Patents

Literature

68results about How to "Short grinding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixed ultra-hard abrasive honing stone

InactiveCN104400614AReduce processing costsEasy to manufactureOther chemical processesAbrasion apparatusNickelHot press

The invention discloses a mixed ultra-hard abrasive honing stone. The mixed ultra-hard abrasive honing stone is characterized by comprising the following components in percentage by weight: 20-40 percent of copper, 2-6 percent of silver, 1-10 percent of aluminum, 2-6 percent of zinc, 2-20 percent of tin, 10-20 percent of iron, 5-10 percent of nickel, 5-30 percent of cobalt, 1-9 percent of lead, 5-10 percent of a bonding agent and the balance of an ultra-hard material, wherein the volume ratio is 60-100 percent; the metal purity of the copper, the silver, the aluminum, the zinc, the tin, the iron, the nickel, the cobalt and the lead is over 99 percent; the granularity of the ultra-hard material is 200-1,000 meshes; the honing stone is prepared by performing mixing, cold press molding and vacuum hot press process on the raw materials according to the mixture ratio. The mixed ultra-hard abrasive honing stone disclosed by the invention has the advantages of sharp grinding, high grinding efficiency, large grinding weight, short grinding time, long service life, superior self-sharpening property, low process cost, easiness and convenience in preparation, and the like.

Owner:YINCHUAN HENGYIDA MACHINERY

Slag-based whole tailing gravity-flow filling cementing material and filling slurry preparation method thereof

The invention relates to a slag-based whole tailing gravity-flow filling cementing material and a filling slurry preparation method thereof. Blast furnace slag is used as a main cementing material, and water glass is used as a slag exciting agent, thereby significantly improving the early-stage strength. According to the invention, hemihydrate gypsum is also added, which shortens the cementing time; quicklime is added to realize volume expansion of the slurry after cementation is started, and thus to improve the tight-filling rate of the filling material. Since the solid concentration is increased, the rheological property of the filling material is reduced; the addition of a powdery water reducer can improve the fluidity and reduce the bleeding rate with the proviso that the solid concentration of the filling slurry is maintained to be high, thus the filling slurry is more uniform and gravity-flow filling is realized. With the addition of the high-efficient water reducer and the cooperative use of citric acid and glucose retarders, the pipe blocking phenomenon caused by fluidity loss during whole tailing filling is improved.

Owner:山东黄金矿业(莱州)有限公司焦家金矿

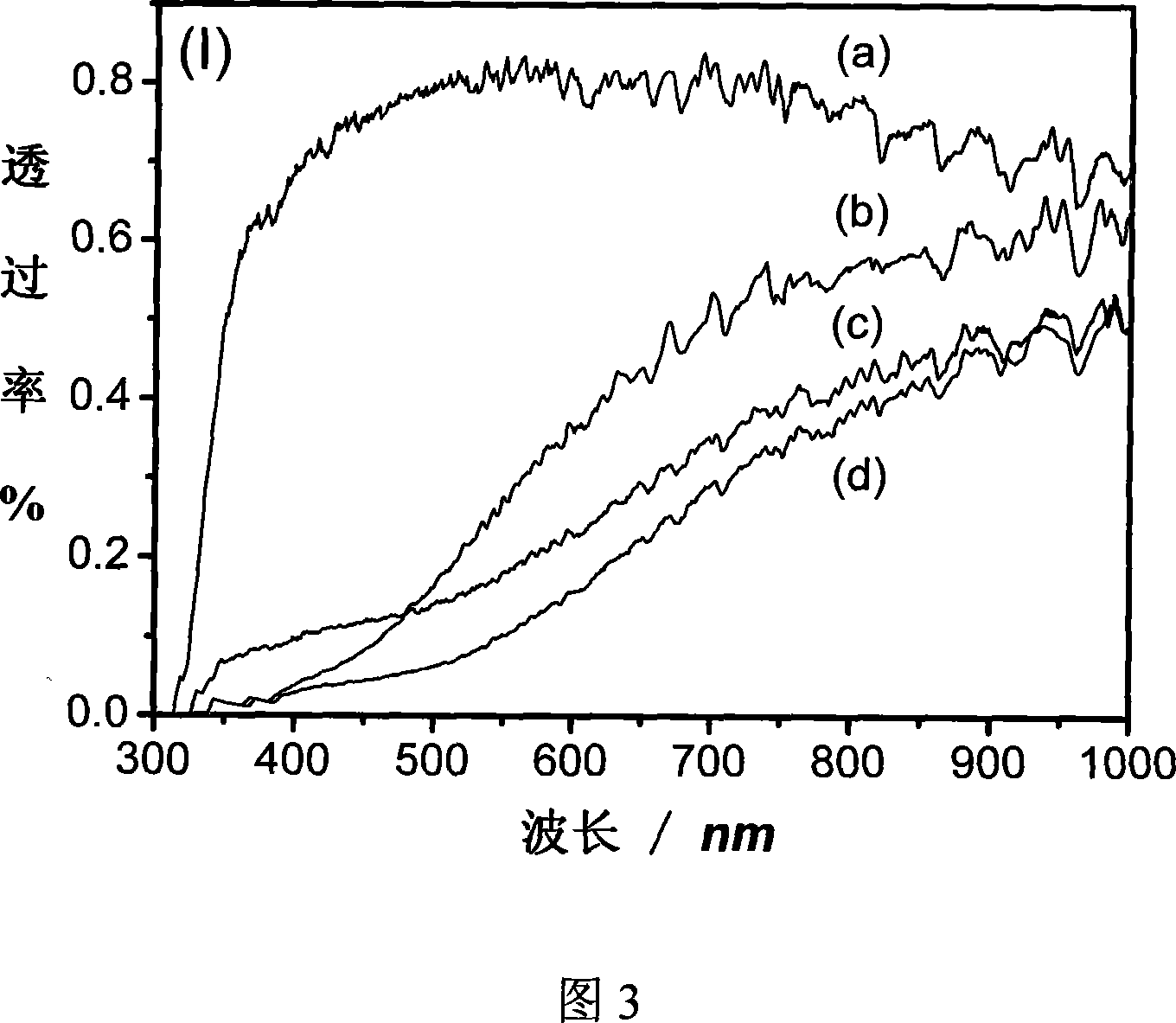

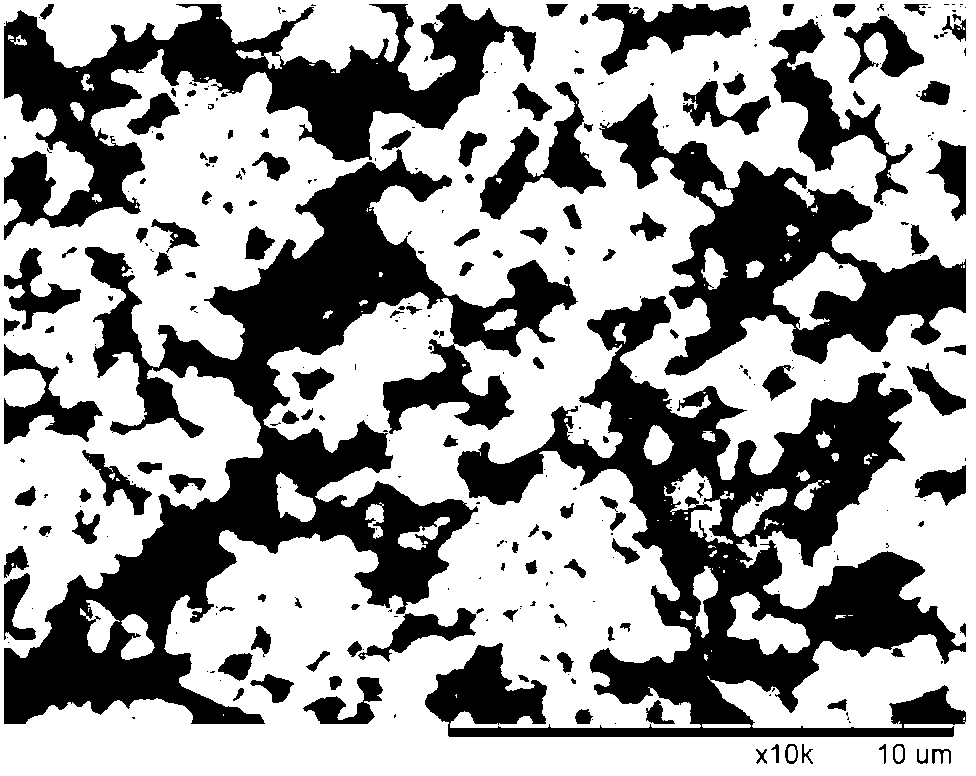

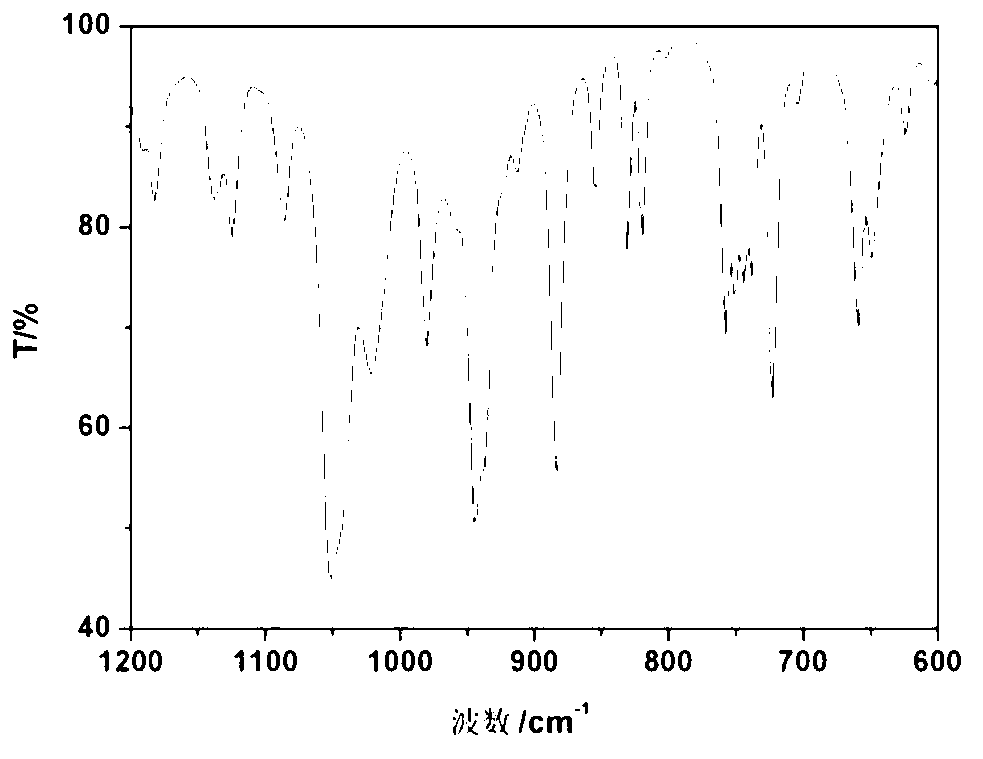

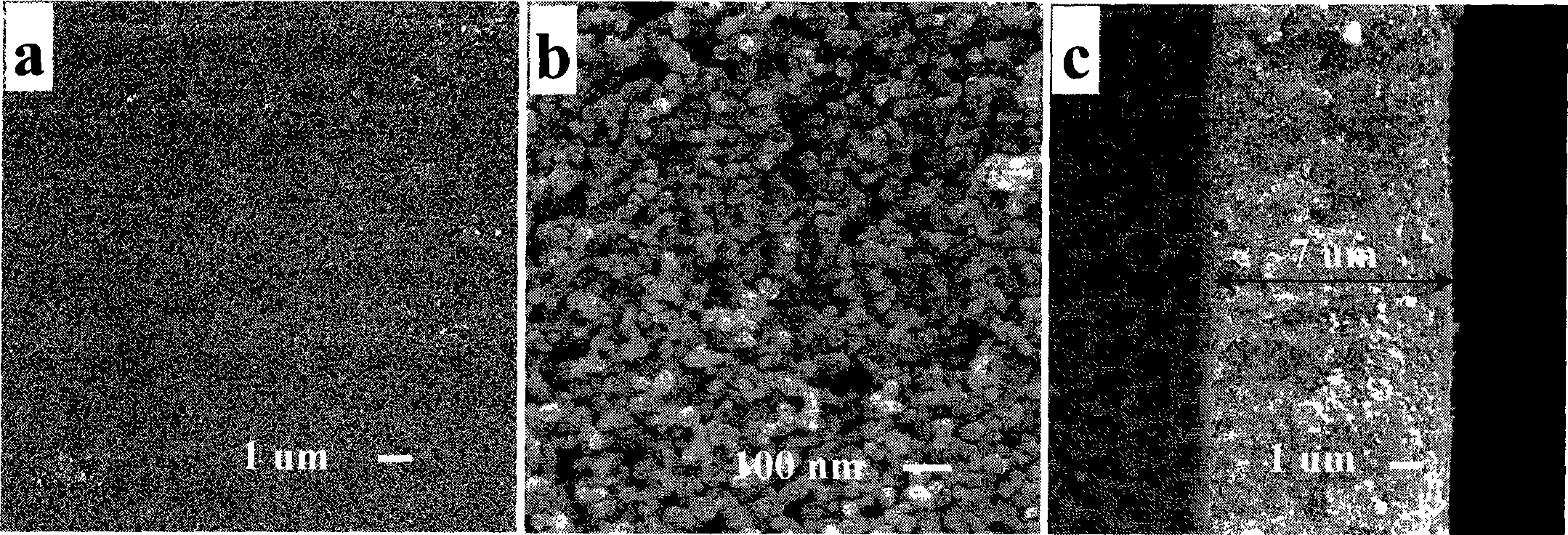

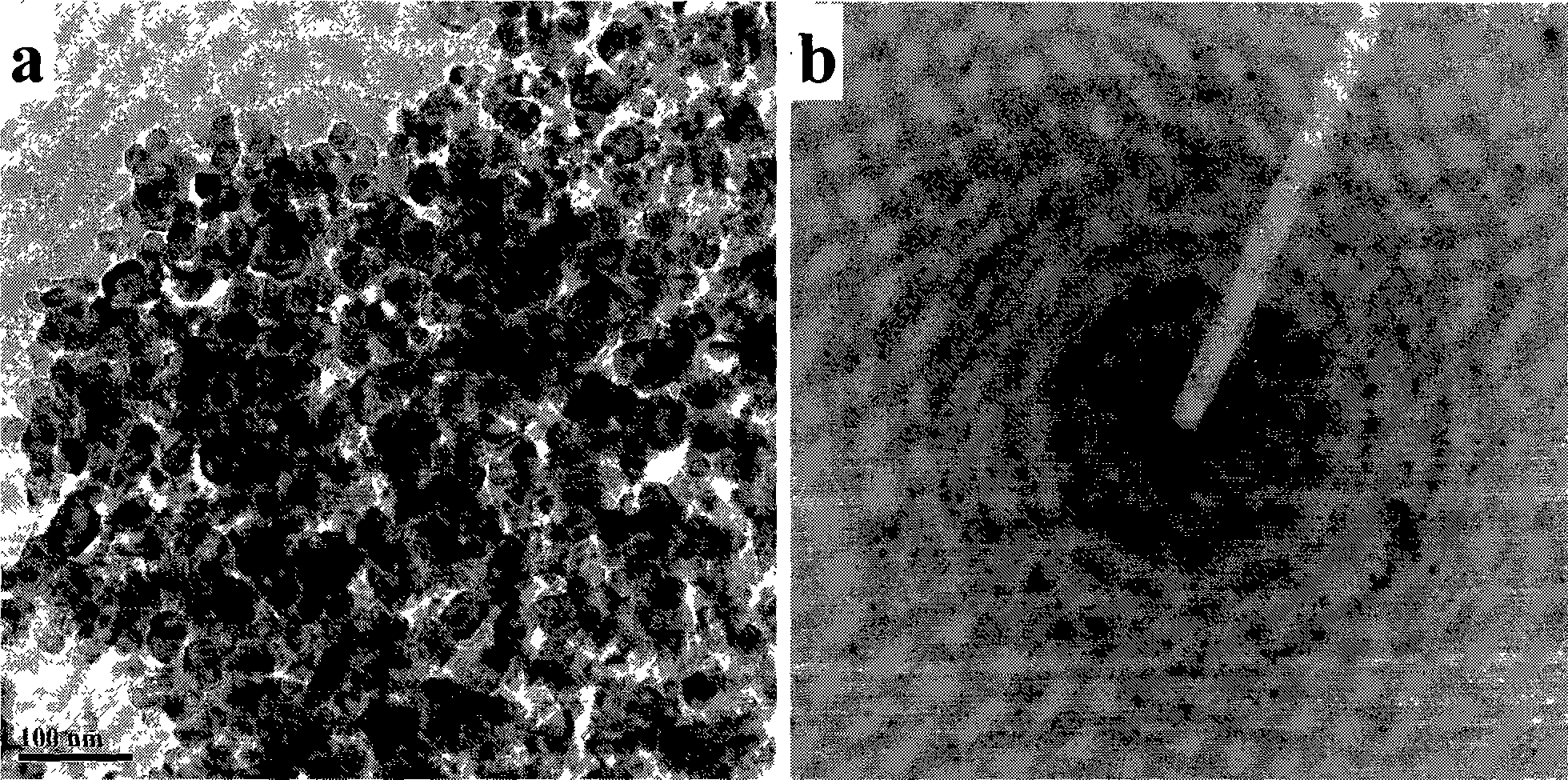

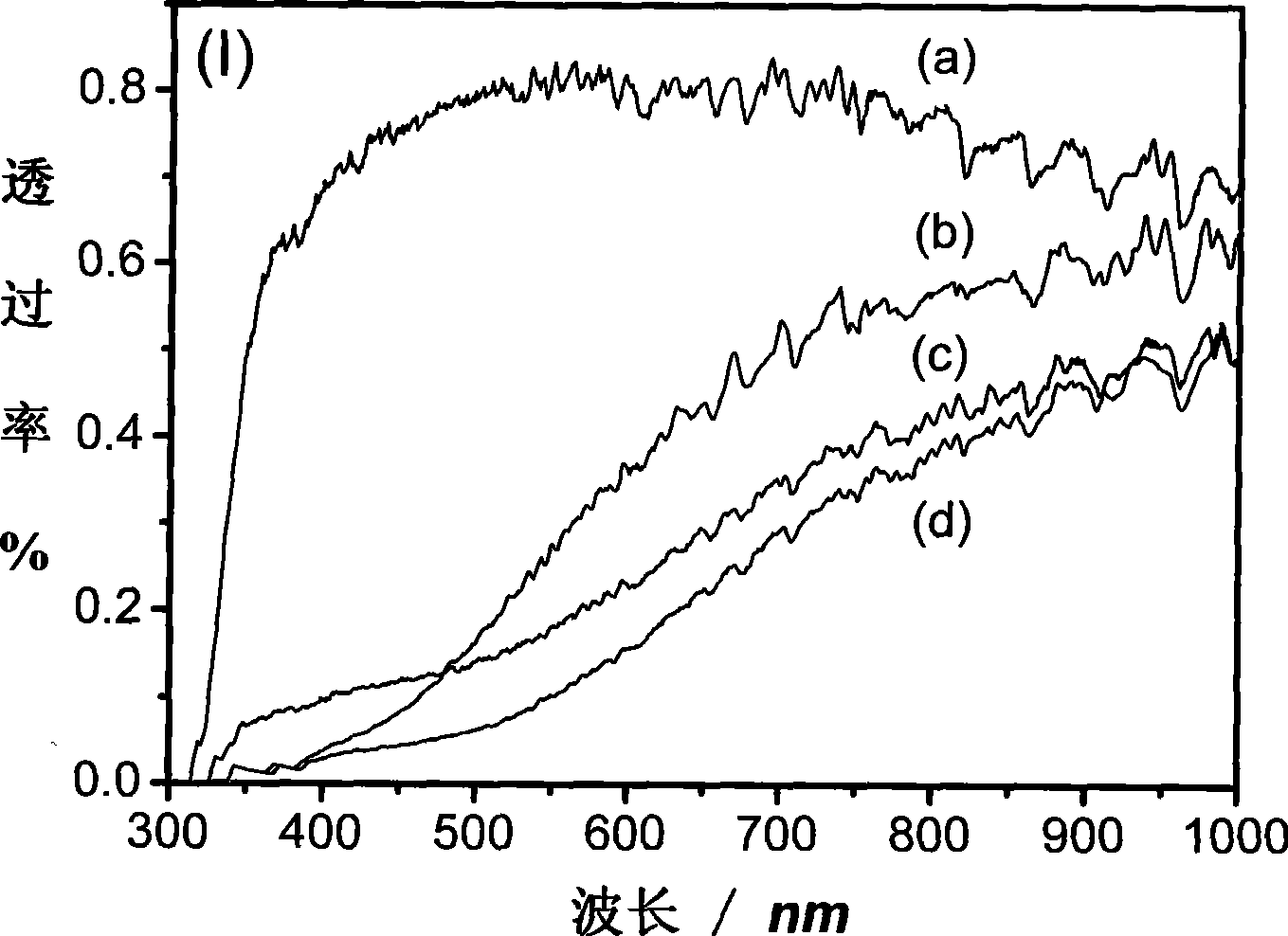

Method for preparing nanometer porous titanium oxide thick film

The invention discloses a making method of nanometer porous thick film of titanium oxide, which comprises the following steps: (1) adopting dilute nitric acid to disperse TiO2 nanometer particle; (2) blending the powder, water and pore former into spread coating slurry; (3) coating the TiO2 slurry on the substrate through glass rod; blowing; (4) repeating the coating for several times until the needed thickness; (5) proceeding high-temperature heat disposal; adopting P-25 nanometer powder of Degussa company as the TiO2 powder, the carbowax as pore former, the glass (quartz glass, ITO or FTO conductive glass), monocrystalline silicon, sapphire and other materials as substrate. The thickness of the TiO2 film is controllable between 1 and 30um with grain size about 20-30nm, which simplifies the making method with cheap cost for large-scale manufacturing.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

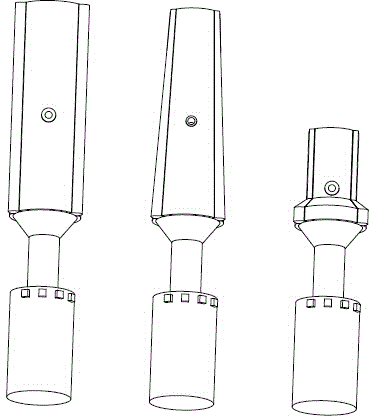

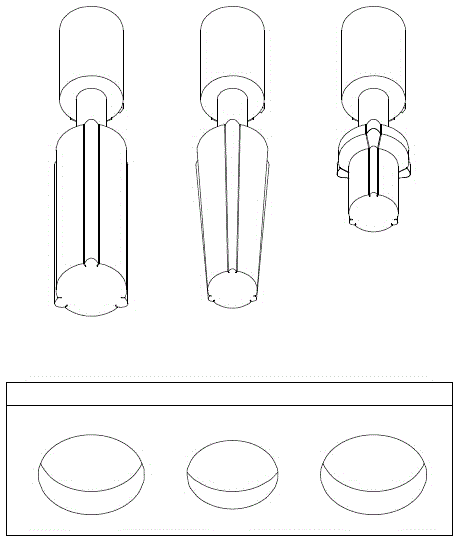

Novel grinding tool for inner bore

ActiveCN105081906AConcentricity unchangedImprove the finishRevolution surface grinding machinesGrinding headsEngineeringRadial surface

The invention discloses a novel grinding tool for an inner bore. The tool comprises a fixed handle and a grinding rod, wherein the fixed handle is provided with a cavity, an outer cover is arranged outside the cavity, and the cavity is provided with an air inlet pipe; the grinding rod is hollow, the radial surface of the grinding rod is uniformly provided with three or more expandable grinding rod capsules. The novel grinding tool for the inner bore provided by the invention has the advantages that the inner core can be enlarged to one thousandth of a millimeter by a grinding way; furthermore, multiple times of grinding can be performed by adopting a grinding piece of same roughness to find out a rule of grinding time in such ways of presetting grinding pressure, adjusting force applied to the inner wall of the bore and performing grinding measurement once according to given revolving speed during grinding, expanding frequencies and grinding time; in addition, by adopting grinding pieces of different roughness to perform process arrangement grinding, the degree of finish of an inner bore surface is higher, and the operating time is shorter.

Owner:余康军

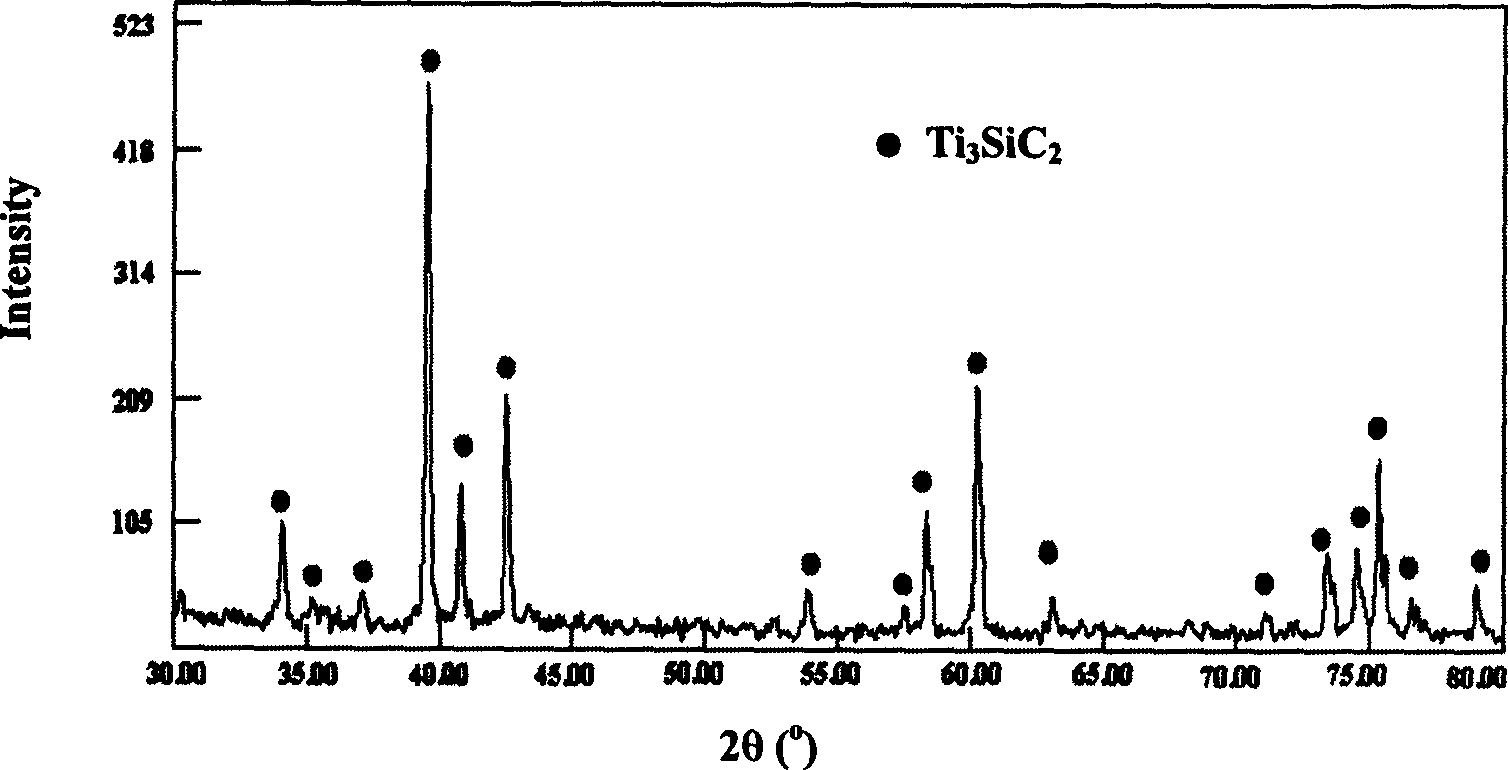

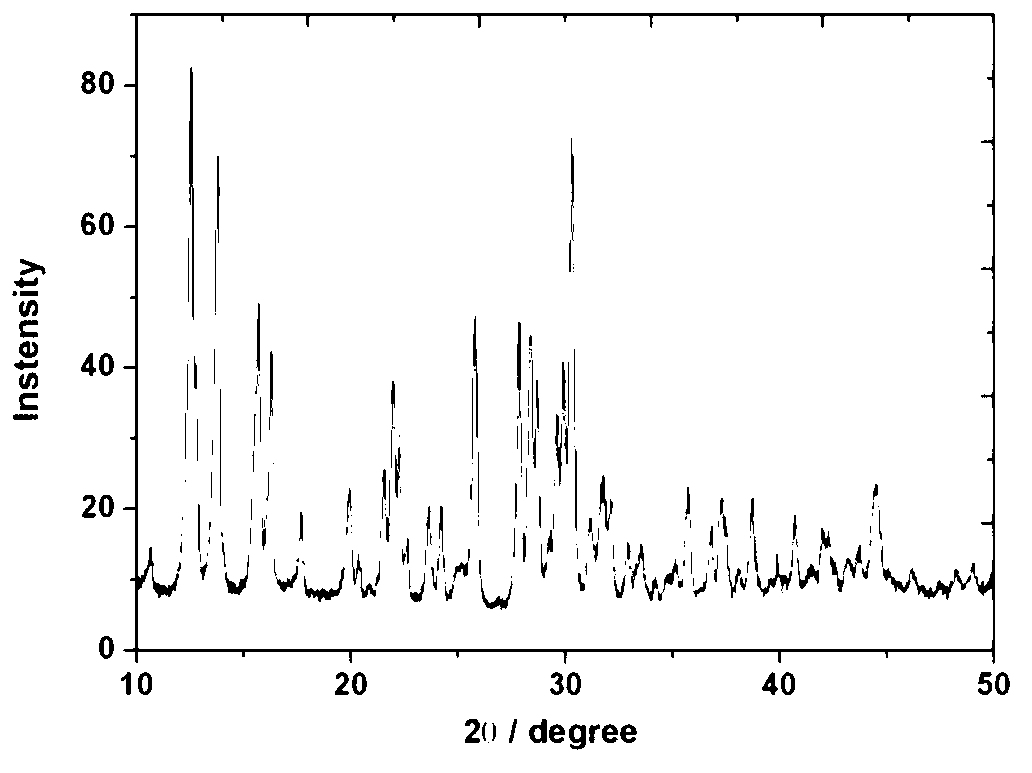

Process for preparing titanium silicon carbon ceramic powder

The invention provides a process for preparing titanium silicon carbon ceramic powder which comprises the steps of, (1) mixing titanium (Ti), silicon (Si), graphite powder (C) by the mol ratio of 3 : (1-2) : (1.5-2), ball grinding to synthesize ceramic powder with Ti, Si and C as the principal phase, (2) acid-washing the synthesized fines 0.5-2 hours through hydrofluoric acid solution to remove the silicides, (3) subjecting the powder to distilled water rinsing and drying, oxidation treating 1-4 hours at 400-500 deg. C to remove titanium carbide, removing the oxides by using the mixed solution of ammonia sulfate and sulfuric acid, water scrubbing and drying to obtain the Ti-Si-C ceramic powder.

Owner:BEIJING JIAOTONG UNIV

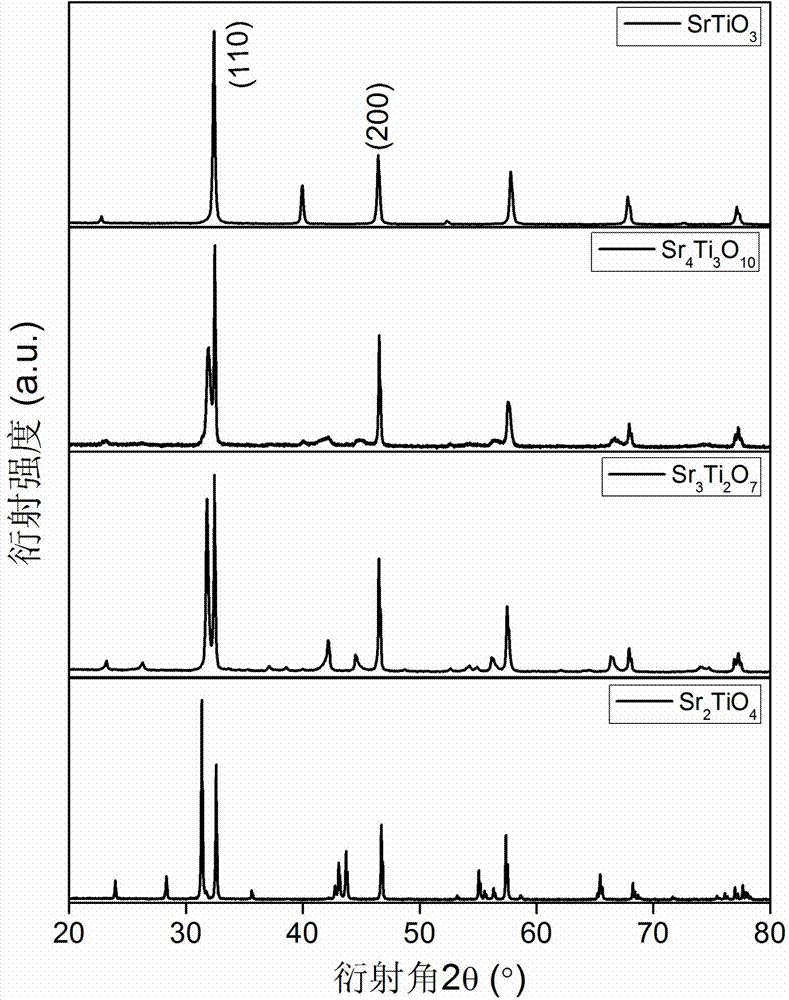

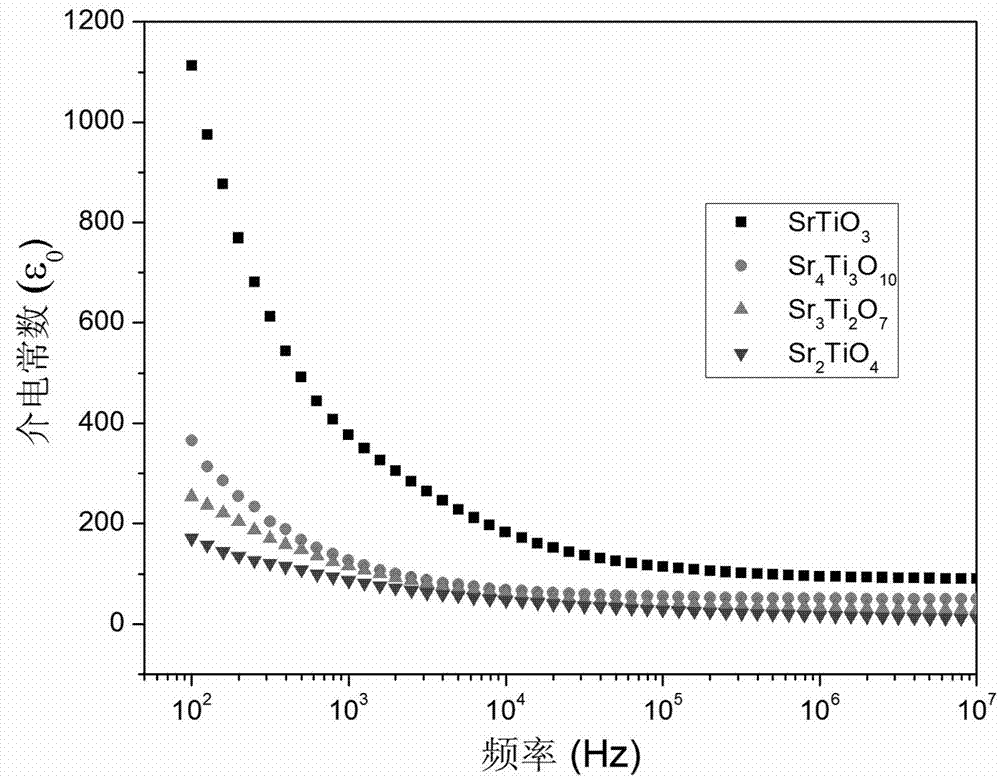

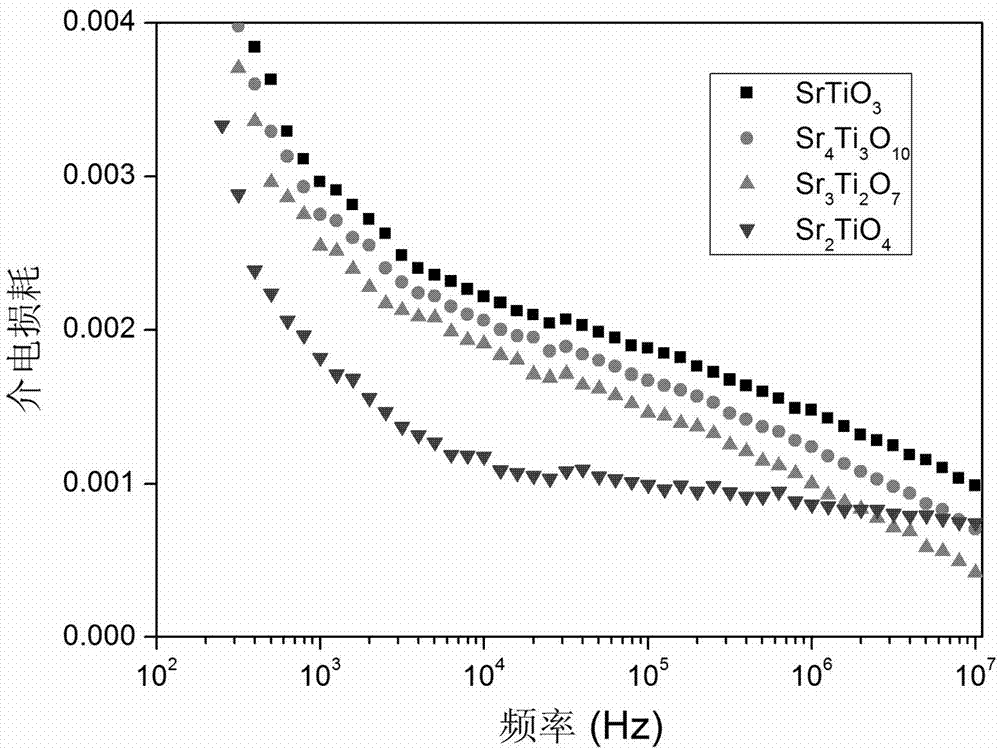

Ruddlesden-popper homologous perovskite structure ceramic powder and preparation method thereof

The present invention discloses a ruddlesden-popper (R-P) homologous perovskite structure ceramic powder. The chemical formula of the powder is: Sr[n+1]Ti[n]O[3n+1], wherein n=1,2,3 to infinite. The preparation method thereof uses a sol-gel method, and has the advantages that the products have high purity and uniformity, sintering temperature is low, the reaction is easy to control, the material composition can be adjusted, the formability is good, and Sr[n+1]Ti[n]O[3n+1] series powder of uniform particles can be prepared. The ceramic powder is a functional material with a wide application range, and shows the advantages of high dielectric constant and low dielectric loss in a dielectric constant test. In particular, the dielectric loss is very small in the high frequency region, so the powder is expected to be applied in the high-frequency field.

Owner:HEBEI NORMAL UNIV

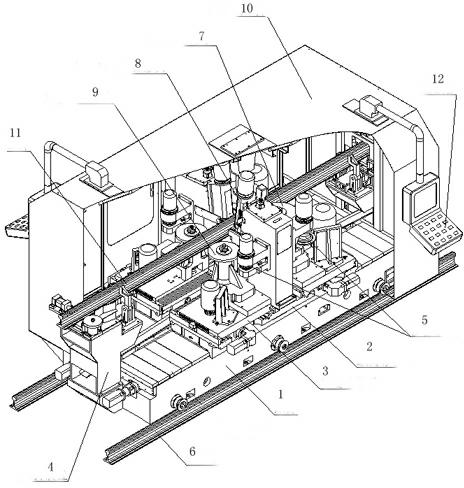

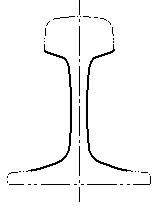

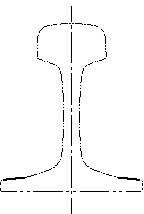

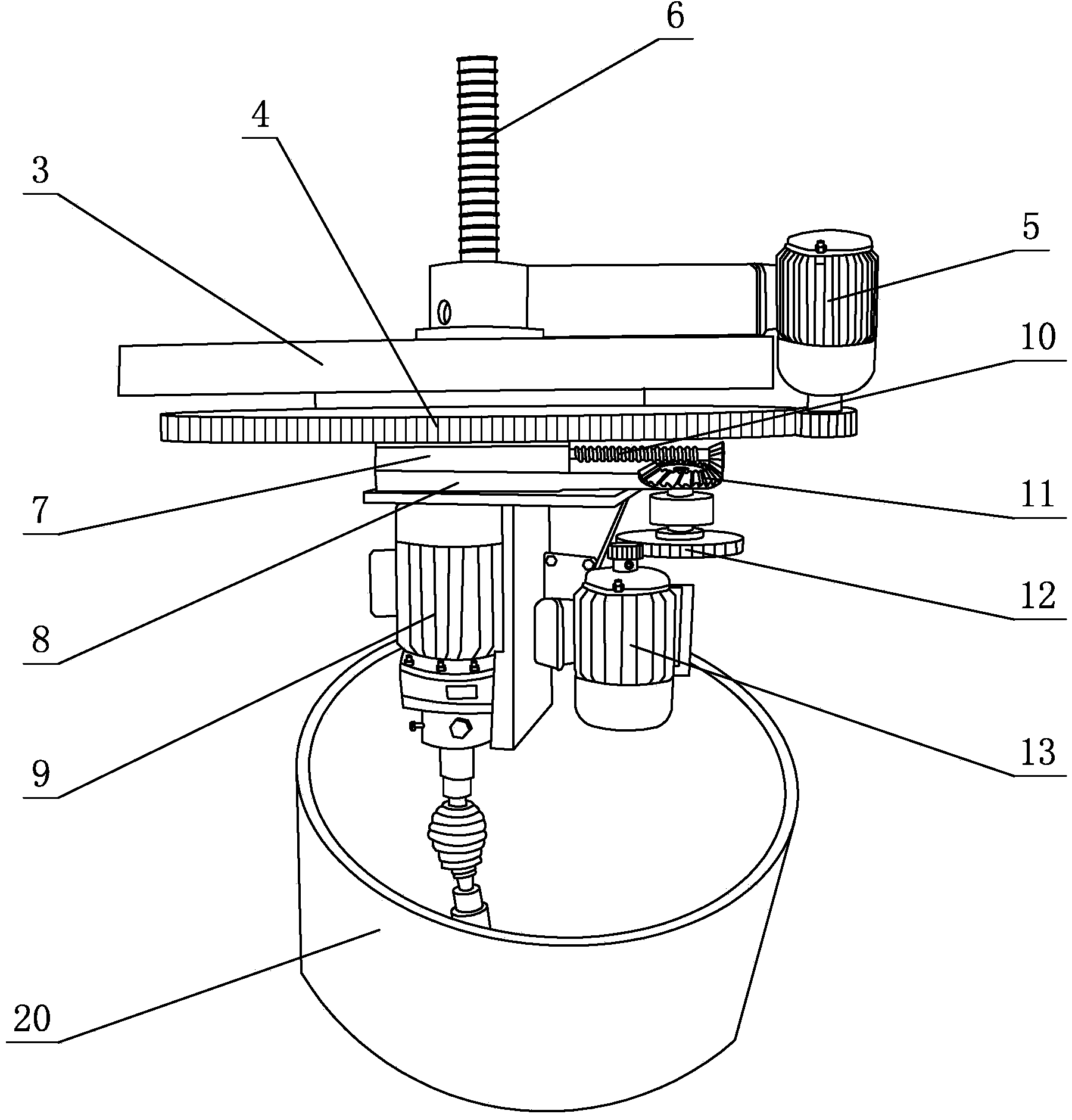

Grinding machine for steel rail welding seam of high-speed railway

InactiveCN102528591AImprove grinding efficiencyShort grinding timePlane surface grinding machinesWeld seamEngineering

The invention discloses a grinding machine for a steel rail welding seam of a high-speed railway, which comprises a machine body (1), a longitudinal moving carriage (2), a transverse feeding carriage (3), a clamping device (4), trimming devices (5) and grinding heads, wherein the machine body (1) is arranged on the foundation of a travelling rail (6); the longitudinal moving carriage (2) is arranged on a V-flat guide rail of the machine body (1); the longitudinal moving carriage (2) is provided with the transverse feeding carriage (3) and the three groups of grinding heads; the three groups of grinding heads are respectively rail waist curve grinding heads (7) arranged at the two sides of a steel rail, rail foot 1: 9 inclined plane grinding heads (8) and rail foot side grinding heads (9); and the trimming devices (5) are respectively arranged on stand columns of the 1: 9 inclined plane grinding heads (8). After being ground by the grinding machine, the steel rail welding seam of the high-speed railway is flat and smooth in surface and has a shape being coincided with that of a base body; and the corresponding grinding heads which are arranged at the two sides of the steel rail are used for grinding at the same time, so that the grinding efficiency is improved.

Owner:GUIYANG XIANFENG MACHINE TOOL WORKS

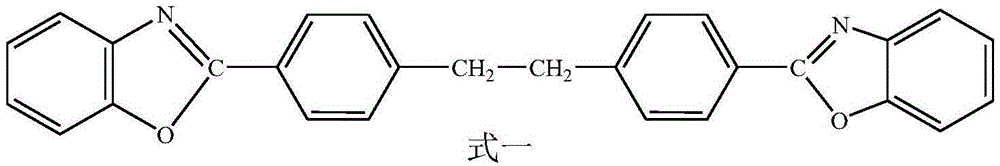

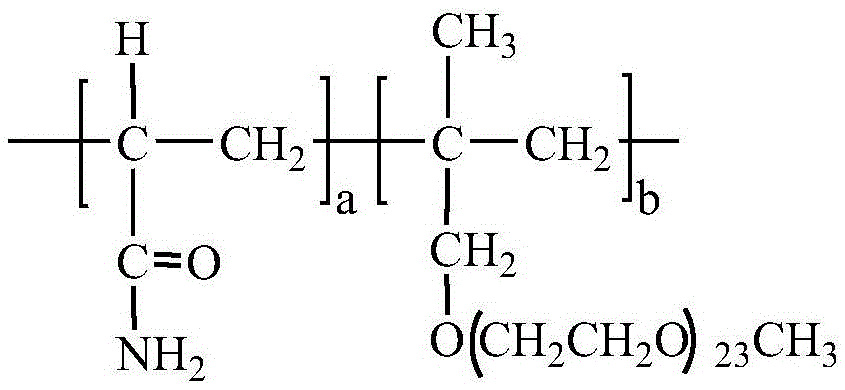

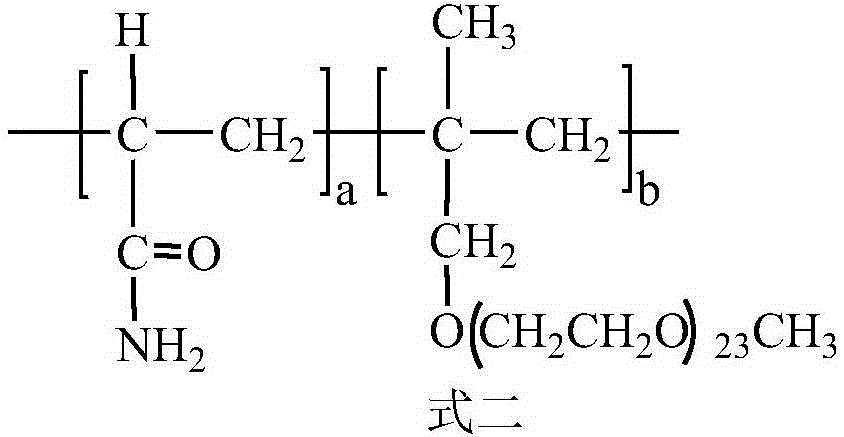

Dispersing agent for fluorescent brightener, fluorescent brightener aqueous dispersion, preparation method of dispersing agent, as well as preparation method and application of fluorescent brightener aqueous dispersion

The invention relates to a dispersing agent for a fluorescent brightener, a fluorescent brightener aqueous dispersion, a preparation method of the dispersing agent, as well as a preparation method and application of the fluorescent brightener aqueous dispersion. The preparation method of the dispersing agent comprises the following steps: firstly, separately dissolving acrylamide and an allyl polyoxyethylene ether monomer of which the polymerization degree is 23 in a proper amount of deionized water; then, controlling the temperature to be 79-81 DEG C under the stirring condition, separately adding the allyl polyoxyethylene ether monomer aqueous solution and an ammonium persulfate initiating agent into a four-mouth flask filled with a certain amount of deionized water drop by drop within 2-3 hours, and carrying out 3-4 hours' heat preservation after the drop-by-drop adding is finished; finally, carrying out cooling to prepare the dispersing agent of which the weight-average molecular weight is 10000-20000. The invention further provides the fluorescent brightener aqueous dispersion which contains the fluorescent brightener OB-1, the prepared dispersing agent and deionized water. When the fluorescent brightener aqueous dispersion is applied to whitening of a fabric, the fabric can be whitened and brightened very uniformly, and the whitening effect is obvious.

Owner:临清三和纺织集团有限公司

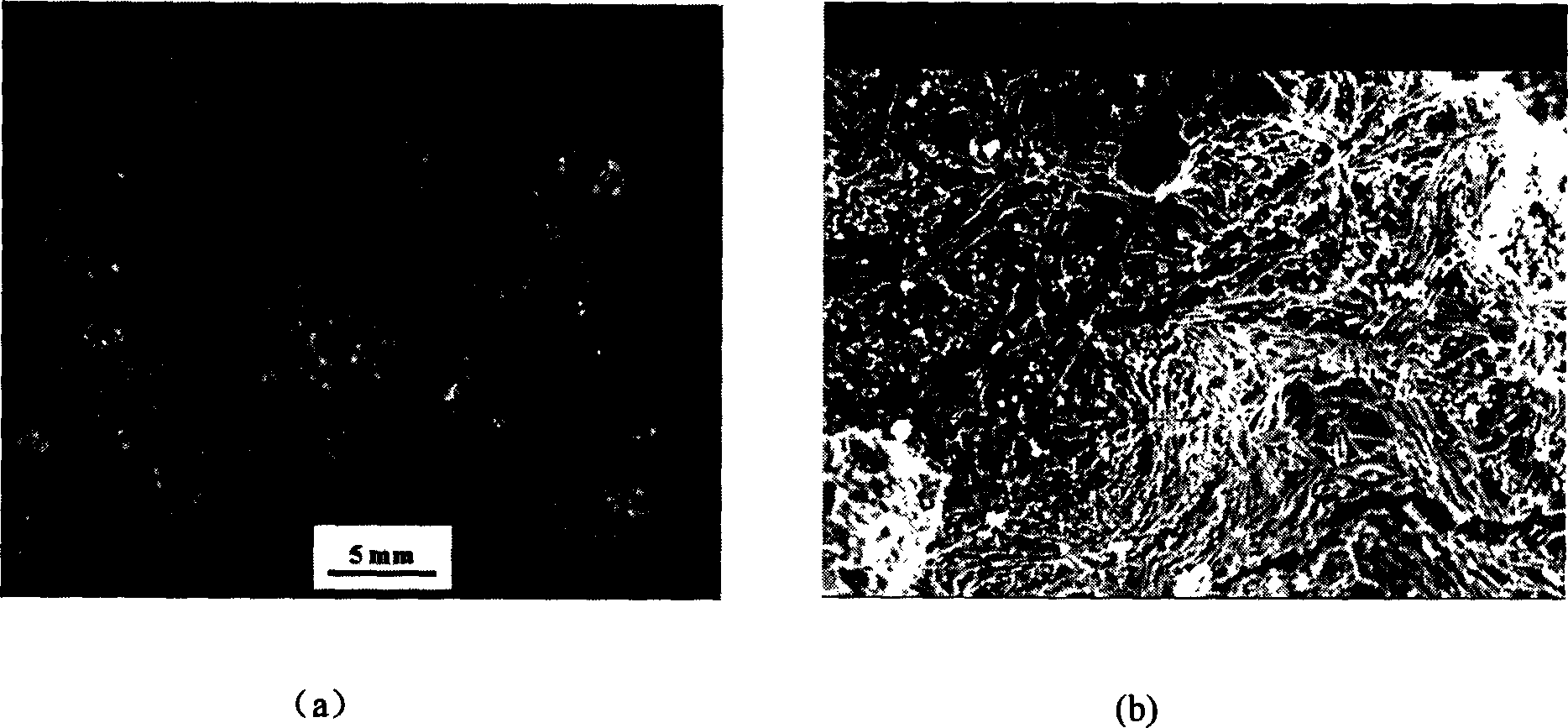

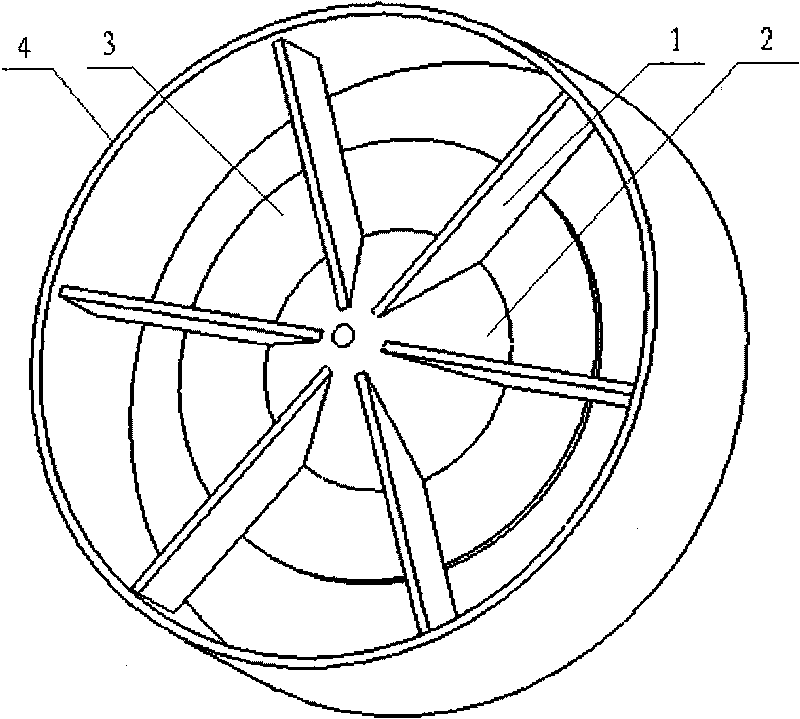

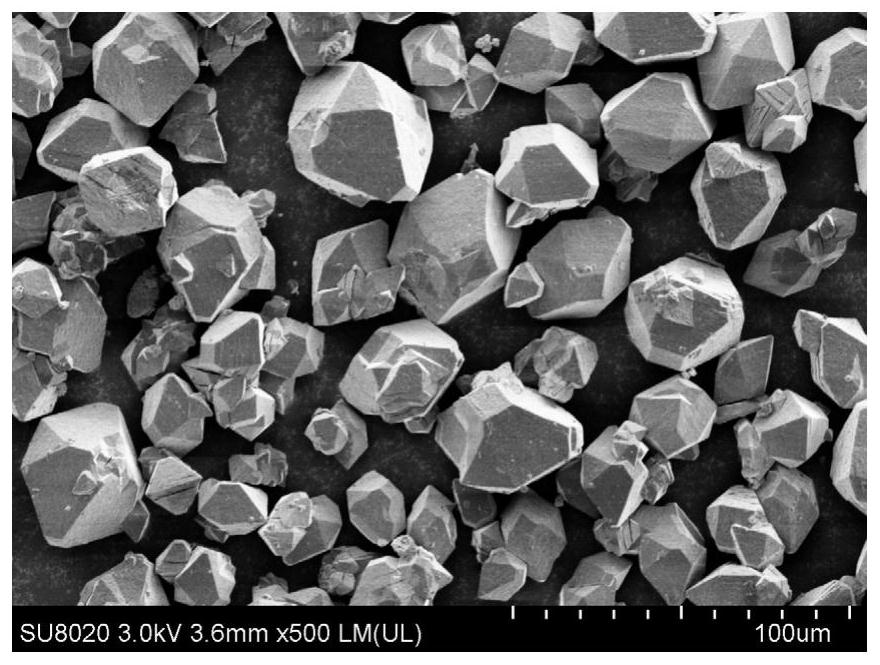

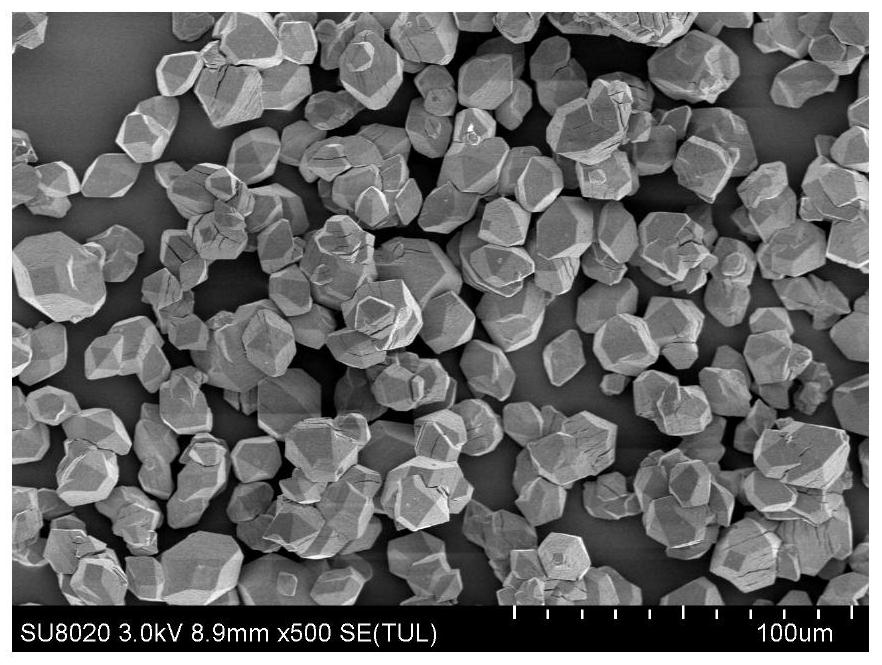

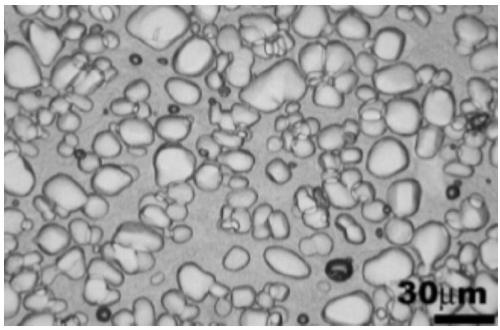

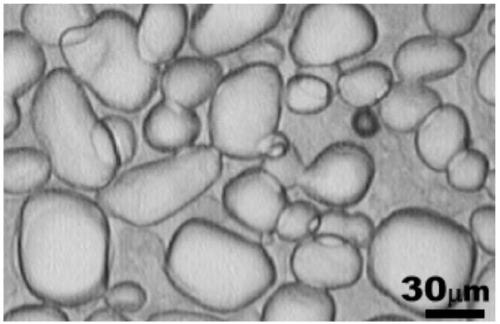

Preparation method of submicron hexanitrohexaazaisowurtzitane in batch

InactiveCN103342618AUniform particle sizeSmooth particle surfaceExplosive working-up apparatusOrganic solventEngineering

The invention discloses a preparation method of submicron hexanitrohexaazaisowurtzitane in batch. The method comprises: adding a surfactant into water to prepare a surfactant solution, grading by using grinding ball mediums with different diameters, adding CL-20, the surfactant solution and the grinding ball mediums into grinding tanks, cooling, symmetrically putting the grinding tanks, fixing the grinding tanks onto a planet grinder for planet grinding, separating a grinded explosive suspension and the grinding ball mediums, performing solid-liquid separation for the explosive suspension, and drying to obtain the submicron CL-20. According to the preparation method provided by the invention, the CL-20 explosive, the surfactant solvent and the grinding ball mediums with different diameters are graded, and the planet grinder is used for repeated grinding. The prepared epsilon-CL-20 is uniform in powder particle size, smooth in particle surface, and regulatable in average particle size; during a preparation process, no organic solvent impurities are introduced, a post treatment is reduced , a total grinding time is 1-10 hours, and a grinding time is short. The method is suitable for production in batch.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

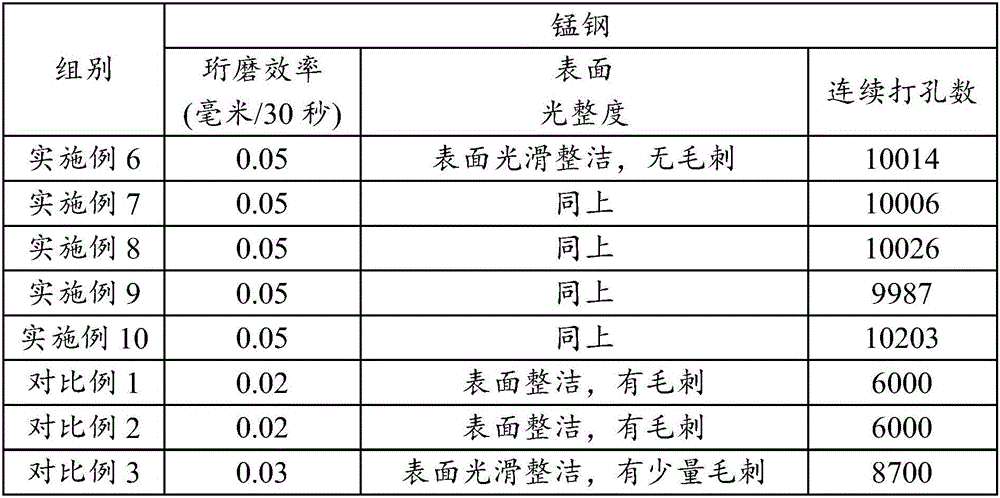

Compound superhard honing oilstone containing zirconium oxide and preparation method of compound superhard honing oilstone

ActiveCN106625198AImprove grinding efficiencyImprove grinding qualityAbrasion apparatusGrinding devicesSuperhard materialAdhesive

The invention provides compound superhard honing oilstone containing zirconium oxide and a preparation method of the compound superhard honing oilstone, and relates to the technical field of precision machining. The honing oilstone is mainly composed of zirconium oxide, copper, silver, aluminum, zinc, tin, iron, nickel, cobalt, lead, an adhesive, a superhard material and the like. According to the honing oilstone, the problems that in the prior art, due to the single grinding property of honing oilstone composed of a single grinding material, the grinding effect on materials hard to machine is not ideal, certain use limitations exist, and even though multi-element mixed type honing oilstone imported from abroad can achieve a very good grinding machining effect, the multi-element mixed type honing oilstone is short in service lie and high in price are solved. The prepared honing oilstone achieves the technical effects of being excellent in self-sharpening performance, sharp in grinding, high in grinding quality, high in grinding speed, resistant to high temperature and long in service life.

Owner:YINCHUAN HENGYIDA MACHINERY

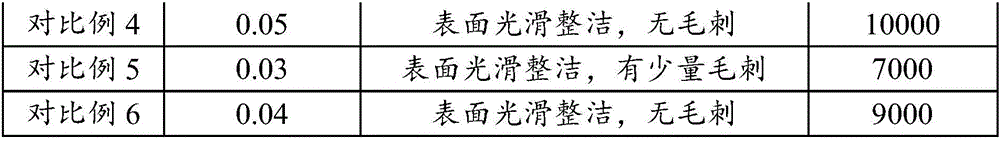

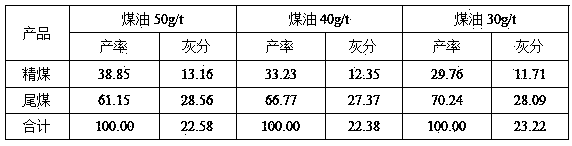

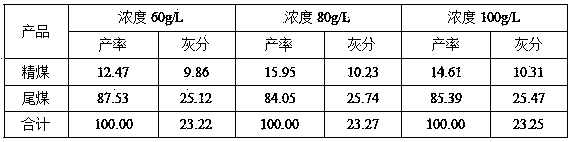

Coking middling coal coarse grinding and flotation method in coking

ActiveCN103816977AImprove utilization efficiencyShort grinding timeFlotationGrain treatmentsBall millEngineering

The invention discloses a coking middling coal coarse grinding and floatation method and belongs to the field of a coal washing and dressing technology. Firstly, granularity of heavy medium middling coal in a coal preparation plant is reduced below 3mm through crushing; then, wet ore grinding is carried out by a ball mill, and granularity of the material is less than 0.5mm after ore grinding; and finally, recovery is conducted by a floatation method. The method provided by the invention is mainly characterized by coarse ore grinding and drug-free floatation. The method has advantages of low energy consumption, simple operation and low investment and operation costs.

Owner:TAIYUAN UNIV OF TECH

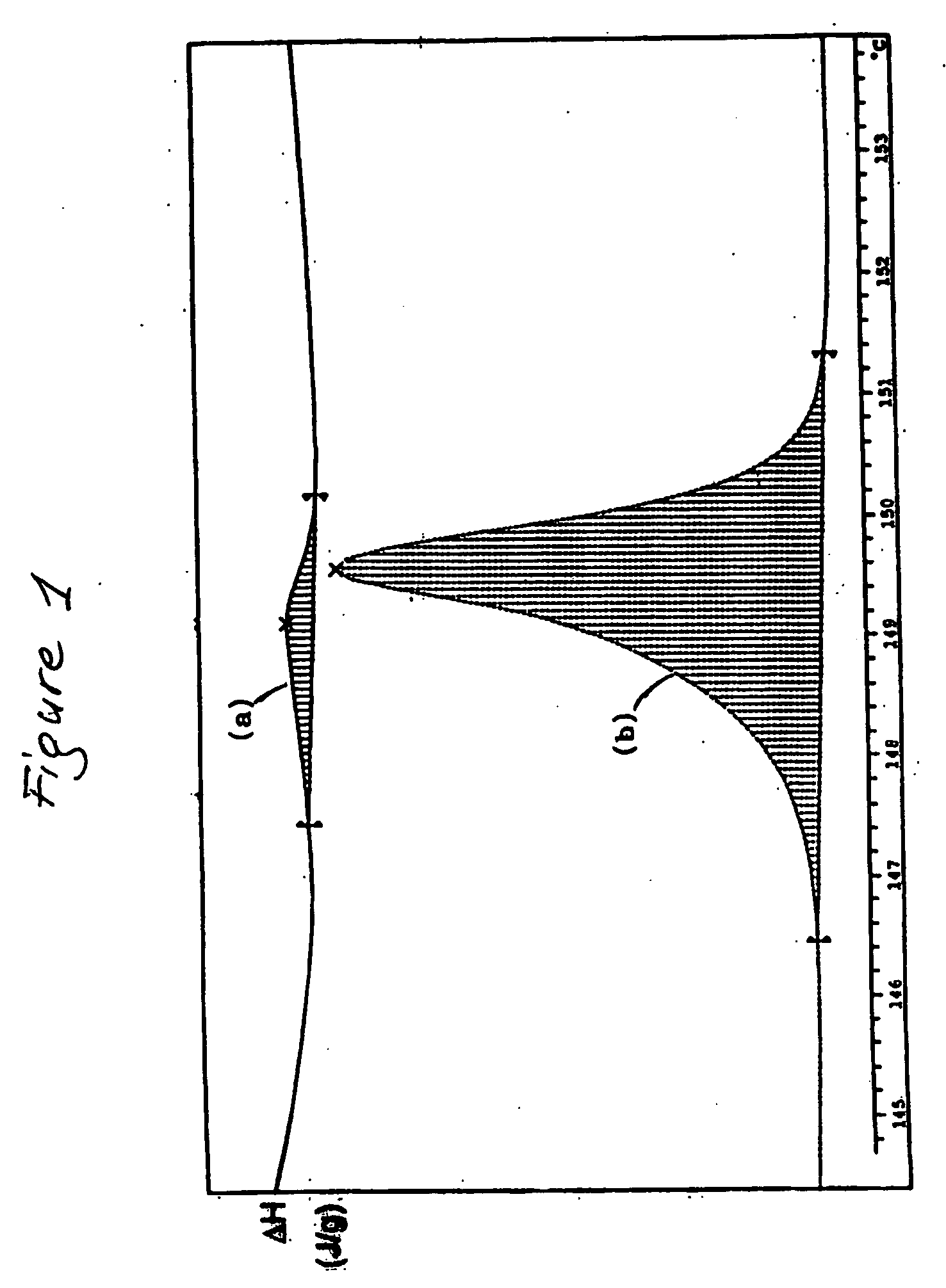

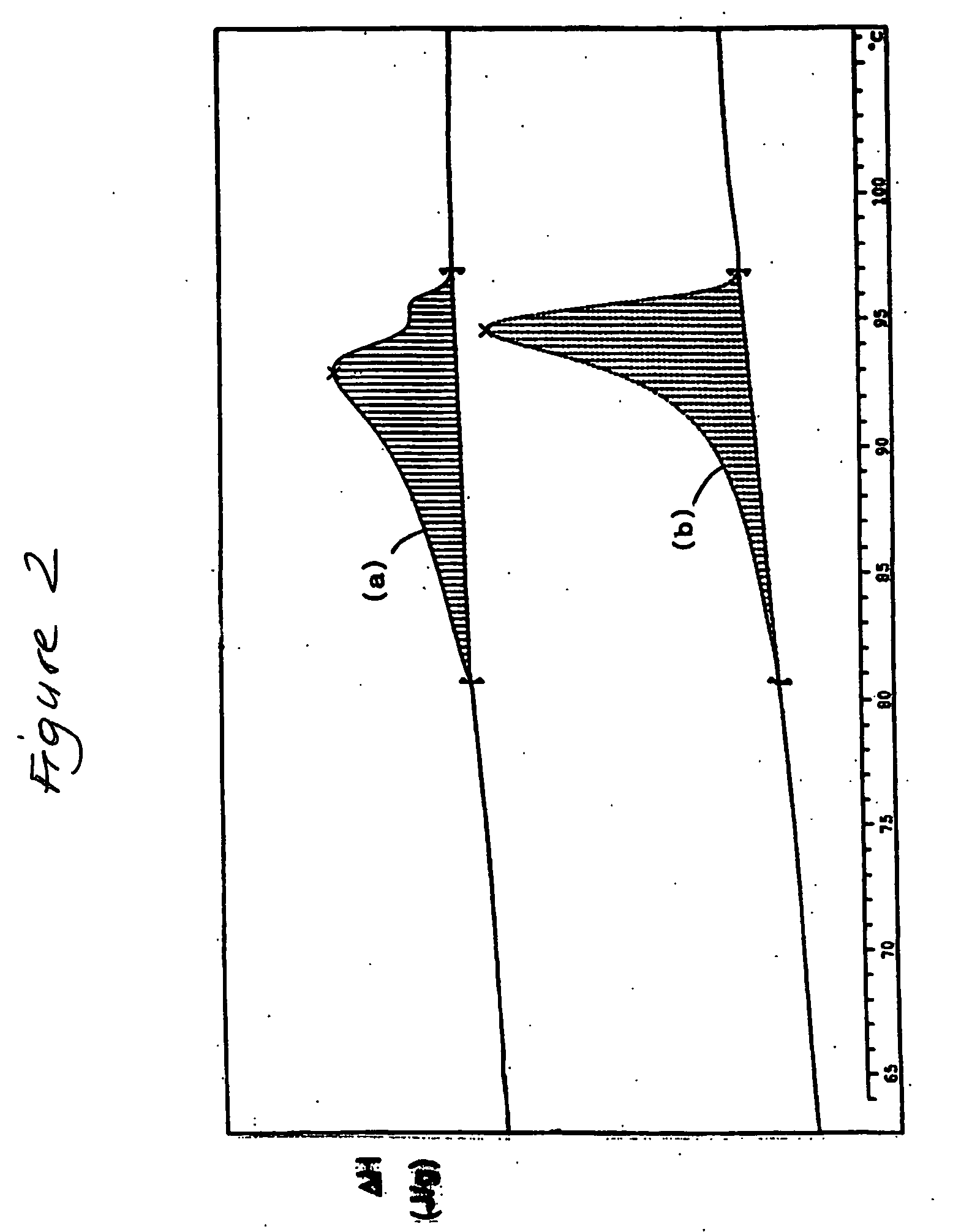

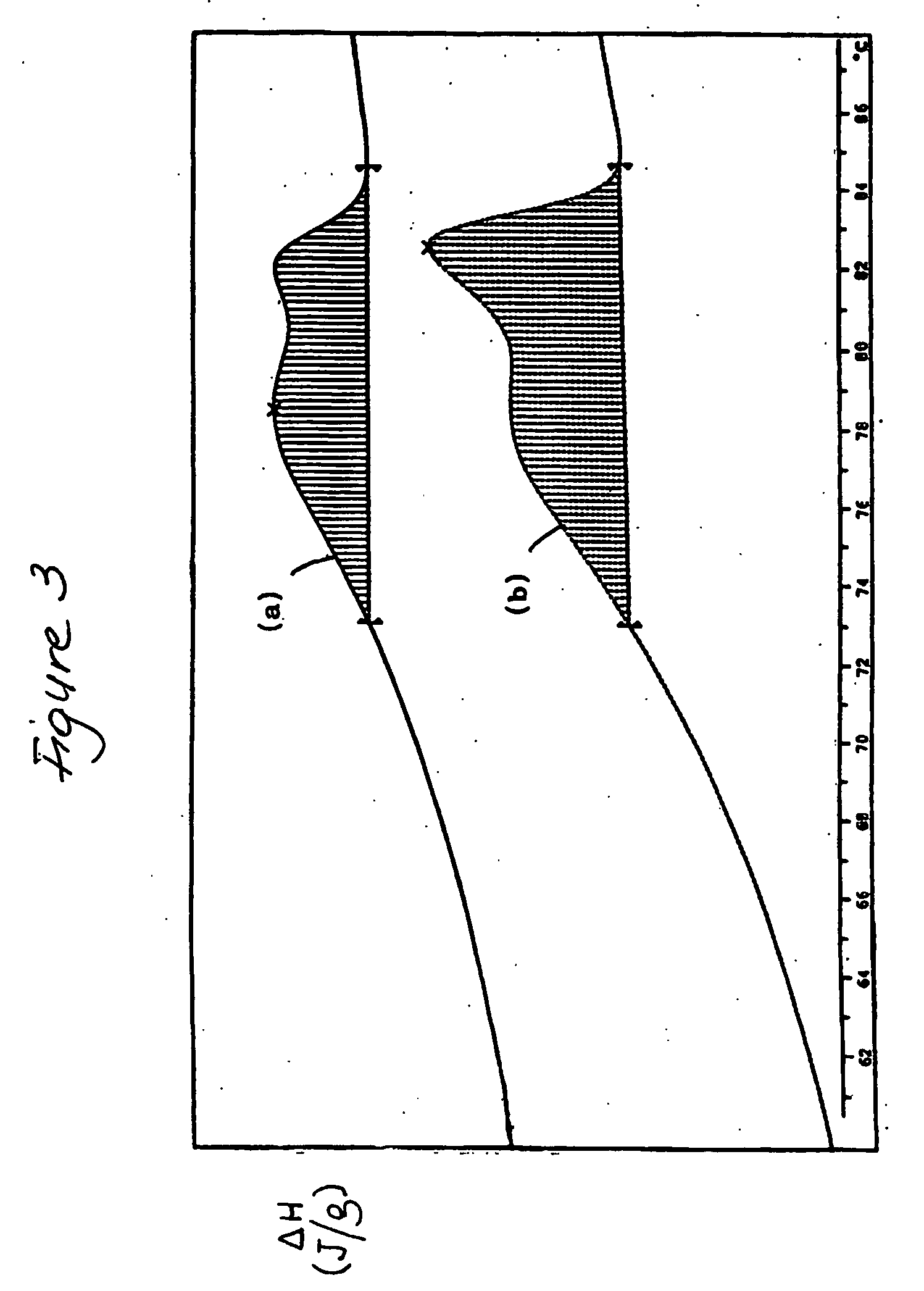

Co-grinding process for the preparation of a ternary composition

InactiveUS20050255163A1Improve efficiencyLower energy levelAntibacterial agentsCosmetic preparationsSolubilityDissolution

A ternary composition comprising an active substance, a hydrophilic or hydrophobic carrier and a co-grinding auxiliary substance and a process for the preparation thereof by the co-grinding of the thee components, in which said process allows operating with drastically reduced co-grinding times with respect to the known art and to obtain ternary compositions in which the active substance shows characteristics of amorphisation, solubility and dissolution speed as requested for the various uses.

Owner:ACTIMEX

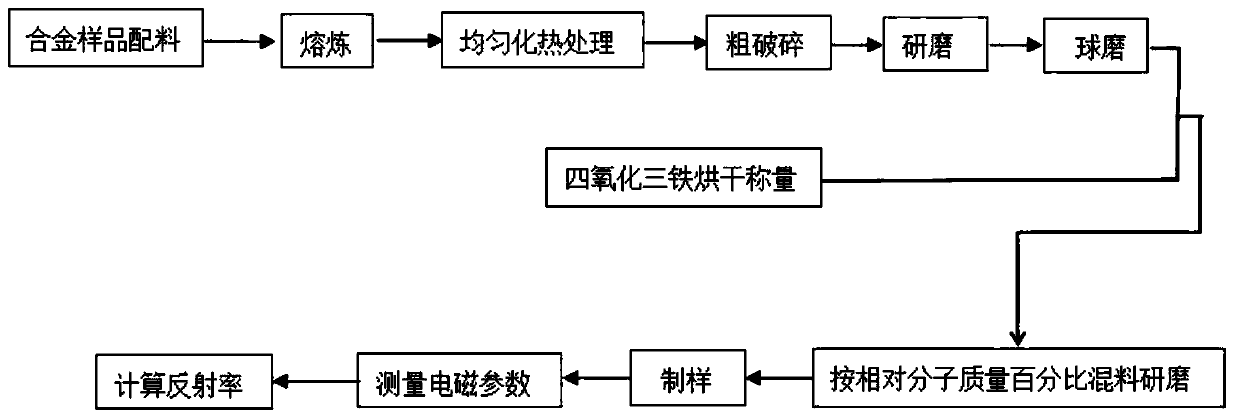

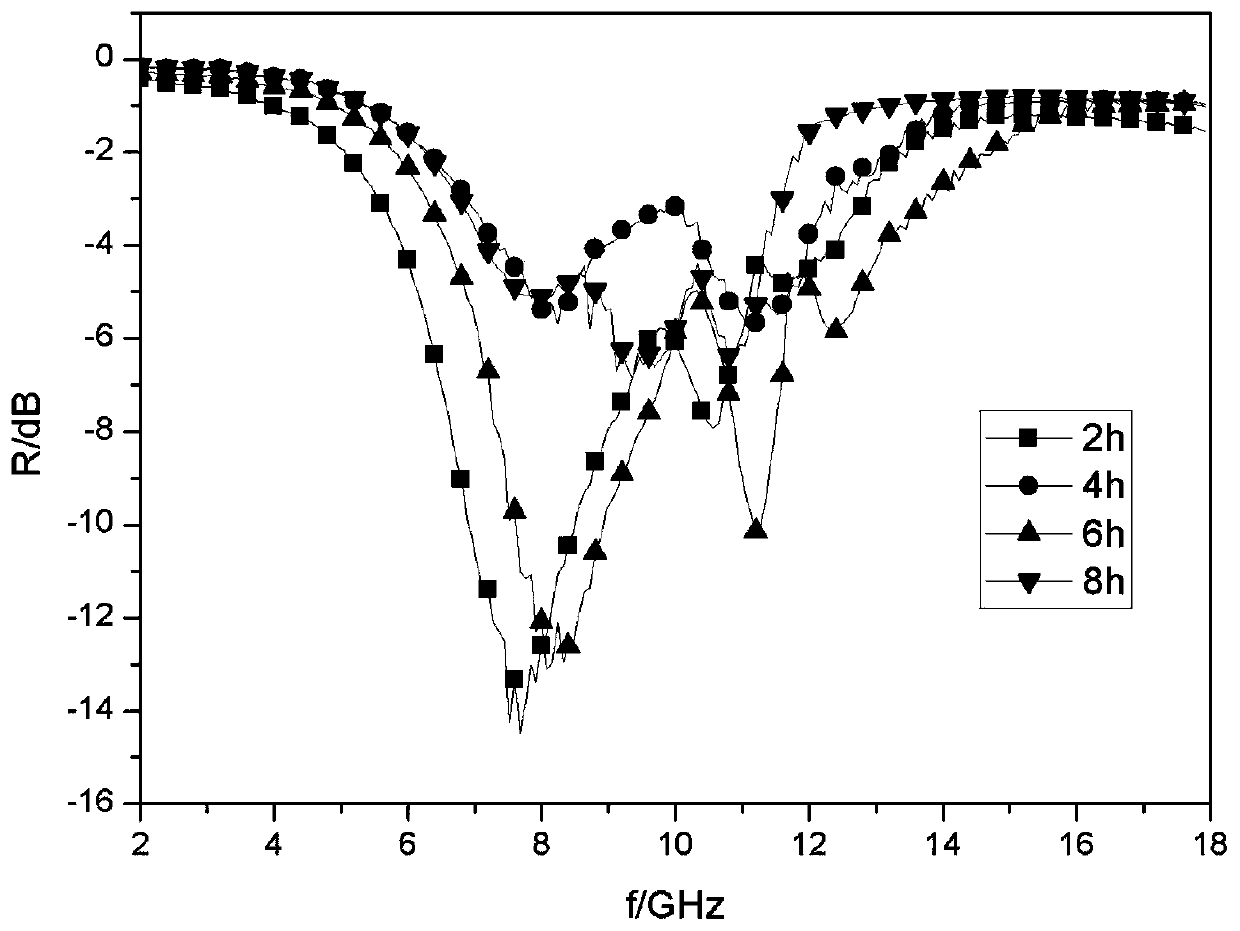

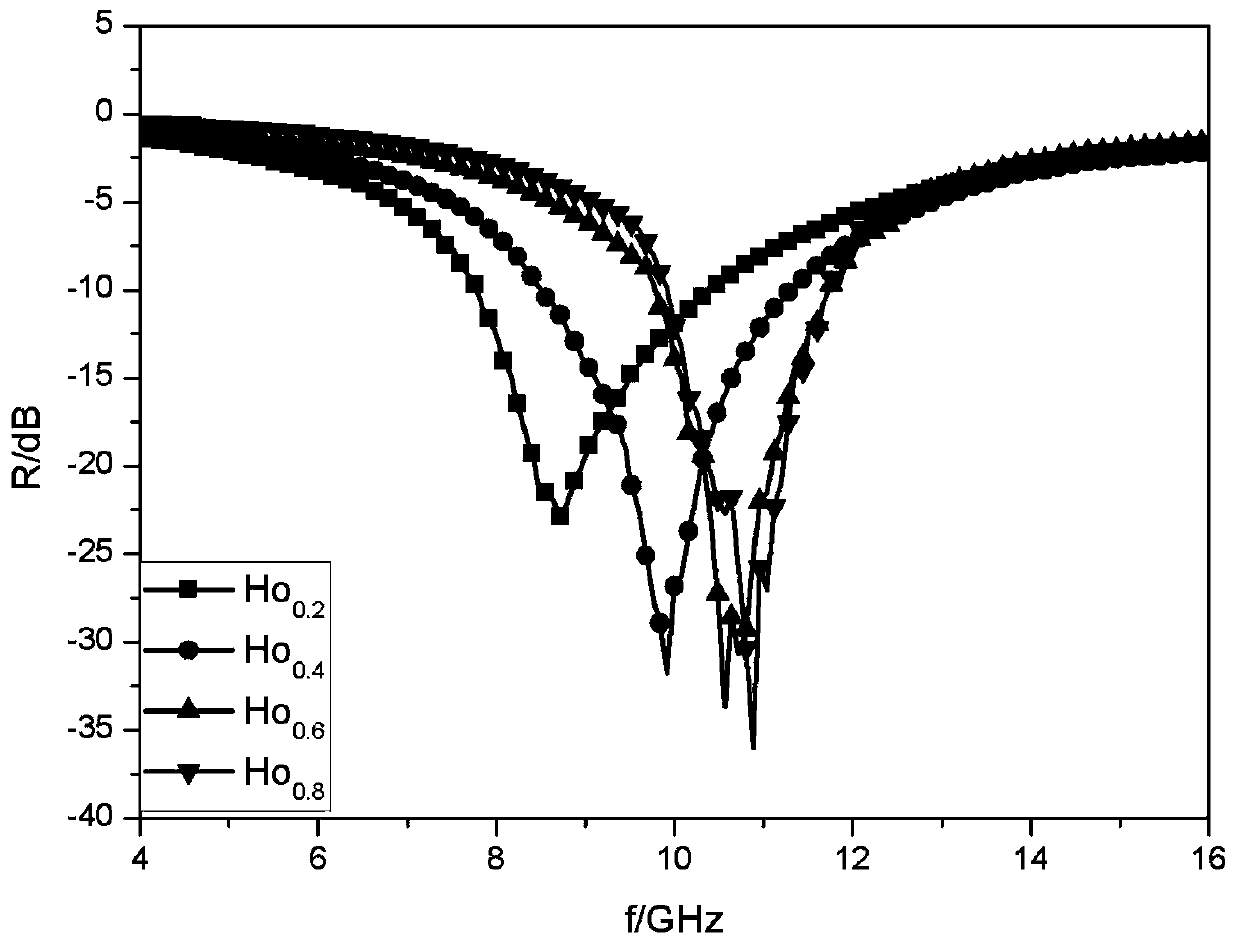

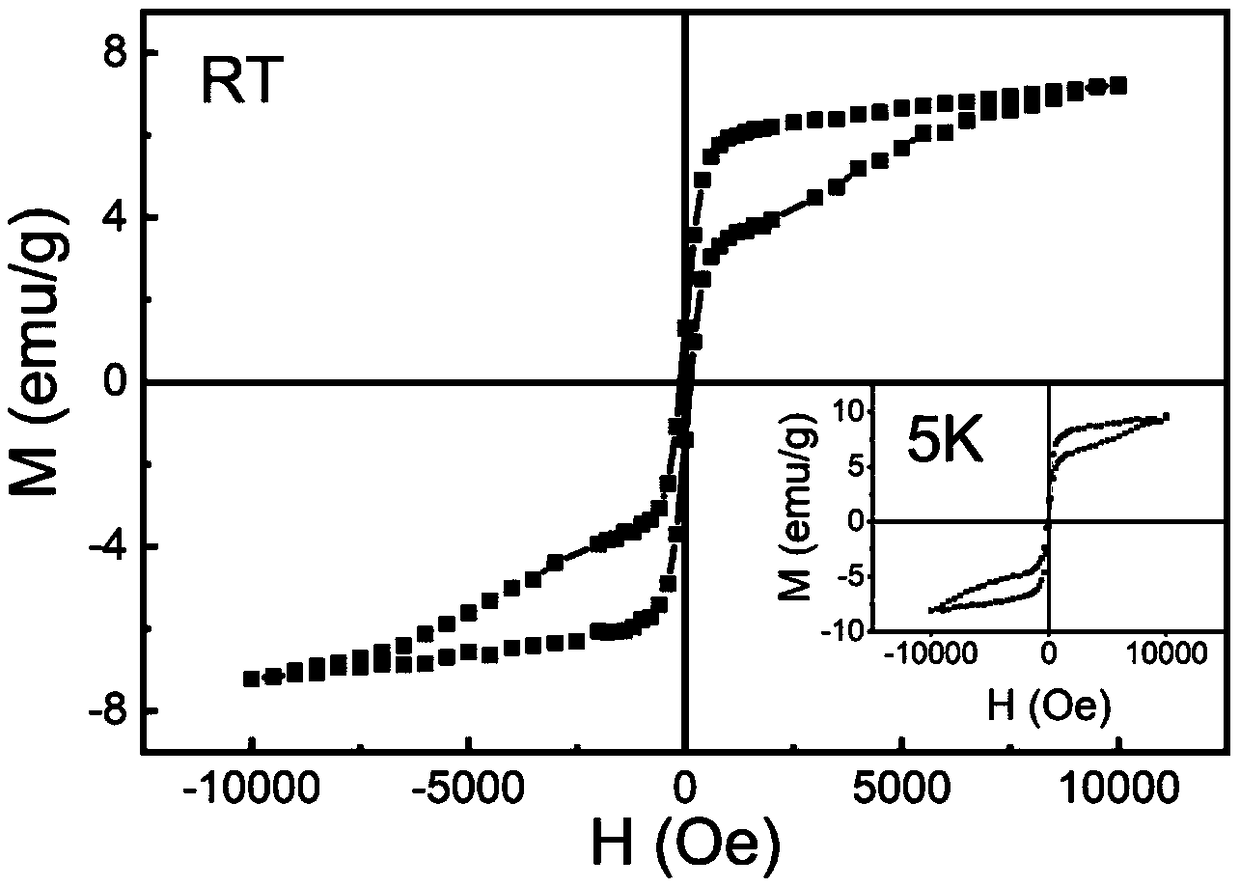

HoFeB/Fe3O4 wave-absorbing composite material and preparation method thereof

ActiveCN110171834AGood broadband effectGood microwave absorption characteristicsInorganic material magnetismFerroso-ferric oxidesIce waterMicrowave

The invention provides a HoFeB / Fe3O4 wave-absorbing composite material and a preparation method thereof. The HoFeB / Fe3O4 wave-absorbing composite material is suitable for the field of microwave absorbing materials. The preparation method includes the following steps that Ho, Fe and B with the purity equal to or more than 99.95% serve as raw materials respectively and are repeatedly molten into ingots with uniform compositions in an argon atmosphere, vacuumizing is conducted, and the ingots are sealed in quartz glass for homogeneous annealing at 800 DEG C, then quenched with an ice-water mixture, mechanically crushed into powder and ball-milled into powder by using high energy; the powder obtained after high-energy ball milling and ferroferric oxide are placed in an agate mortar for grinding and mixing according to the relative molecular mass ratio, and the HoFeB / Fe3O4 composite material is obtained. The wave-absorbing composite material has a very good microwave absorbing effect in themicrowave frequency band of 2-18 GHz and a wide wave-absorbing bandwidth, has the advantages of a simple preparation process, high oxidation resistance and the like, and can be suitable for preparation of microwave absorption products which require wide wave-absorbing bandwidth, good wave-absorbing performance and high oxidation resistance.

Owner:GUILIN UNIV OF ELECTRONIC TECH

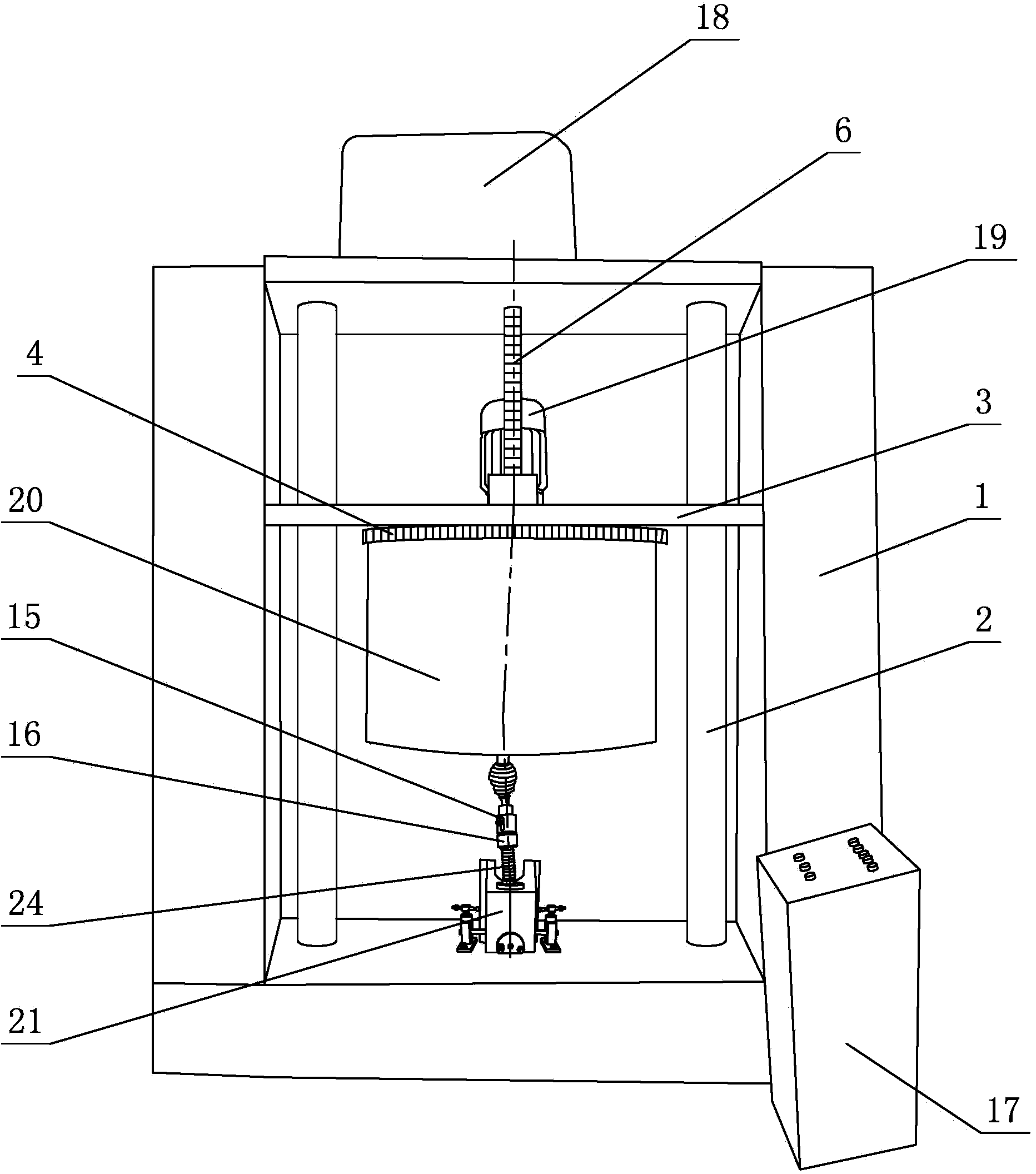

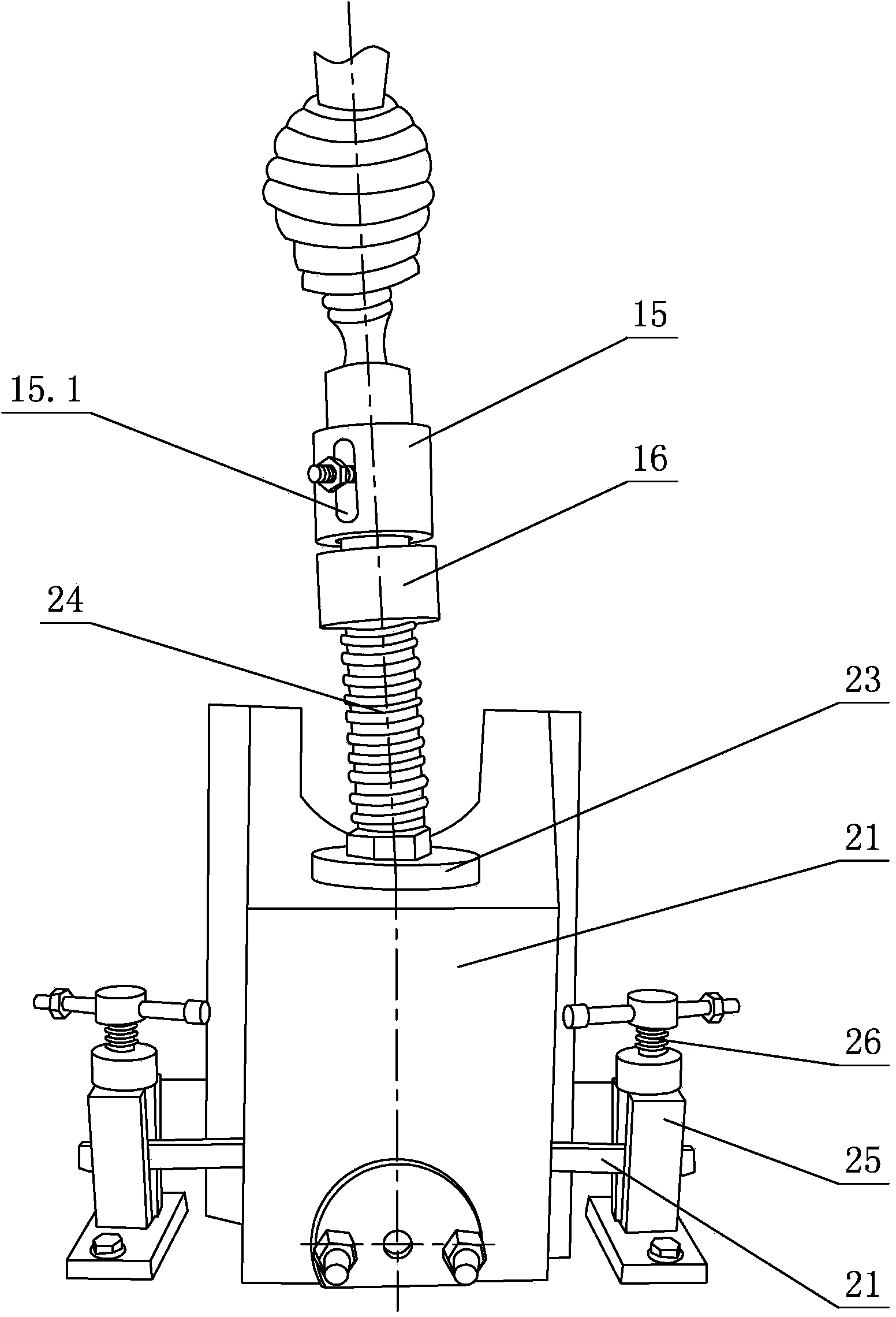

Ball head grinding machine for press machines

ActiveCN103481184AEliminate cumulative errorsImprove compactnessLapping machinesPosition toleranceEngineering

A ball head grinding machine for press machines comprises a machine body, stand columns, a ball head screw, a rotary power head and a lifting mechanism. A main motor and a lifting board are arranged on the machine body, and a lifting screw arranged on the lifting board which is in driving connection with the main motor through the lifting screw can move on the stand columns. A regulating and grinding mechanism is arranged on the rotary power head, and operation position of a grinding motor is regulated through the regulating and grinding mechanism. The upper portion of the ball head screw is in driving connection with the grinding motor, while the lower portion of the same is arranged in a slider and drives the ball head screw to be ground in the slider through the grinding motor. A clamping mechanism used for fixing the slider is further arranged on a workbench of the machine body. By the ball head grinding machine, errors and shape-position tolerances accumulated in the processing of a ball head are beneficially removed, cooperative compactness between the slider and the ball head is improved, and abrasion between the same at work is reduced, and unsteadiness of the slider at work is solved, so that the slider is enabled to be stable and smooth at work. Therefore, the press machine is higher in pressing precision, longer in service life and high in practicability.

Owner:GUANGDONG LIANXING FORGING MASCH IND CO LTD

Method for preparing high-bioavailability high-stability carotenoid preparation

InactiveCN111714466AEasy to operateShort grinding timeHydrocarbon active ingredientsHydroxy compound active ingredientsMicroparticleSpray dried

The invention provides a method for preparing a high-bioavailability high-stability carotenoid preparation. The method comprises the steps of dissolving part of water-soluble colloids and filling substances in water to form an aqueous phase, dispersing carotenoid crystals in the aqueous phase, carrying out primary grinding, then, supplementing the rest water-soluble colloids and filling substances, and carrying out secondary grinding, thereby obtaining a nano-disperse water-soluble suspension of carotenoid, wherein microcapsule dry powder or microparticles of the carotenoid can be prepared from the water-soluble suspension through a spray drying or spray congealing process as required. The method has the advantages that the carotenoid preparation is obtained through the twice-grinding twice-embedding process; the production process is short in grinding time and low in energy consumption; and liquid droplets in the end product reach nano-scale dispersion and are uniform in dispersion, small in particle size span, good in stability and easy in tabletting forming.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

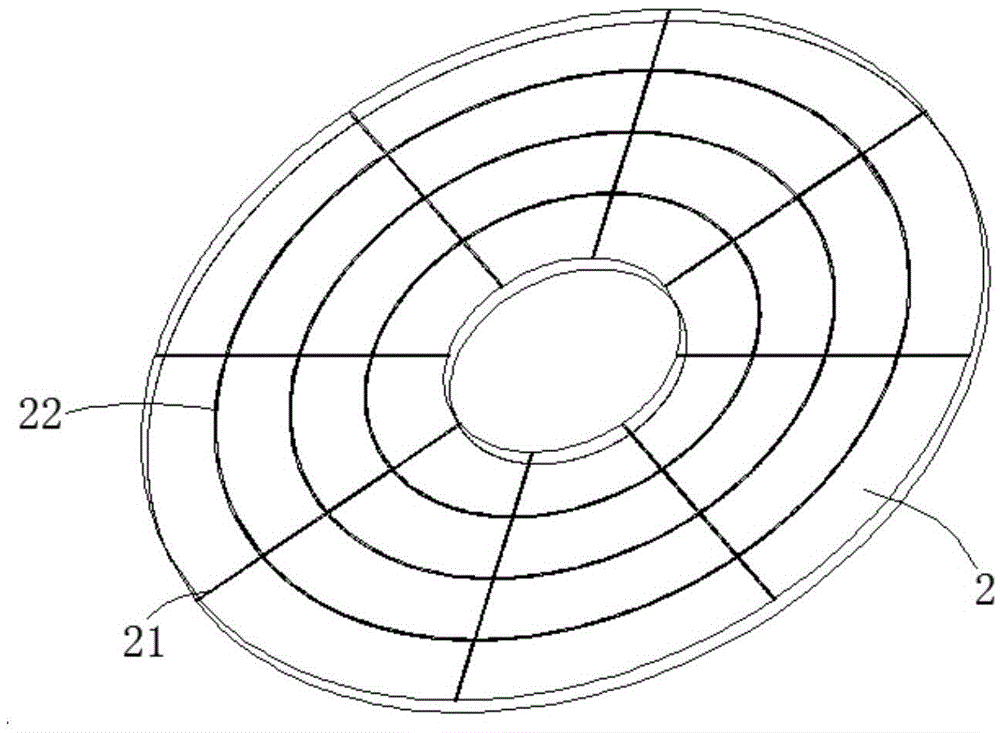

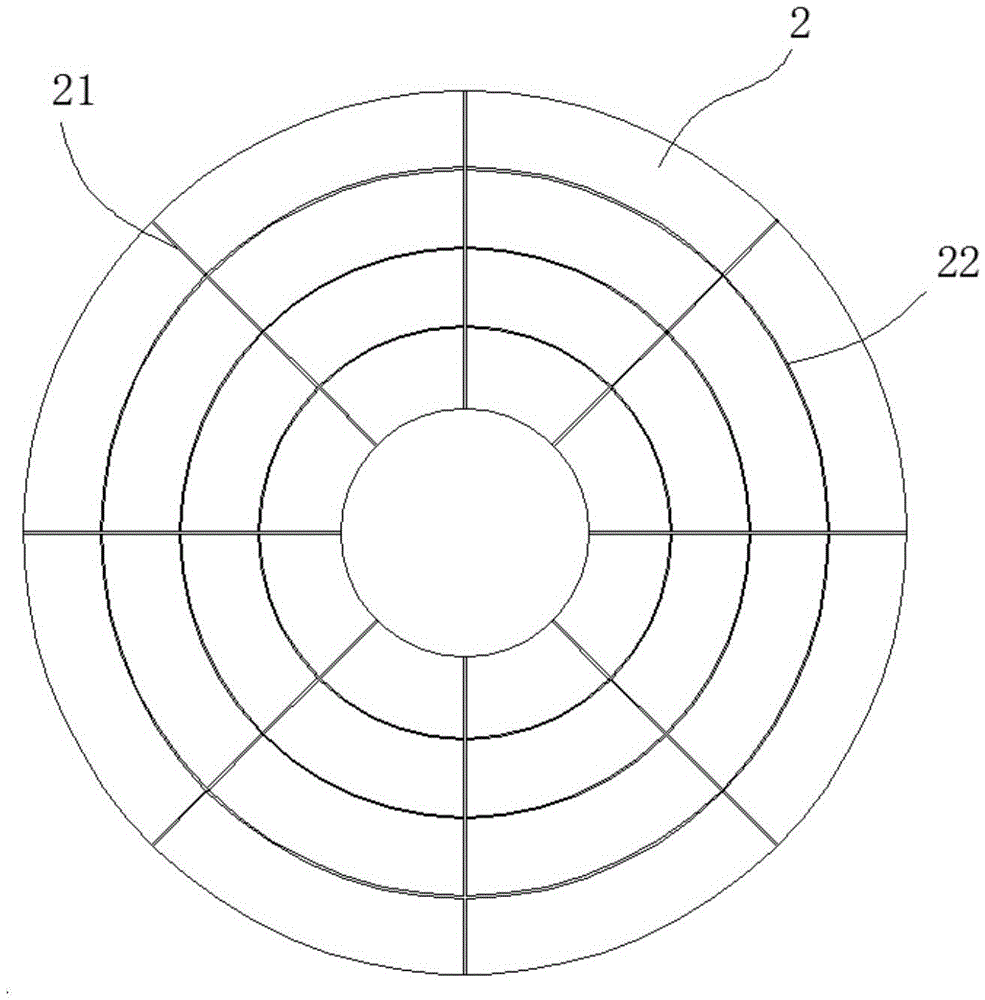

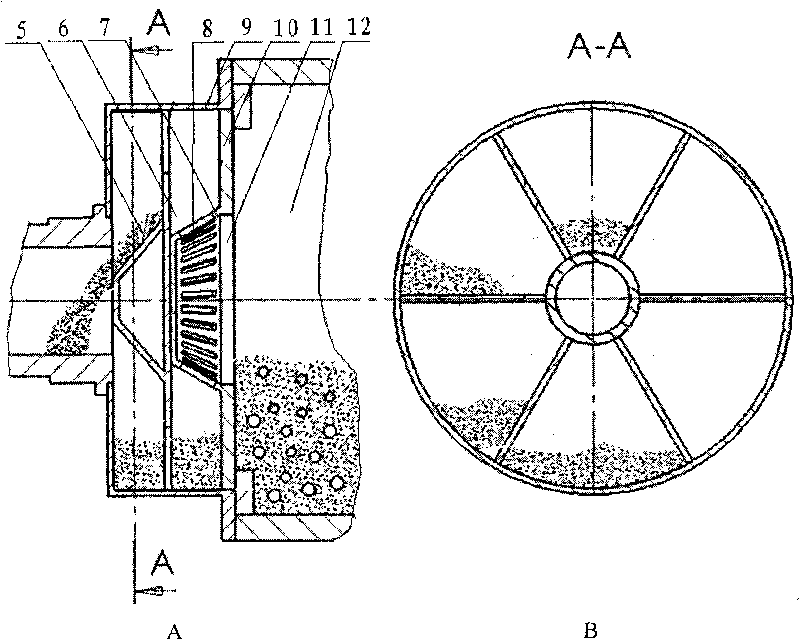

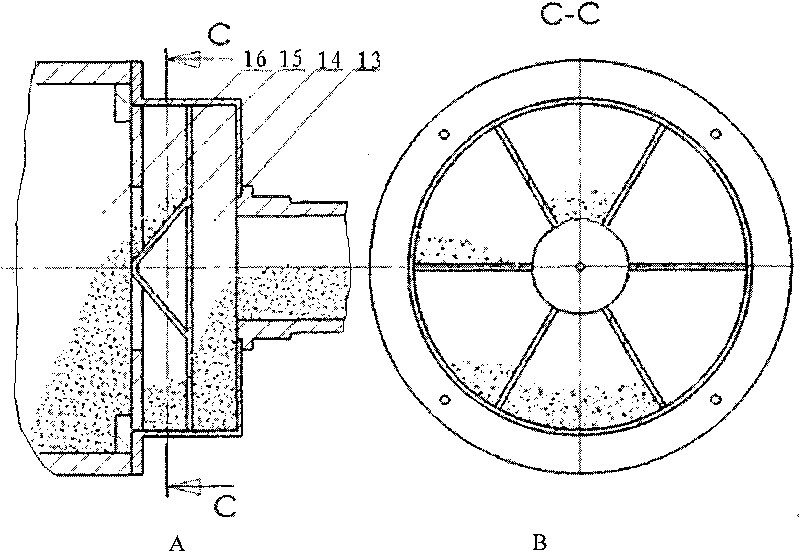

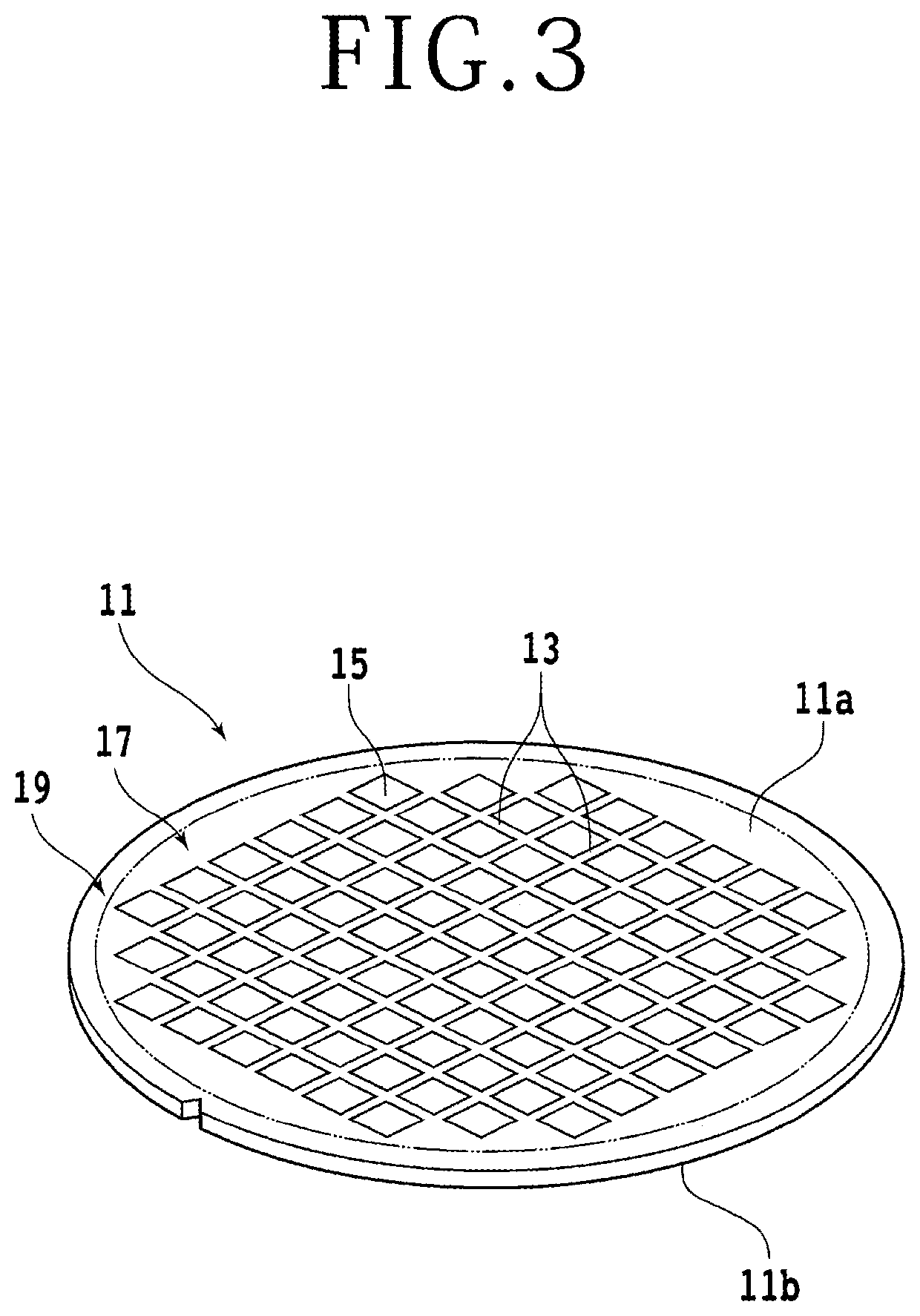

Polishing disk, polishing device and high-brightness abrasion-resistant metal mirror surface rough polishing technology

InactiveCN105666315AThe amount of grinding is easy to controlShort grinding timeLapping machinesLapping toolsEngineeringCopper

The invention discloses a polishing disk which is a copper round disk. Chip discharging grooves are formed in the polishing face of the polishing disk. The invention further provides a polishing device which comprises the polishing disk. A loading jig is arranged on the top face of the polishing disk; a clump weight is arranged on the top of the loading jig; the loading jig and the clump weight are sleeved with a ceramic check ring; a ground product is arranged between the loading jig and the polishing disk; and the ground product is fixed to the inner side of the ceramic check ring by the ceramic check ring. The invention further provides a high-brightness abrasion-resistant metal mirror surface rough polishing technology achieved through the polishing device. The technology includes the following steps that the polishing disk is washed; the ground product is installed; the loading jig is installed; the clump weight is installed; and the ceramic check ring is installed. By means of the polishing disk, the polishing device and the high-brightness abrasion-resistant metal mirror surface rough polishing technology, the grinding quantity can be easily controlled, chips can be discharged in time, and therefore it can be avoided that the surface of the ground product is scratched by waste chips generated in the grinding process, the grinding time is short, and the rate of good products is high.

Owner:KESEN SCI & TECH DONGTAI CO LTD

Method for controlling retaining ring planeness and produced retaining ring and semiconductor manufacturing system

InactiveCN107717639AShort grinding timeComply with flatness requirementsWork carriersEngineeringSemiconductor

The invention relates to the technical field of semiconductor manufacturing, in particular to a method for controlling retaining ring planeness and a produced retaining ring and semiconductor manufacturing system. The method comprises the following steps that a basic disc face of a retaining ring is turned, and then the basic disc face is ground; and a resin face of the retaining ring is turned and is then ground. The planeness of the basic disc face of a base basically trends to be coincident before the resin face of the retaining ring is machined by increasing the step of grinding the basicdisc face of the retaining ring, and the planeness is smaller than or equal to 0.008 mm; and then the resin face is turned to enable the planeness of the turned resin face finished product to meet therequirement for the planeness of semiconductor consumable items. According to the method, the resin face grinding time is short, the using amount of grinding fluid is saved, the using number of polishing mats is saved, the production efficiency is improved, and cost is saved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

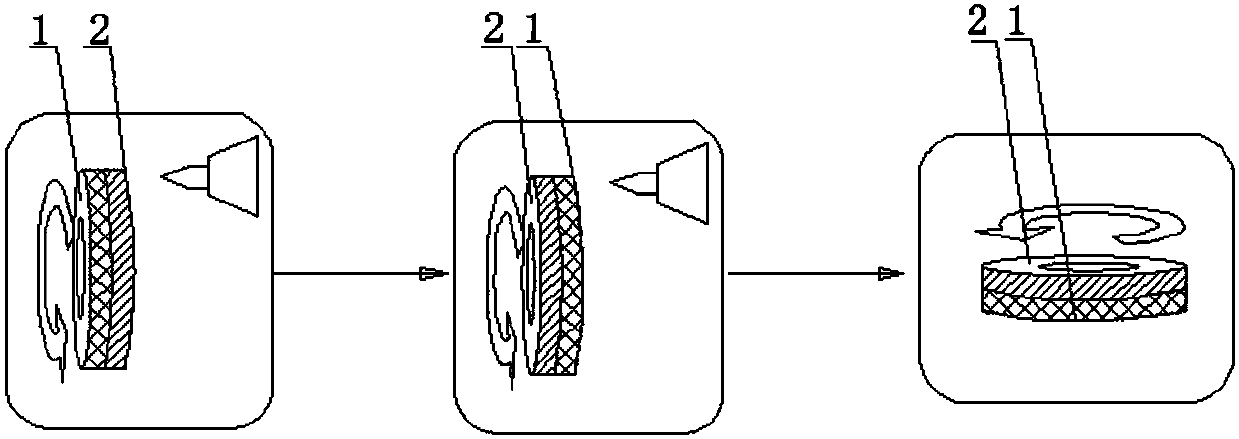

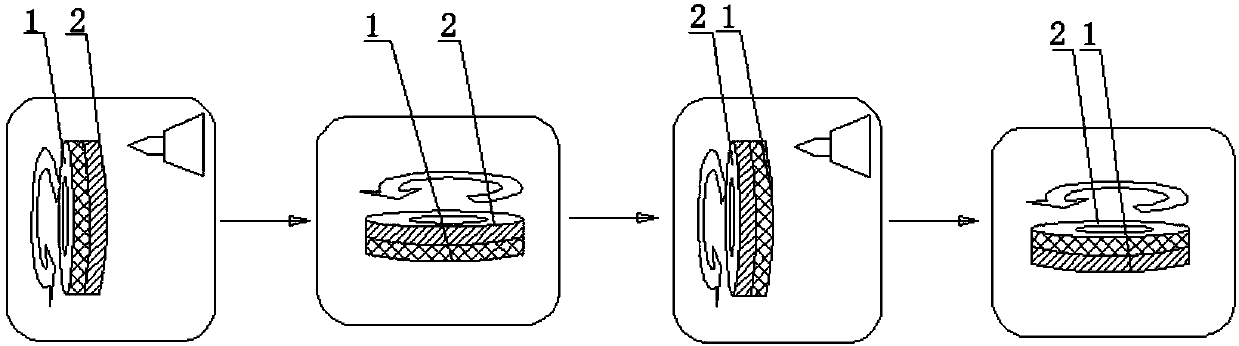

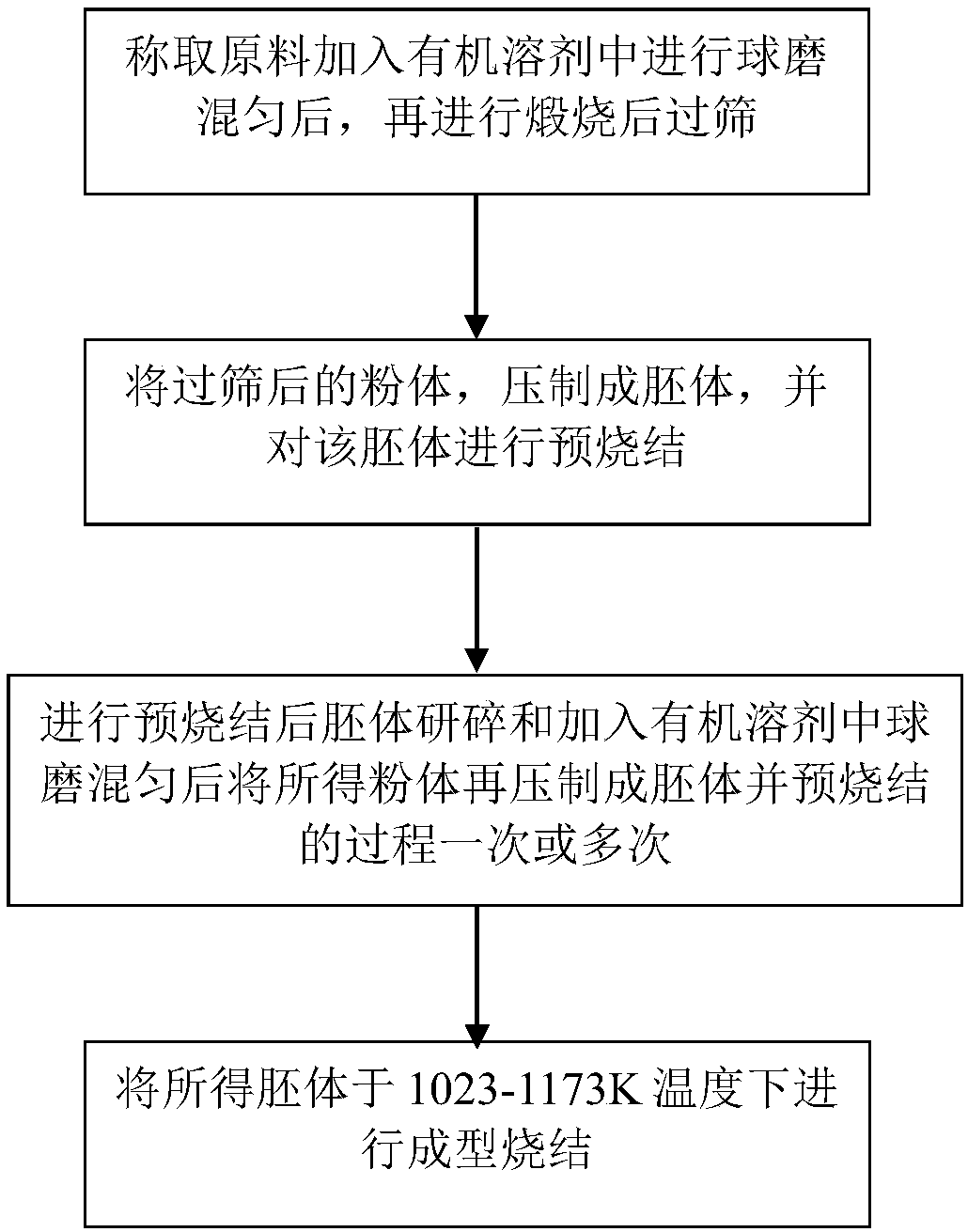

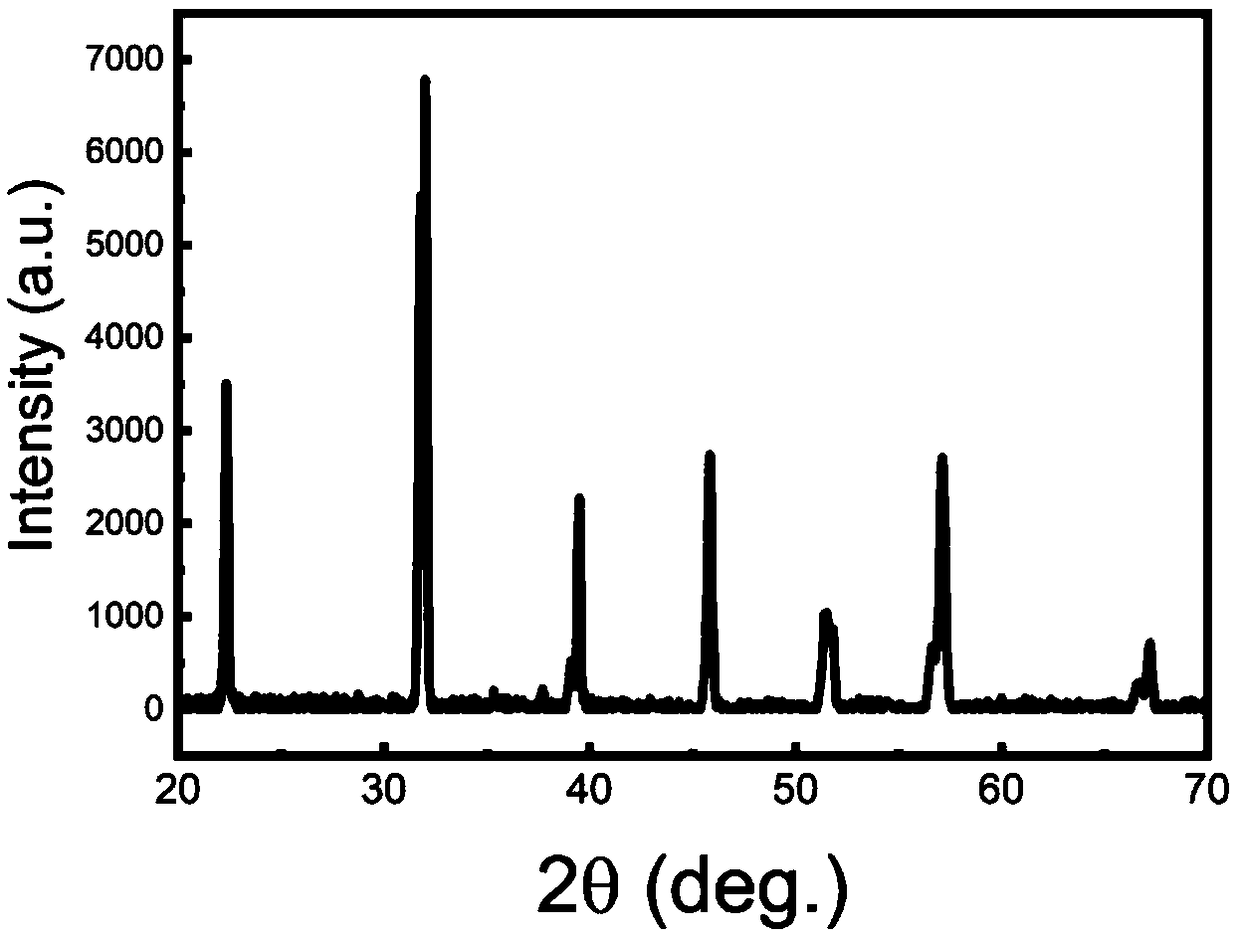

Single-phase ceramic target and preparation method and application thereof

ActiveCN108793993AFerromagneticLower operating temperatureVacuum evaporation coatingSputtering coatingOrganic solventRoom temperature

The invention discloses a preparation method of a single-phase ceramic target. The preparation method comprises the steps of weighing raw materials, adding the raw materials into an organic solvent, ball milling and mixing uniformly, then calcining and screening; pressing screened powder into a base, and pre-sintering the base; grinding the pre-sintered base and adding the base into the organic solvent, ball milling and mixing uniformly, pressing the obtained powder to obtain a base, and pre-sintering, wherein the process is performed once or for many times; and sintering the base at a temperature of 1023-1173K to shape the target. Through adoption of the preparation method, time for grinding, calcining and sintering is short, the operation temperature is low, and a sintering additive is not added in sintering. The method has low requirements on equipment, has high preparation efficiency, and can help save energy and lower cost. The invention further discloses the single-phase ceramictarget and application thereof in an electronic device. The prepared ceramic target is uniform and compact, has ferromagnetism at both room temperature and low temperature, and can be used for preparing a film material in the electronic device.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

High-thermal-expansion glass powder for copper paste as well as preparation method and application of high-thermal-expansion glass powder

ActiveCN112125527ALower sintering temperatureIncreased thermal expansionOxide ceramicThermal dilatation

The invention discloses high-thermal-expansion glass powder for copper paste as well as a preparation method and application of the high-thermal-expansion glass powder.The high-thermal-expansion glasspowder comprises the following components in percentage by mass: 52-62% of BaO, 19-25% of ZnO, 8-10% of B2O3, 4-8% of Al2O3, 2.5-5% of CaO, 0.1-3% of Fe2O3, 1-3% of SiO2, 0.1-3% of SrO, 0.1-5% of SnO2,0.1-3% of CoO, 0.1-3% of ZrO2 and 0.5-1% of Bi2O3. The preparation method comprises the following steps of: uniformly mixing the raw materials to obtain a glass batch; melting the glass batch, flattening the molten glass batch on a mold; naturally cooling the glass batch under an air condition; and performing crushing, ball-milling and sieving to obtain the high-thermal-expansion glass powder for the copper paste. The glass powder has the advantages of low sintering temperature, high thermal expansion coefficient, favorable dielectric constant, simple preparation method and cheap and accessible raw materials, and can be used for sealing magnesium oxide ceramic substrates.

Owner:WUHAN UNIV OF TECH

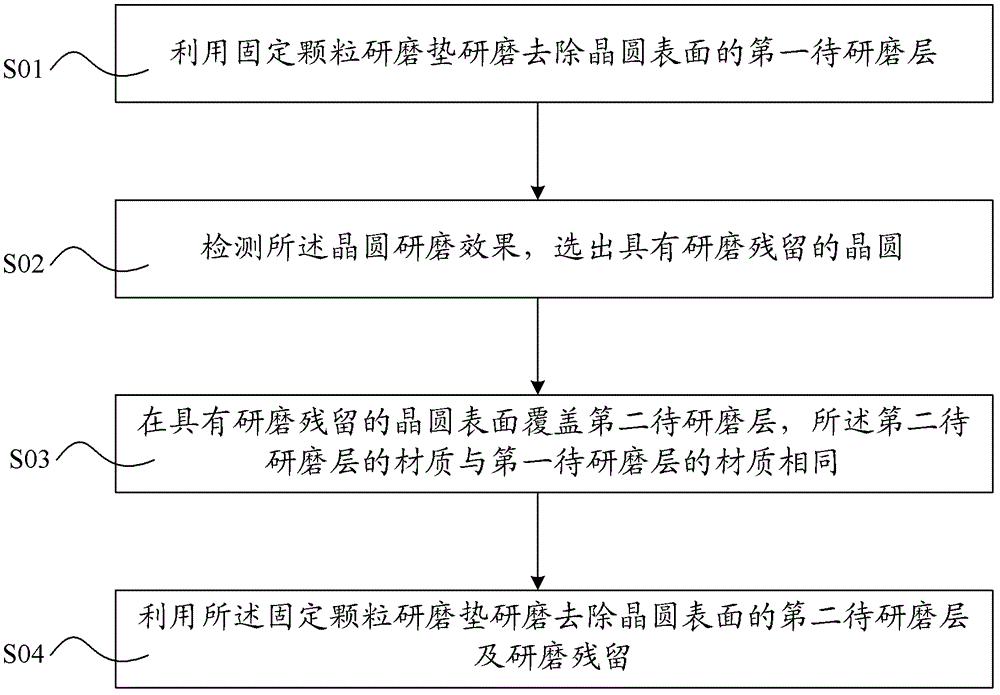

Chemical mechanical grinding method

ActiveCN102909646BIncrease grinding rateImprove grinding effectLapping machinesMetallurgyGround layer

Owner:SEMICON MFG INT (SHANGHAI) CORP

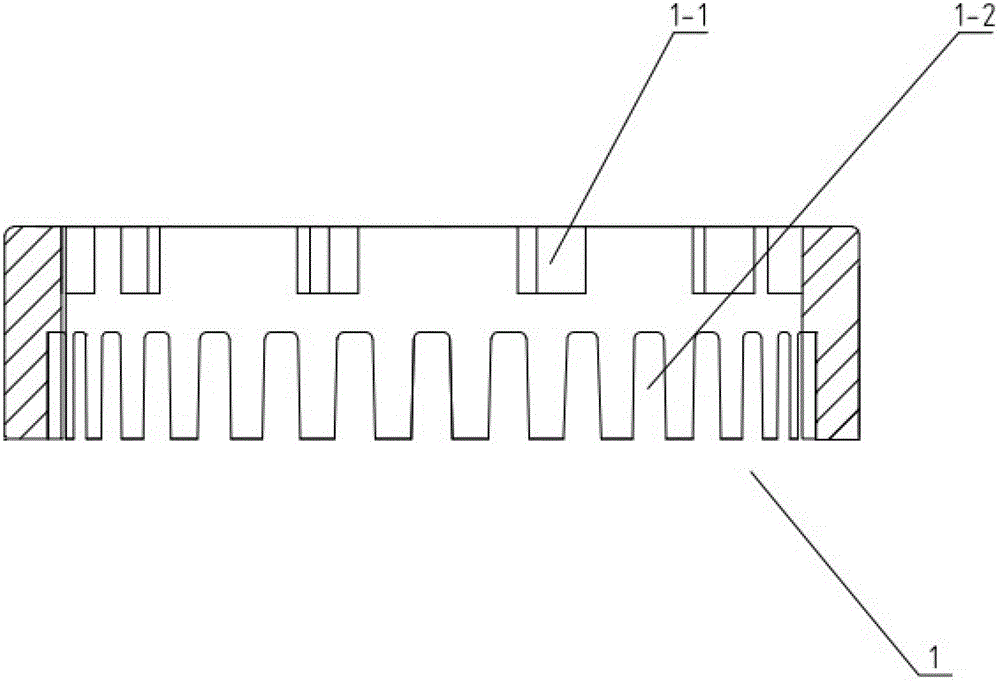

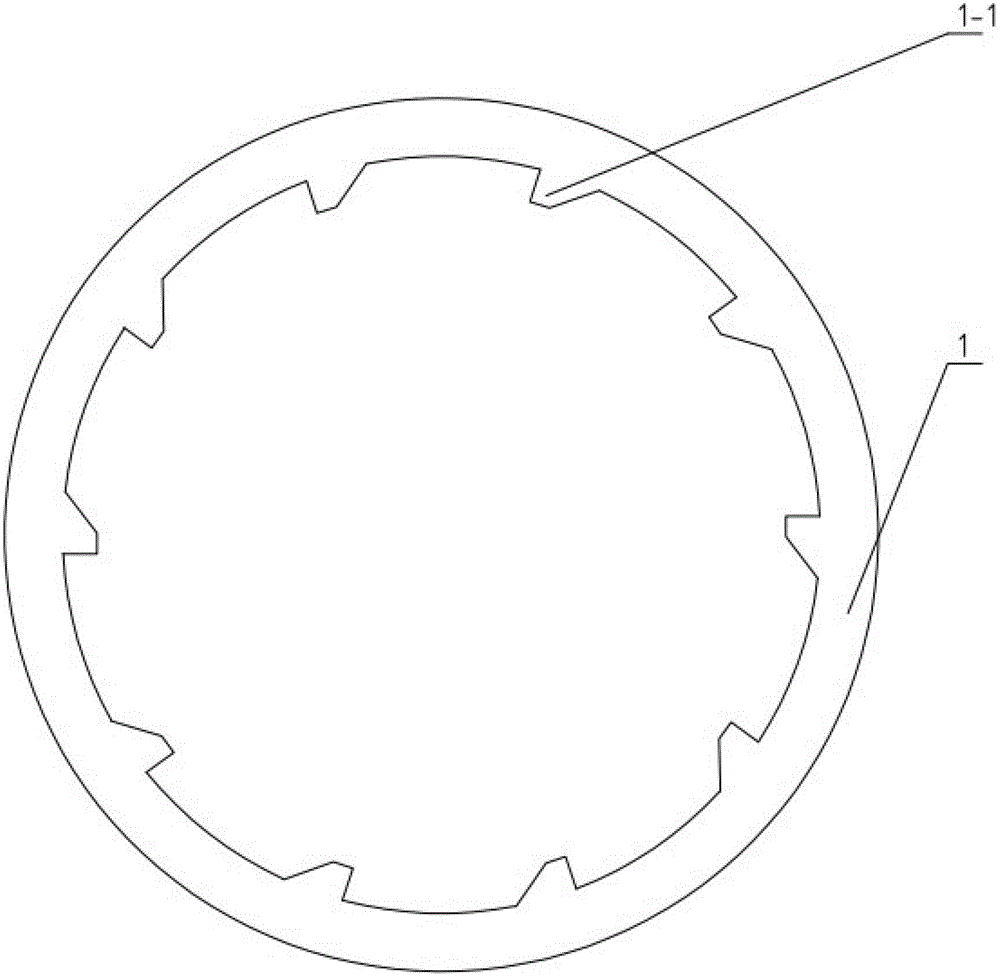

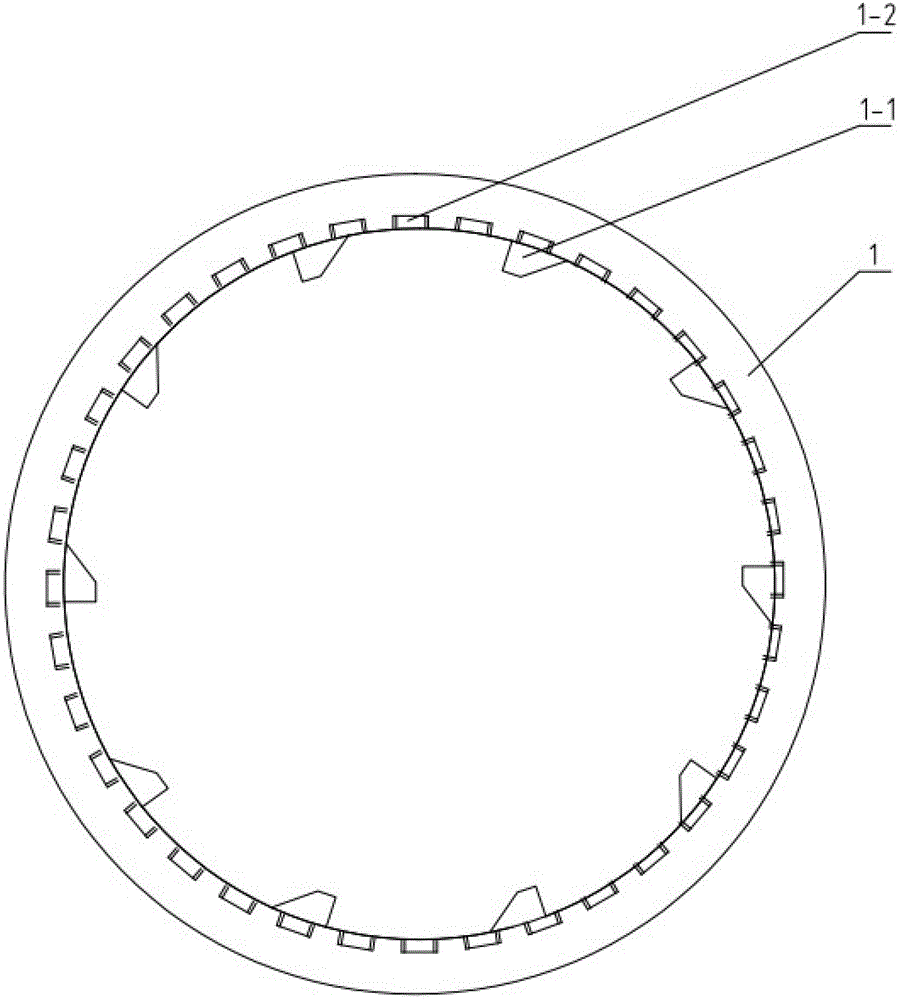

Bull ring of food waste disposer

The invention discloses a bull ring of a food waste disposer. The bull ring of the food waste disposer comprises a bull ring body. Pluralities of crushing convex teeth are arranged on the outer wall of the upper portion of the bull ring body along the direction of the circumference, wherein the pluralities of crushing convex teeth protrude outwards. Pluralities of grinding grooves are arranged on the inner wall of the lower portion of the bull ring body. The bull ring body is made of high alumina porcelain materials. The bull ring of the food waste disposer has the advantages of being simple in structure, capable of satisfying processing demands of the food waste, high in hardness and wear-resisting, and therefore, milling time is saved, and disposal efficiency of grinding garbage is increased.

Owner:LILING SHANGPIN ELECTRICAL APPLIANCE MFG

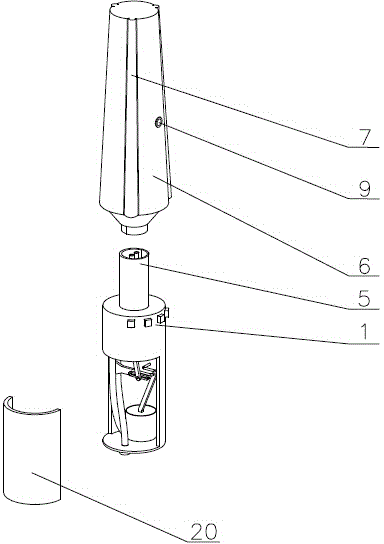

Automatic and rapid feed delivery device and discharge device

InactiveCN101690904AShort grinding timeRealize bin grindingGrain treatmentsSieveAerospace engineering

The invention provides an automatic and rapid feed delivery device, comprising a back panel, wherein the back panel is provided with a cone; a wing plate is connected to the cone and is arranged vertically on the back panel; the wing plate extends outside the back plate from the back plate area; the wing plate is sheathed with a cylinder body; the feed inlet of the feed delivery device is an annular hole which is formed between the back panel and a port of the cylinder body; and the discharge hole of the feed delivery device is the other port of the cylinder body. The invention also provides a discharge device, comprising a feed delivery device and a flash sieve, wherein the feed delivery device is the same as the automatic and rapid feed delivery device; the flash sieve comprises an annular back panel which is provided with a cylinder and a conical cap; the conical cap is provided with sieve pores; the inner bore of the annular back panel is arranged at one side of the conical cap; a cabin which is constituted by the annular back panel and the cylinder is arranged at the other side of the conical cap; the feed delivery device is connected with the flash sieve; and the cabin of the flash sieve is connected with the feed inlet of the feed delivery device.

Owner:SOUTHEAST UNIV

High strength cement

The invention discloses high strength cement. The high strength cement is prepared from 85-95 parts by weight of portland cement clinker, 20-25 parts by weight of desulfurized gypsum, 2-5 parts by weight of vulcanic ash, 15-25 parts by weight of fly ash, 10-15 parts by weight of bauxite, 5-10 parts by weight of slag, 10-18 parts by weight of gangue, 5-8 parts by weight of silica, 5-10 parts by weight of industrial waste residues, 5-8 parts by weight of a grinding aid and 1-3 parts by weight of one or more conditioning agents. The one or more conditioning agents are selected from tartaric acid, sodium chloride and boric acid. The high strength cement has the advantages of high strength, good freezing tolerance and small dry shrinkage.

Owner:QINGDAO HONGYU ENVIRONMENTAL PROTECTION AIR CONDITIONING EQUIP

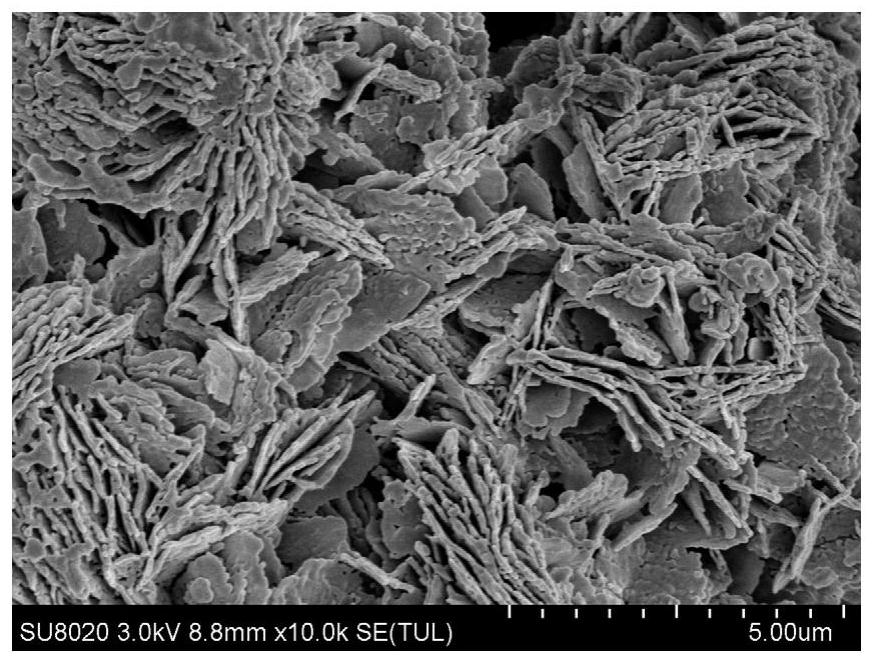

Preparation method and application of iron phosphate

PendingCN114644327AEasy to controlRaw materials are simpleCell electrodesSecondary cellsIron phosphateLithium electrode

The invention belongs to the technical field of lithium ion battery positive electrode materials, and particularly provides a preparation method of iron phosphate which is low in cost, low in specific surface area (less than 3m < 2 > / g), low in impurity content, high in performance and suitable for industrial production and application of the iron phosphate. According to the method, the iron source and the phosphoric acid react under certain conditions such as low temperature, then the filtrate after the reaction and the hydrogen peroxide are subjected to oxidation reaction, the iron phosphate is directly prepared, and the prepared iron phosphate can be used as a precursor and can be used for preparing the lithium iron phosphate / carbon composite material with excellent performance. In the whole process, the acid-base adjusting process and the surfactant using process of a traditional iron phosphate production process are avoided. The iron phosphate prepared by the method has the advantages of special morphology, few types of byproducts (only phosphoric acid is left), small specific surface area, facilitation of washing, reduction of the use amount of washing water, facilitation of improvement of the recycling rate of mother liquor, avoiding of the introduction of sulfate ions and some cations, and further reduction of the pollution to the environment.

Owner:上海鑫忆丹新材料有限公司

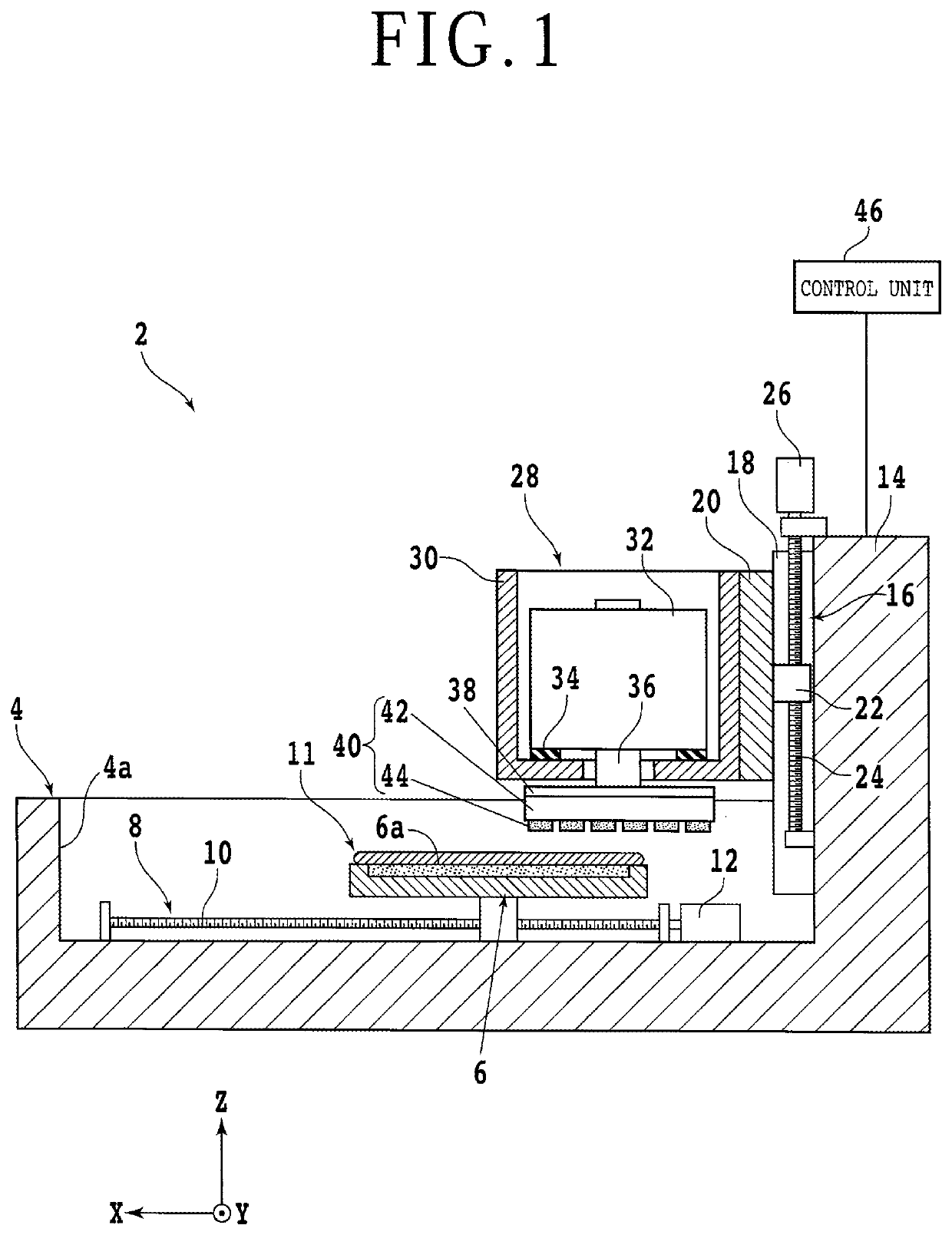

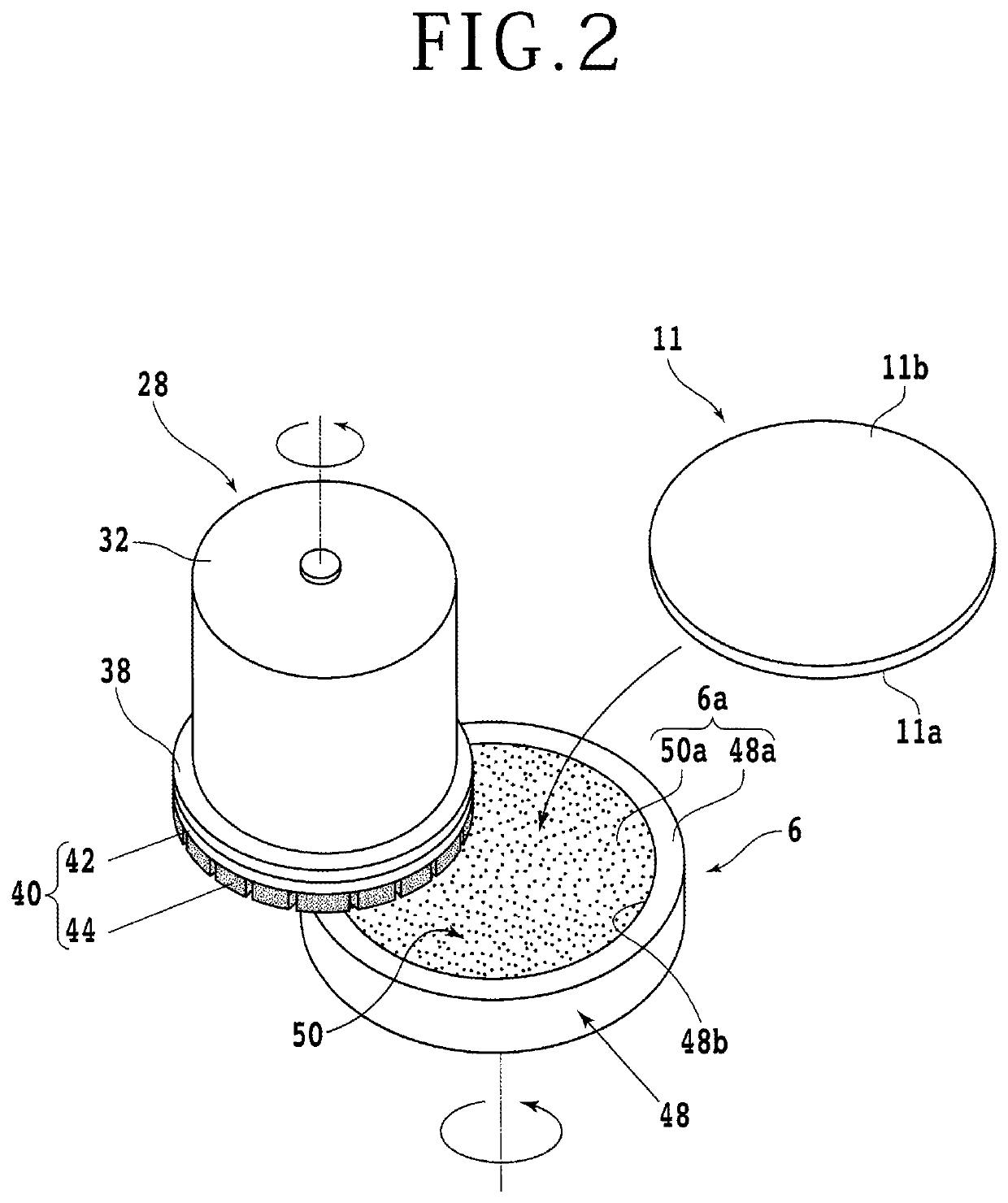

Processing method of workpiece

PendingUS20220324082A1Short grinding timeSuppress failureGrinding drivesSemiconductor/solid-state device manufacturingAbrasiveGrinding

There is provided a processing method of grinding a workpiece. The processing method includes a holding step of holding the workpiece on a side of its front surface on a chuck table, a coarse grinding step of grinding the workpiece on a side of its back surface with first grinding stones until the workpiece has a predetermined thickness, an auxiliary grinding step of grinding the workpiece on the side of its back surface with the first grinding stones such that an unground region remains at an outer peripheral portion of the workpiece, an unground region grinding step of grinding the unground region with second grinding stones having an average abrasive grain size smaller than that of the first grinding stones, and a finish grinding step of grinding the workpiece on the side of its back surface with the second grinding stones until the workpiece has a predetermined finish thickness.

Owner:DISCO CORP

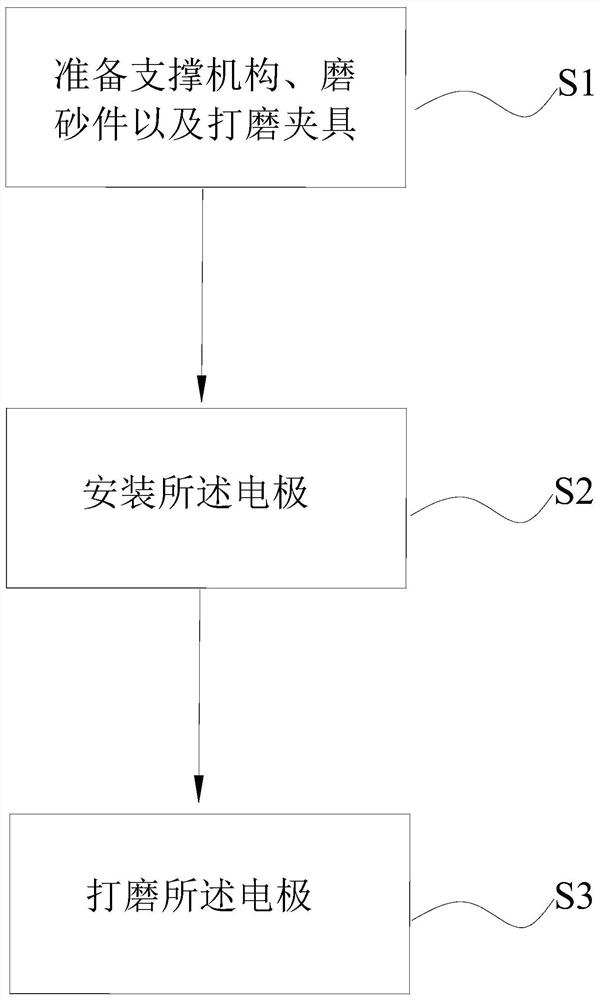

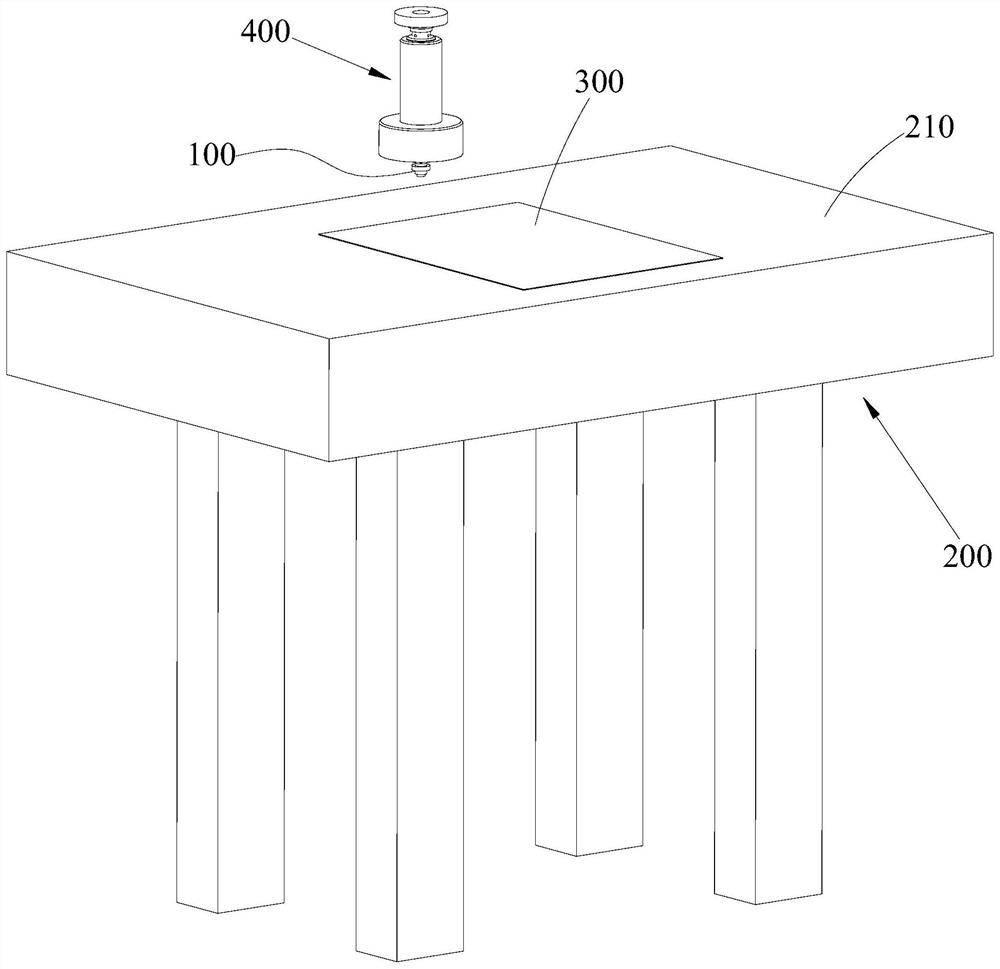

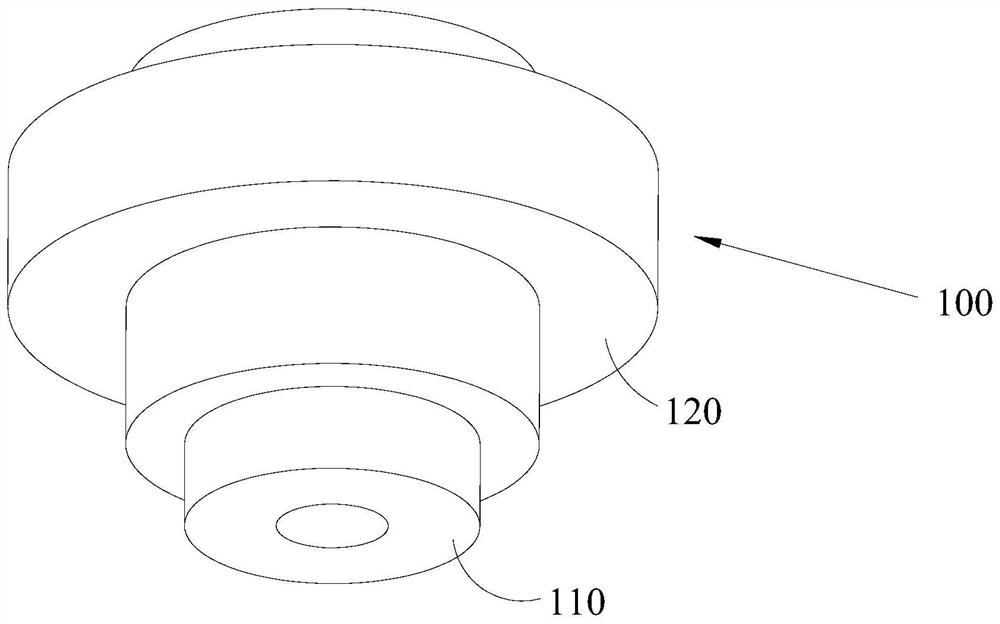

Electrode grinding method and clamp

PendingCN112828688ASolve technical problems of low operating efficiencyShort grinding timeEdge grinding machinesGrinding carriagesGrindingMaterials science

The invention provides an electrode grinding method and a clamp. The electrode grinding method comprises the steps of firstly preparing a supporting mechanism, a grinding part and a grinding clamp, secondly installing an electrode in the grinding clamp and enabling the contact end face of the electrode to be in contact with the grinding part, finally moving the end, provided with the electrode, of the grinding clamp towards the grinding part to enable the contact end face of the electrode to abut against the grinding face of the grinding part, and moving the grinding clamp on the grinding face of the grinding part, so that the contact end face is polished. Compared with a grinding machine for grinding, the method does not need to consume long-time preparation work for the situation that only a small number of electrodes need to be ground, the grinding time is shorter, the operation efficiency is improved, and the cost is reduced.

Owner:深圳市东飞凌科技有限公司

Polishing wheel piece and production method

ActiveCN103495939AGood shape retentionReduce the number of repairsAbrasion apparatusGrinding devicesVulcanizationGranularity

The invention relates to a polishing wheel piece. The polishing wheel piece comprises butadiene styrene rubber, pine tar, stearic acid, alumina, resin powder, zinc oxide, an accelerant DM and an accelerant M. Meanwhile, the invention further provides a production method of the polishing wheel piece. The method includes the steps of weighing materials, mixing the materials, conducting forming and conducting vulcanization. A polishing wheel sheet abrasive produced through the production method is under 280 meshes and used for polishing automobile connecting rods and shock absorber pipes, the surface roughness Ra can be less than or equal to 0.05, the polishing wheel piece can effectively replace a resin fine-granularity polishing grinding wheel and has the advantages of having a high shape protection property, less in the number of maintenance times, short in grinding time, low in cost and the like, and the polishing wheel piece can not burn a workpiece in the use process. The polishing wheel piece can partly replace a nylon polishing wheel imported from Japan. Cost is effectively reduced.

Owner:江苏好帮手砂轮有限公司

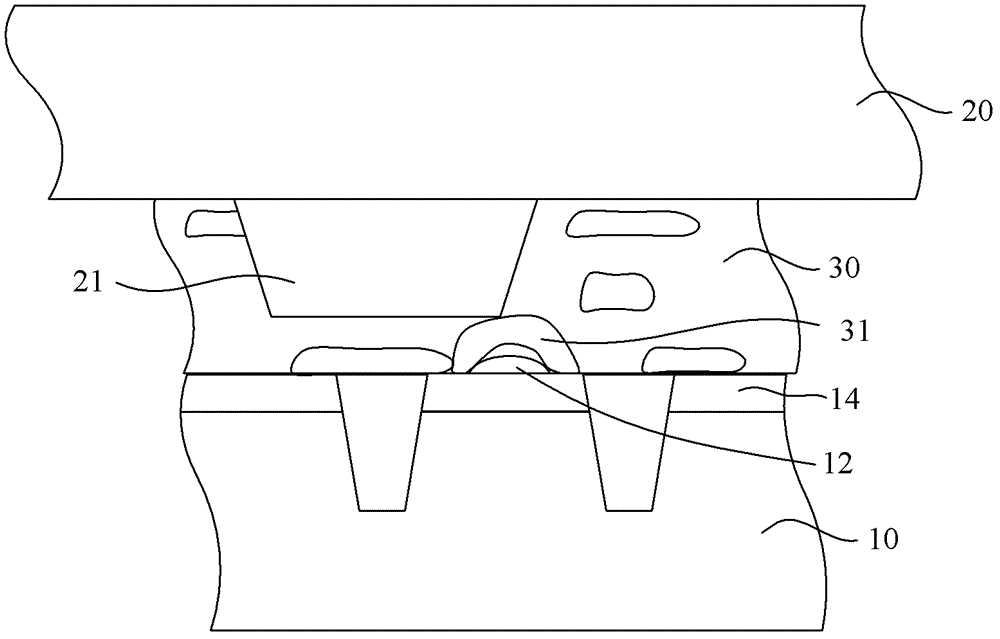

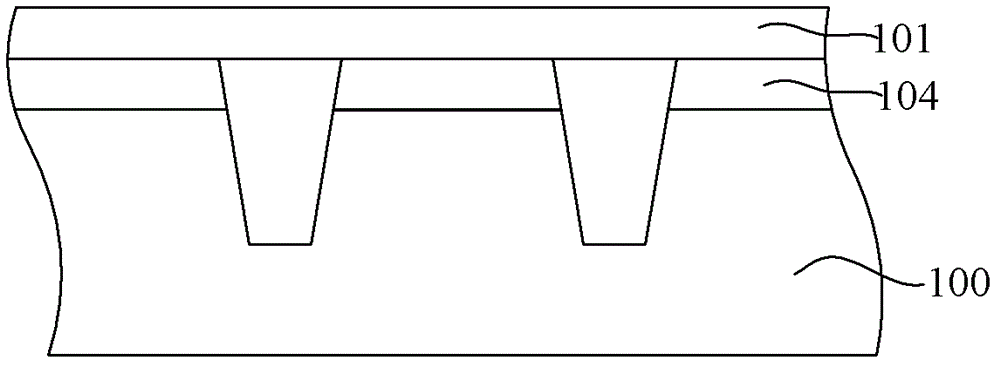

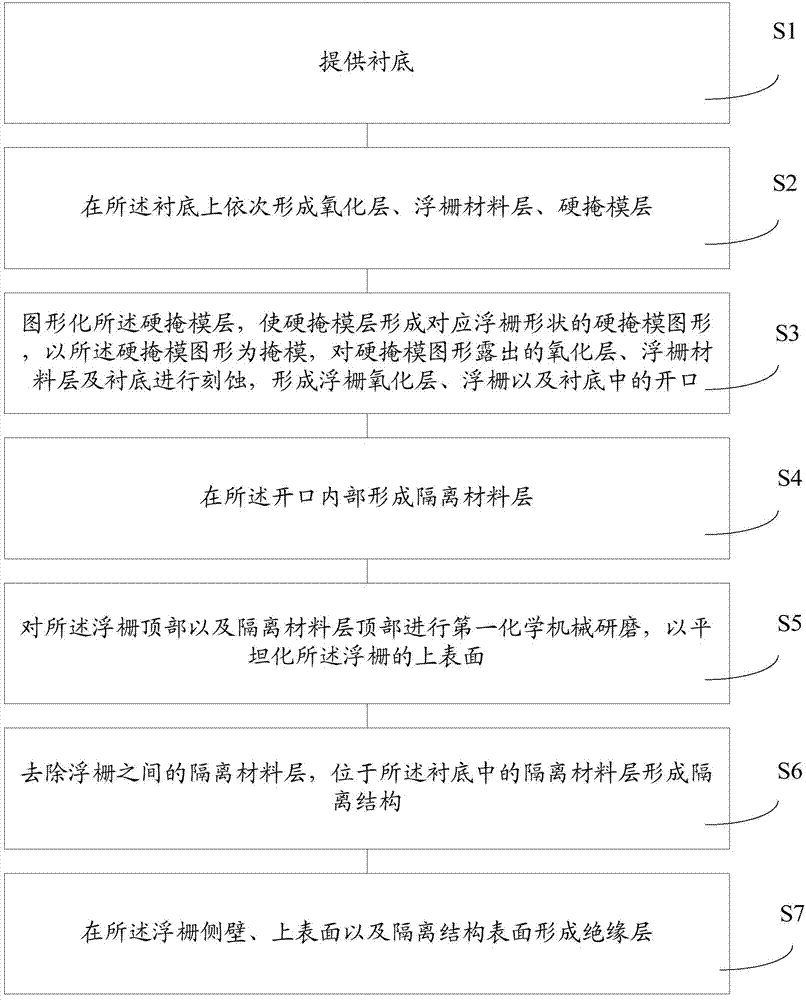

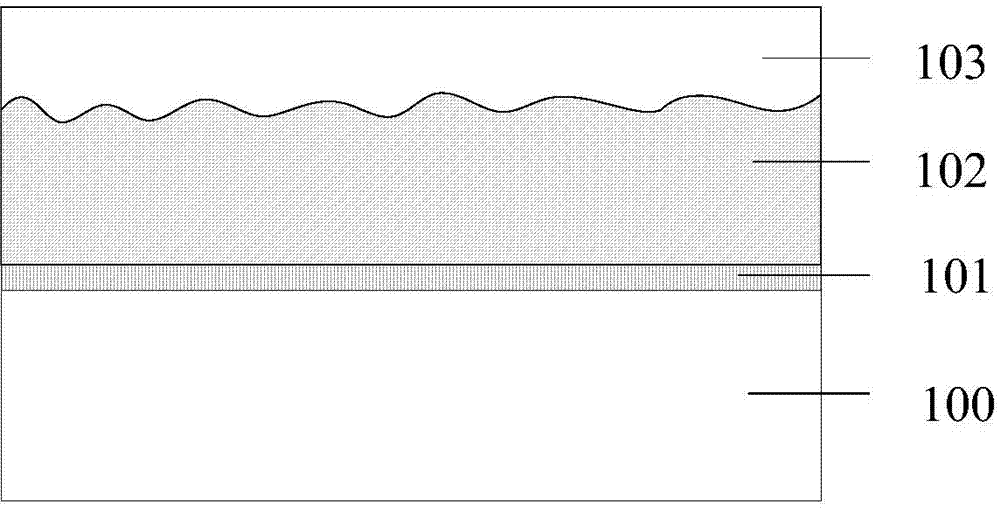

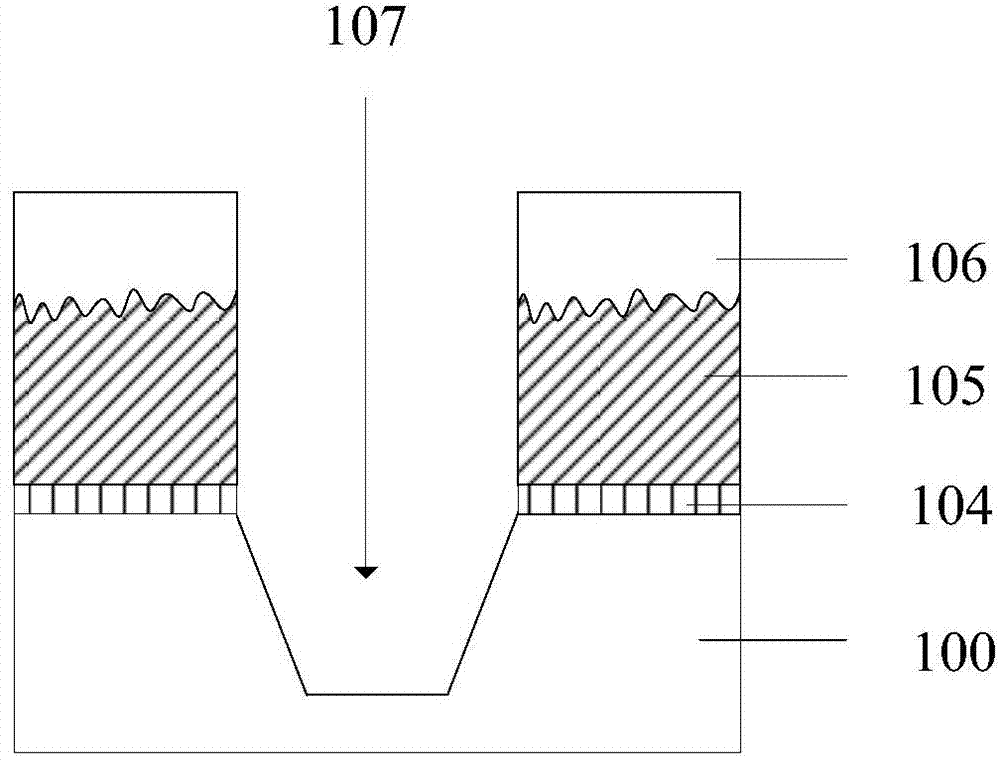

Forming method of storage

ActiveCN104752362AIncreased ability to hold chargeUniform thicknessSemiconductor/solid-state device manufacturingElectric fieldSurface flatness

The invention provides a forming method of a storage. The forming method includes providing a substrate; forming a floating gate material layer on the substrate; imaging the floating gate material layer and the substrate, and forming floating gates on the substrate and an opening formed in the substrate positioned between the floating gates; forming an isolation material layer in the opening; performing first chemical and mechanical lapping on the tops of the floating gates and the top of the isolation material layer, to planarize the upper surfaces of the floating fates; removing the isolation material layer between the gloating gates, thus allowing the isolation material layer in the substrate to form an isolation structure; forming an insulating layer on the side walls and upper surfaces of the floating gate and the surface of the isolation structure. As the upper surfaces of the floating gates are high in evenness, the insulating layer formed on the upper surfaces of the floating gates are uniform in thickness, sand thereby the local electric field intensity adjacent to the insulating layer is close to the electric field intensity of other areas, and the electric charge maintaining capacity of the floating gates can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for preparing nanometer porous titanium oxide thick film

The invention discloses a making method of nanometer porous thick film of titanium oxide, which comprises the following steps: (1) adopting dilute nitric acid to disperse TiO2 nanometer particle; (2) blending the powder, water and pore former into spread coating slurry; (3) coating the TiO2 slurry on the substrate through glass rod; blowing; (4) repeating the coating for several times until the needed thickness; (5) proceeding high-temperature heat disposal; adopting P-25 nanometer powder of Degussa company as the TiO2 powder, the carbowax as pore former, the glass (quartz glass, ITO or FTO conductive glass), monocrystalline silicon, sapphire and other materials as substrate. The thickness of the TiO2 film is controllable between 1 and 30um with grain size about 20-30nm, which simplifies the making method with cheap cost for large-scale manufacturing.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Yogurt taste chocolate coating composition and preparation method thereof

The invention belongs to the technical field of food processing and in particular relates to a yogurt taste chocolate coating composition and a preparation method thereof. The composition comprises the following components: white granulated sugar, a milk solid, edible oil, whey powder, yogurt powder, cocoa butter, lecithin, polyglycerol polyricinoleate and an emulsifier of which the iodine value is 18-24. Due to cooperation of the components and adjustment on amounts, the product, namely the yogurt taste chocolate coating composition provided by the invention, is pure and thick in flavor, outstanding in early fragrance, long-lasting in after fragrance, good in both stickiness and flowability and rapid in drying and shaping speed after coating and hanging, and requirements of coating and hanging processes of chocolate coatings can be met. The yogurt taste chocolate coating composition provided by the invention needs no sourness regulating agent and is pure in yogurt taste and rich in nutrition, and the yogurt flavor and the fragrant taste of the product can be improved; and due to adoption of the emulsifier of which the iodine value is 18-24, bubbling and cracking of the chocolate coatings can be avoided, and the product is well accepted by customers.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com