OTP device and manufacturing method thereof

A technology for controlling gates and memory cells, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems such as failure to meet requirements, improve the ability to store charges, avoid charge leakage, and improve data retention force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

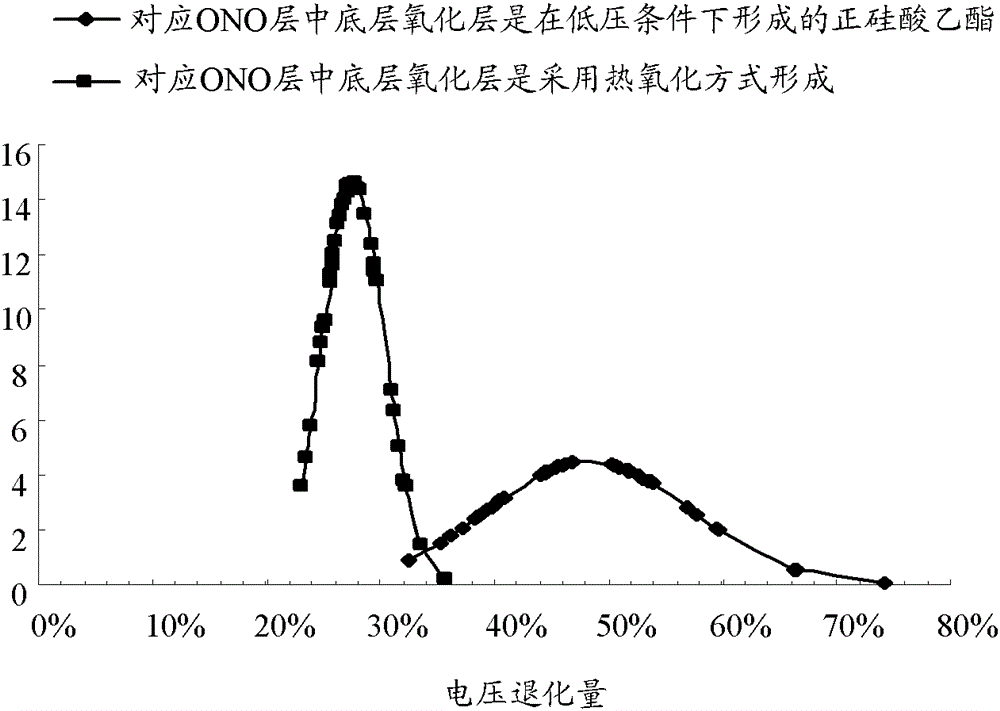

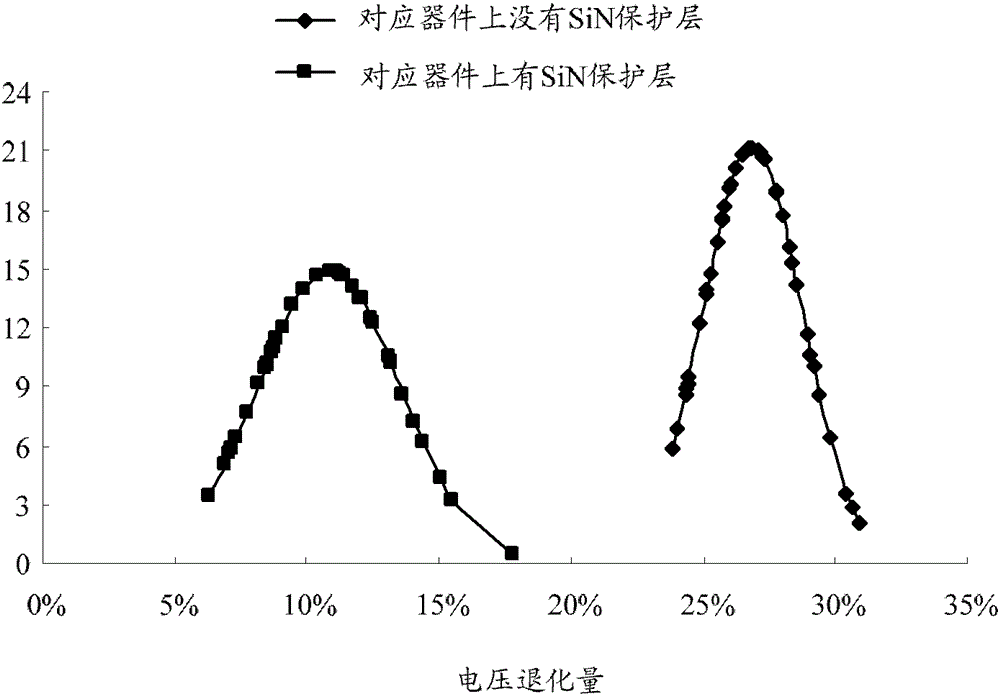

[0040] As mentioned in the background technology section, the accelerated test was used to evaluate the existing 0.5μm OTP device in the laboratory, and the results showed that the degradation of the threshold voltage of the device was far below the expected requirement, and thus the data retention of the device was poor . OTP devices have poor data retention, which means that the charge stored in them is easily lost. After the OTP device is programmed, the programmed data (that is, the charge) is stored in the storage unit of the device. Therefore, in order to make the charge in the storage unit not easy to lose, it is necessary to have a good connection between it and the surrounding components. isolation effect.

[0041] Based on this, the present invention provides a kind of OTP device, and this OTP device comprises: substrate; The storage unit that is positioned on described substrate, described storage unit comprises: gate dielectric layer, floating gate, laminated diel...

Embodiment 2

[0043] The OTP device provided by the present invention will be described in detail below with specific embodiments in conjunction with the accompanying drawings.

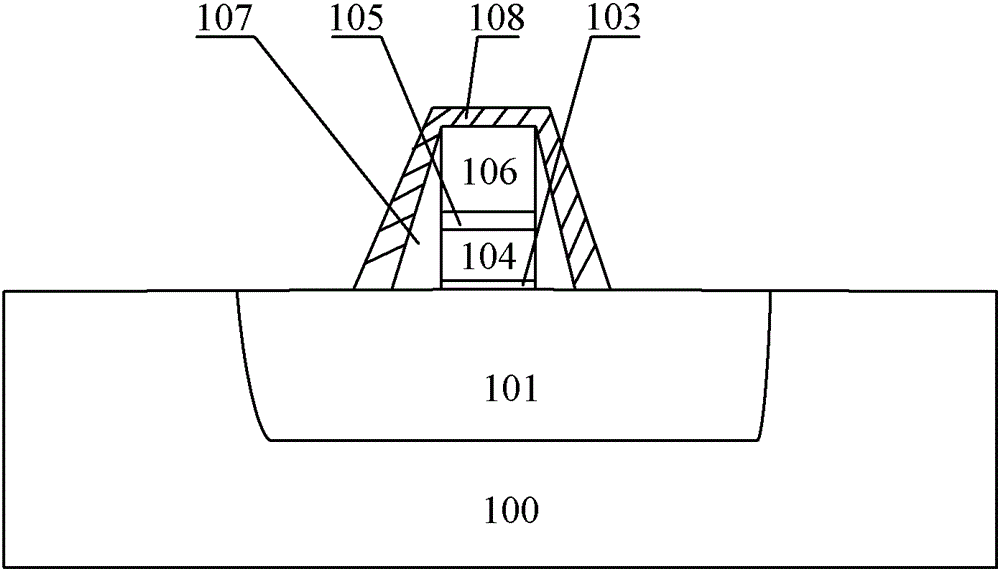

[0044] refer to figure 1 , figure 1 A schematic structural diagram of an OTP device provided by an embodiment of the present invention, the OTP device includes: a substrate 100; a well region 101 located in the substrate 100; a gate dielectric layer 103 located on the well region 101; the gate dielectric layer 103 A floating gate 104, a stacked dielectric layer 105 and a control gate 106 are sequentially arranged on the upper surface, and the well region 101, the gate dielectric layer 103, the floating gate 104, the stacked dielectric layer 105 and the control gate 106 together constitute the memory of the OTP device. unit; the two sides of the storage unit are provided with sidewalls 107, the existence of the sidewalls 107 can prevent the charge in the storage unit from leaking out on the one hand, and on the o...

Embodiment 3

[0055] refer to Figure 5 , the OTP device provided in this embodiment adds a protection gate 109 on the basis of the second embodiment, and the protection gate 109 is located above the control gate 106 and belongs to a part of the memory cell. Since the control gate 106 includes metal silicide (generally tungsten silicide) in addition to the polysilicon gate, the metal silicide is often peeled off in other processes (such as high-temperature processes such as annealing), which will cause the control gate The resistance of 106 becomes higher, the actual working voltage decreases, and affects the performance of the device. Therefore, by forming a protective gate 109 on the control gate 106, the peeling of the metal silicide on the control gate 106 can be prevented, the gate control capability is improved, and the device performance is improved. Data retention of OTP devices.

[0056] The OTP device provided by the present invention has been described in detail above, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com