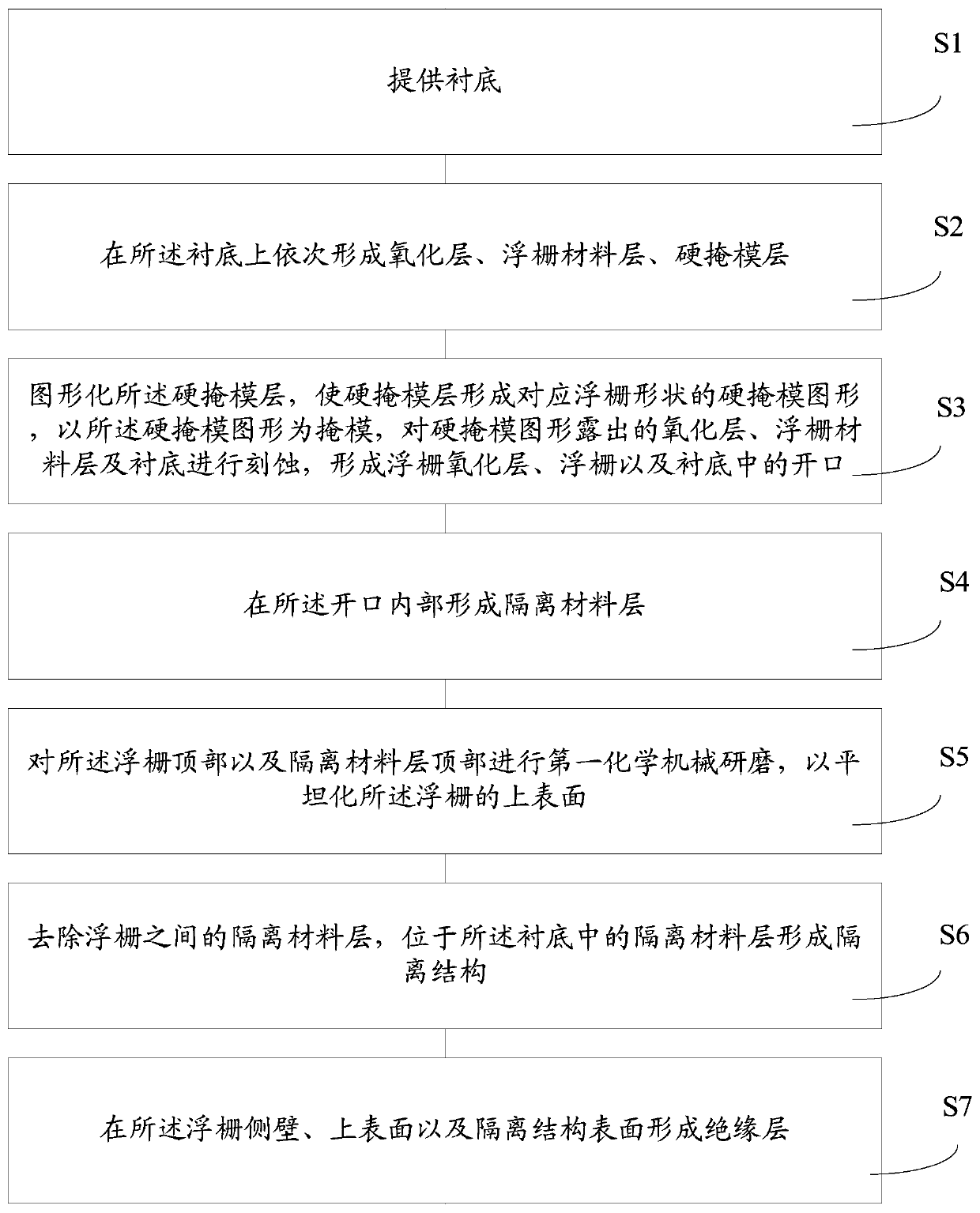

Method of forming memory

A memory and graphics technology, applied in semiconductor devices, electric solid devices, electrical components, etc., can solve the problem of poor storage capacity of floating gates, achieve high flatness, uniform thickness, and improve the ability to hold charges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

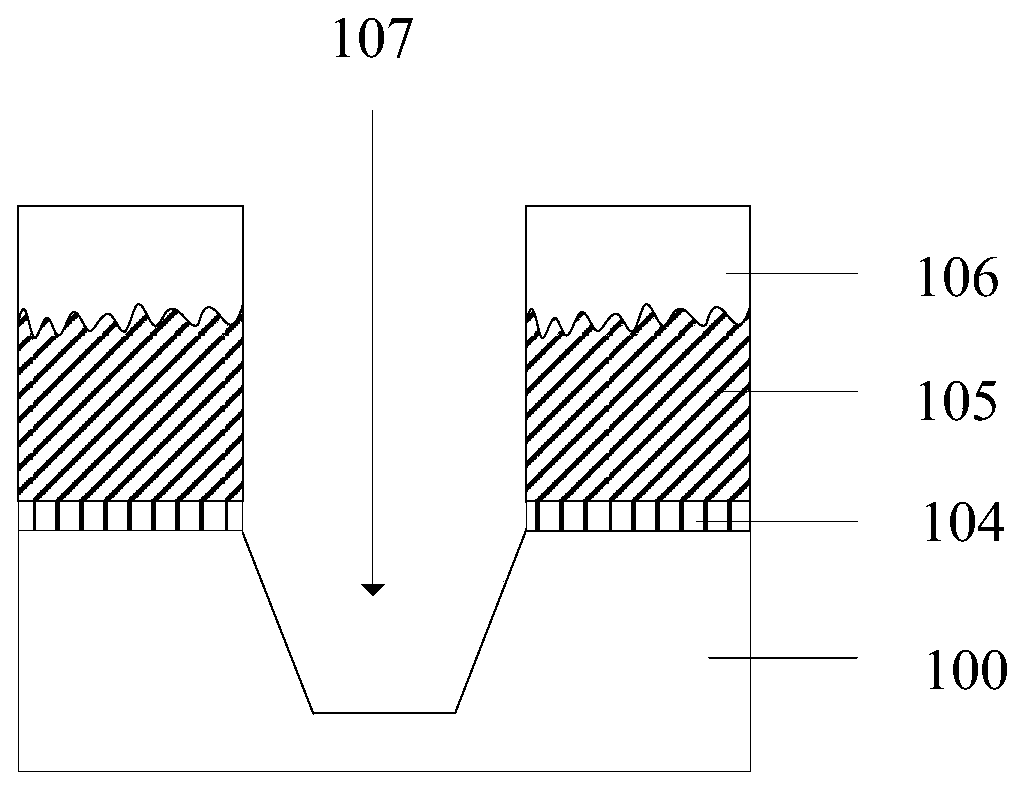

[0032] With the shrinking of the semiconductor feature size, the thickness of the insulating layer in the memory, especially in ETOX, is constantly decreasing. It often occurs that the local electric field strength near the insulating layer is greater than the surrounding electric field strength, which makes the ability of the floating gate to hold charges worse.

[0033] The phenomenon that the local electric field intensity near the insulating layer of the existing technology is greater than the intensity of the surrounding electric field is analyzed. The uniformity is poor, causing the local electric field strength near the insulating layer to be greater than that of the surrounding electric field.

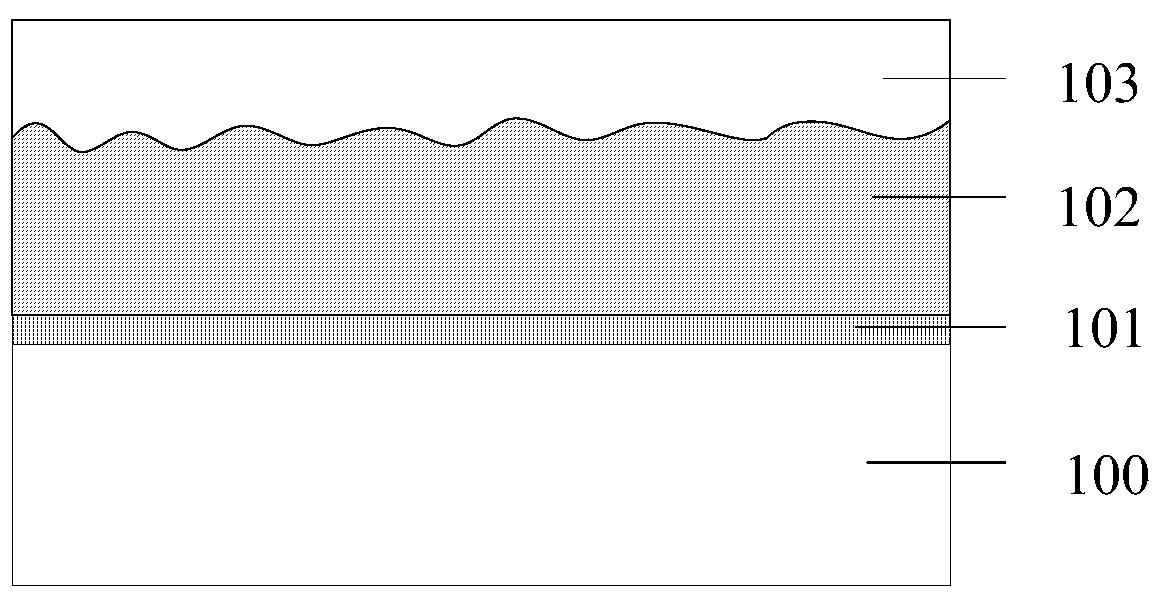

[0034] In order to solve the technical problem, the present invention provides a method for forming a memory, using a self-aligned isolation structure process, after forming the floating gate and the isolation material layer between the floating gates, the top of the floating ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com