A high-efficiency electrostatic protection component of disc type tvs tube for bridge wire electric detonator

An electrostatic protection device and electrostatic protection technology, which are used in weapon accessories, fuzes, offensive equipment, etc., can solve the problems of open circuit protection, melting and deformation of saw teeth, and no resistance to multiple electrostatic shocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

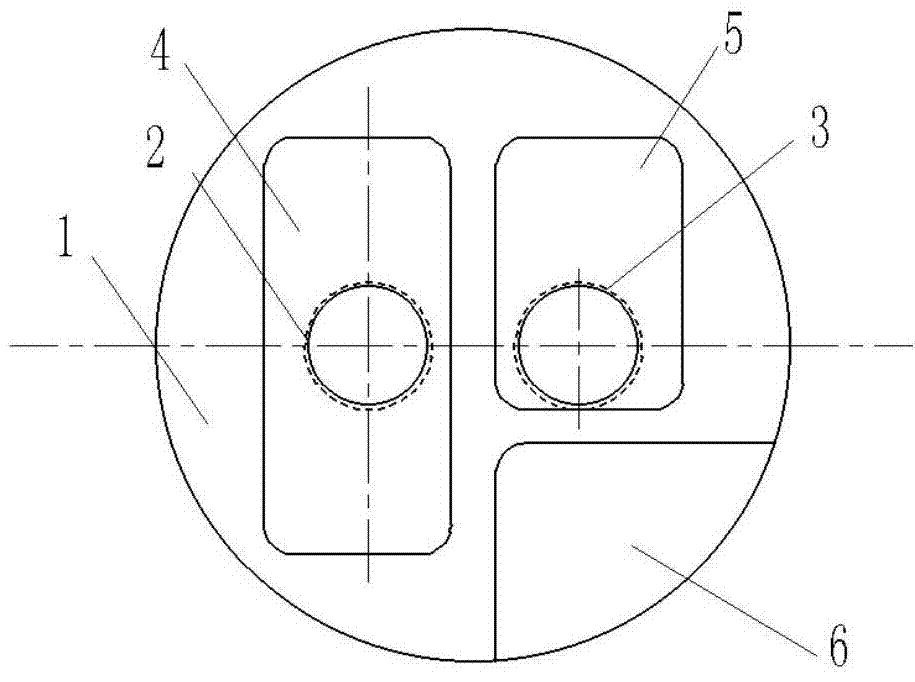

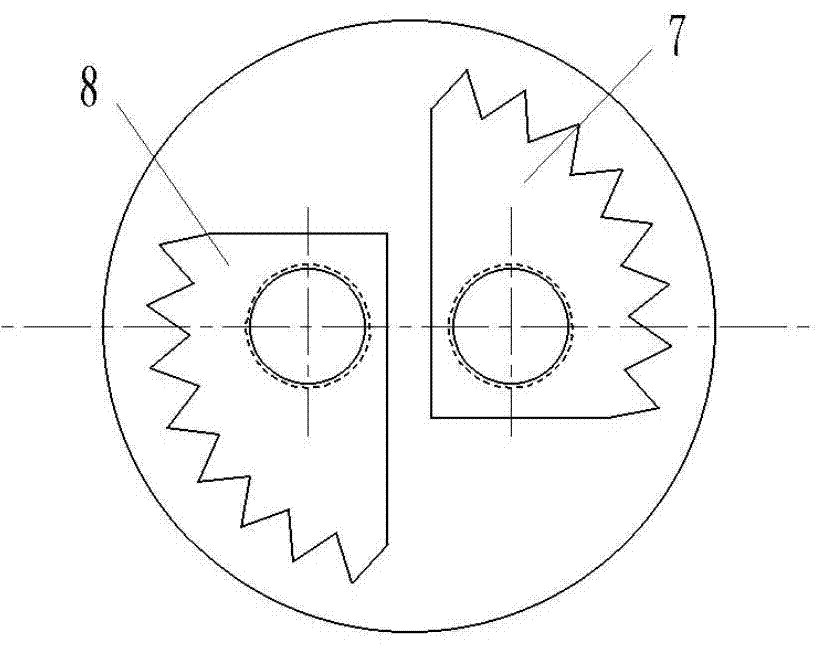

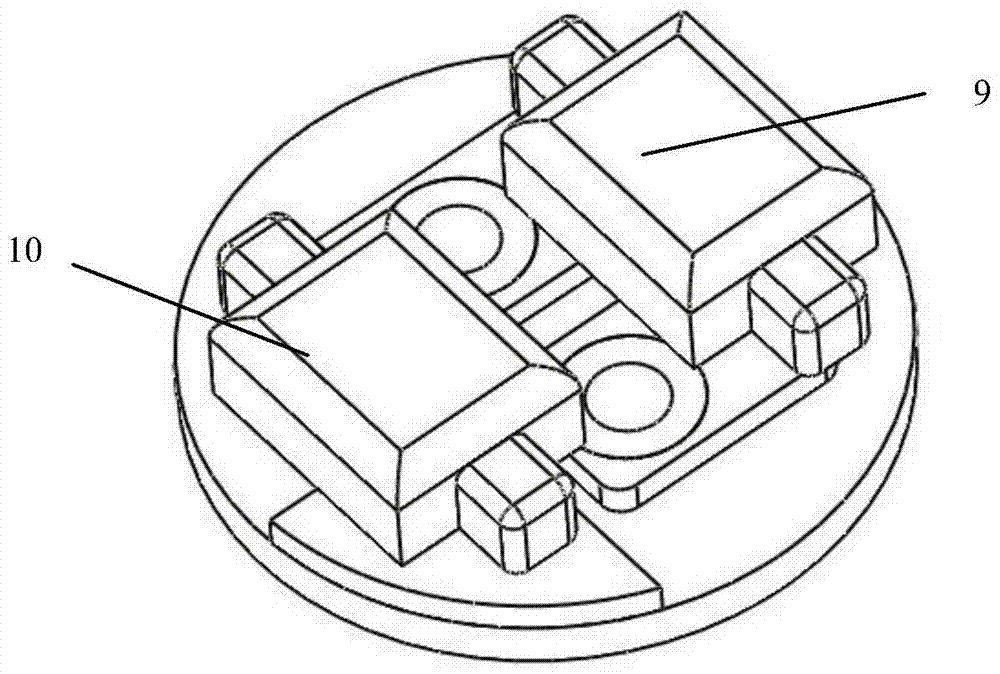

[0025] Combine figure 1 , figure 2 , image 3 , The anti-static sheet includes a PCB circular board with two holes 1, three metal pads 2, 5, 6, two metalized vias 2, 3, and two serrated copper clad laminates 7, 8, with two After the two holes of the PCB board 1 with two holes are metalized, two metalized vias 2 and 3 are formed. The upper side of the hole is the same as the height of the metal pad, and the lower side is the same as the height of the copper clad board. The metalized via 2 is connected to a rectangular metal pad 4 with chamfered corners and the center of the hole; another metalized via 3 is connected to another short rectangular metal pad 5; under this short pad 5 there is a and The arc-shaped pads 6 with the edges of the PCB circular board are aligned; two arc-shaped copper clad laminates 7, 8 with multiple serrations are connected to the two metalized vias 2, 3 under the PCB board. Two rectangular metal pads 4 and 5 are welded to the two poles of the protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com