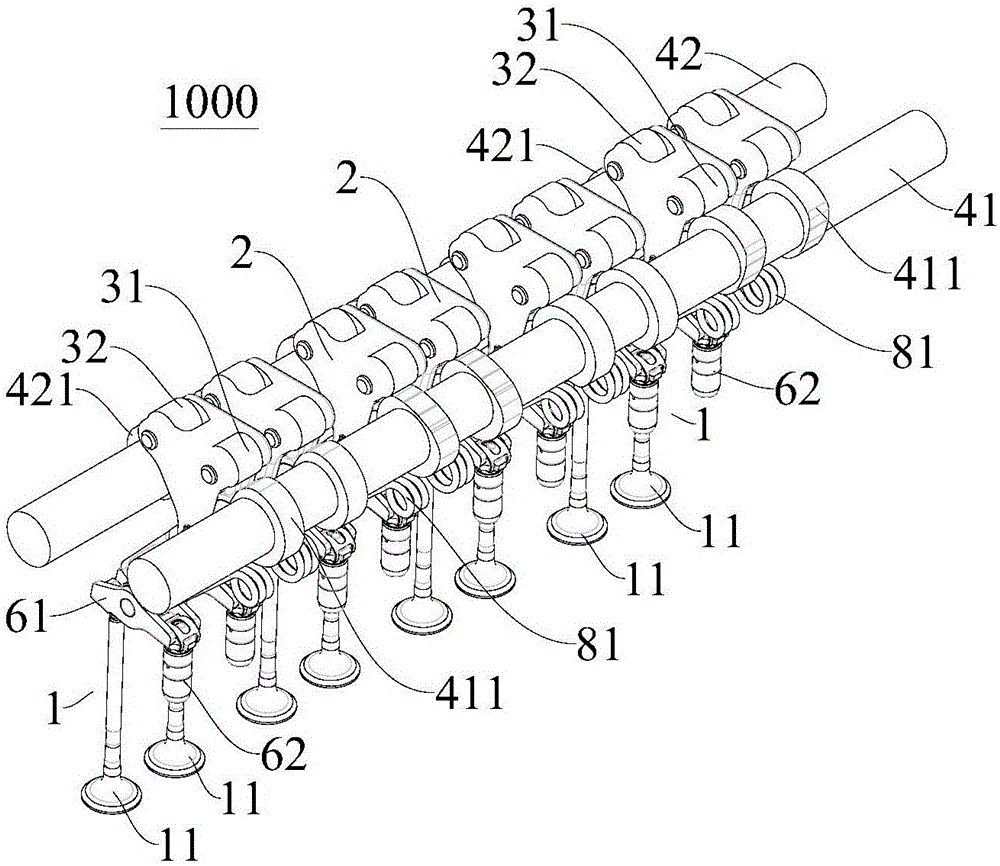

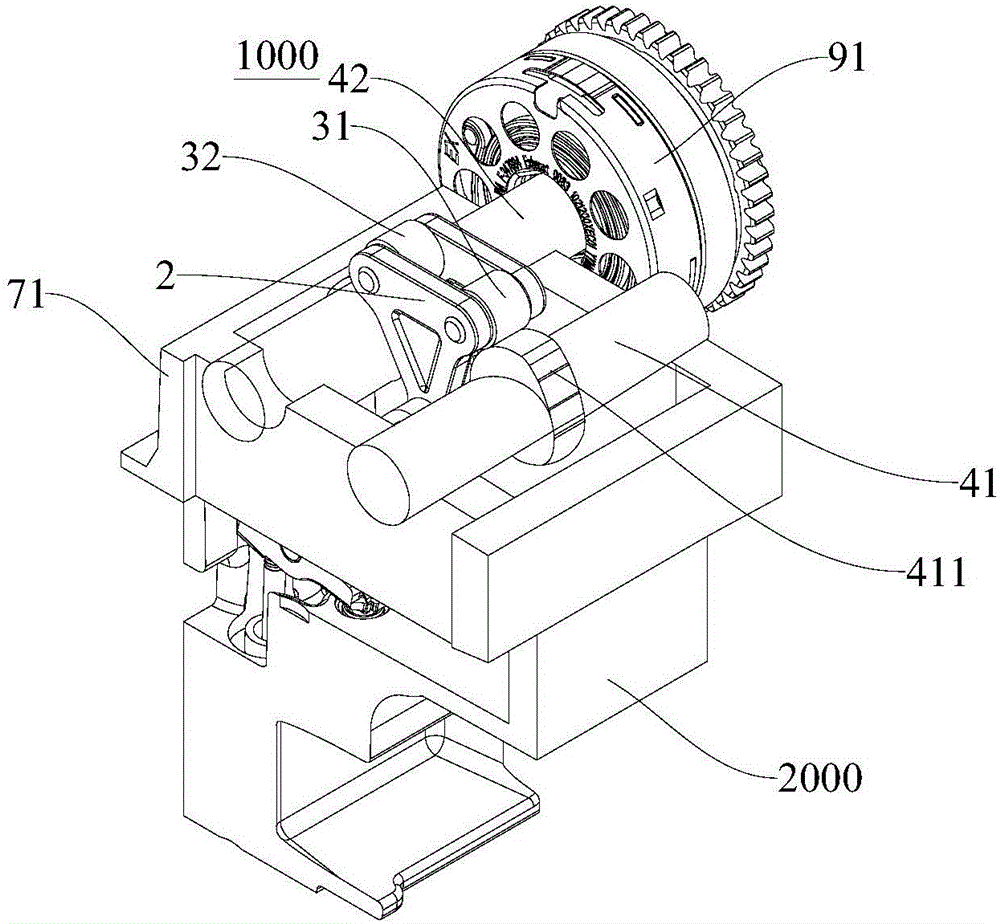

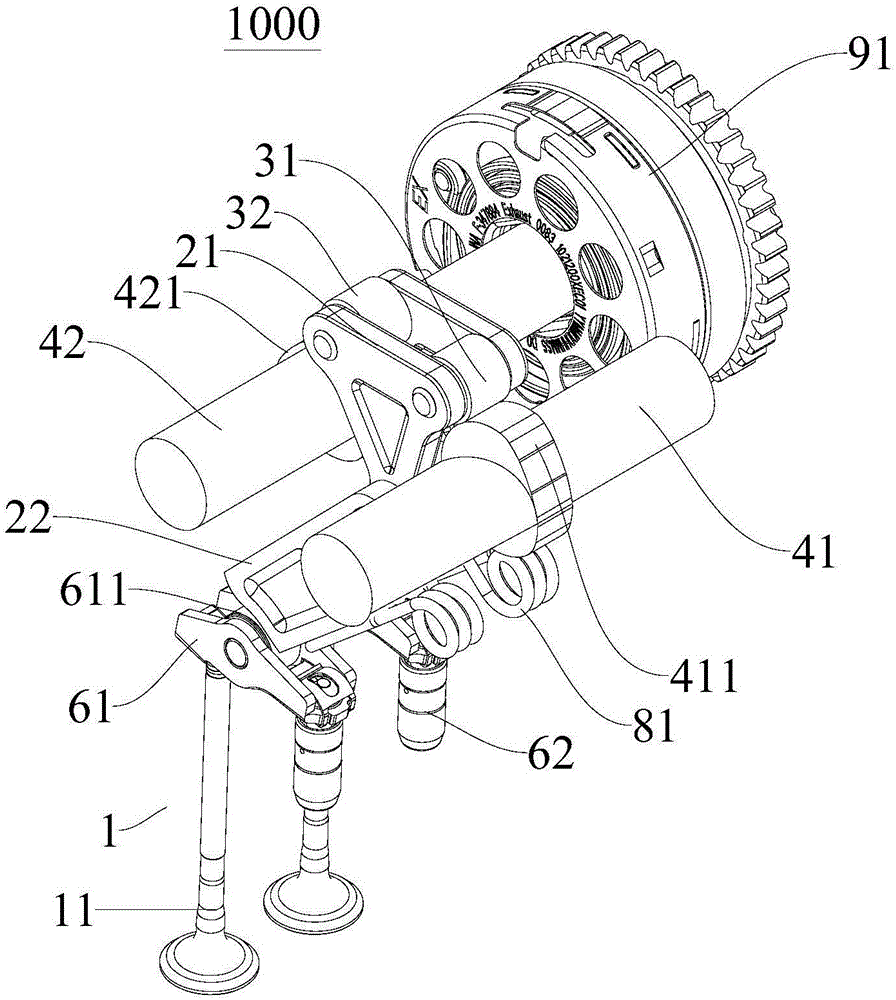

Valve actuating mechanism for engine and cam of valve actuating mechanism

A valve train, engine technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of cumbersome control, many parts, and single functions, and achieve simple swing arm components, few parts, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0053] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0054] The body group of the engine is the bracket of the engine, and it is the base body for the assembly of the crank connecting rod mechanism, the gas distribution mechanism and various systems. In this field, generally, the body group is mainly composed of cylinder block, cylinder head, cylinder head gasket and oil pan, etc., the oil pan is generally set at the bottom of the cylinder block, and the cylinder head is set at the top of the cylinder block. A head gasket is provided between the top surface of the cylinder block and the bottom surface of the cylinder head to seal the gap therebetween.

[0055] The cylinder head forms a combustion chamber together with the top of the pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com