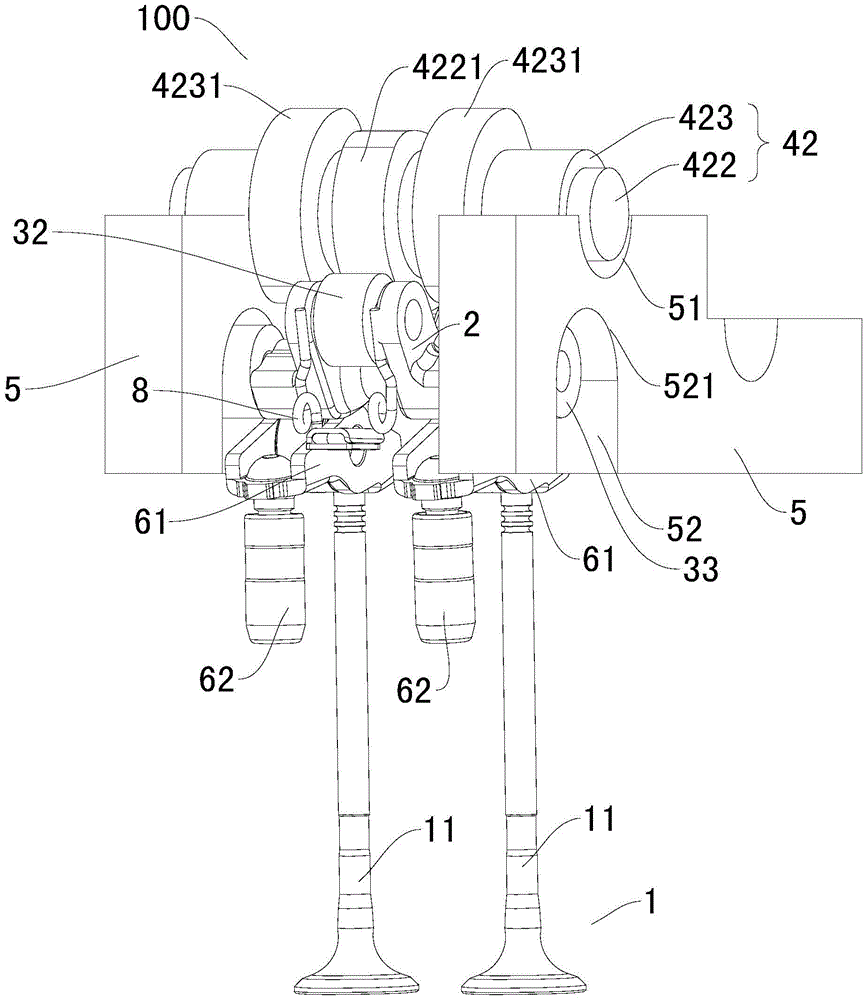

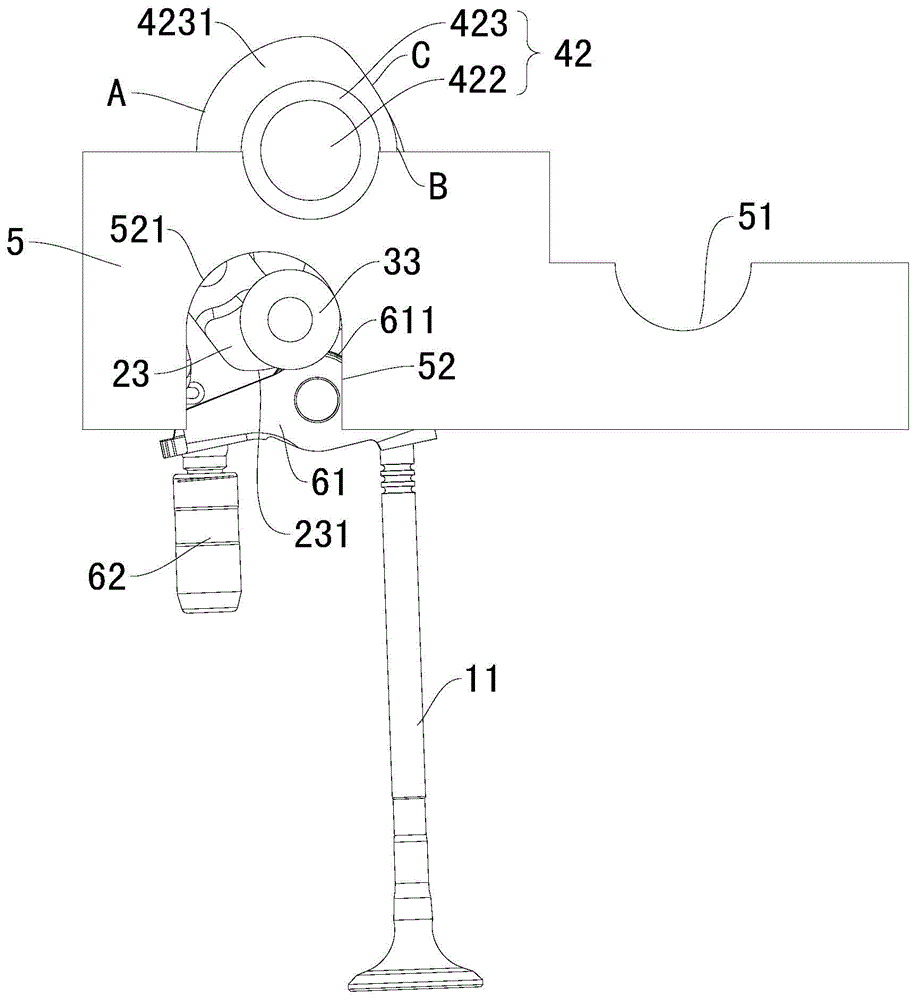

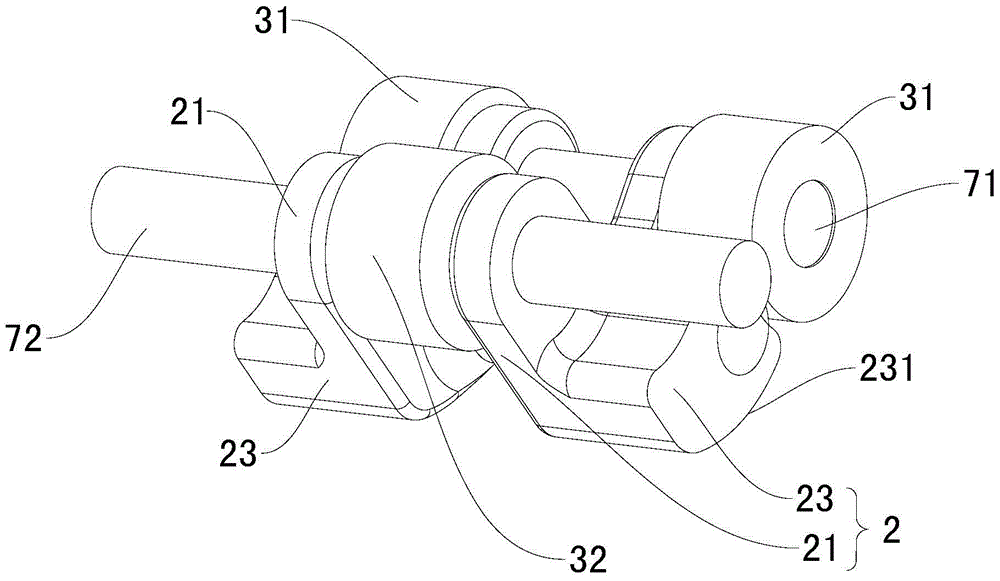

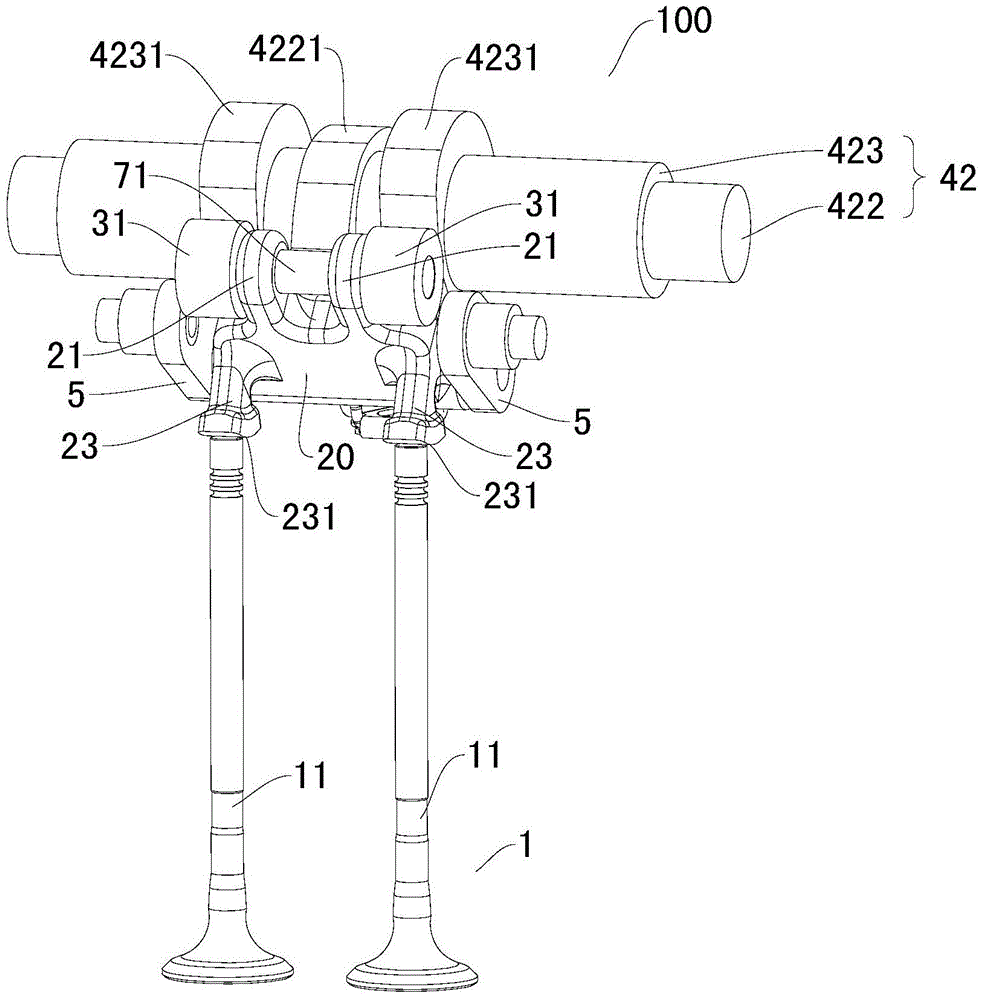

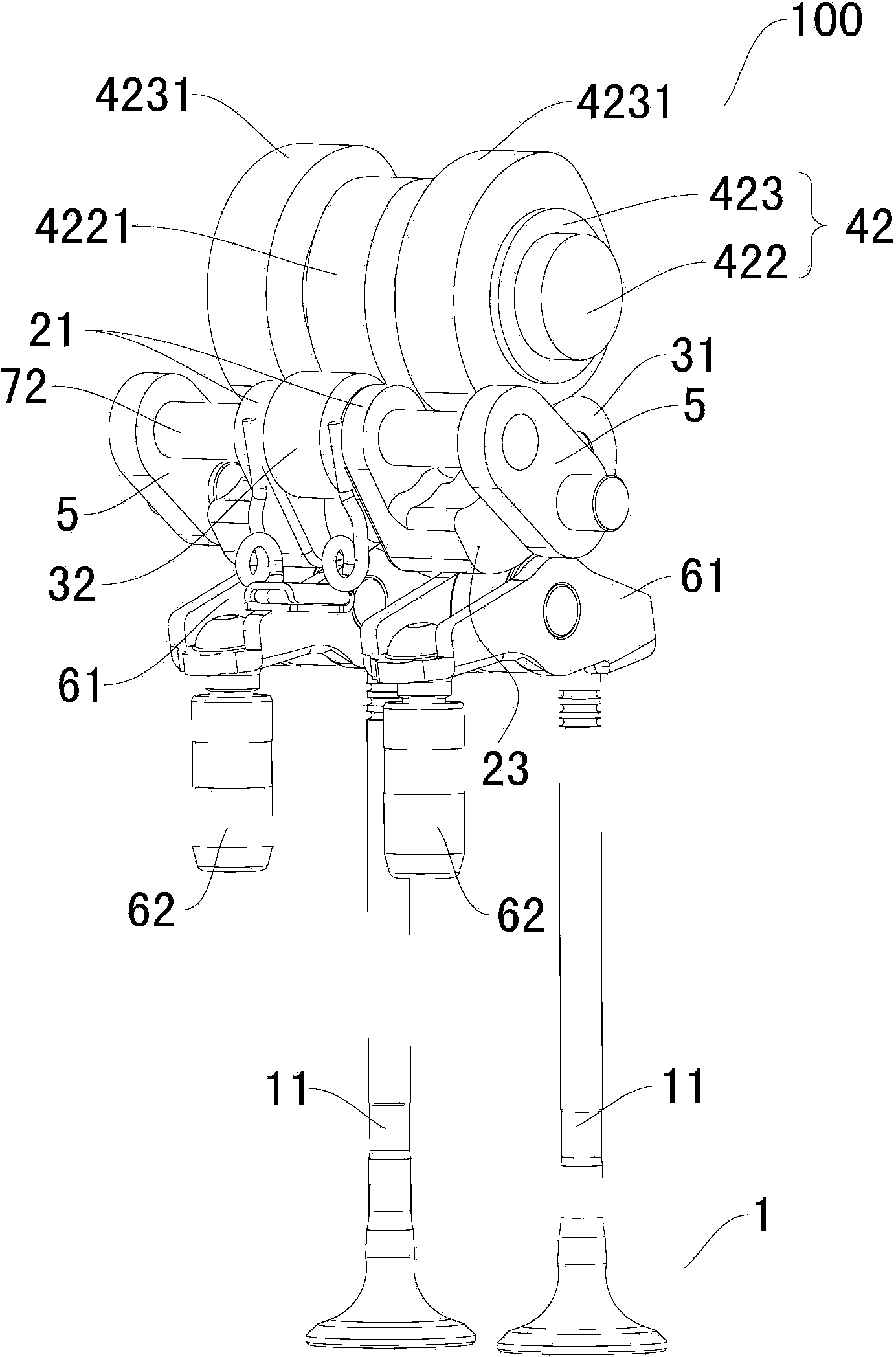

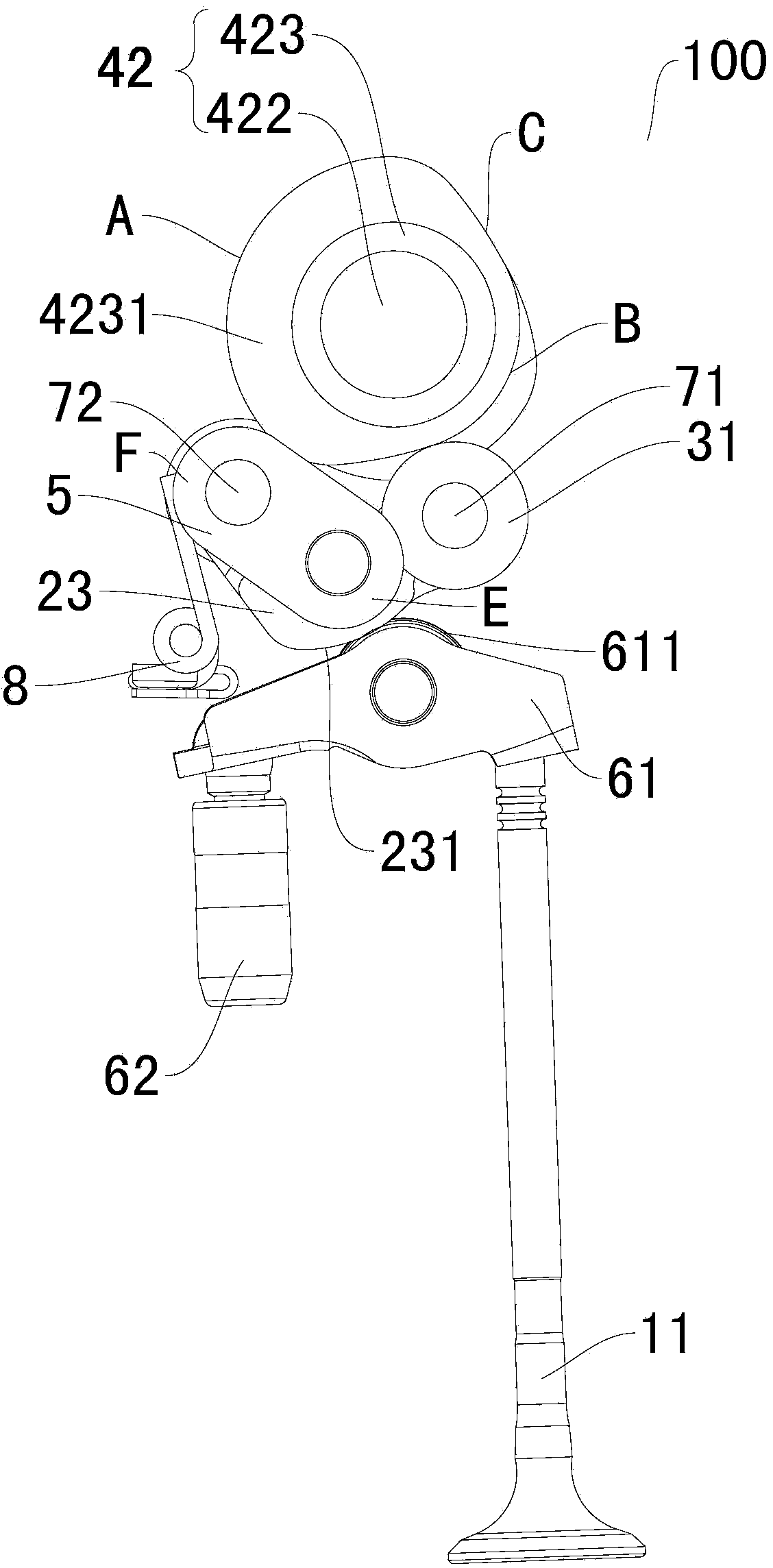

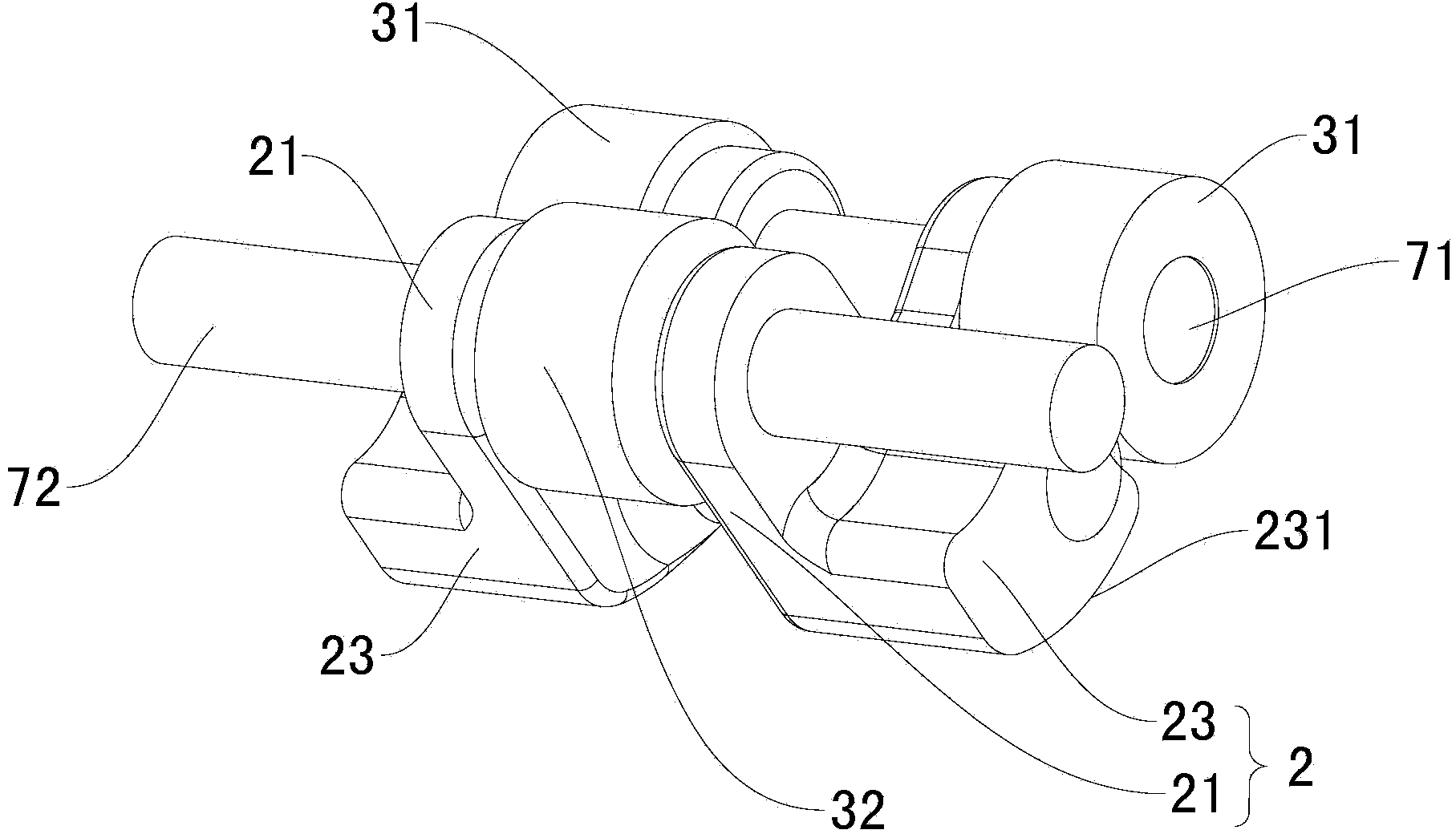

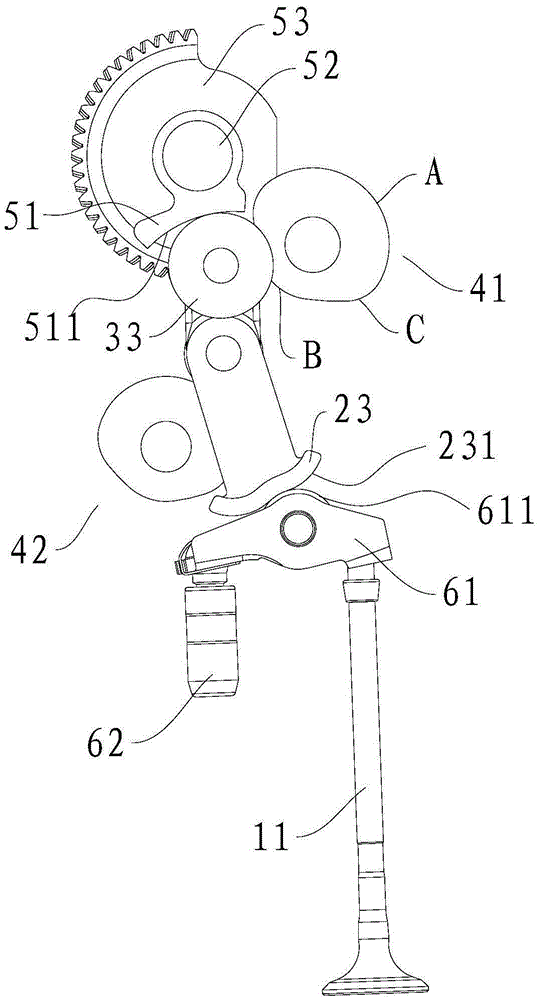

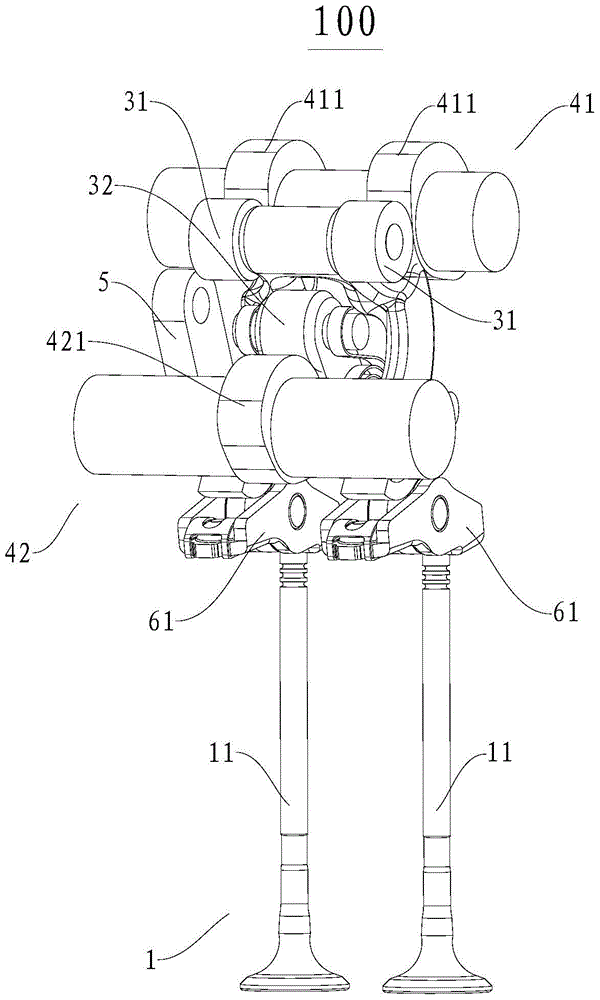

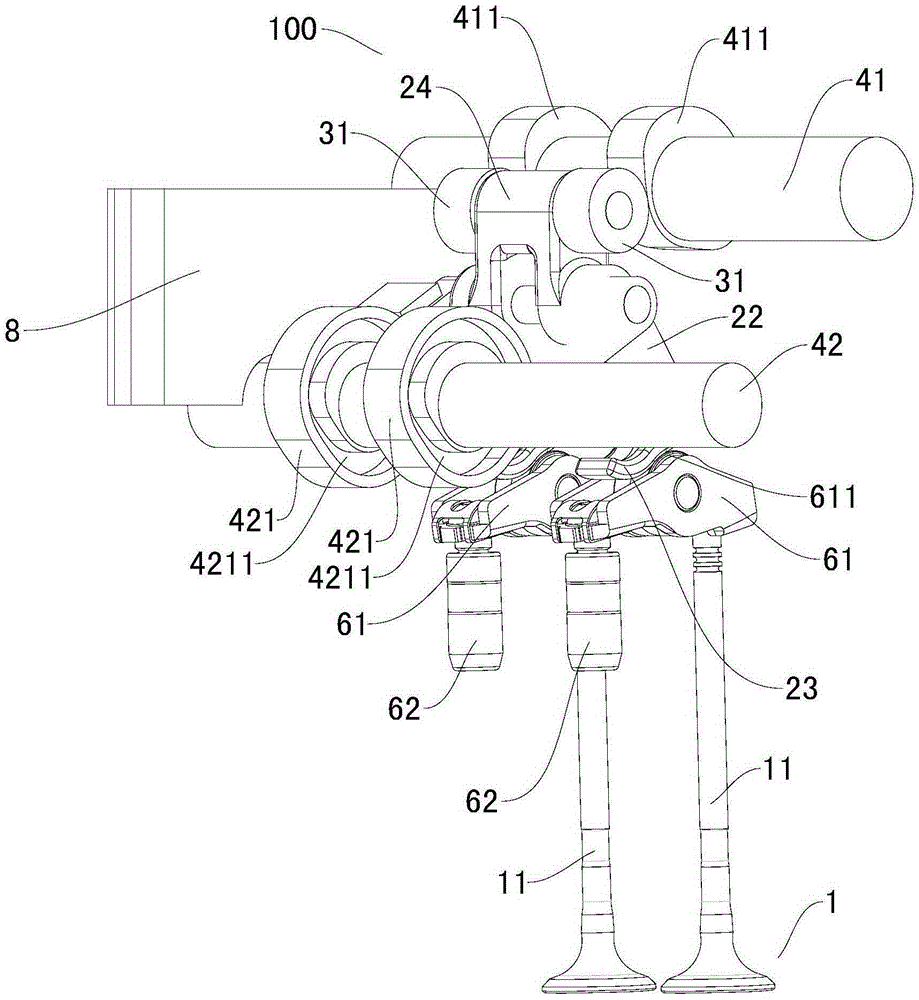

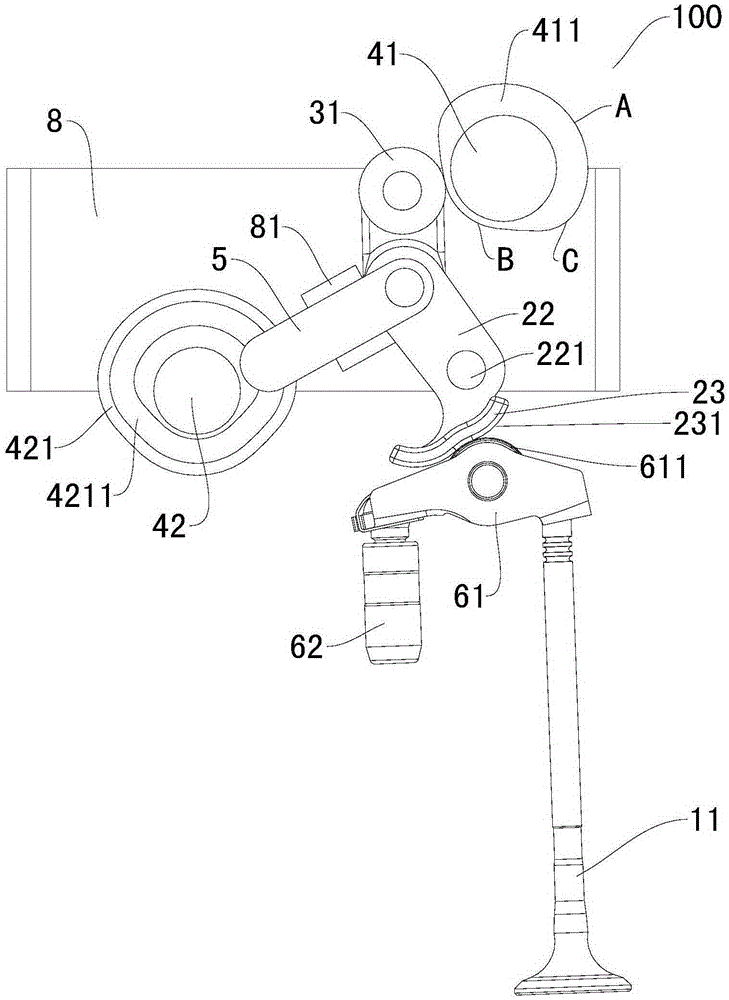

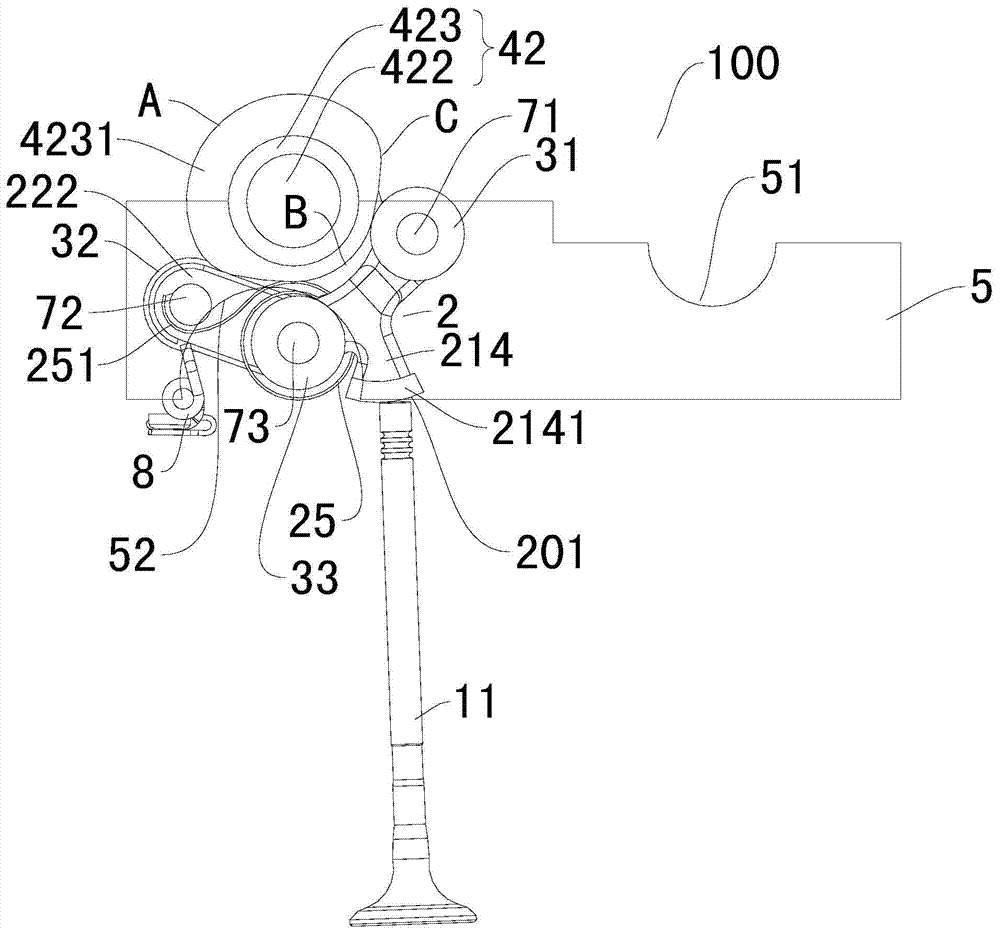

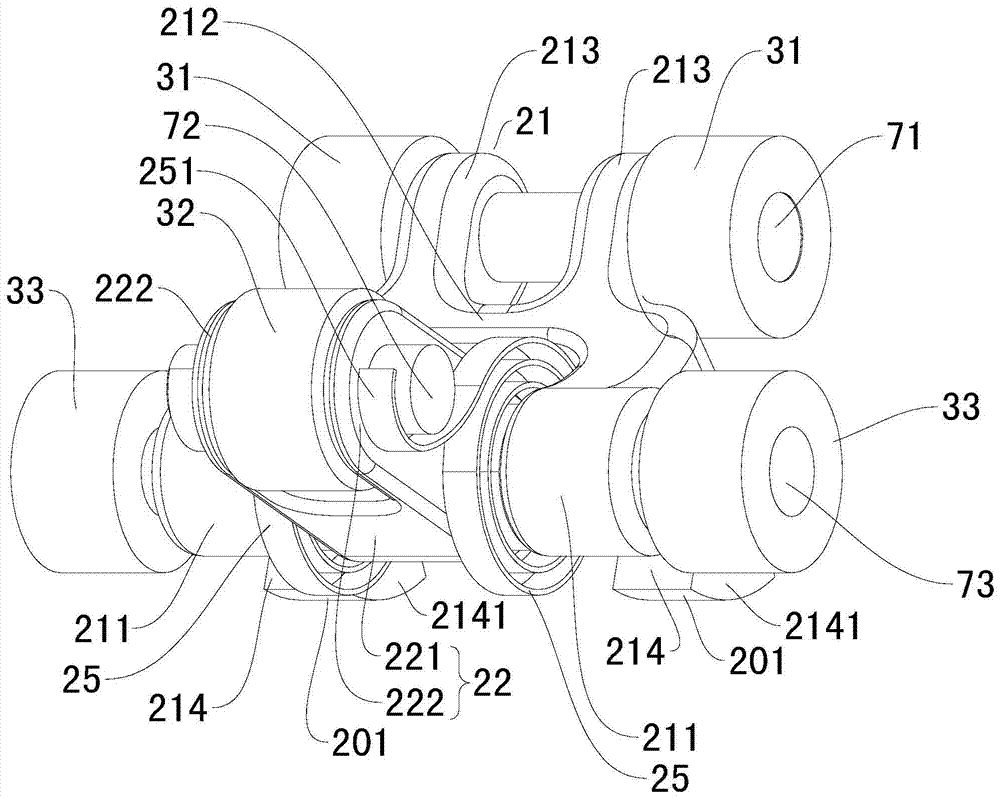

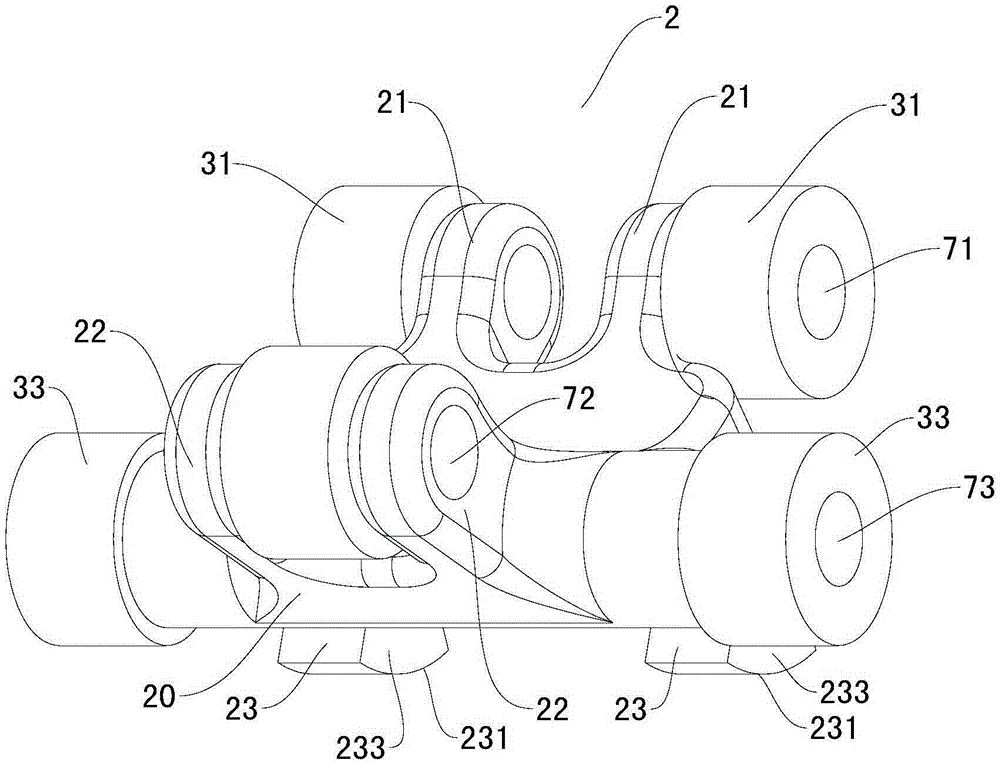

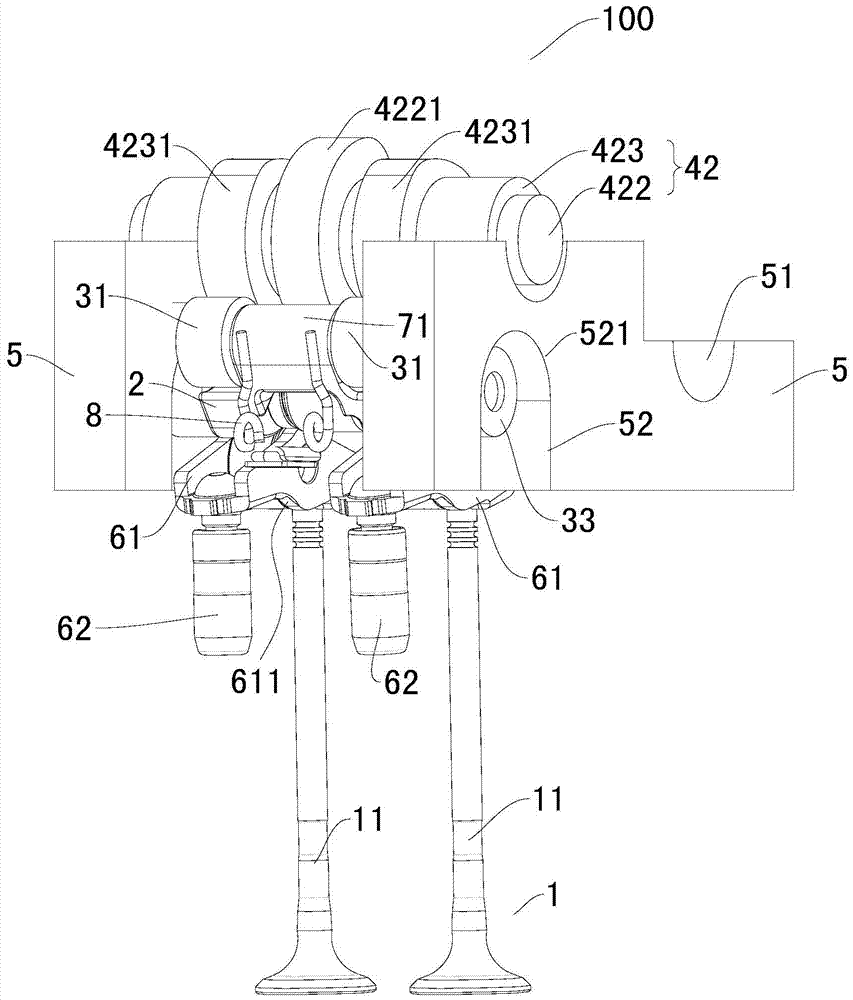

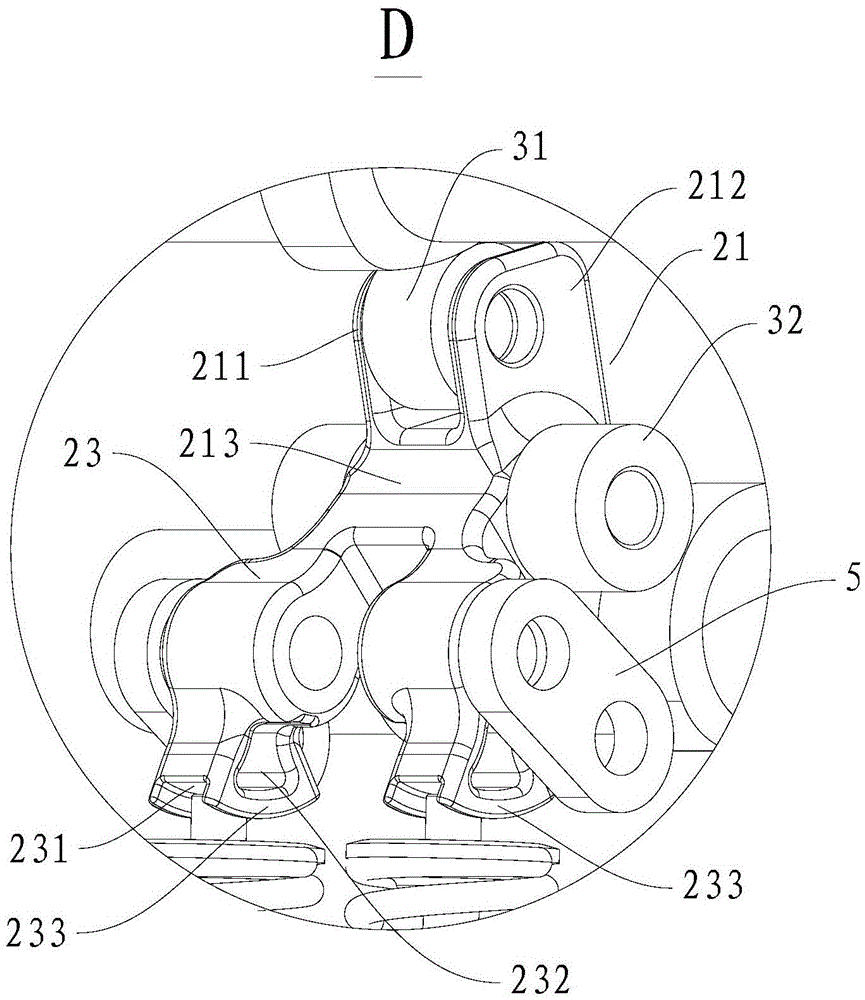

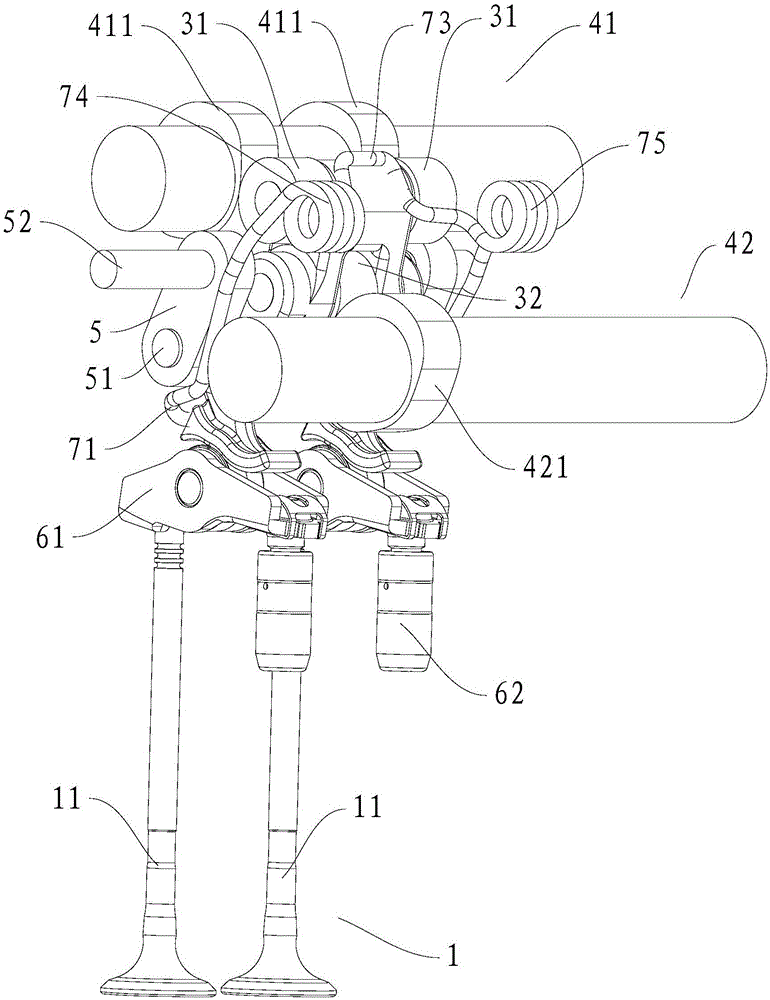

The invention discloses an air distribution mechanism for an engine and a vehicle comprising same. The air distribution mechanism comprises an air valve mechanism, a rocker arm assembly, a roller, an integrated push rod, a first cam shaft, a second cam shaft and a phase adjusting mechanism which is used for adjusting relative phase positions of the first cam shaft and the second cam shaft; the bottom of the rocker arm assembly is provided with a driving profile surface; the driving profile surface which is suitable for driving an air valve of the air valve mechanism to move along the direction which is parallel to the air valve central line; the roller is arranged on the rocker arm assembly in a pivot rotation mode; the integrated push rod and the rocker arm assembly are connected in a pivot mode; the first cam shaft is provided with a first cam and the second cam shaft is provided with a second cam; the first cam is abut against the roller; the peripheral surface of the second cam is matched with the integrated push rod in an abutting mode to drive the integrated push rod to move along the length direction which is parallel to the integrated push rod. The air distribution mechanism for the engine has the advantages of achieving opening of the air valve for a second time, meanwhile prolonging the continuous time for air valve opening and being simple in structure and few in part.

Owner:GREAT WALL MOTOR CO LTD

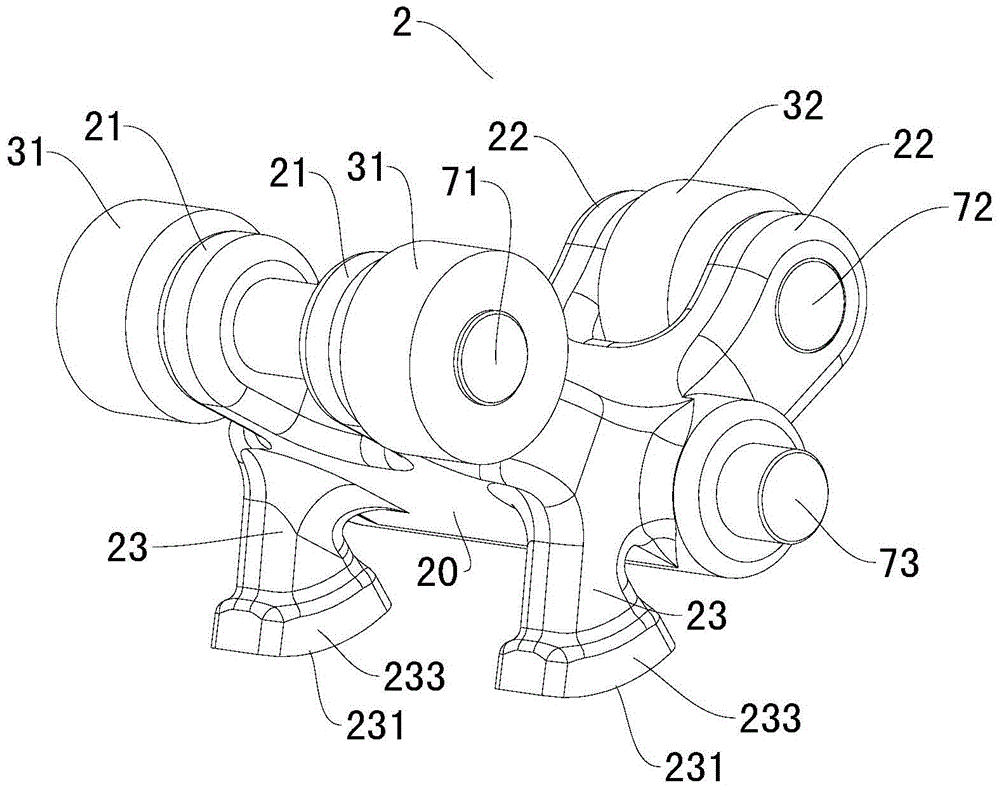

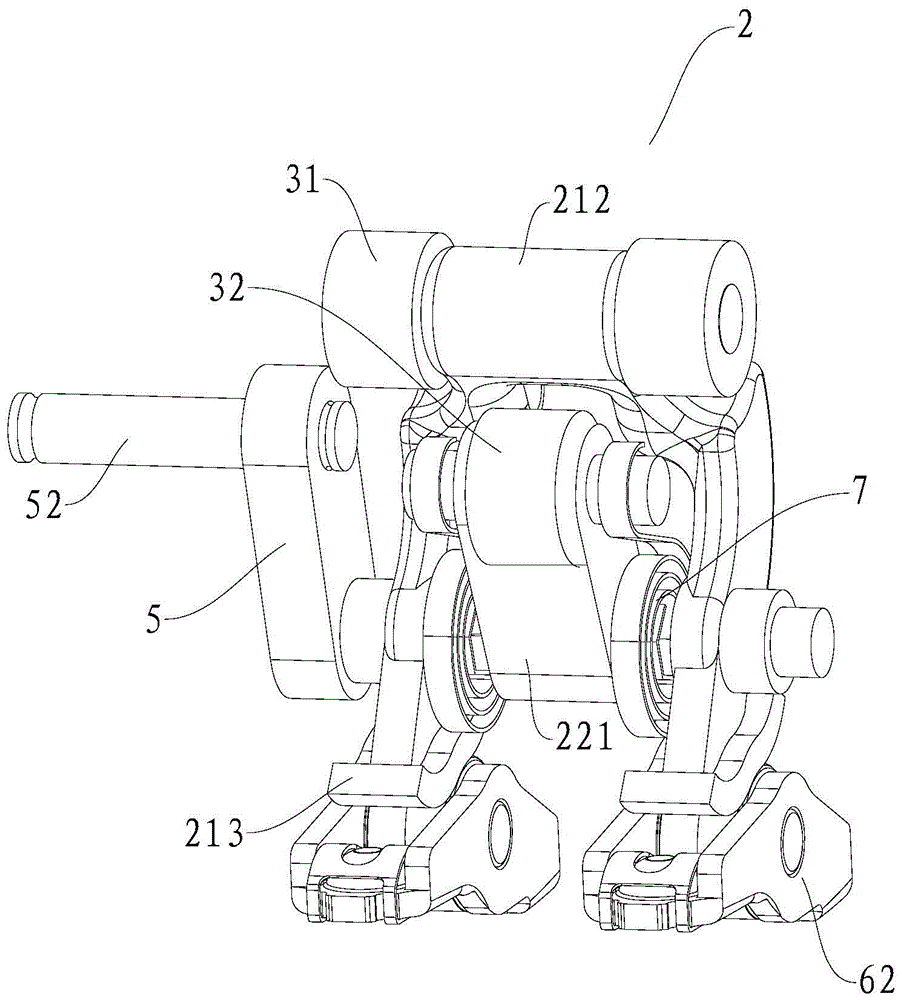

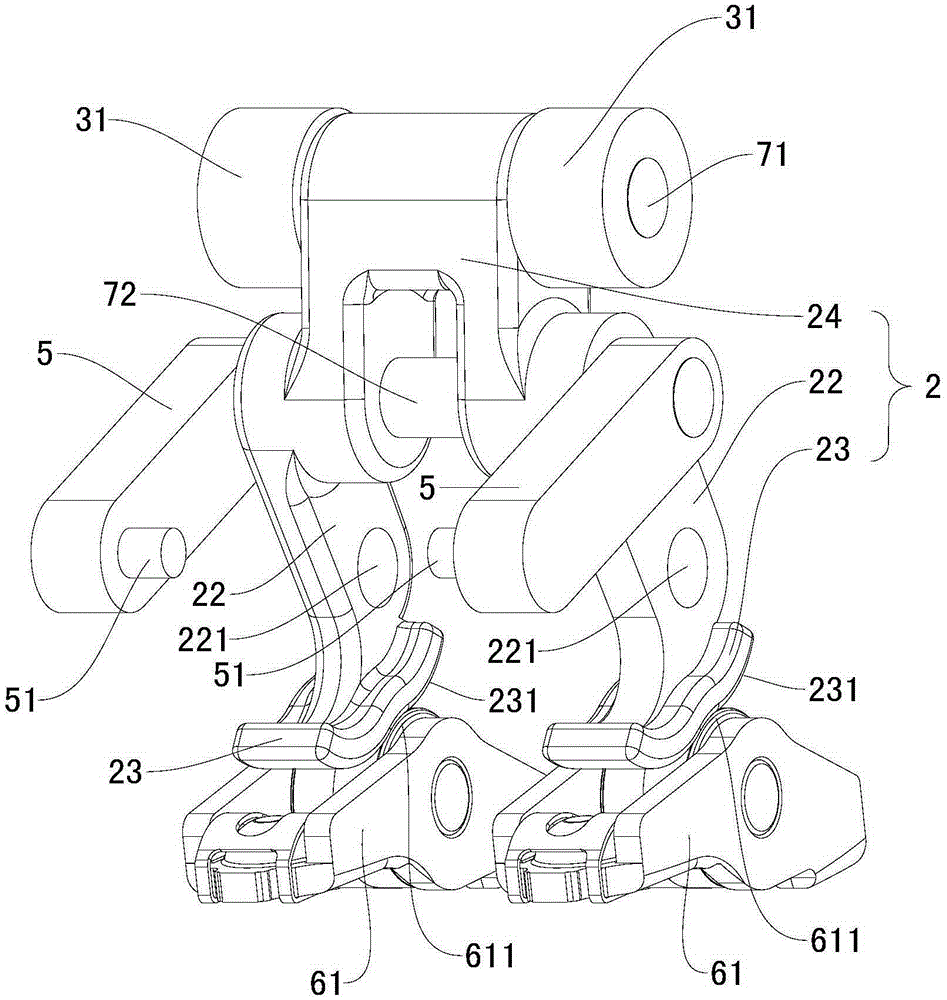

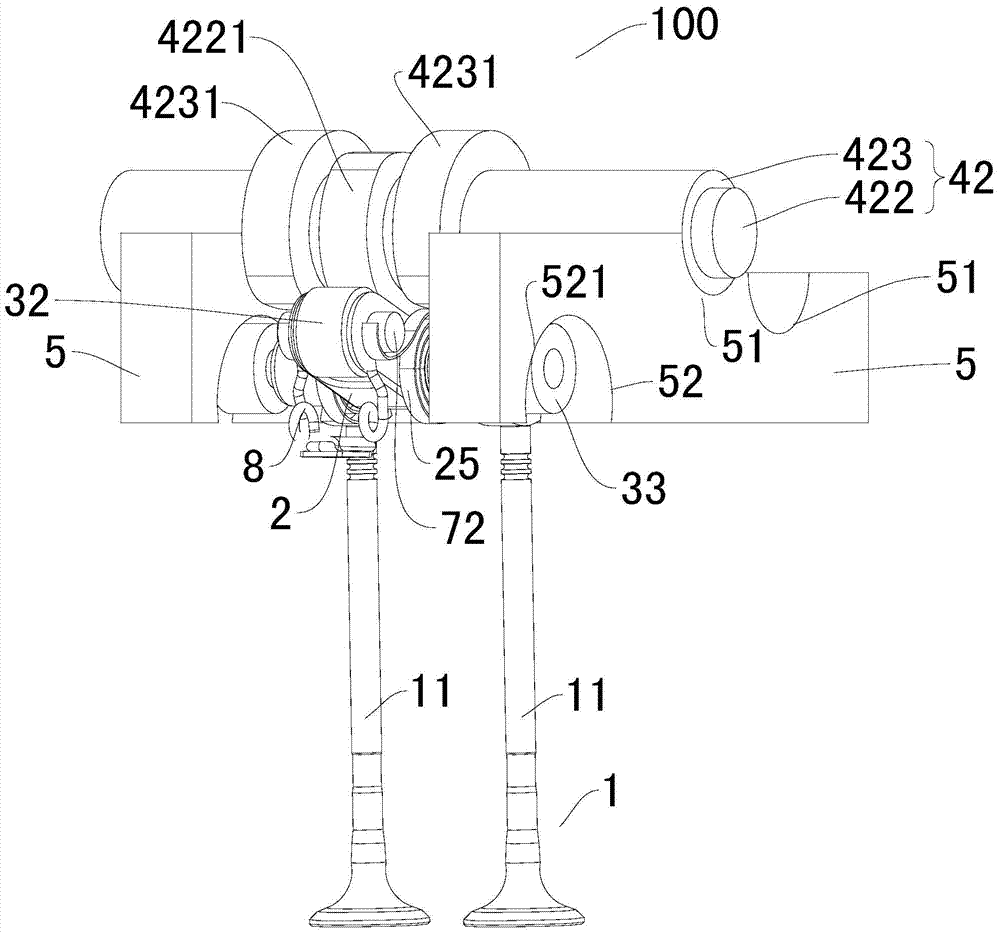

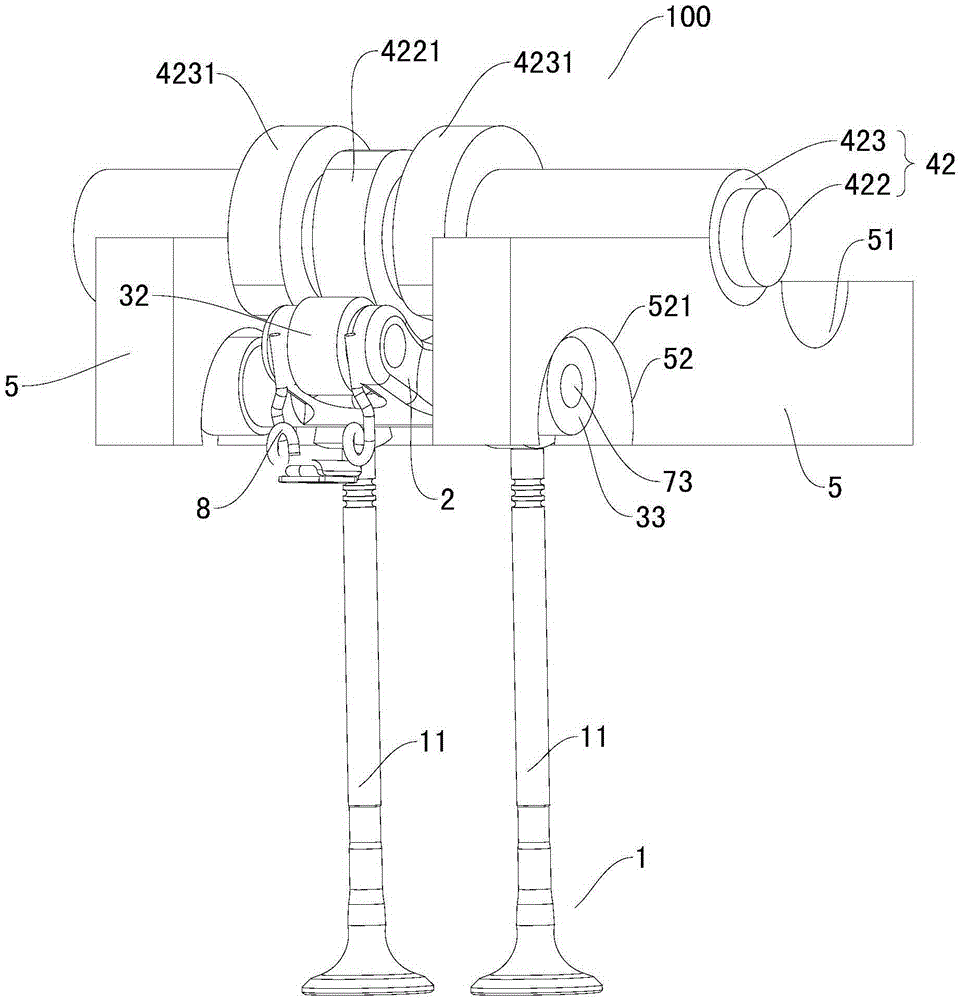

Valve timing mechanism for engine and vehicle with same

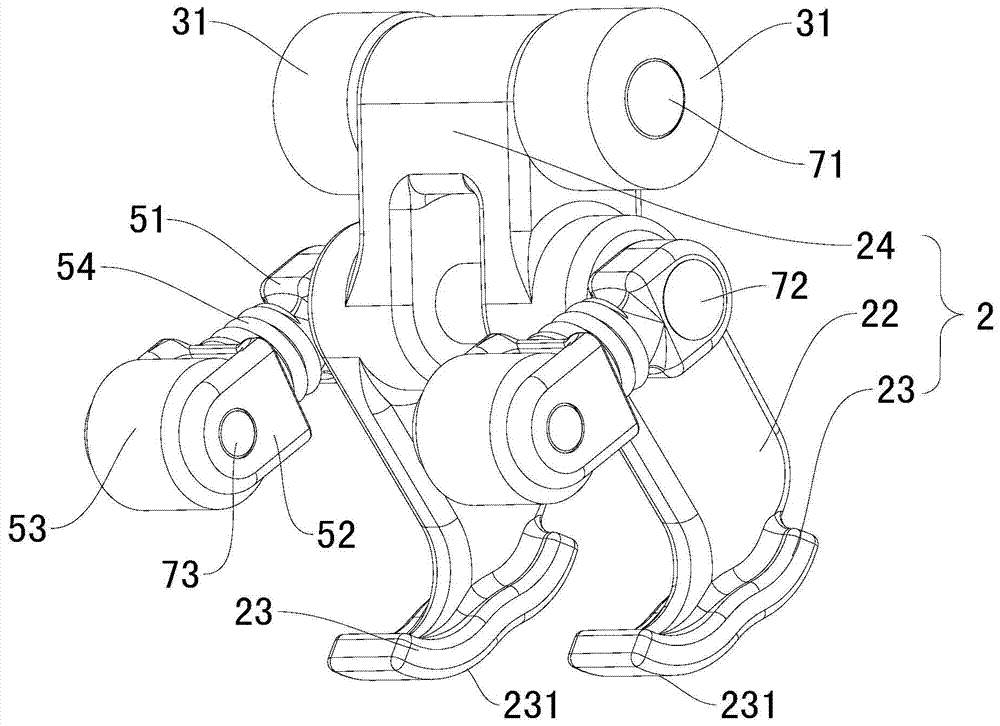

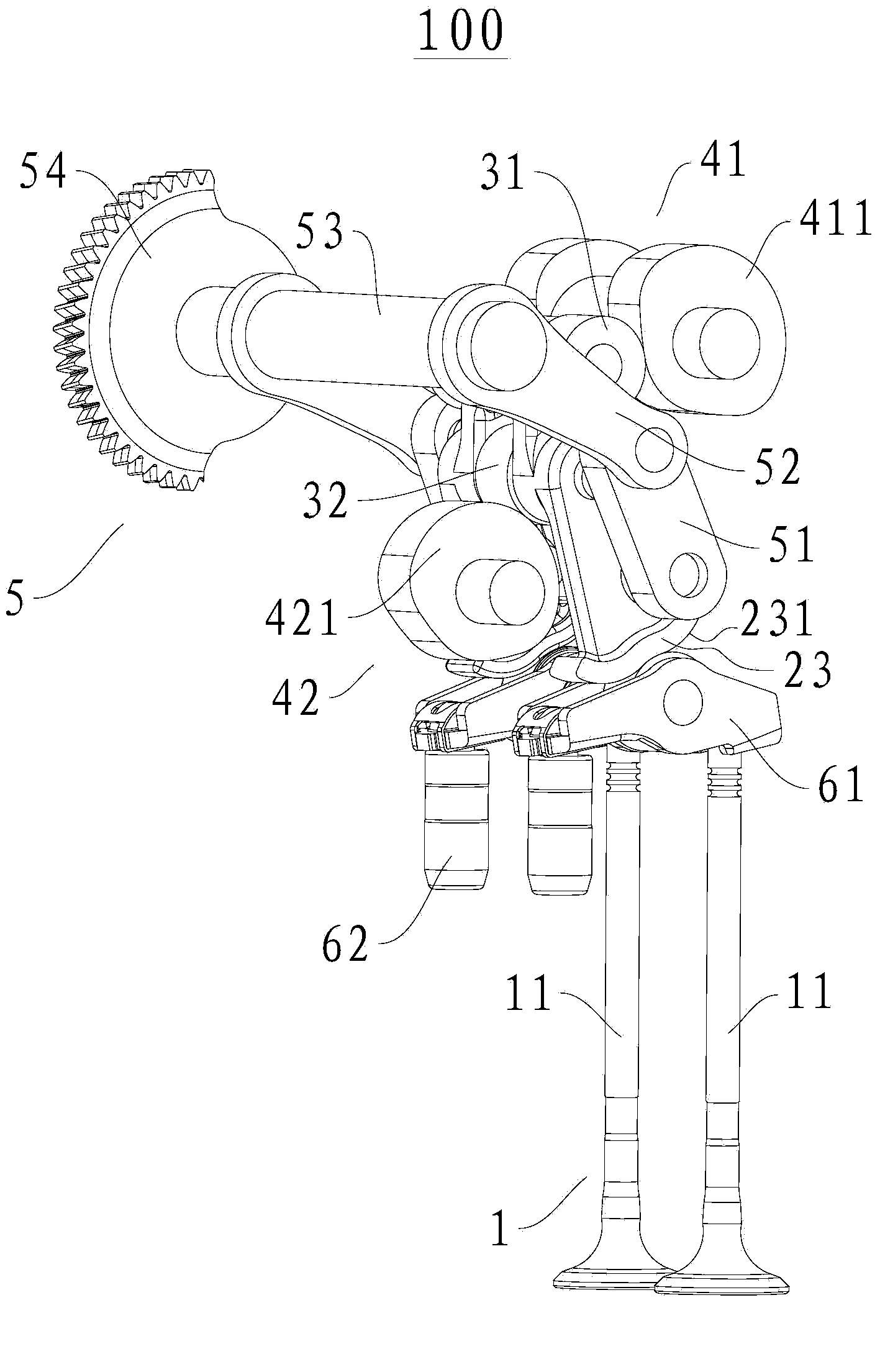

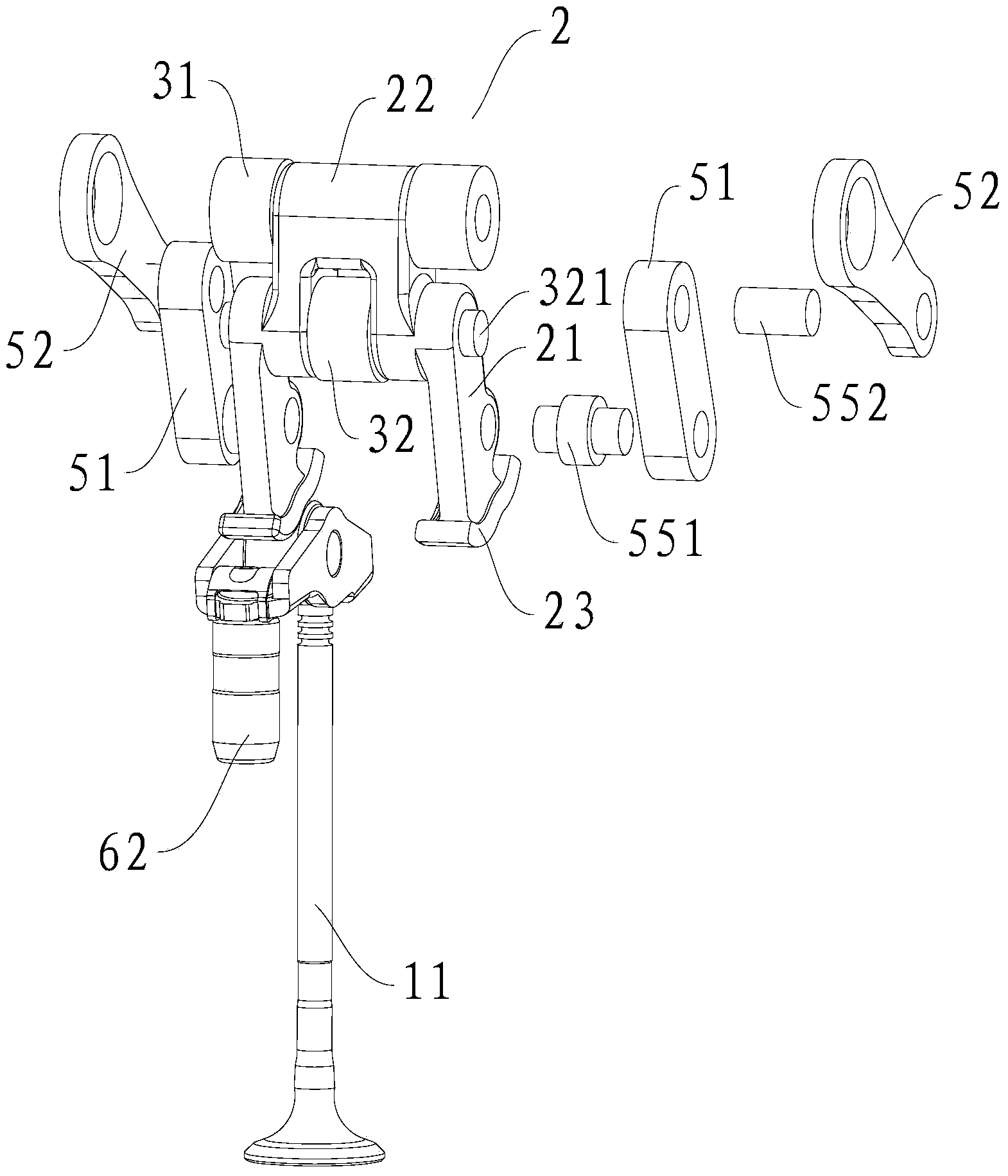

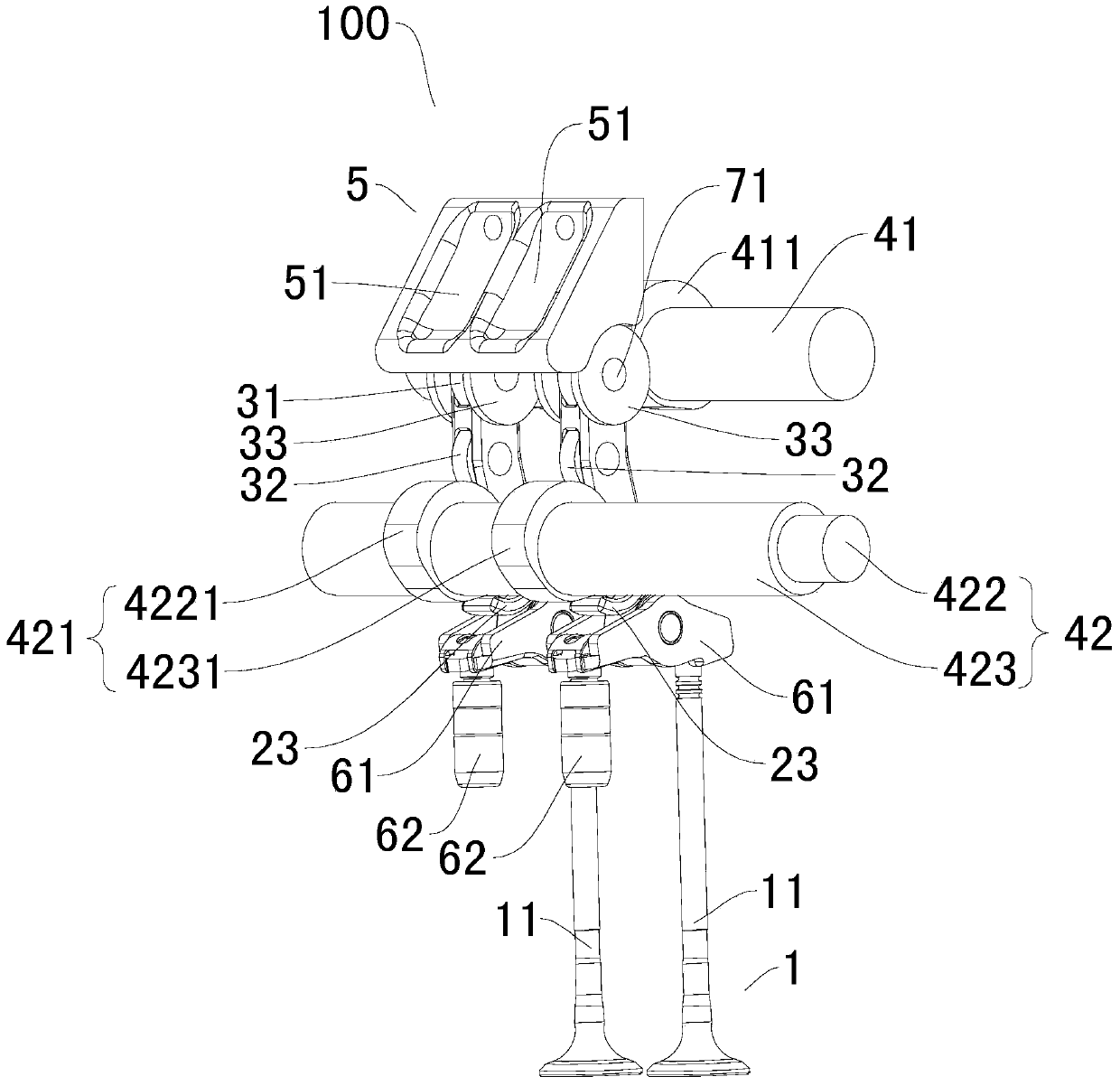

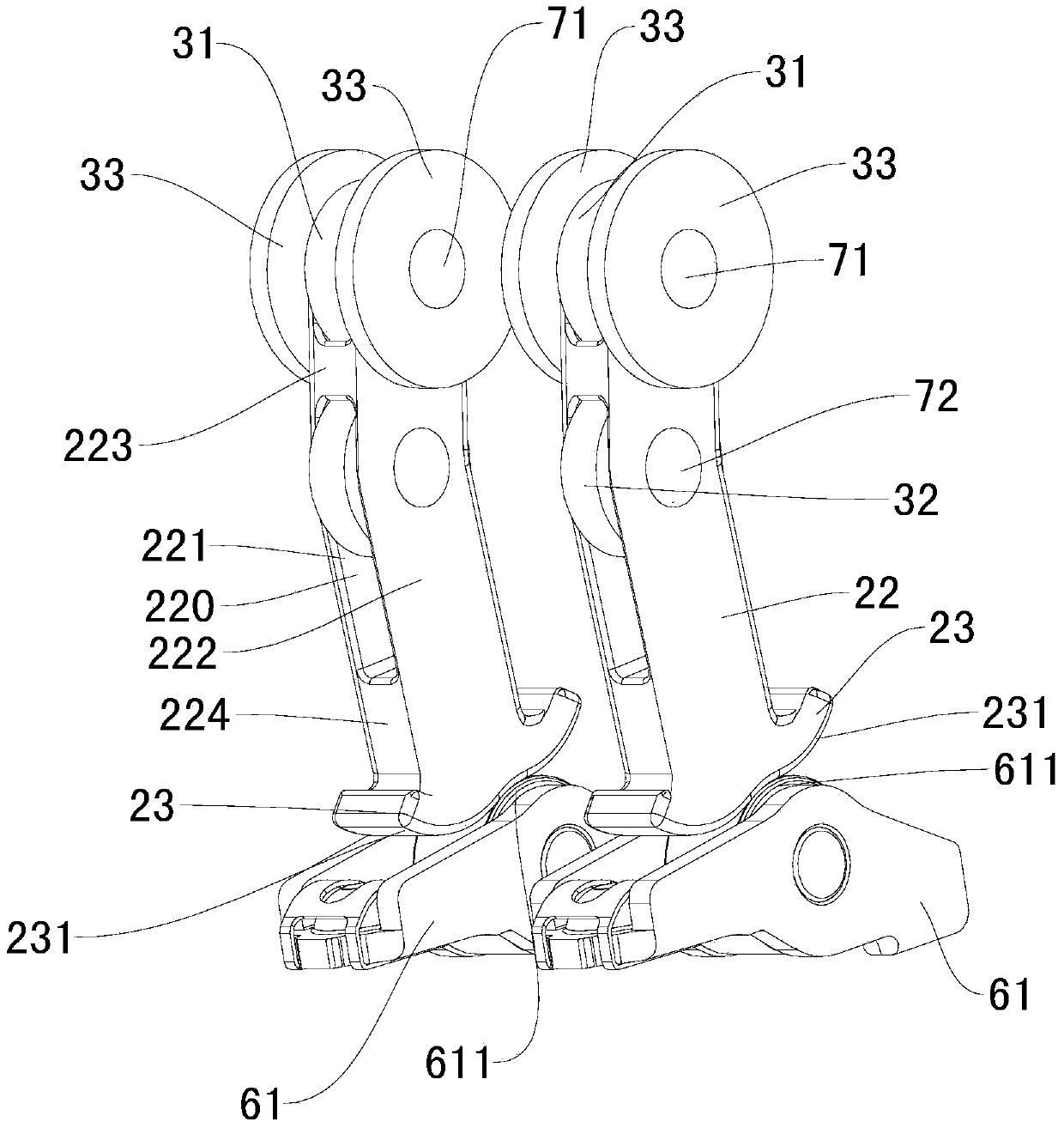

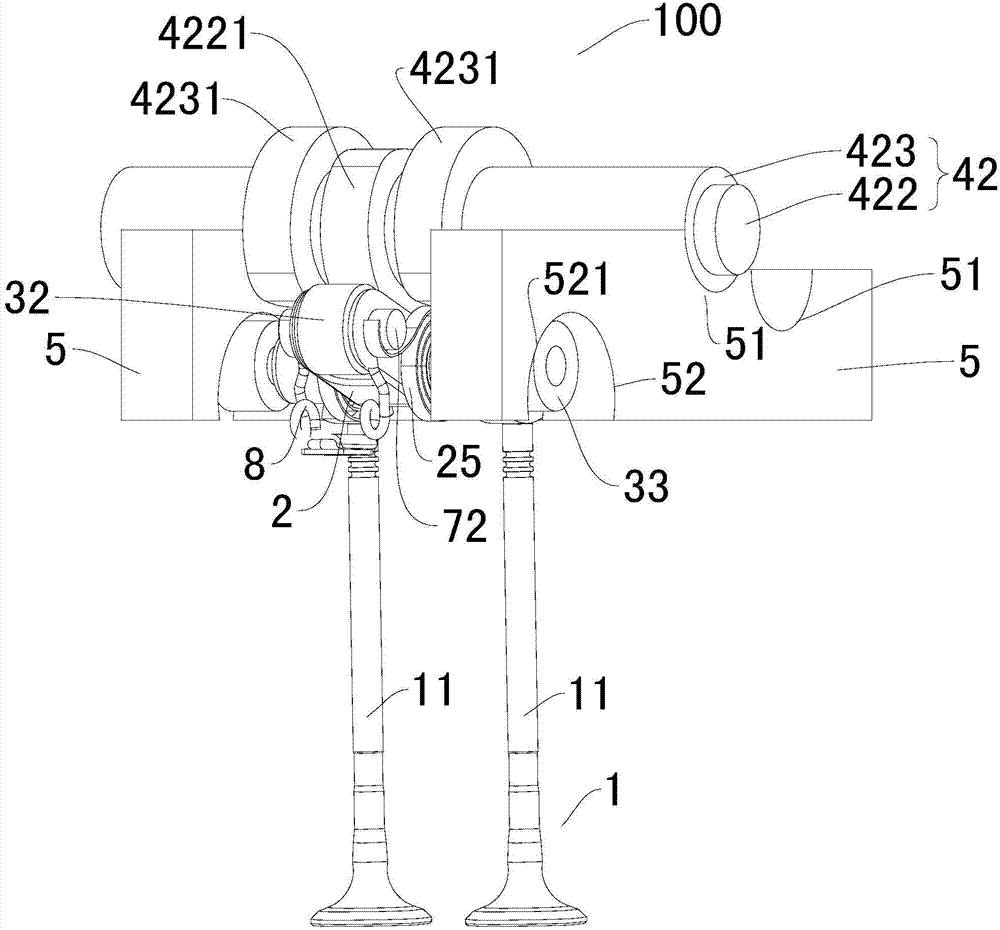

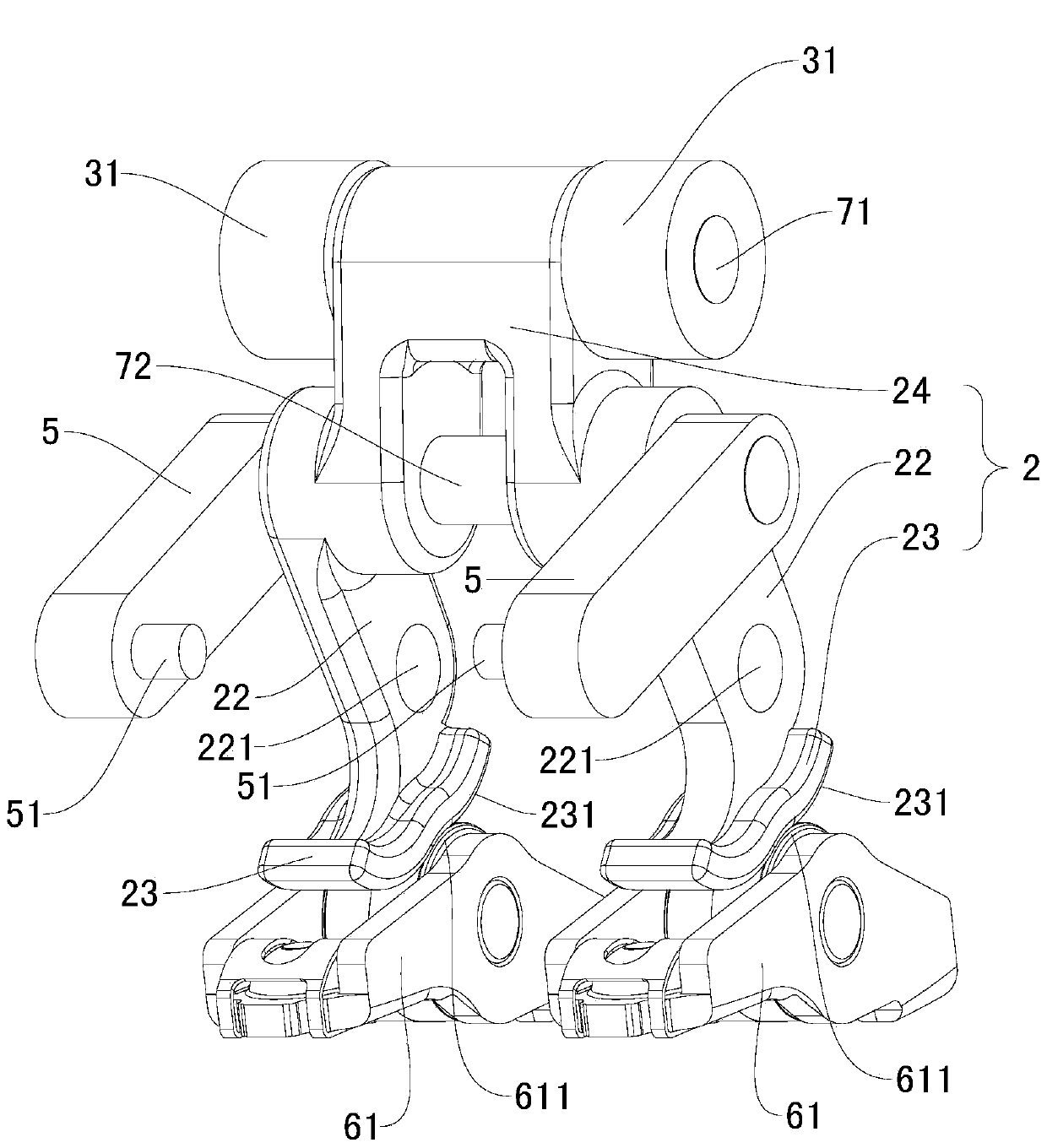

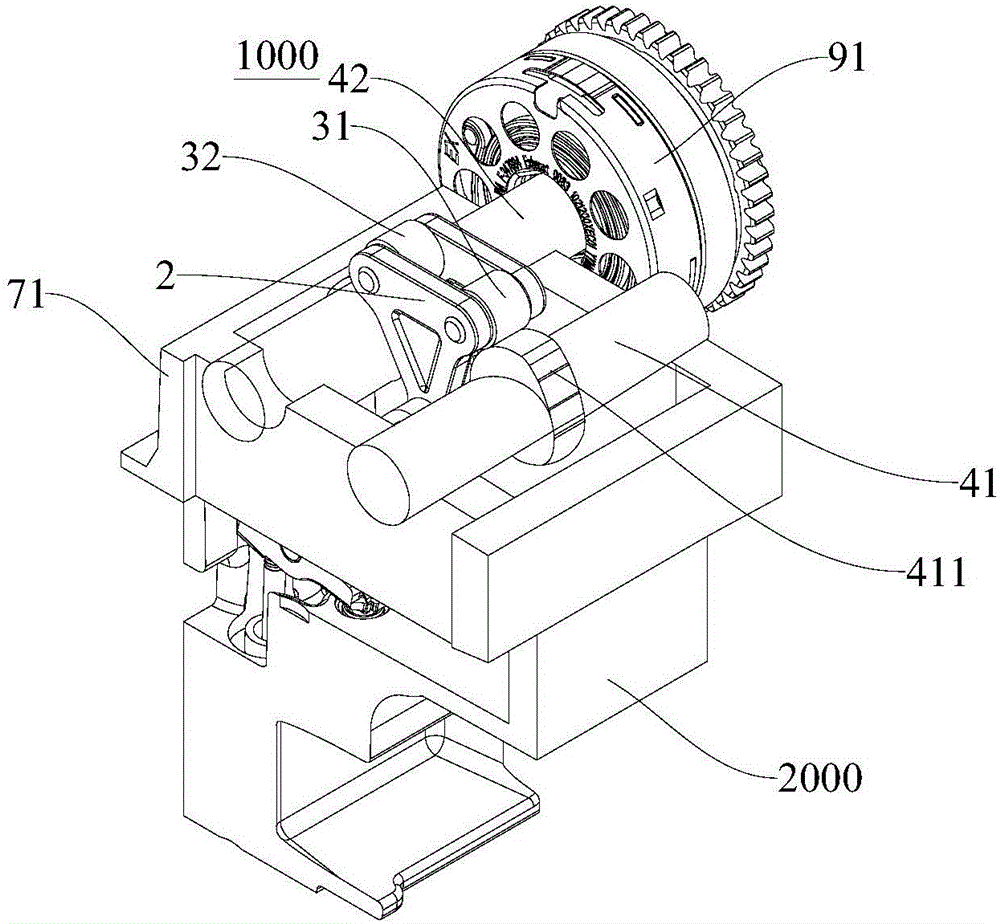

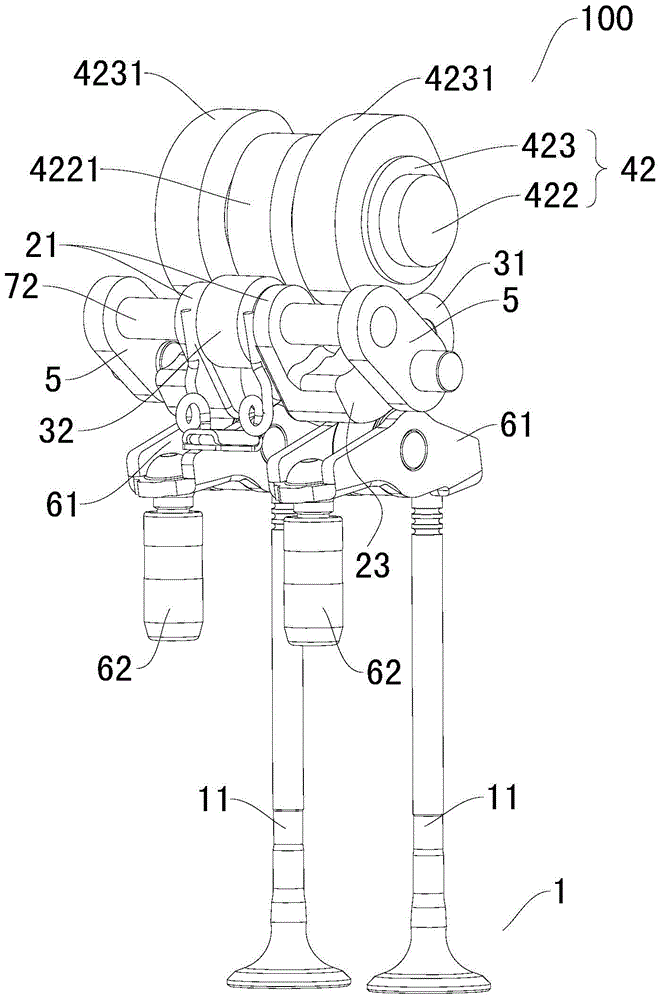

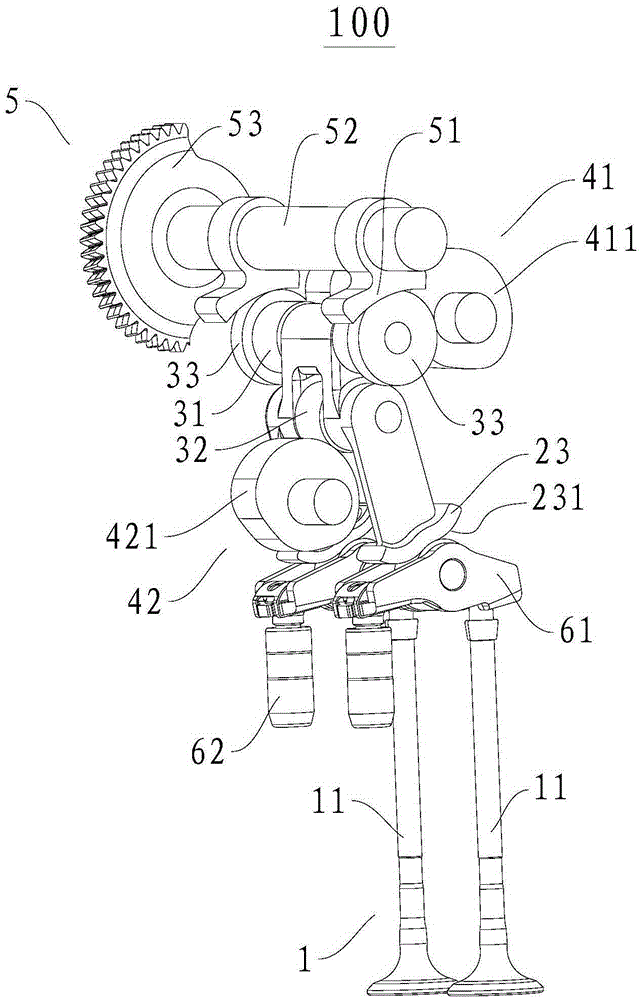

The invention discloses a valve timing mechanism for an engine and a vehicle with the valve timing mechanism. The valve timing mechanism comprises valve mechanisms, rocker arm components, first rollers, second rollers, first cam shafts, second cam shafts, lift adjusting mechanisms and phase adjusting mechanisms. Driving molded surfaces are constructed at the bottoms of the rocker arm components, the first rollers and the second rollers are arranged on the rocker arm components in a pivotal mode, the first cam shafts are provided with first cams, the second cam shafts are provided with second cams, the first cams abut against the first rollers, the second cams abut against the second rollers, the lift adjusting mechanisms comprise driving components, adjusting arms and connecting arms, the two ends of each connecting arm are connected with each rocker arm component and one end of each adjusting arm respectively in a pivotal mode, the driving components drive the other ends of the adjusting arms to enable the adjusting arms to rotate around the adjusting axes, and the phase adjusting mechanisms are used for adjusting the relative phase between the first cam shafts and the second cam shafts. The valve timing mechanism can achieve secondary opening of valves, meanwhile can prolong the continuous time of valve opening, and is simple in structure and small in number of parts.

Owner:GREAT WALL MOTOR CO LTD

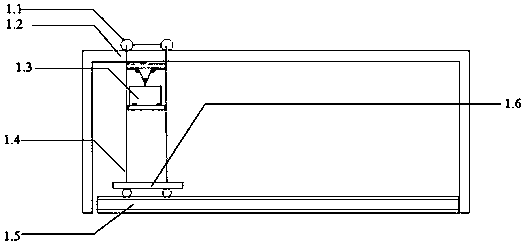

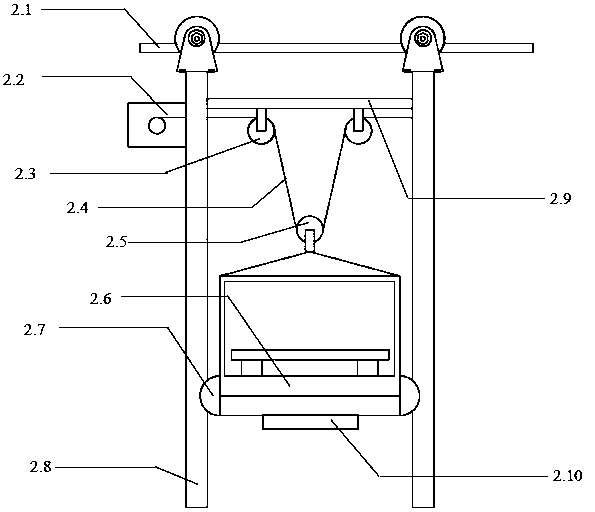

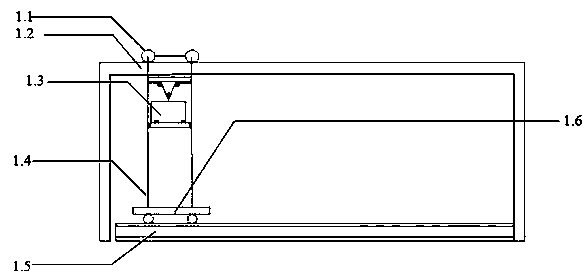

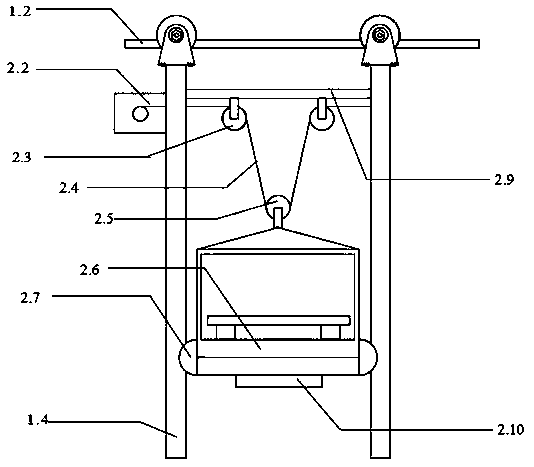

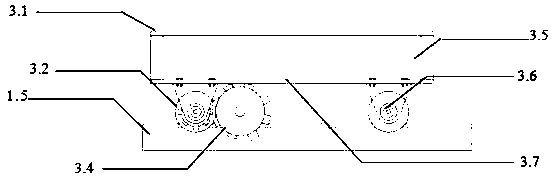

Stacker simulation experiment platform and stacker fault judgment method

ActiveCN108415405AFor subsequent analysisSimulate faults in real timeElectric testing/monitoringEducational modelsControl signalStacker

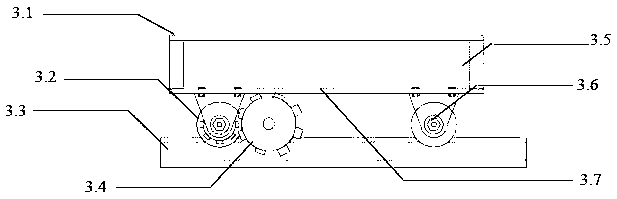

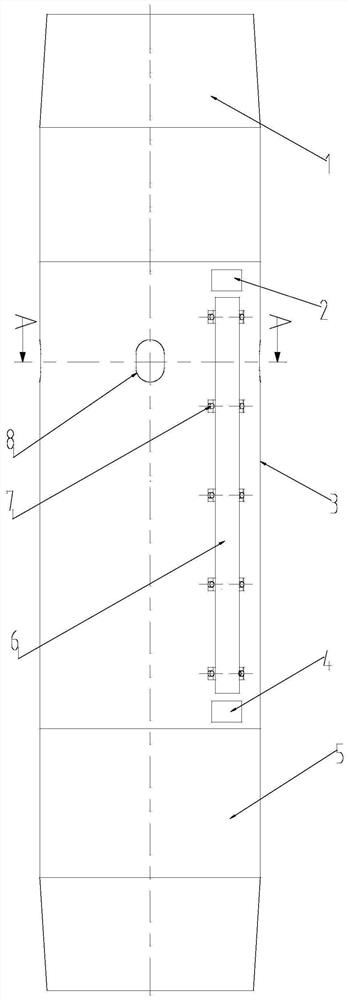

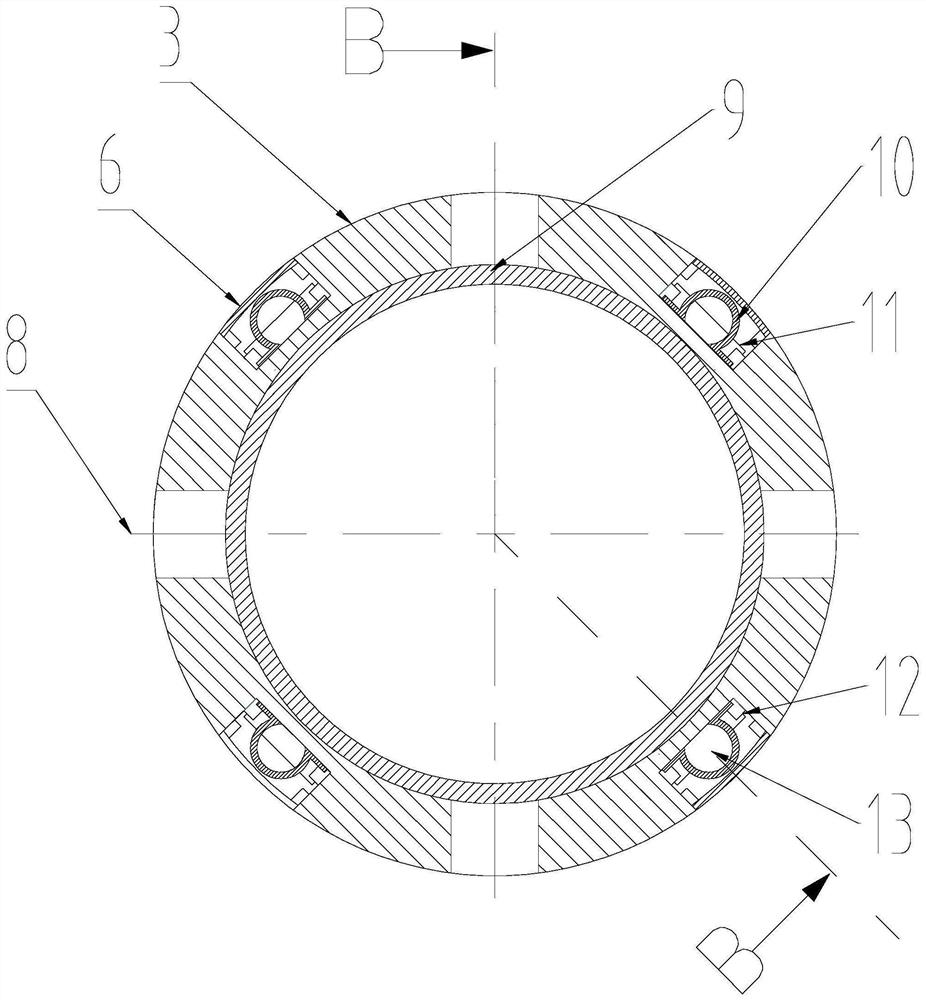

The invention discloses a stacker simulation experiment platform comprising a master control chip, a translation mechanism, an elevating mechanism, a pallet fork telescopic mechanism, a communicationmechanism and an upper computer. The master control chip is connected with the translation mechanism, the elevating mechanism and the pallet fork telescopic mechanism. The master control chip is alsoconnected with the upper computer through the communication mechanism. The upper computer is used for transmitting the control signal to the master control chip. The master control chip is used for controlling movement of any one or multiple of the translation mechanism, the elevating mechanism and the pallet fork telescopic mechanism according to the control signal transmitted by the upper computer. According to the stacker simulation experiment platform, the simulated stacker fault can be simulated and the stacker fault data can be collected; the fault possibility of large stacker and the fault type can be predicted by using the fault data; and the stacker simulation experiment platform can also be applied to research of colleges and universities to perform secondary development of the stacker so as to enhance the performance of the stacker.

Owner:CHONGQING JIAOTONG UNIVERSITY

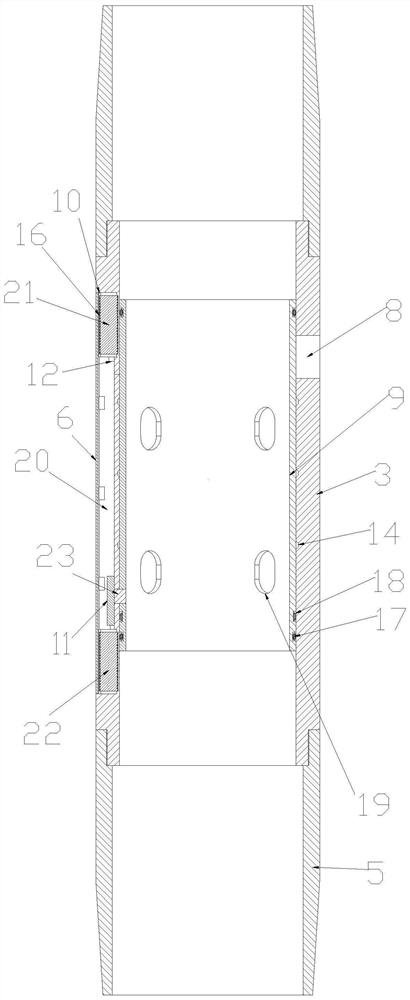

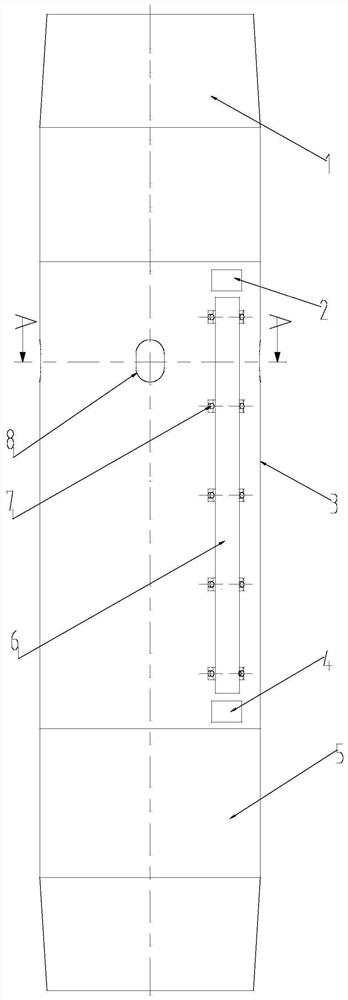

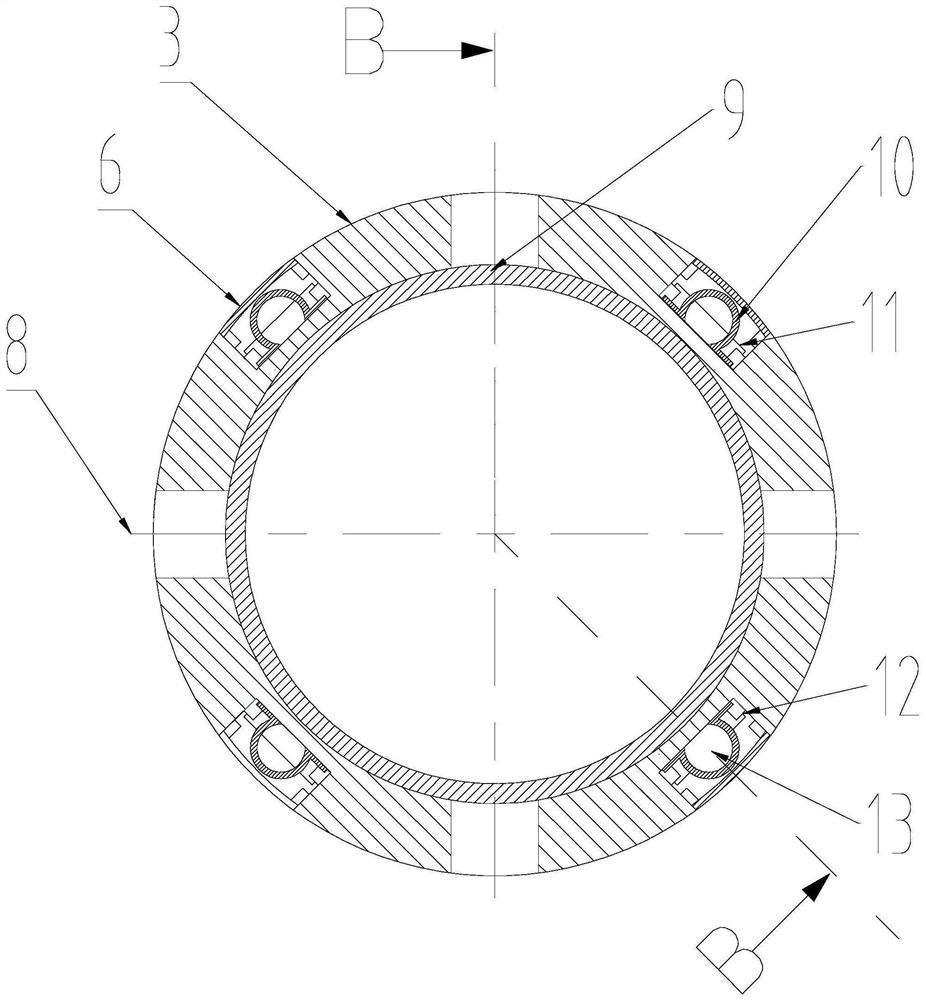

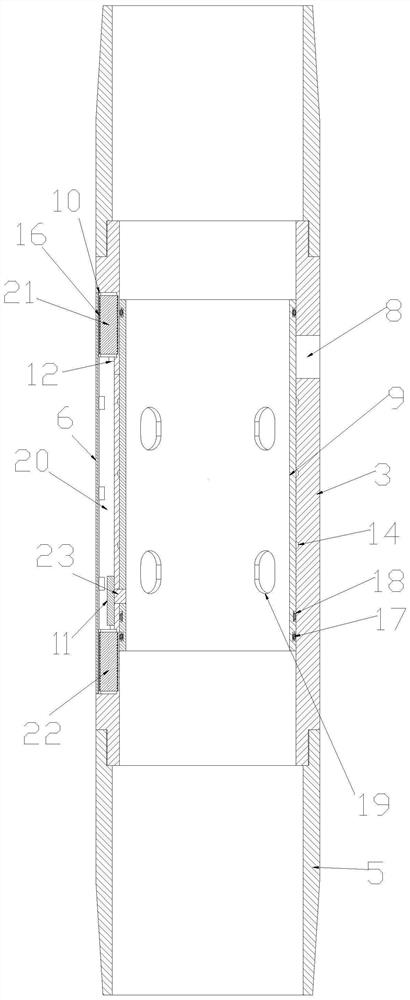

Full-bore switch well cementation sliding sleeve and method for infinite-level alternate fracturing of horizontal well

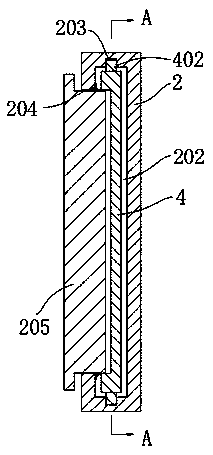

The invention discloses a full-bore switch well cementation sliding sleeve and method for infinite-level alternate fracturing of a horizontal well. The full-bore switch well cementation sliding sleeve comprises an upper connector, an outer sleeve, an inner sliding sleeve and a lower connector; the outer sleeve and the inner sliding sleeve are provided with an outer sleeve fracturing hole and an inner sliding sleeve fracturing hole correspondingly; the outer sleeve is sequentially provided with an upper annular groove, a T-shaped sliding groove and a lower annular groove; the upper annular groove and the lower annular groove are internally provided with an electromagnet I and an electromagnet II correspondingly; the electromagnet I and the electromagnet II are both sleeved with annular circuits; the upper end and the lower end of the outer sleeve are provided with a control circuit power source I and a control circuit power source II correspondingly; the inner sliding sleeve is provided with a sliding block capable of sliding in the T-shaped sliding groove; the inner wall of the outer sleeve is provided with a clamp spring groove; and the outer wall of the inner sliding sleeve is provided with a clamp spring. According to the full-bore switch well cementation sliding sleeve and method for infinite-level alternate fracturing of the horizontal well, a fracturing channel at any position can be opened and closed at the same time, alternate sequential fracturing is achieved, the interference effect between fractures is improved, and a complex fracture net is formed; and after all the fractures are fractured, the fracturing channel is opened completely, and oil and gas production operation is conducted synchronously.

Owner:SOUTHWEST PETROLEUM UNIV

Valve timing mechanism for engine and vehicle with same

ActiveCN103726898AImprove emission performanceImprove fuel economyValve arrangementsMachines/enginesEngineeringCam

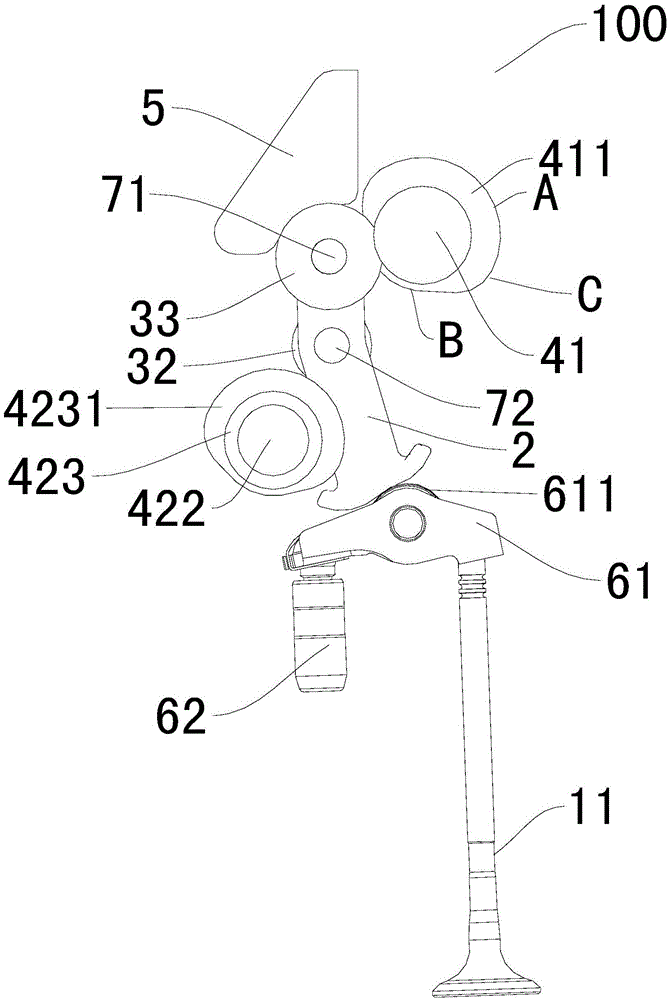

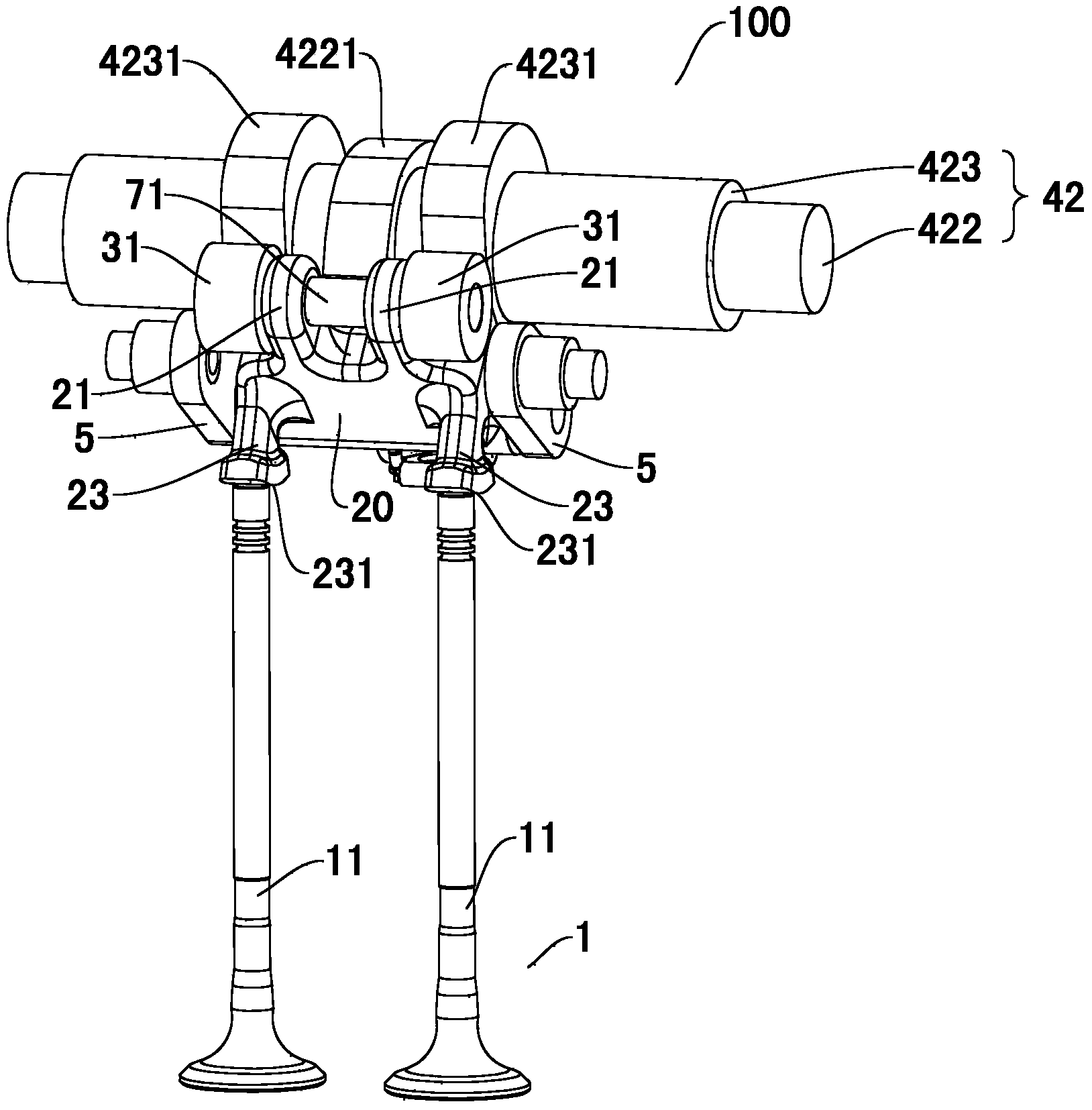

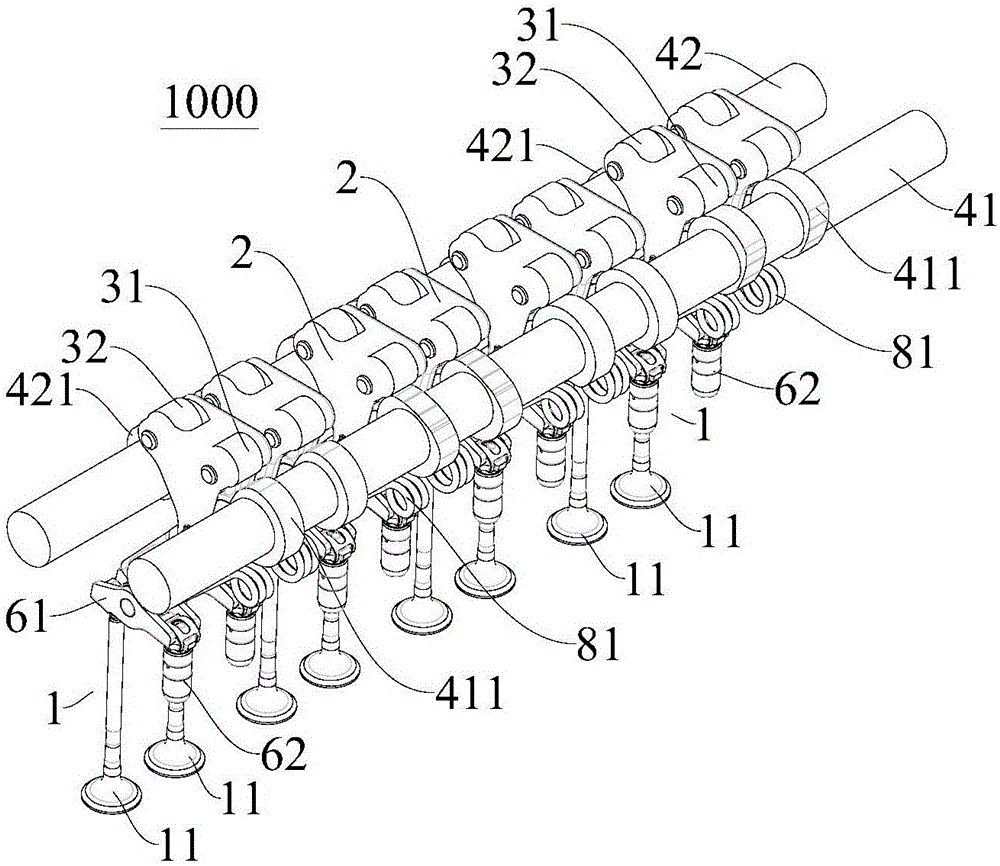

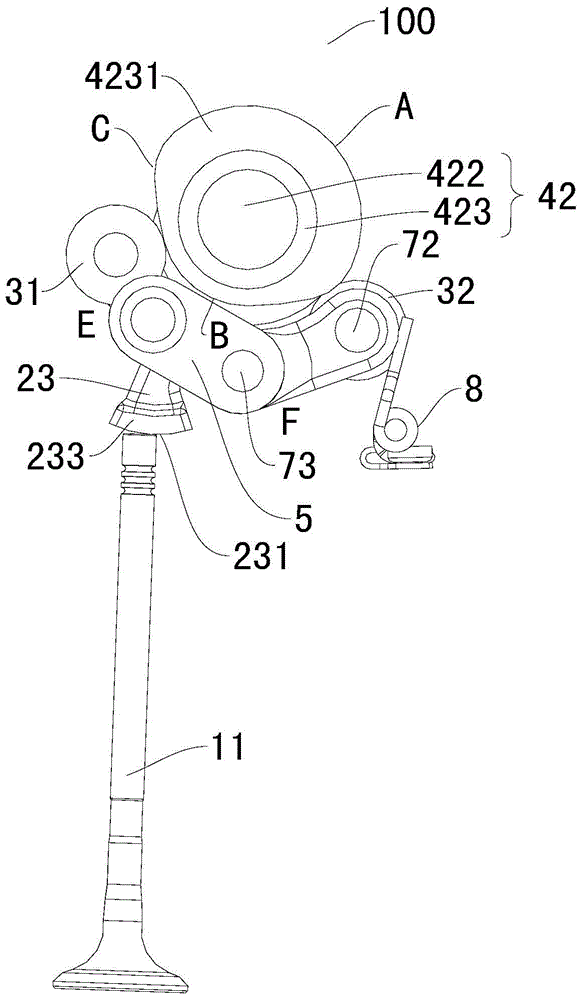

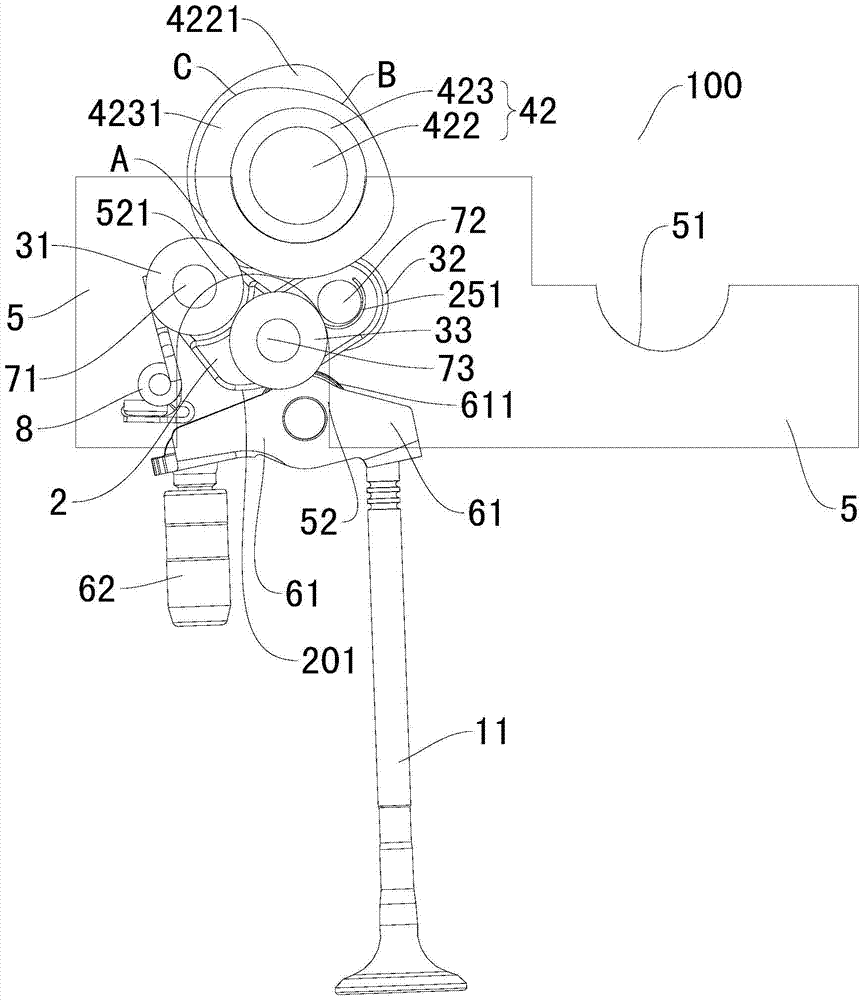

The invention discloses a valve timing mechanism for an engine and a vehicle with the valve timing mechanism. The valve timing mechanism comprises a plurality of valve mechanisms, a plurality of rocker arm components, a plurality of sets of first rollers, a plurality of sets of second rollers, first cam shafts, second cam shafts and a phase adjusting mechanism. Driving molded surfaces are constructed at the bottoms of the rocker arm components, the first rollers and the second rollers are arranged on the rocker arm components in a pivotal mode, the first cam shafts comprise inner shafts and outer shafts, the inner shafts and the outer shafts are coaxially arranged, a plurality of inner shaft cams are arranged on the inner shafts, a plurality of outer shaft cams are arranged on the outer shafts, the inner shaft cams abut against some first rollers respectively, the outer shaft cams abut against the other first rollers respectively, the second cam shafts are provided with a plurality of driving cams, the driving cams abut against the second rollers, and the phase adjusting mechanism is used for adjusting the relative phase between the outer shafts and the second cam shafts, and the relative phase between the outer shafts and the inner shafts. The valve timing mechanism can achieve secondary opening of valves, meanwhile can prolong the continuous time of valve opening, and is simple in structure and small in number of parts.

Owner:GREAT WALL MOTOR CO LTD

Valve timing mechanism for engine and vehicle with the same

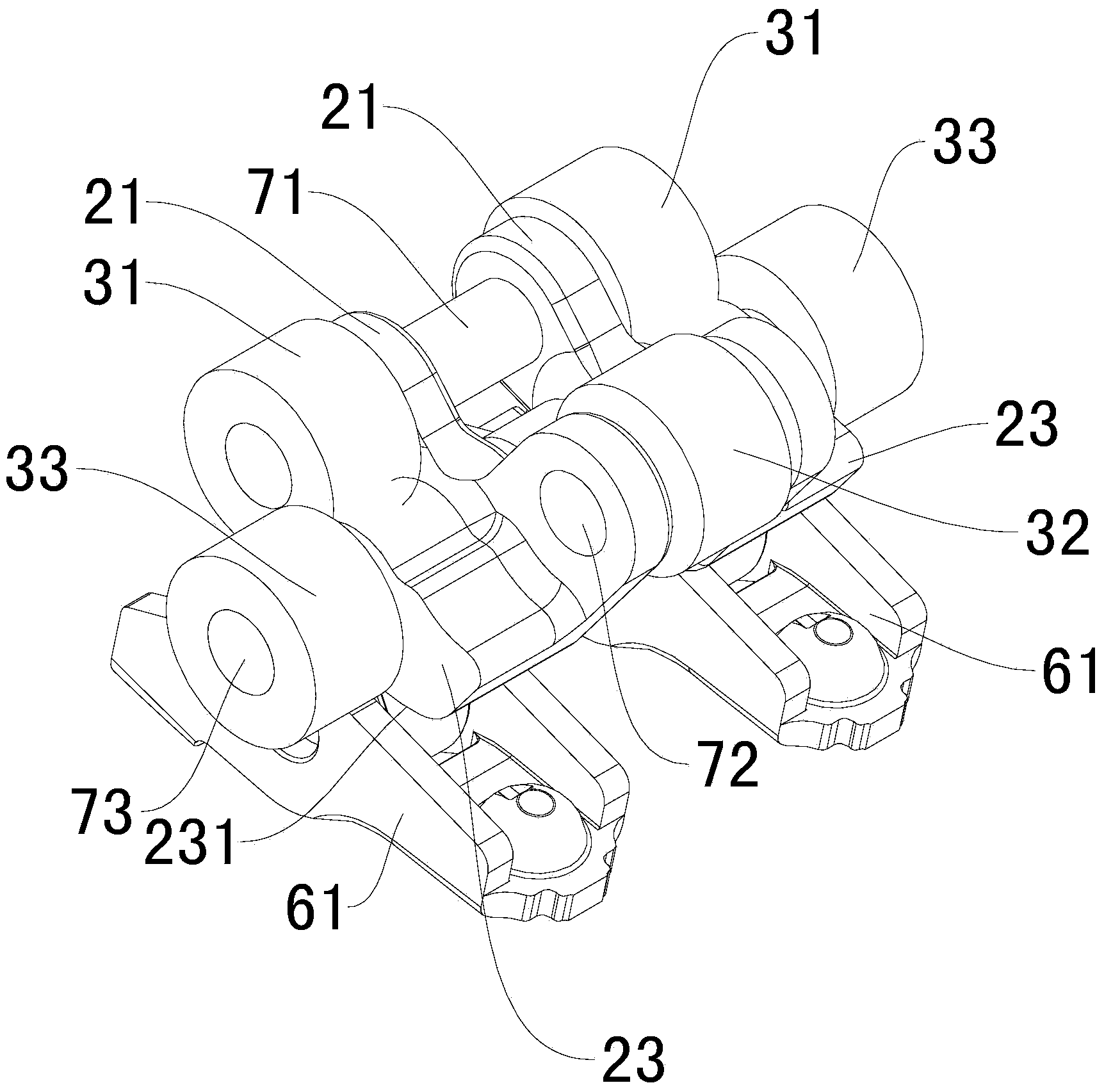

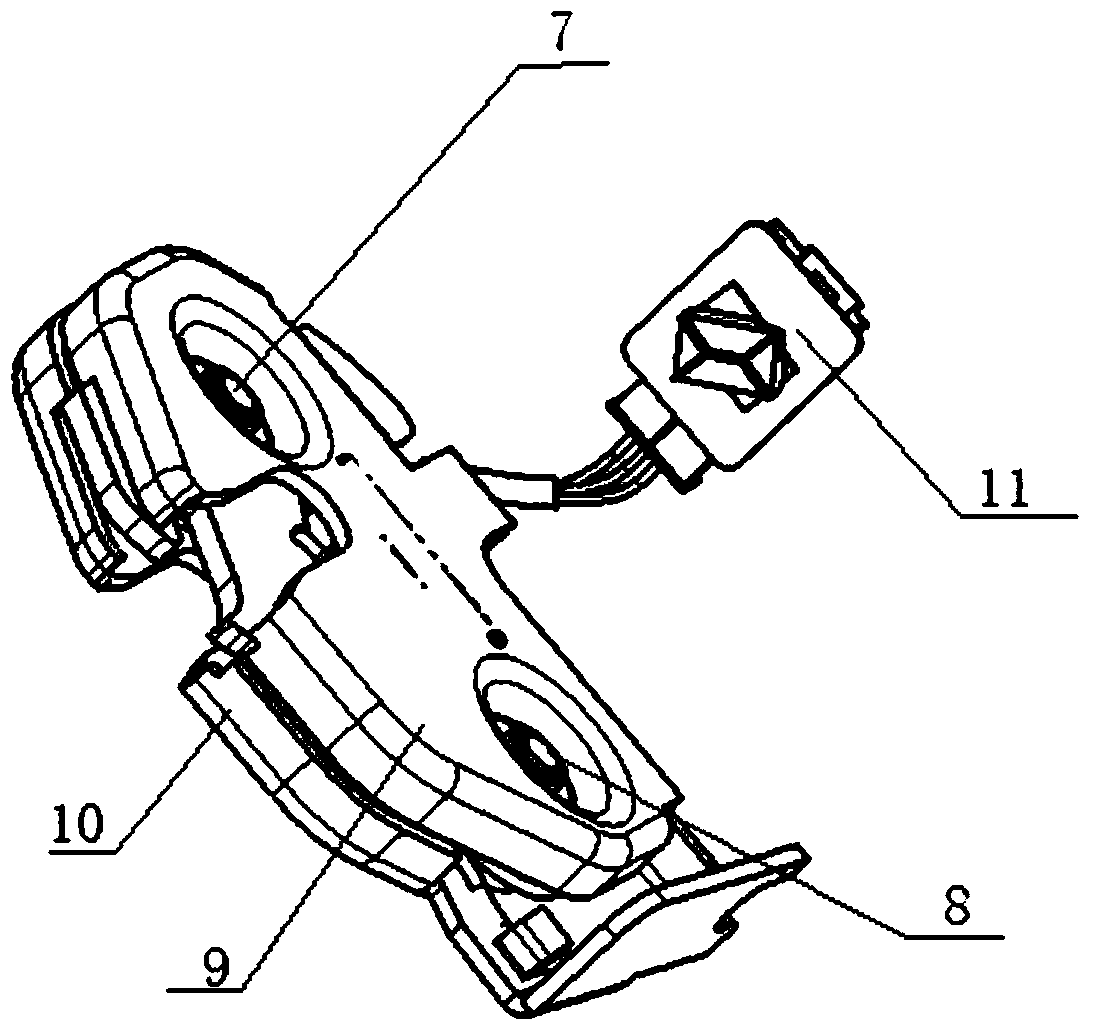

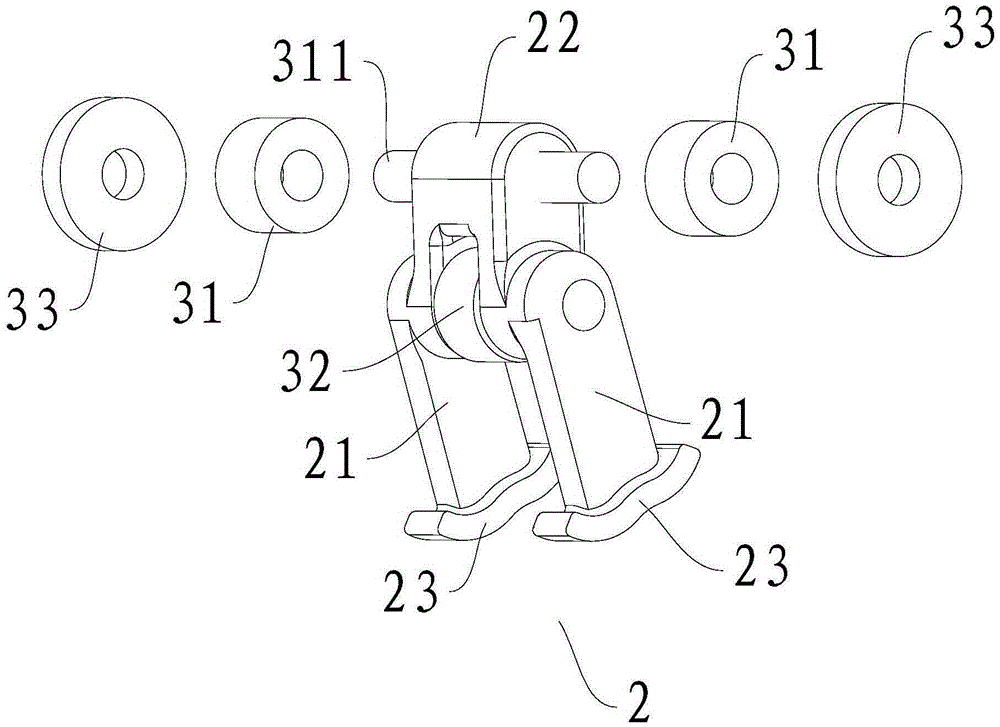

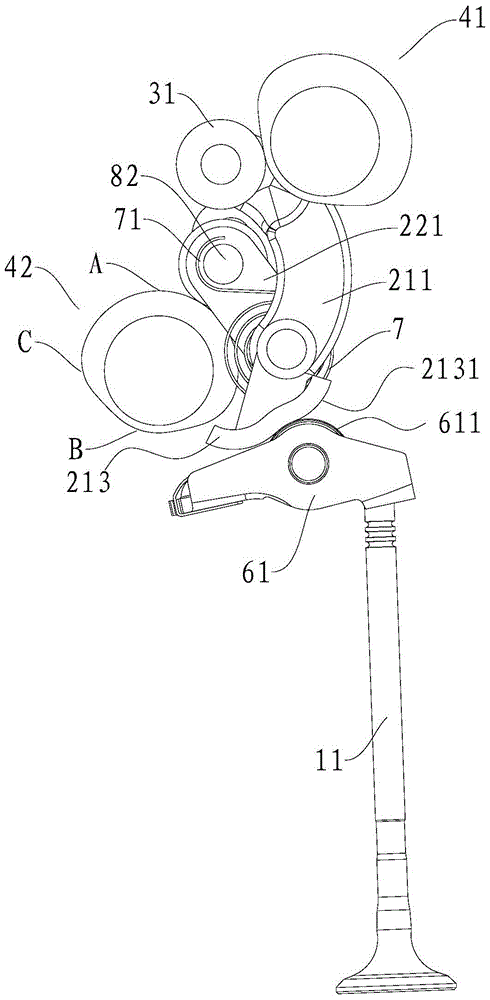

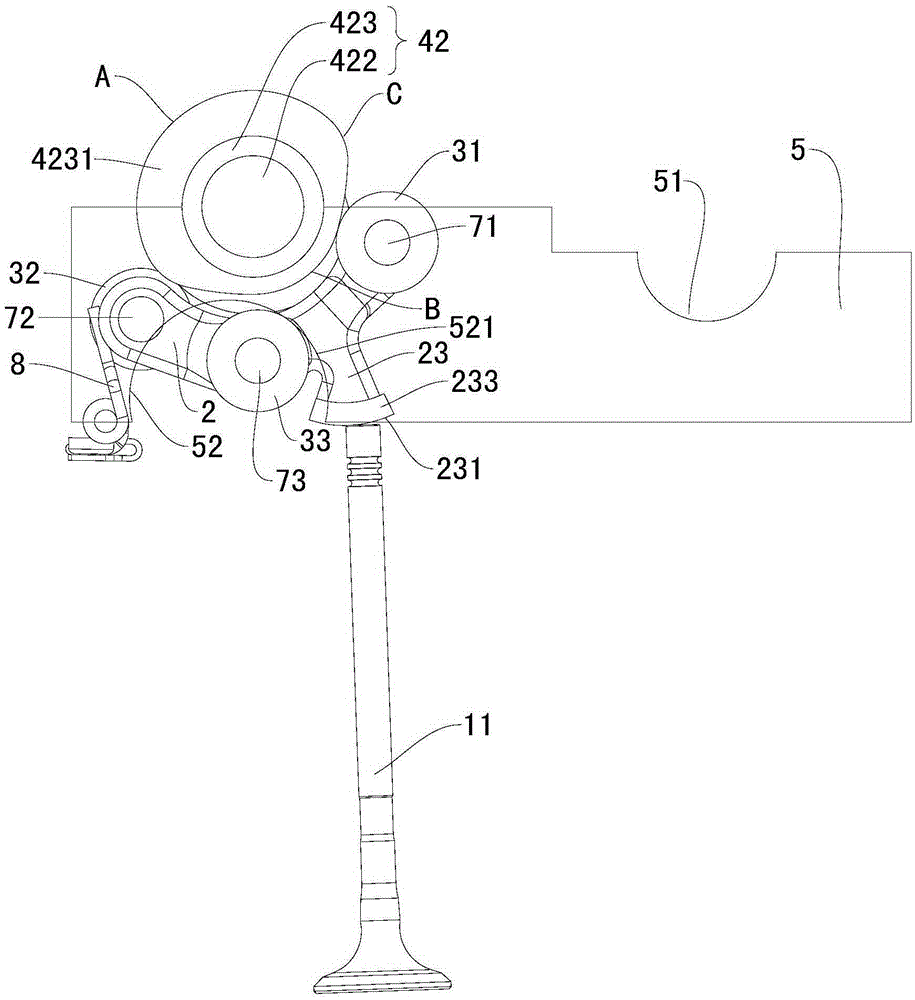

ActiveCN103742219ASimple rocker assemblyRocker arm assembly is compactValve arrangementsMachines/enginesCombustion chamberEngineering

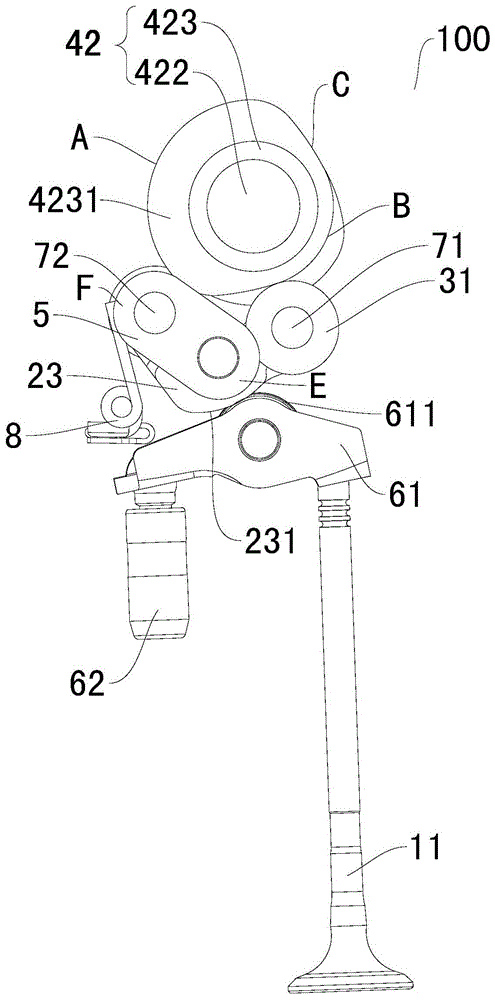

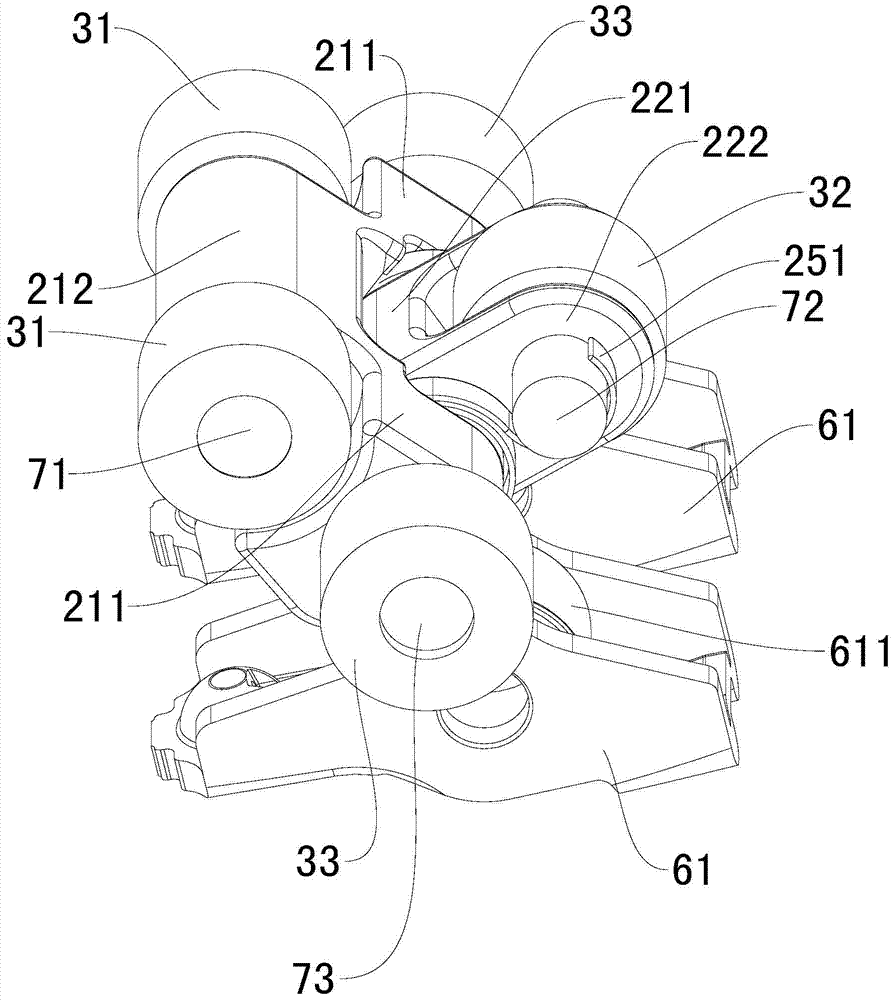

The invention discloses a valve timing mechanism for an engine and a vehicle with the same. The valve timing mechanism comprises a valve mechanism, a rocker component, a first, a second and a third roller, a first cam shaft, a second cam shaft, a press block and a phase regulating mechanism, wherein a drive molded surface which is used for driving the valve mechanism is formed at the bottom of the rocker component; the first, second and third rollers are pivotally mounted on the rocker component, and the first and third rollers are arrayed coaxially; the first cam shaft comprises a first cam, the second cam shaft comprises a second cam, and the first cam is propped against the first roller while the second cam is propped against the second roller; the press block is static relatively to the engine body and is formed with a circular arc camber, and the third roller is clung to the circular arm camber; the phase regulating mechanism is used for regulating the relative phases of the first cam shaft and the second cam shaft. The valve timing mechanism is capable of realizing the secondary open of the valve, prolonging the valve opening duration, realizing the asynchronous work of two valves at the same side of the same cylinder, is capable of changing the vortex and tumble in the combustion chamber, and is capable of improving the combustion.

Owner:GREAT WALL MOTOR CO LTD

Valve mechanism for engine and vehicle comprising valve mechanism

ActiveCN103790669AImprove inflation efficiencyMeet the needs of valve movement rules in different working conditionsValve arrangementsMachines/enginesEngineeringCam

The invention discloses a valve mechanism for an engine and a vehicle comprising the valve mechanism. The valve mechanism comprises a valve mechanism body, a rocker component, a first roller, a second roller, a camshaft, supporting structures, a phase adjusting mechanism, and a third roller or limit pins. The bottom of the rocker component is provided with a drive molded surface which is suitable for directly driving a valve to move. The first roller and the second roller both can be arranged on the rocker component in a pivoting mode. The camshaft comprises an inner shaft and an outer shaft, the inner shaft and the outer shaft are coaxially arranged and provided with an inner shaft cam and an outer shaft cam respectively, and the inner shaft cam and the outer shaft cam can rotate along the corresponding shafts respectively. The outer shaft cam abuts against the first roller, the inner shaft cam abuts against the second roller, the supporting structures are arranged on the two sides of the rocker component and provided with circular arc cambers or sliding grooves, the third roller can be attached to the circular arc cambers in a rolling mode, and the limit pins can be matched in the sliding grooves in a sliding mode. The valve mechanism can achieve secondary opening of the valve, can lengthen the opening lasting time of the valve, and is simple in structure, and low in influence on the height of the engine.

Owner:GREAT WALL MOTOR CO LTD

Valve train for engine and vehicle having same

ActiveCN103742219BRealize the second openingExtension of timeValve arrangementsMachines/enginesCombustion chamberEngineering

Owner:GREAT WALL MOTOR CO LTD

Valve timing mechanism for engine and vehicle with the same

ActiveCN103742221ARealize the second openingExtension of timeValve arrangementsMachines/enginesEngineeringCam

The invention discloses a valve timing mechanism for an engine and a vehicle with the same. The valve timing mechanism comprises a valve mechanism, a rocker component, rollers, a push rod, a first cam shaft, a second cam shaft and a phase adjusting mechanism, wherein a drive profile is formed at the bottom of the rocker component and is used for driving the valve of the valve mechanism to move in the direction parallel to the the central line of the valve; the rollers are pivotally mounted on the rocker component; the first end of the push rod is pivotally connected with the rocker component; the first cam shaft comprises a first cam, the second cam shaft comprises a second cam, the first cam is propped against the rollers, the second cam drives the second end of the push rod so as to make the push rod move in the direction parallel to the lengthwise direction of the push rod; the phase adjusting mechanism is used for adjusting the relative phases of the first cam shaft and the second cam shaft. The valve timing mechanism for the engine is capable of realizing the secondary open of the valve and prolonging the valve opening duration and has advantages of simple structure and less parts.

Owner:GREAT WALL MOTOR CO LTD

Valve mechanism for engine and vehicle with same

ActiveCN103758603ALittle impact on altitudeGuaranteed uptimeValve arrangementsMachines/enginesEngineeringCam

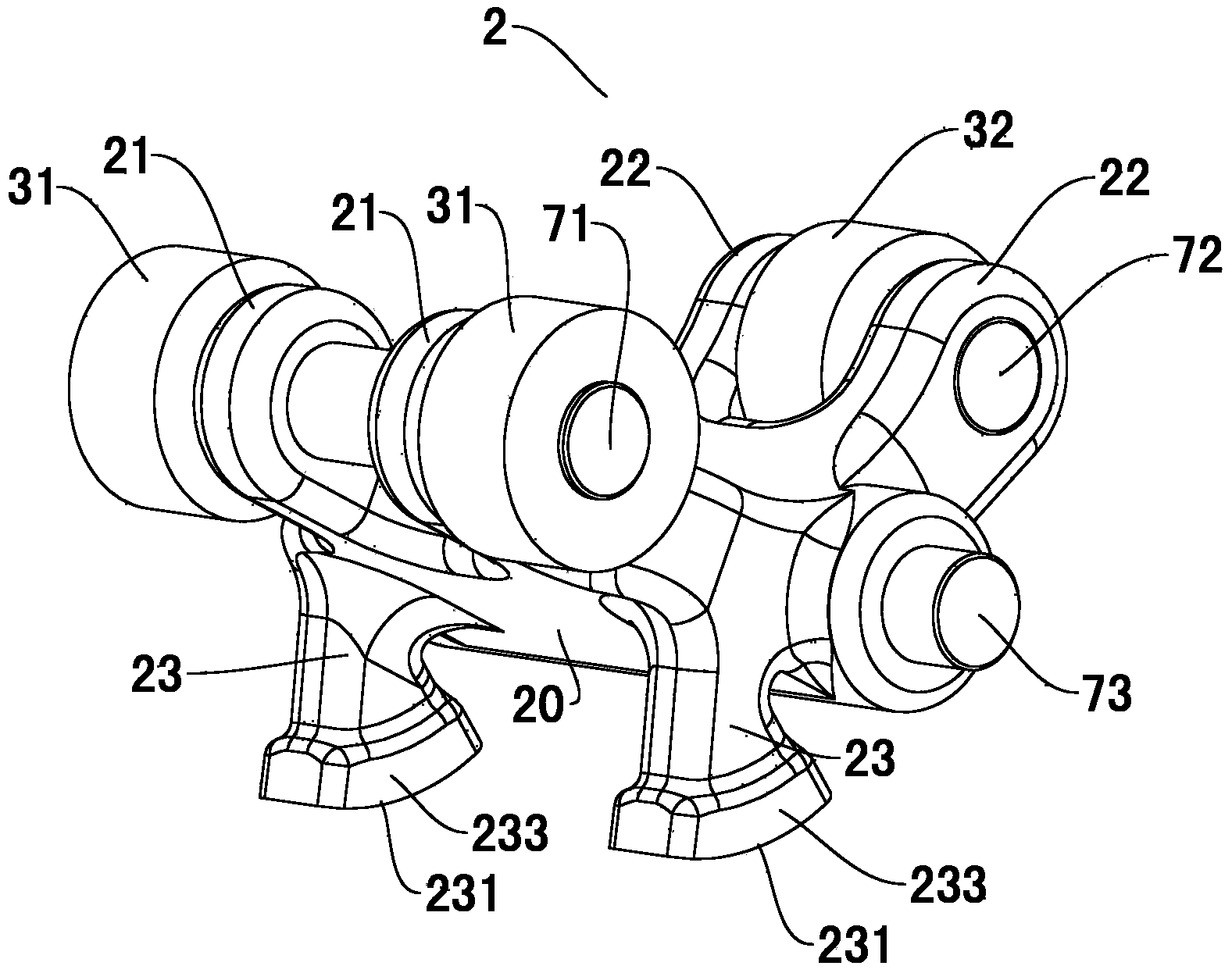

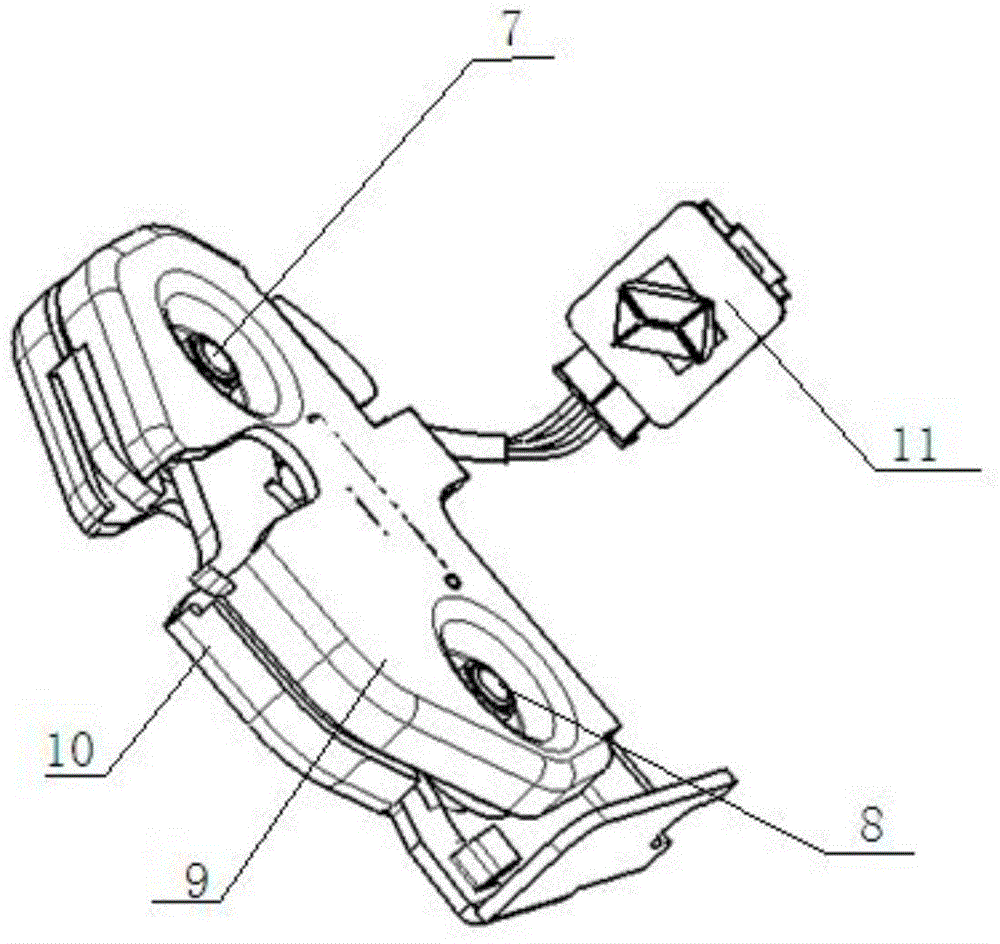

The invention discloses a valve mechanism for an engine and a vehicle with the same. The valve mechanism comprises a valve gear, a rocker arm assembly, a first roller, a second roller, a cam shaft, a connecting arm and a phase adjusting mechanism. The bottom of the rocker arm assembly is provided with a driving type face which is directly in contact with the top of a valve of the valve gear to drive the valve to move. The first roller and the second roller can both be arranged on the rocker arm assembly in a pivoted mode. The cam shaft comprises an inner shaft and an outer shaft which are coaxially arranged, the inner shaft and the outer shaft are provided with an inner shaft cam and an outer shaft cam which rotate along corresponding shafts respectively, the outer shaft cam abuts against the first roller, and the inner shaft cam abuts against the second roller. The first end of the connecting arm is connected with the rocker arm in a pivoted mode, and the second end of the connecting arm is arranged on an engine body set of the engine in a pivoted mode. The phase adjusting mechanism is used for adjusting the relative phase of the inner shaft and the outer shaft. The valve mechanism for the engine can achieve secondary opening of the valve, meanwhile, the duration time of opening of the valve can also be prolonged, the structure is simple and compact, and the influence on the height of the engine is small.

Owner:GREAT WALL MOTOR CO LTD

Valve actuating mechanism for engine and cam of valve actuating mechanism

InactiveCN106382137ASimple swing arm assemblyRealize the second openingValve drivesMachines/enginesEngineeringCamshaft

The invention discloses a valve actuating mechanism for an engine and a cam of the valve actuating mechanism. The valve actuating mechanism for the engine comprises a valve mechanism, a swing arm assembly, a first roller, a second roller, a first cam shaft, a second cam shaft and a phase adjusting mechanism. A first cam profile comprises a first profile first section, a first profile second section, a first profile third section, a first profile fourth section, a first profile fifth section, a first profile sixth section and a first profile seventh section which are connected end to end, and a second cam profile comprise a second profile first section, a second profile second section, a second profile third section, a second profile fourth section, a second profile fifth section, a second profile sixth section and a second profile seventh section which are connected end to end. When the first roller abuts against the first profile first section, the first profile second section, the first profile third section, the first profile fourth section, the first profile fifth section, the first profile sixth section and the first profile seventh section respectively and the second roller correspondingly abuts against the second profile first section, the second profile second section, the second profile third section, the second profile fourth section, the second profile fifth section, the second profile sixth section and the second profile seventh section respectively, a valve is sequentially in a first closed state, a primary open stage, a primary closed stage, a secondary open stage, a secondary closed stage, a second closed state and a third closed state. The phase adjusting mechanism is used for adjusting the opposite phases of the first cam shaft and the second cam shaft. According to the valve actuating mechanism for the engine in the embodiment, secondary valve open can be achieved, and the open persistent period is adjustable.

Owner:GREAT WALL MOTOR CO LTD

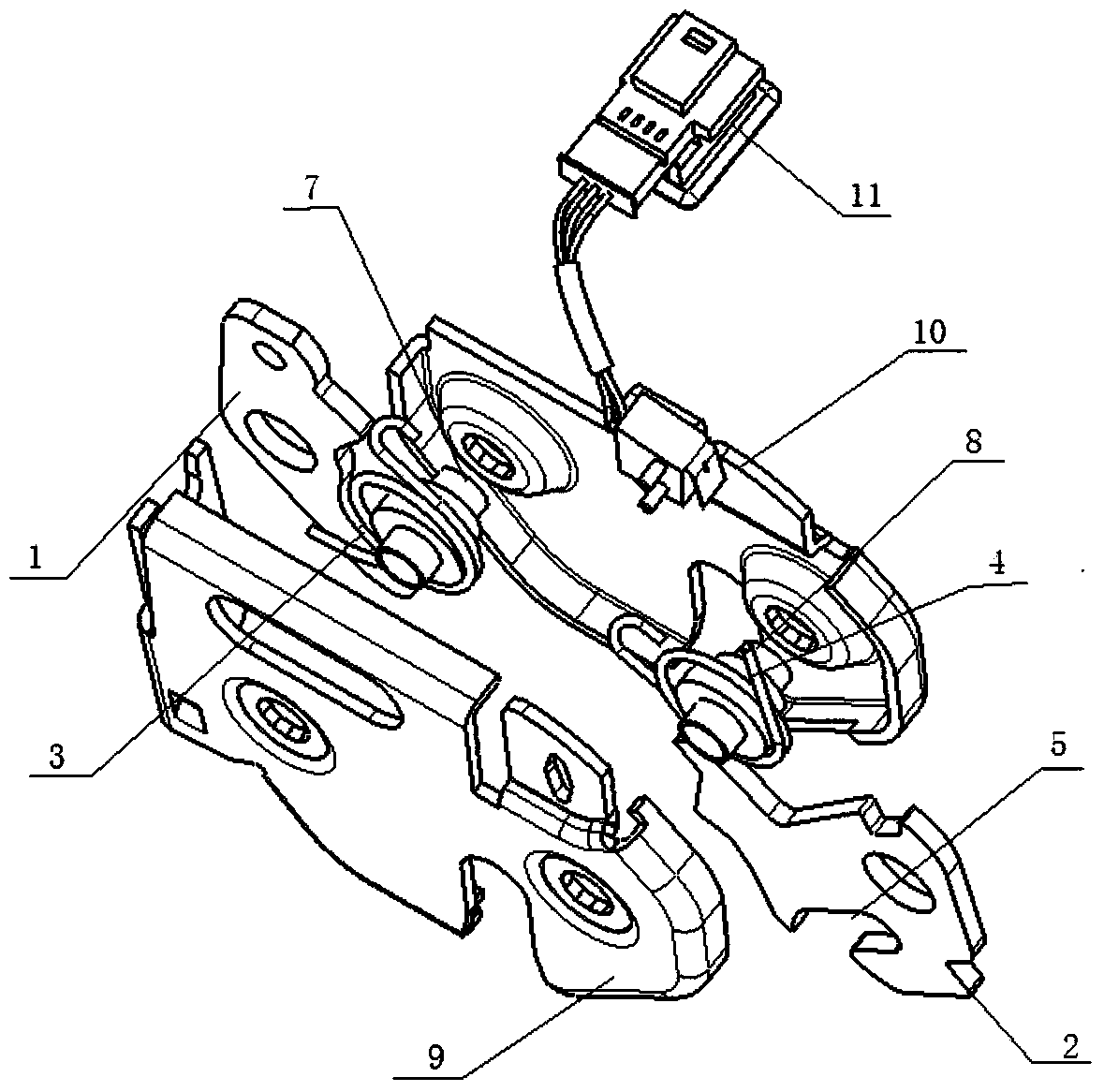

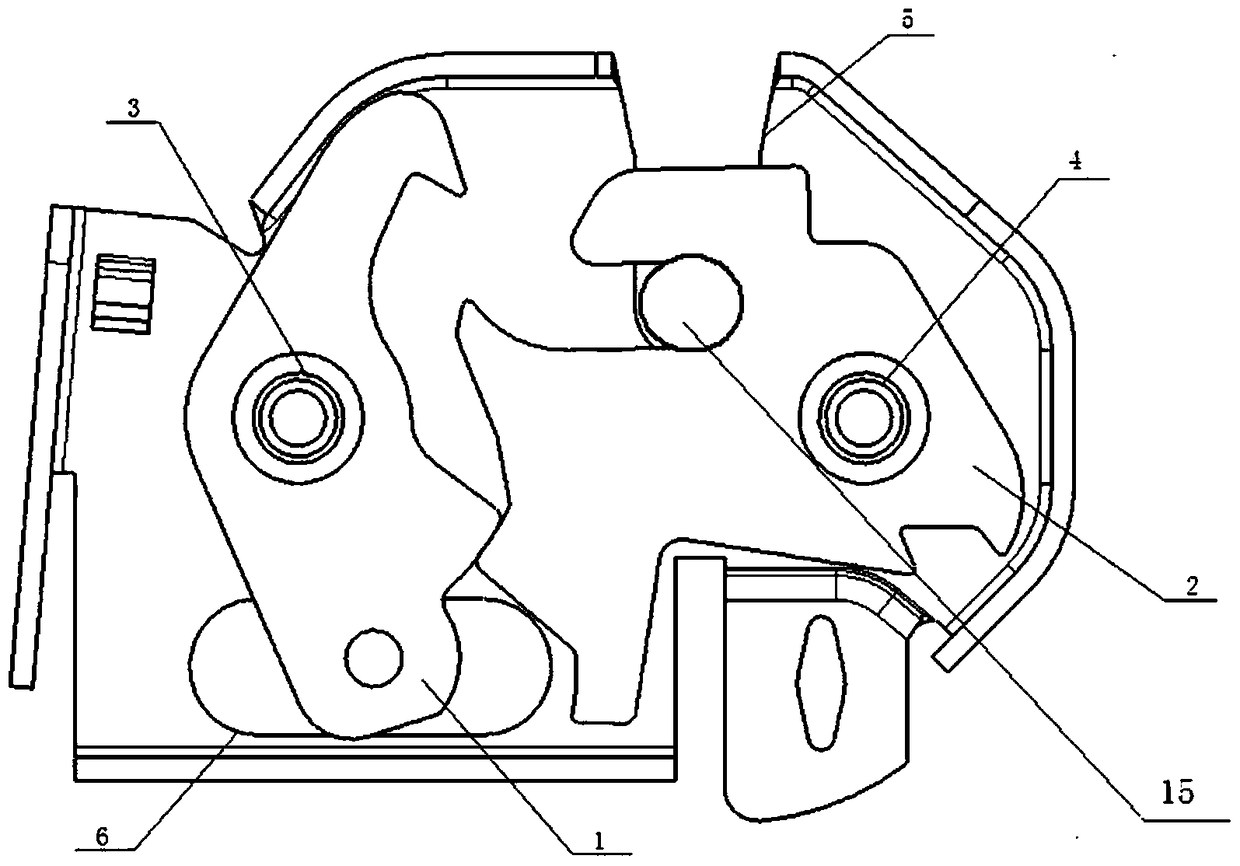

Luggage lock structure

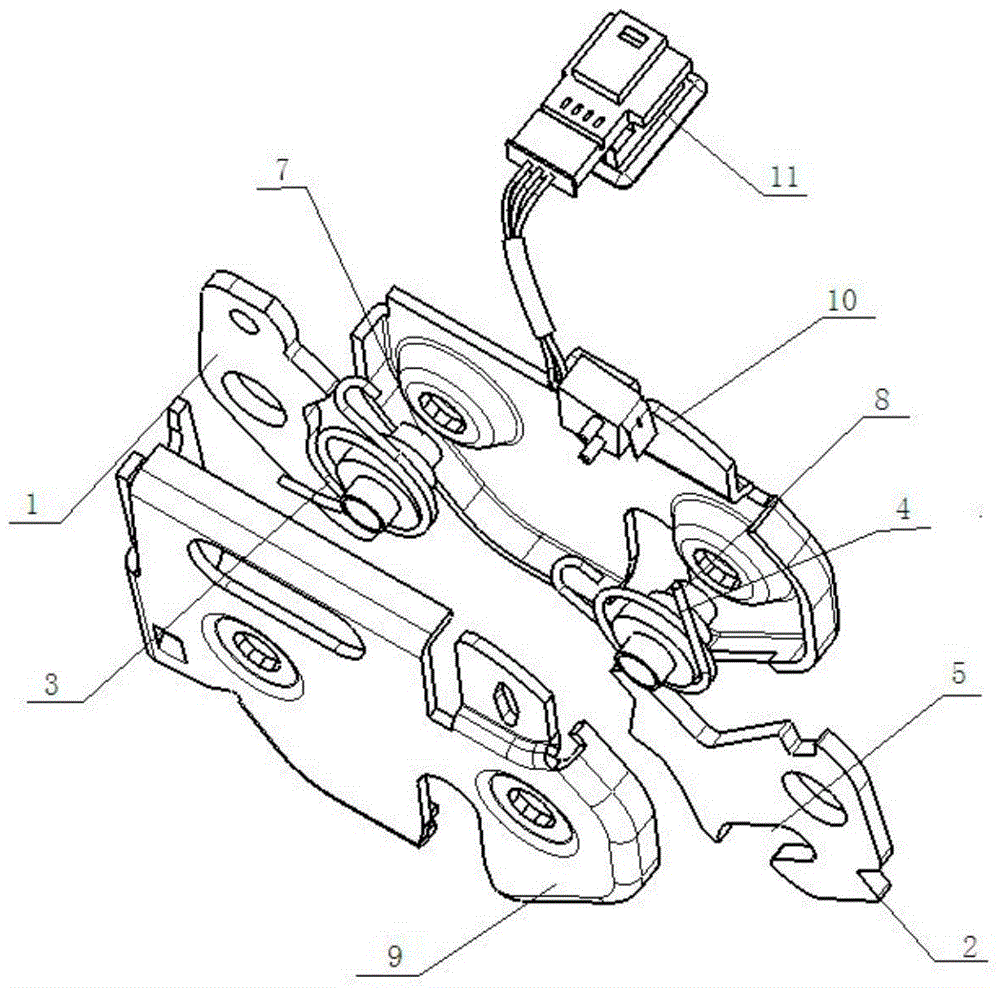

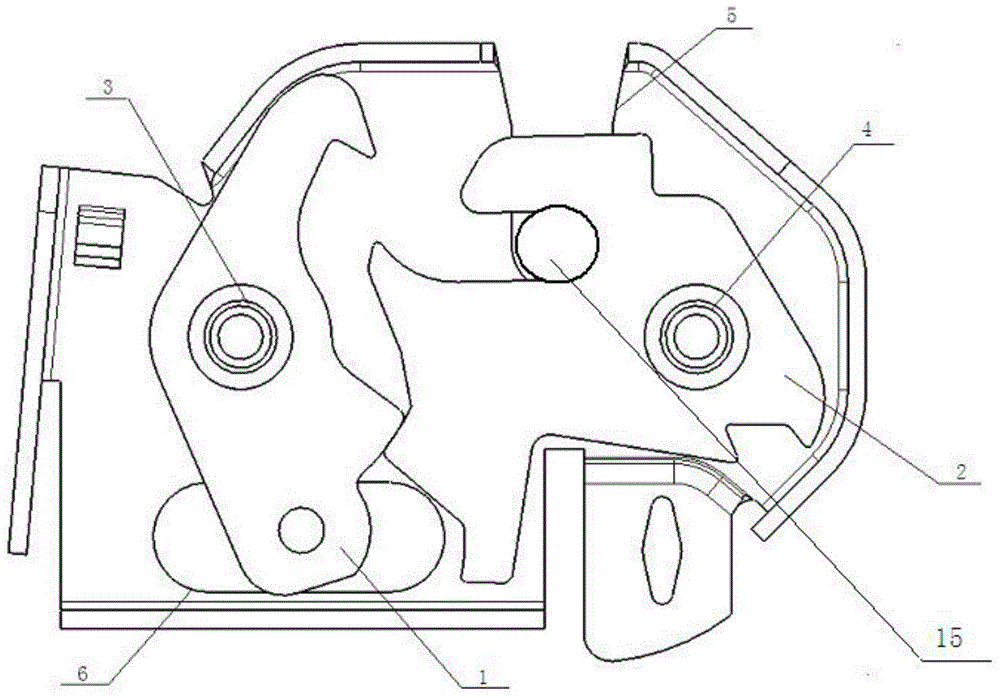

The invention provides a luggage lock structure. The luggage lock structure comprises a housing, a clamping plate and a pawl, wherein the clamping plate and the pawl are arranged in the housing; a groove is formed in the top part of the housing; a locking column is mounted in the groove and is arranged into the housing through the pawl as a first rivet rotates; a first pre-tensioning spring is arranged at the part in which the pawl rotates; a drawing wire is arranged at the bottom part of the pawl; a bulge is arranged at the inner side of the pawl; the clamping plate is arranged into the housing as a second rivet rotates; a second pre-tensioning spring of which the pre-tensioning force is opposite to the first pre-tensioning spring is arranged on the rotating part of the clamping plate; an opening groove in match with the groove is formed in the top part of the clamping plate; a clamping part in match with the bulge is arranged at the inner side of the clamping plate. According to the luggage lock structure, the pawl and the special structure of the inner side of the clamping plate can be matched to open a luggage lock for the second time, and thus the risk and loss caused by mis-operation can be avoided.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Gas distributing mechanism for engine and car with same

ActiveCN103758604ALittle impact on altitudeRealize the second openingValve arrangementsMachines/enginesCamRocker arm

The invention discloses a gas distributing mechanism for an engine and a car with the gas distributing mechanism. The gas distributing mechanism comprises a valve mechanism, a rocker arm assembly, a first roller, a second roller, a cam shaft, a bearing structure, a phase adjusting mechanism, and a third roller or a limiting pin. A driving molded surface is constructed at the bottom of the rocker arm assembly and is suitable for driving a valve to move, the first roller and the second roller can be arranged on the rocker arm assembly in a pivoted mode, the cam shaft comprises an inner shaft and an outer shaft, the inner shaft and the outer shaft are coaxially arranged, an inner shaft cam and an outer shaft cam which rotate along with the corresponding shafts are arranged on the inner shaft and the outer shaft respectively, the outer shaft cam abuts against the first roller, the inner shaft cam abuts against the second roller, the phase adjusting mechanism is used for adjusting the relative phase of the inner shaft and the outer shaft, a circular-arc curved surface or a sliding groove is formed in the bearing structure, the third roller can be tightly attached to the circular-arc curved surface in a rolling mode, and the limiting pin can be arranged in the sliding groove in a sliding and matching mode. The gas distributing mechanism can achieve secondary opening of the valve, the continuous opening time of the valve can be prolonged at the same time, the structure is simple and compact, and the influence on the height of the engine is small.

Owner:GREAT WALL MOTOR CO LTD

A luggage lock structure

The invention provides a suitcase lock structure, which includes a housing, a clamping plate and a pawl arranged in the housing; a groove is provided on the top of the housing, and a lock column is installed in the groove, and the pawl passes through the first The rivet is installed in the shell for rotation, and a first preload spring is provided on the rotation part of the pawl; the bottom of the pawl is provided with a wire drawing, and the inner side of the pawl is provided with a protrusion; the clamping plate is rotated by the second rivet It is installed in the housing, and the second pre-tensioning spring opposite to the pre-tensioning force of the first pre-tensioning spring is provided on the rotation part of the clamping plate, and the top of the clamping plate is provided with an opening groove matching the groove , on the inner side of the clamping plate, there is an engaging portion matched with the protrusion. This scheme realizes the secondary opening of the luggage lock through the cooperation of the pawl and the inner special structure of the clamping plate, so as to avoid the danger and loss caused by misoperation.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Valve train for engine and vehicle having same

ActiveCN103758601BRealize the second openingExtension of timeValve arrangementsMachines/enginesRelative phaseEngineering

Owner:GREAT WALL MOTOR CO LTD

Full-diameter switchable cementing sliding sleeve and method for infinite-stage alternate fracturing in horizontal wells

The invention discloses a full-diameter switch cementing sliding sleeve and a method for infinite-stage alternate fracturing in horizontal wells, including an upper joint, an outer casing, an inner sliding sleeve, and a lower joint. The fracturing hole and the fracturing hole of the inner sliding sleeve are provided with an upper annular groove, a T-shaped chute, and a lower annular groove in sequence on the outer casing, and an electromagnet I and an electromagnet II are respectively arranged in the upper annular groove and the lower annular groove. The electromagnet Ⅰ and electromagnet Ⅱ are equipped with ring circuits, and the upper and lower ends of the outer casing are respectively equipped with control circuit power supply Ⅰ and control circuit power supply Ⅱ; block, the inner wall of the outer casing is provided with a circlip groove, and the outer wall of the inner sliding sleeve is provided with a circlip. At the same time, the present invention can open and close the fracturing channel at any certain position, realize alternate sequential fracturing, increase the interference between fractures, and form a complex fracture network. Simultaneously carry out oil and gas production operations.

Owner:SOUTHWEST PETROLEUM UNIV

Valve train for engine and vehicle with same

ActiveCN103758602BLittle impact on altitudeGuaranteed uptimeValve arrangementsMachines/enginesEngineeringCam

The invention discloses a valve mechanism for an engine and a vehicle with the same. The valve mechanism comprises a vale gear, a rocker arm assembly, a first roller, a second roller, a cam shaft, a connecting arm and a phase adjusting mechanism. The bottom of the rocker arm assembly is provided with a driving type face which is directly in contact with the top of a valve to drive the valve of the valve gear to move. The first roller and the second roller can both be arranged on the rocker arm assembly in a pivoted mode. The cam shaft comprises an inner shaft and an outer shaft which are coaxially arranged, the inner shaft and the outer shaft are provided with an inner shaft cam and an outer shaft cam which can rotate along with corresponding shafts respectively, the outer shaft cam abuts against the first roller, and the inner shaft cam abuts against the second roller. The connecting arm is placed on the two sides of the rocker arm assembly respectively, the first end of the connecting arm is connected with the rocker arm assembly in a pivoted mode, and the second end of the connecting arm is arranged on an engine body set of the engine in a pivoted mode. The phase adjusting mechanism is used for adjusting the relative phase of the inner shaft and the outer shaft. The valve mechanism for the engine can achieve secondary opening of the valve, meanwhile, the duration time of opening of the valve can further be prolonged, the structure is simple and compact, and the influence on the height of the engine is small.

Owner:GREAT WALL MOTOR CO LTD

Valve train for engine and vehicle having same

ActiveCN103758604BLittle impact on altitudeRealize the second openingValve arrangementsMachines/enginesEngineeringCam

The invention discloses a gas distributing mechanism for an engine and a car with the gas distributing mechanism. The gas distributing mechanism comprises a valve mechanism, a rocker arm assembly, a first roller, a second roller, a cam shaft, a bearing structure, a phase adjusting mechanism, and a third roller or a limiting pin. A driving molded surface is constructed at the bottom of the rocker arm assembly and is suitable for driving a valve to move, the first roller and the second roller can be arranged on the rocker arm assembly in a pivoted mode, the cam shaft comprises an inner shaft and an outer shaft, the inner shaft and the outer shaft are coaxially arranged, an inner shaft cam and an outer shaft cam which rotate along with the corresponding shafts are arranged on the inner shaft and the outer shaft respectively, the outer shaft cam abuts against the first roller, the inner shaft cam abuts against the second roller, the phase adjusting mechanism is used for adjusting the relative phase of the inner shaft and the outer shaft, a circular-arc curved surface or a sliding groove is formed in the bearing structure, the third roller can be tightly attached to the circular-arc curved surface in a rolling mode, and the limiting pin can be arranged in the sliding groove in a sliding and matching mode. The gas distributing mechanism can achieve secondary opening of the valve, the continuous opening time of the valve can be prolonged at the same time, the structure is simple and compact, and the influence on the height of the engine is small.

Owner:GREAT WALL MOTOR CO LTD

Valve train for engine and vehicle having same

ActiveCN103775159BLittle impact on altitudeGuaranteed uptimeValve arrangementsMachines/enginesRelative phaseEngineering

The invention discloses an air distribution mechanism for an engine and a vehicle with the same. The distribution mechanism comprises an air valve mechanism, a rocker arm assembly, a camshaft, a first roller, a second roller, a connecting arm and a phase adjusting mechanism, wherein the bottom of the rocker arm assembly is provided with a driving molded surface which is suitable for driving an air valve of the air valve mechanism to move along the direction which is parallel to the central line of the air valve; the first roller and the second roller are respectively arranged on the rocker arm assembly in a pivoting manner; the camshaft comprises an inner shaft and an outer shaft, which are coaxial with each other, the inner shaft and the outer shaft are respectively provided with an inner shaft cam and an outer shaft cam, which can rotate along with the corresponding shaft, the outer shaft cam pushes against the first roller, and the inner shaft cam pushes against the second roller; a first end of the connecting arm is connected with the rocker arm assembly in a pivoting manner, and a second end of the connecting arm is arranged on to a body group of the engine in a pivoting manner; the phase adjusting mechanism is used for adjusting the relative phase of the inner shaft and the outer shaft. By adopting the air distribution mechanism, the secondary opening of the air valve can be realized; meanwhile, the opening duration of the air valve can be prolonged; moreover, the structure is simple and compact, and the influence on the height of the engine is small.

Owner:GREAT WALL MOTOR CO LTD

Valve train for engine and vehicle having same

ActiveCN103758603BLittle impact on altitudeGuaranteed uptimeValve arrangementsMachines/enginesEngineeringCam

The invention discloses a valve mechanism for an engine and a vehicle with the same. The valve mechanism comprises a valve gear, a rocker arm assembly, a first roller, a second roller, a cam shaft, a connecting arm and a phase adjusting mechanism. The bottom of the rocker arm assembly is provided with a driving type face which is directly in contact with the top of a valve of the valve gear to drive the valve to move. The first roller and the second roller can both be arranged on the rocker arm assembly in a pivoted mode. The cam shaft comprises an inner shaft and an outer shaft which are coaxially arranged, the inner shaft and the outer shaft are provided with an inner shaft cam and an outer shaft cam which rotate along corresponding shafts respectively, the outer shaft cam abuts against the first roller, and the inner shaft cam abuts against the second roller. The first end of the connecting arm is connected with the rocker arm in a pivoted mode, and the second end of the connecting arm is arranged on an engine body set of the engine in a pivoted mode. The phase adjusting mechanism is used for adjusting the relative phase of the inner shaft and the outer shaft. The valve mechanism for the engine can achieve secondary opening of the valve, meanwhile, the duration time of opening of the valve can also be prolonged, the structure is simple and compact, and the influence on the height of the engine is small.

Owner:GREAT WALL MOTOR CO LTD

Air distribution mechanism for engine and vehicle with same

ActiveCN103775159ALittle impact on altitudeGuaranteed uptimeValve arrangementsMachines/enginesRelative phaseEngineering

The invention discloses an air distribution mechanism for an engine and a vehicle with the same. The distribution mechanism comprises an air valve mechanism, a rocker arm assembly, a camshaft, a first roller, a second roller, a connecting arm and a phase adjusting mechanism, wherein the bottom of the rocker arm assembly is provided with a driving molded surface which is suitable for driving an air valve of the air valve mechanism to move along the direction which is parallel to the central line of the air valve; the first roller and the second roller are respectively arranged on the rocker arm assembly in a pivoting manner; the camshaft comprises an inner shaft and an outer shaft, which are coaxial with each other, the inner shaft and the outer shaft are respectively provided with an inner shaft cam and an outer shaft cam, which can rotate along with the corresponding shaft, the outer shaft cam pushes against the first roller, and the inner shaft cam pushes against the second roller; a first end of the connecting arm is connected with the rocker arm assembly in a pivoting manner, and a second end of the connecting arm is arranged on to a body group of the engine in a pivoting manner; the phase adjusting mechanism is used for adjusting the relative phase of the inner shaft and the outer shaft. By adopting the air distribution mechanism, the secondary opening of the air valve can be realized; meanwhile, the opening duration of the air valve can be prolonged; moreover, the structure is simple and compact, and the influence on the height of the engine is small.

Owner:GREAT WALL MOTOR CO LTD

Valve train for engine and vehicle having the same

The invention discloses a valve timing mechanism for an engine and a vehicle with the same. The valve timing mechanism comprises a valve mechanism, a rocker component, a first, a second and a third roller, a first and a second cam shaft, a lift adjusting mechanism and a phase adjusting mechanism, wherein a drive profile is formed at the bottom of the rocker component; the first, second and third rollers are pivotally mounted on the rocker component, and the first and third rollers are arrayed coaxially; the first cam shaft comprises a first cam, the second cam shaft comprises a second cam, and the first cam is propped against the first roller while the second cam is propped against the second roller; the lift adjusting mechanism comprises a drive component and a press block, the bottom of the press block is formed into a lift profile which is clung to the third roller in fit manner, and the drive component drives the press block to rotate; the phase adjusting mechanism is used for adjusting the relative phases of the first cam shaft and the second cam shaft. The valve timing mechanism for the engine is capable of realizing the secondary open of the valve and prolonging the valve opening duration and has advantages of simple structure and less parts.

Owner:GREAT WALL MOTOR CO LTD

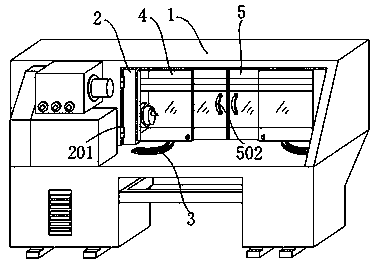

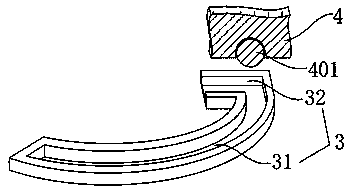

A machine tool protective cover capable of realizing secondary door opening

ActiveCN108381286BImprove the protective effectPrevent movementMaintainance and safety accessoriesStructural engineeringMachine tool

The invention discloses a machine tool protective hood capable of secondary opening of doors. The machine tool protective hood comprises a machine tool, rotary limiting plates are movably arranged onthe two sides of a working area in the machine tool through hinges, the rotating protective doors are movably arranged on the outer side end faces of the two rotary limiting plates, balls are movablyembedded in the bottom ends of the rotary protective doors and clamped in sliding rails in a rolling mode, and the sliding rails are fixedly installed at the part, on the outer side of the working area, of the machine tool. In the machine tool protective hood, the protective doors include the rotary protective doors and mobile protective doors, generally, the working area can be closed and openedonly by pulling the mobile protective doors instead of opening the rotary protective doors, and the protective doors can be opened for the first time by moving the mobile protective doors on the two sides leftwards and rightwards; and when the machine tool needs to be overhauled, a fixing bolt block can be pulled, the rotary protective doors are pulled out, the balls at the bottoms of the rotary protective doors are located at the inner ends of the straight sliding rails accordingly, the rotary protective doors can be opened along the track of the arc sliding rails, and secondary opening of the protective doors is achieved.

Owner:滁州市成业机械制造股份有限公司

Valve train for engine and vehicle having same

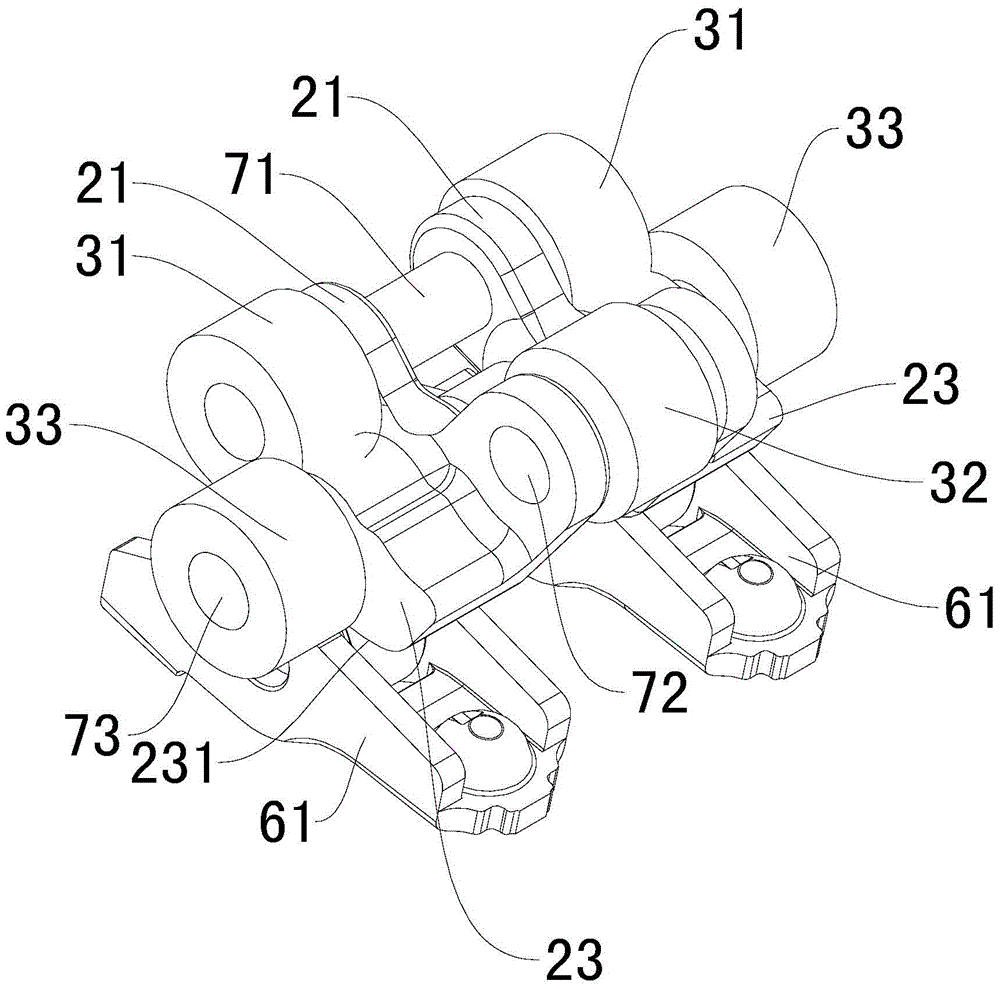

ActiveCN103742215BSimple rocker mechanismRocker mechanism is compactValve arrangementsMachines/enginesAbutmentCam

The invention discloses a gas distribution mechanism for an engine and a vehicle with the same. The valve mechanism includes: a valve mechanism; a rocker arm mechanism, the rocker arm mechanism includes first and second rocker arm assemblies, the bottom of the first rocker arm assembly is configured with a driving profile, and the lower end of the second rocker arm assembly is pivotally provided on the first rocker arm assembly; the first and second rollers, the first and second rollers are pivotally provided on the first and second rocker arm assemblies respectively; the first and second camshafts, the first The first and second camshafts respectively have first and second cams, the first cam abuts against the first roller and the second cam abuts against the second roller; a connecting arm, the first end of which is pivotable with the rocker mechanism The second end of the connecting arm is pivotally arranged on the body group of the engine; a phase adjustment mechanism for adjusting the relative phase of the first and second camshafts. The gas distribution mechanism of the invention can realize the secondary opening of the valve, and at the same time can prolong the opening duration of the valve, has simple structure and few parts.

Owner:GREAT WALL MOTOR CO LTD

Valve train for engine and vehicle having same

ActiveCN103742221BRealize the second openingExtension of timeValve arrangementsMachines/enginesEngineeringCam

The invention discloses a valve timing mechanism for an engine and a vehicle with the same. The valve timing mechanism comprises a valve mechanism, a rocker component, rollers, a push rod, a first cam shaft, a second cam shaft and a phase adjusting mechanism, wherein a drive profile is formed at the bottom of the rocker component and is used for driving the valve of the valve mechanism to move in the direction parallel to the the central line of the valve; the rollers are pivotally mounted on the rocker component; the first end of the push rod is pivotally connected with the rocker component; the first cam shaft comprises a first cam, the second cam shaft comprises a second cam, the first cam is propped against the rollers, the second cam drives the second end of the push rod so as to make the push rod move in the direction parallel to the lengthwise direction of the push rod; the phase adjusting mechanism is used for adjusting the relative phases of the first cam shaft and the second cam shaft. The valve timing mechanism for the engine is capable of realizing the secondary open of the valve and prolonging the valve opening duration and has advantages of simple structure and less parts.

Owner:GREAT WALL MOTOR CO LTD

Valve train for engine and vehicle having same

ActiveCN103790669BImprove inflation efficiencyMeet the needs of valve movement rules in different working conditionsValve arrangementsMachines/enginesEngineeringCam

The invention discloses a valve mechanism for an engine and a vehicle comprising the valve mechanism. The valve mechanism comprises a valve mechanism body, a rocker component, a first roller, a second roller, a camshaft, supporting structures, a phase adjusting mechanism, and a third roller or limit pins. The bottom of the rocker component is provided with a drive molded surface which is suitable for directly driving a valve to move. The first roller and the second roller both can be arranged on the rocker component in a pivoting mode. The camshaft comprises an inner shaft and an outer shaft, the inner shaft and the outer shaft are coaxially arranged and provided with an inner shaft cam and an outer shaft cam respectively, and the inner shaft cam and the outer shaft cam can rotate along the corresponding shafts respectively. The outer shaft cam abuts against the first roller, the inner shaft cam abuts against the second roller, the supporting structures are arranged on the two sides of the rocker component and provided with circular arc cambers or sliding grooves, the third roller can be attached to the circular arc cambers in a rolling mode, and the limit pins can be matched in the sliding grooves in a sliding mode. The valve mechanism can achieve secondary opening of the valve, can lengthen the opening lasting time of the valve, and is simple in structure, and low in influence on the height of the engine.

Owner:GREAT WALL MOTOR CO LTD

Valve train for engine and vehicle with same

ActiveCN103758605BLittle impact on altitudeGuaranteed uptimeValve arrangementsMachines/enginesMechanical engineering

The invention discloses a gas distributing mechanism for an engine and a car with the gas distributing mechanism. The gas distributing mechanism comprises a valve mechanism, a rocker arm assembly, a first roller, a second roller, a cam shaft, a bearing structure, a phase adjusting mechanism, and a third roller or a limiting pin. A driving molded surface which is constructed at the bottom of the rocker arm assembly directly drives a valve to move, the first roller and the second roller can be arranged on the rocker arm assembly in a pivoted mode, the cam shaft comprises an inner shaft and an outer shaft, the inner shaft and the outer shaft are coaxially arranged, an inner shaft cam and an outer shaft cam which rotate along with the corresponding shafts are arranged on the inner shaft and the outer shaft respectively, the outer shaft cam abuts against the first roller, the inner shaft cam abuts against the second roller, the phase adjusting mechanism is used for adjusting the relative phase of the inner shaft and the outer shaft, a circular-arc curved surface or a sliding groove is formed in the bearing structure, the third roller can be tightly attached to the circular-arc curved surface in a rolling mode, and the limiting pin can be arranged in the sliding groove in a sliding and matching mode. The gas distributing mechanism can achieve secondary opening of the valve, the continuous opening time of the valve can be prolonged at the same time, the structure is simple and compact, and the influence on the height of the engine is small.

Owner:GREAT WALL MOTOR CO LTD

Valve train for engine and vehicle having same

ActiveCN103775153BImprove inflation efficiencyMeet the needs of valve movement rules in different working conditionsValve arrangementsMachines/enginesCamRocker arm

The invention discloses a gas distribution mechanism for an engine and a vehicle with the same. The gas distribution mechanism includes: a valve train; a rocker arm assembly with a drive profile adapted to drive the movement of the valve at the bottom; first and second rollers that are pivotally arranged on the rocker arm assembly; including a coaxial arrangement The camshafts of the inner shaft and the outer shaft have an inner shaft cam and an outer shaft cam that rotates with the corresponding shaft respectively, the outer shaft cam abuts against the first roller, and the inner shaft cam abuts against the second roller ; The support structure arranged on both sides of the rocker arm assembly; the phase adjustment mechanism; the gas distribution mechanism also includes a third roller or a limit pin, and the support structure is also configured with an arc surface or a sliding groove, and the third roller can roll Closely attached to the arc surface, the limit pin is slidably fitted in the slide groove. The valve mechanism of the present invention can realize the secondary opening of the valve, and at the same time can prolong the opening duration of the valve, has a simple and compact structure, and has little influence on the height of the engine.

Owner:GREAT WALL MOTOR CO LTD

A stacker crane simulation experiment platform and a stacker crane fault judgment method

ActiveCN108415405BFor subsequent analysisSimulate faults in real timeElectric testing/monitoringEducational modelsControl signalStack machine

The invention discloses a stacker simulation experiment platform comprising a master control chip, a translation mechanism, an elevating mechanism, a pallet fork telescopic mechanism, a communicationmechanism and an upper computer. The master control chip is connected with the translation mechanism, the elevating mechanism and the pallet fork telescopic mechanism. The master control chip is alsoconnected with the upper computer through the communication mechanism. The upper computer is used for transmitting the control signal to the master control chip. The master control chip is used for controlling movement of any one or multiple of the translation mechanism, the elevating mechanism and the pallet fork telescopic mechanism according to the control signal transmitted by the upper computer. According to the stacker simulation experiment platform, the simulated stacker fault can be simulated and the stacker fault data can be collected; the fault possibility of large stacker and the fault type can be predicted by using the fault data; and the stacker simulation experiment platform can also be applied to research of colleges and universities to perform secondary development of the stacker so as to enhance the performance of the stacker.

Owner:洛阳甲佳智能装备有限公司

Valve train for engine and vehicle having same

ActiveCN103758598BRealize the second openingExtension of timeValve arrangementsMachines/enginesCamRocker arm

Owner:GREAT WALL MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com