A hydraulic pressure booster

A hydraulic and pressurized plate technology, applied in forging/pressing/hammering machinery, forging press driving device, forging/pressing/hammer device, etc., can solve problems such as low working speed, reduced life span, and large structure, and achieve Improve production efficiency, increase forming force, and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

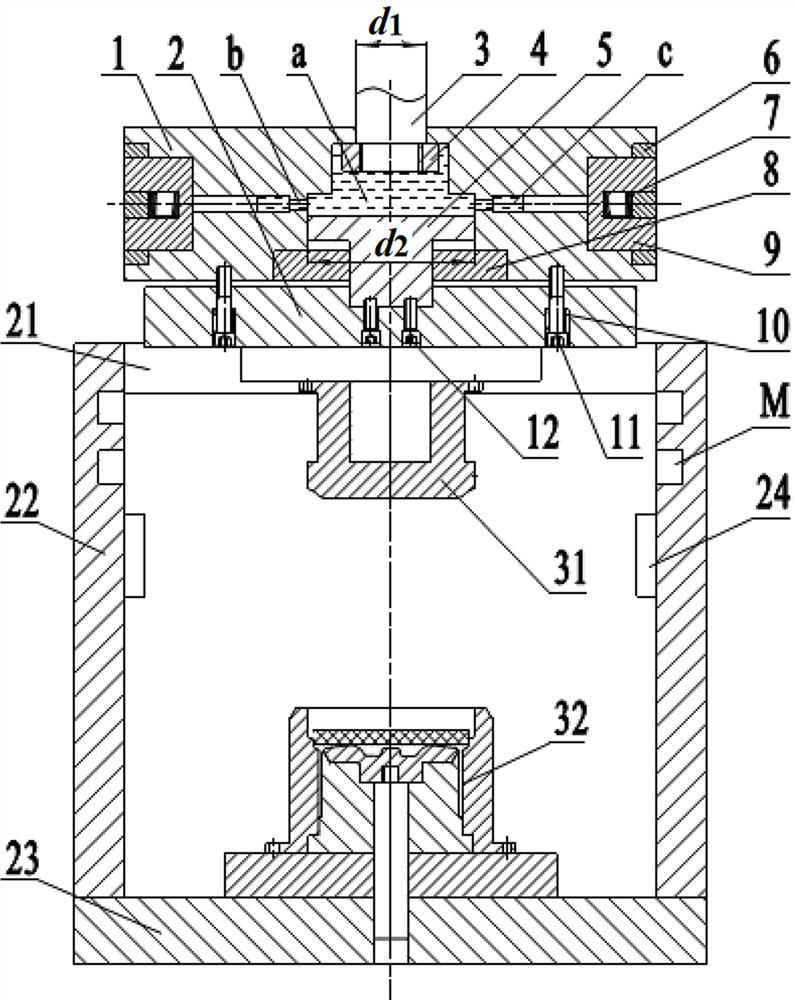

[0028] The specific structure of one of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings: figure 1 As shown, a hydraulic pressurizing mechanism, the pressurizing mechanism includes a constraining frame and a pressurizing mechanism, the constraining frame includes a horizontal plate 21, a vertical plate 22 and a bottom plate 23 that are integrally connected, and the vertical plate 22 is provided with pin holes M and fixedly connected with a stopper 24;

[0029] In this embodiment, the booster mechanism is composed of a booster plate 1 with a combined hydraulic chamber a and a lateral locking mechanism for locking the position of the booster plate 1 . From top to bottom in the vertical direction, there are a small-diameter pressure chamber and a large-diameter pressurization chamber in order. Passing through the pressurizing plate 1 and having a protruding end for connecting with the movable beam of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com