Polishing disk, polishing device and high-brightness abrasion-resistant metal mirror surface rough polishing technology

A technology of polishing device and polishing disc, which is applied in the field of grinding, can solve the problems of unstable grinding amount, high scrap, long polishing time, etc., and achieve the effect of easy control of grinding amount, high quality products, and short grinding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

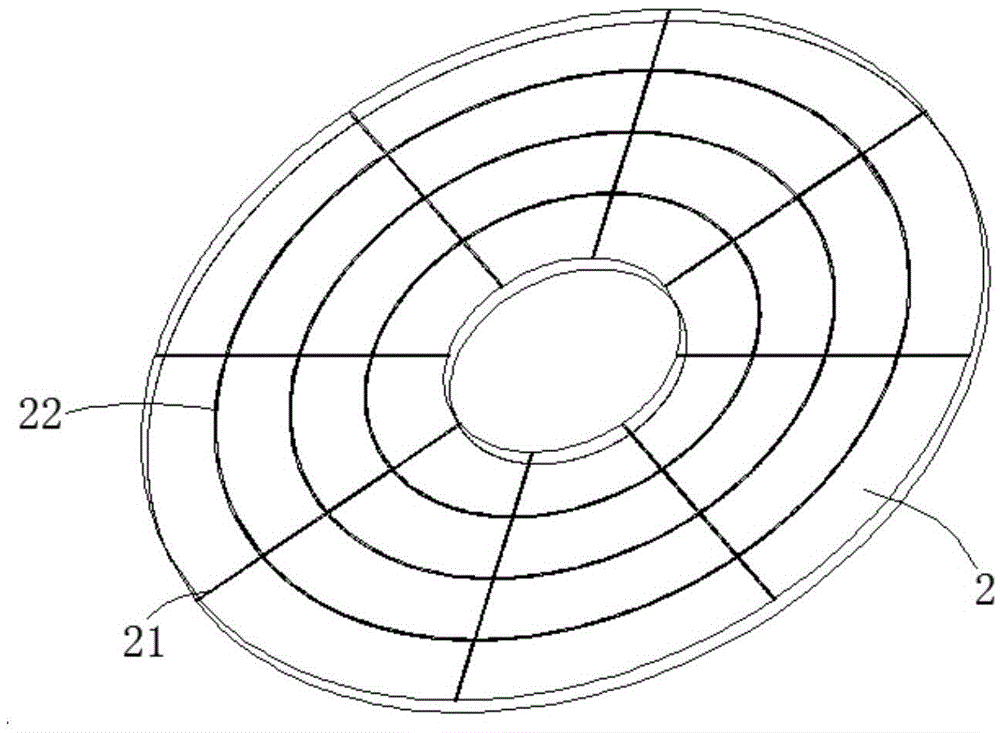

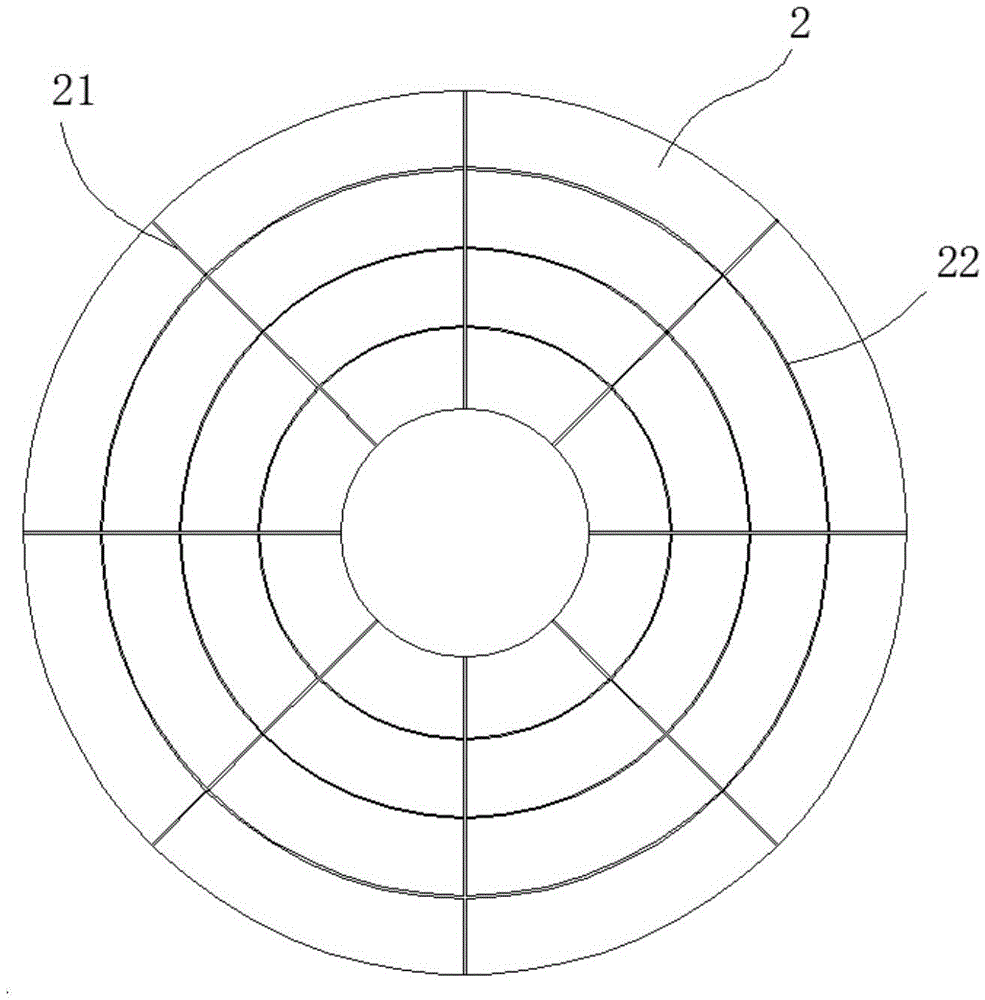

[0027] Such as Figures 2 to 4 As shown, the present invention provides a polishing disc, the polishing disc 2 is a copper circular disc, and the polishing surface of the polishing disc 2 is provided with chip removal grooves.

[0028] Due to the use of copper circular discs, the amount of grinding is easy to control during the grinding process due to its soft material, and the waste chips generated by grinding can be discharged in time through the set chip removal groove, which is conducive to the continuation of the grinding process, which is also It can prevent the grinding waste from scratching the surface of the grinding product, the grinding time is short and the yield is high.

[0029] Specifically, the chip removal groove includes a radial chip removal groove 21 along the radial direction, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com