High-grade pressure bicycle with tubeless shock-proof wheels

A technology for bicycles and inner tubes, used in bicycle frames, bicycle accessories, bicycle brakes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

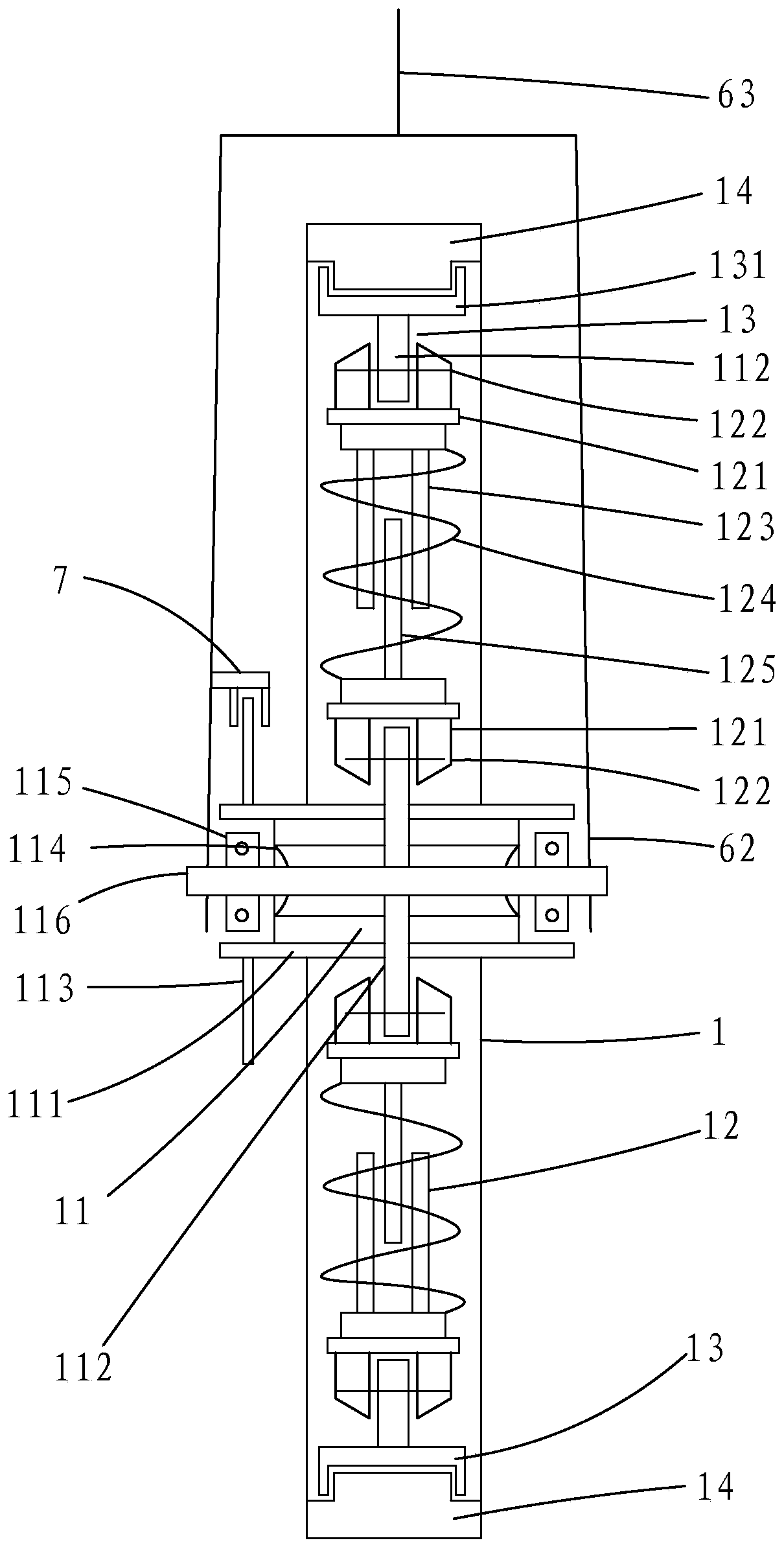

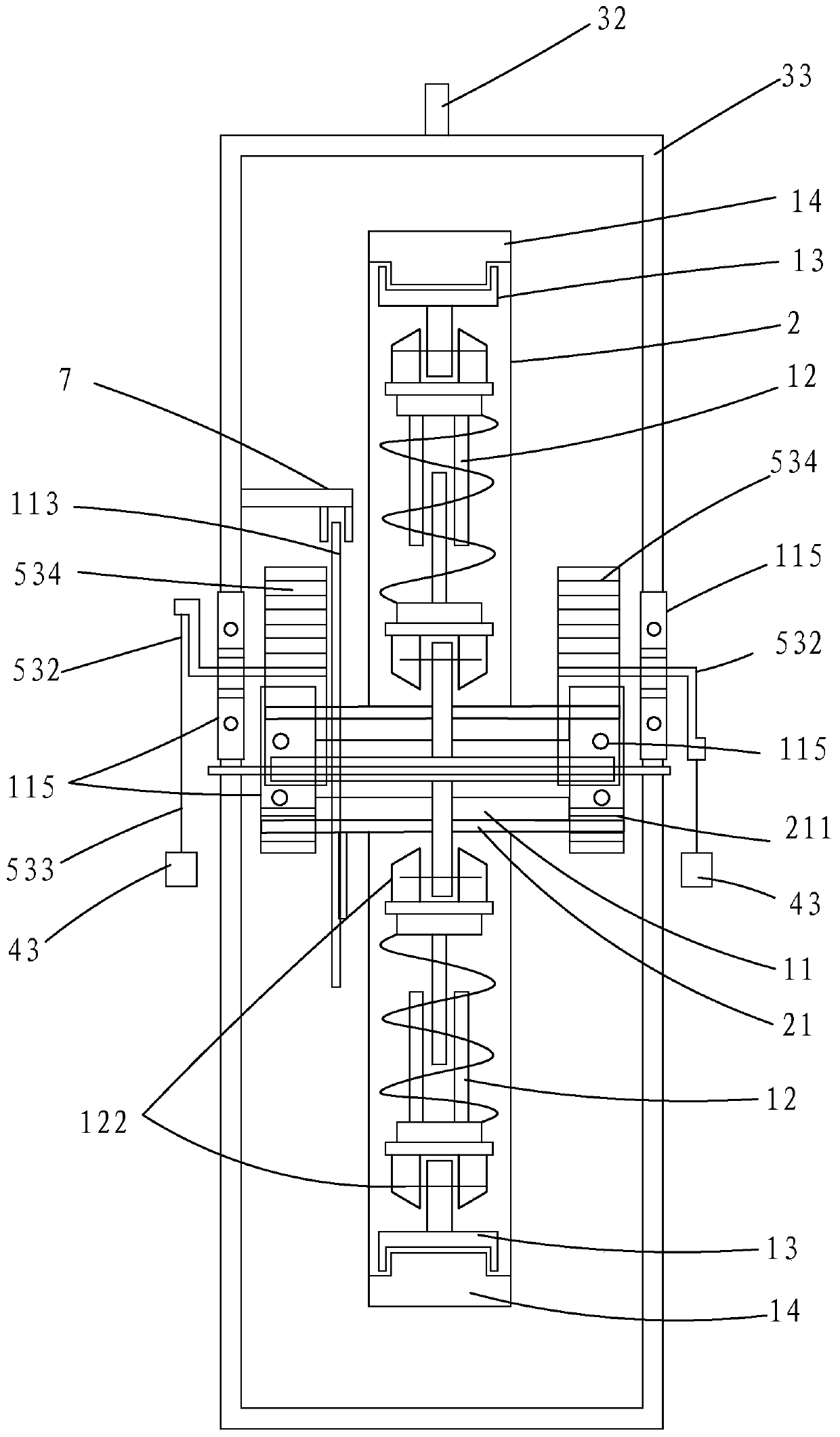

[0034] see Figure 1 to Figure 4 shown. Such as image 3 and Figure 4 The driving cylinder 21, the pinion 211, and the bull gear 534 are all models of the same size, but on the accompanying drawings, the image 3 Transmission cylinder 21, pinion 211, bull gear 534 enlarged expression.

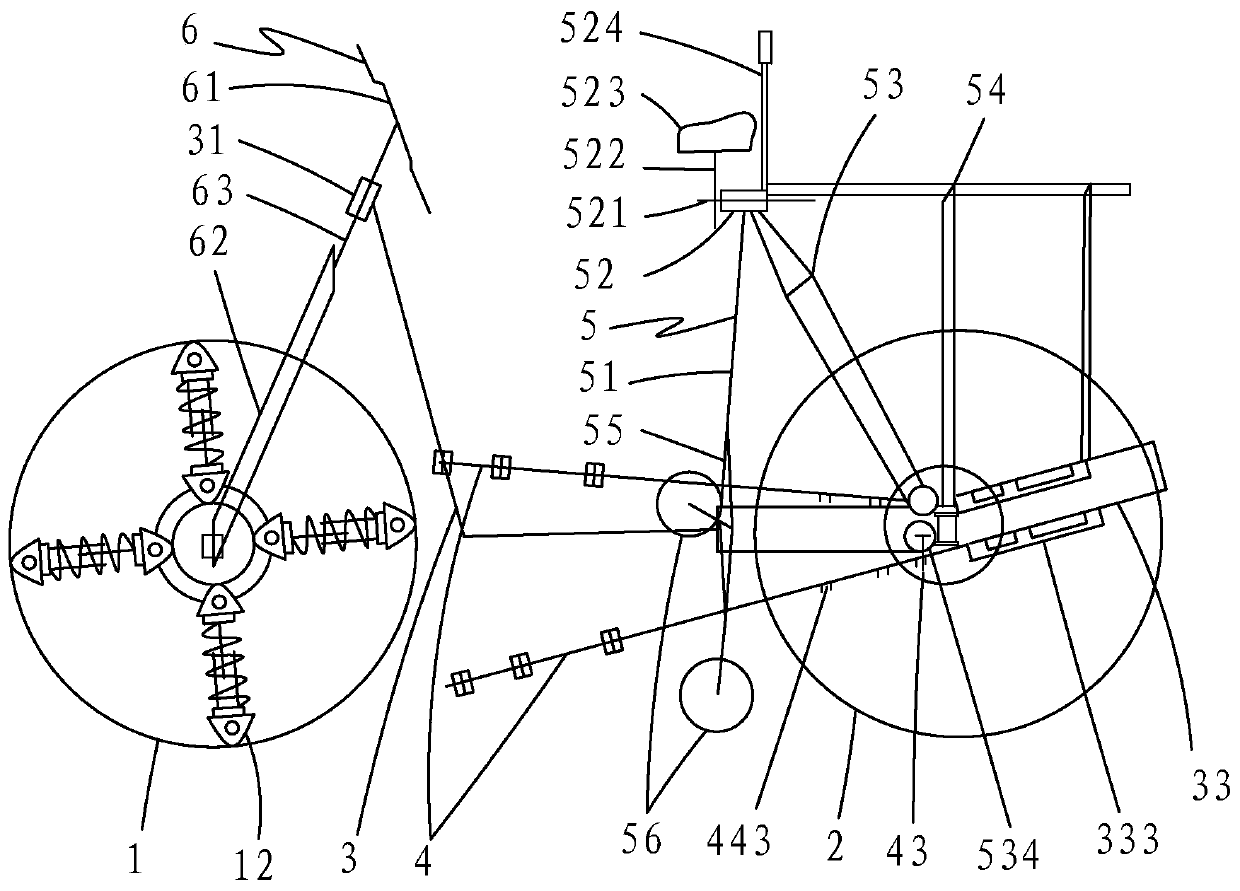

[0035] The invention provides a high-grade pressure bicycle 100 with tubeless shock-absorbing wheels. The components include a tubeless shock-absorbing front wheel 1, a tubeless shock-absorbing rear wheel 2, a dragon frame 3, an iron beam 4, and a rear tripod 5. A headstock 6 and a brake caliper 7;

[0036] The assembly of the tubeless shock-absorbing front wheel 1 includes at least one hub tube 11, a pressureless shock absorber 12, an inner convex outer tooth steel ring 13 and a tire 14; the assembly of the hub tube 11 includes at least A large steel pipe 111, a protruding piece 112, a brake disc 113, a small steel pipe 114, a small bearing 115 and a shaft 116; Linked to the large conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com