Yogurt taste chocolate coating composition and preparation method thereof

A chocolate coating and composition technology, applied in food ingredients as coating agents, food science, cocoa, etc., can solve problems such as not rich, long dispersion time, affecting yogurt flavor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

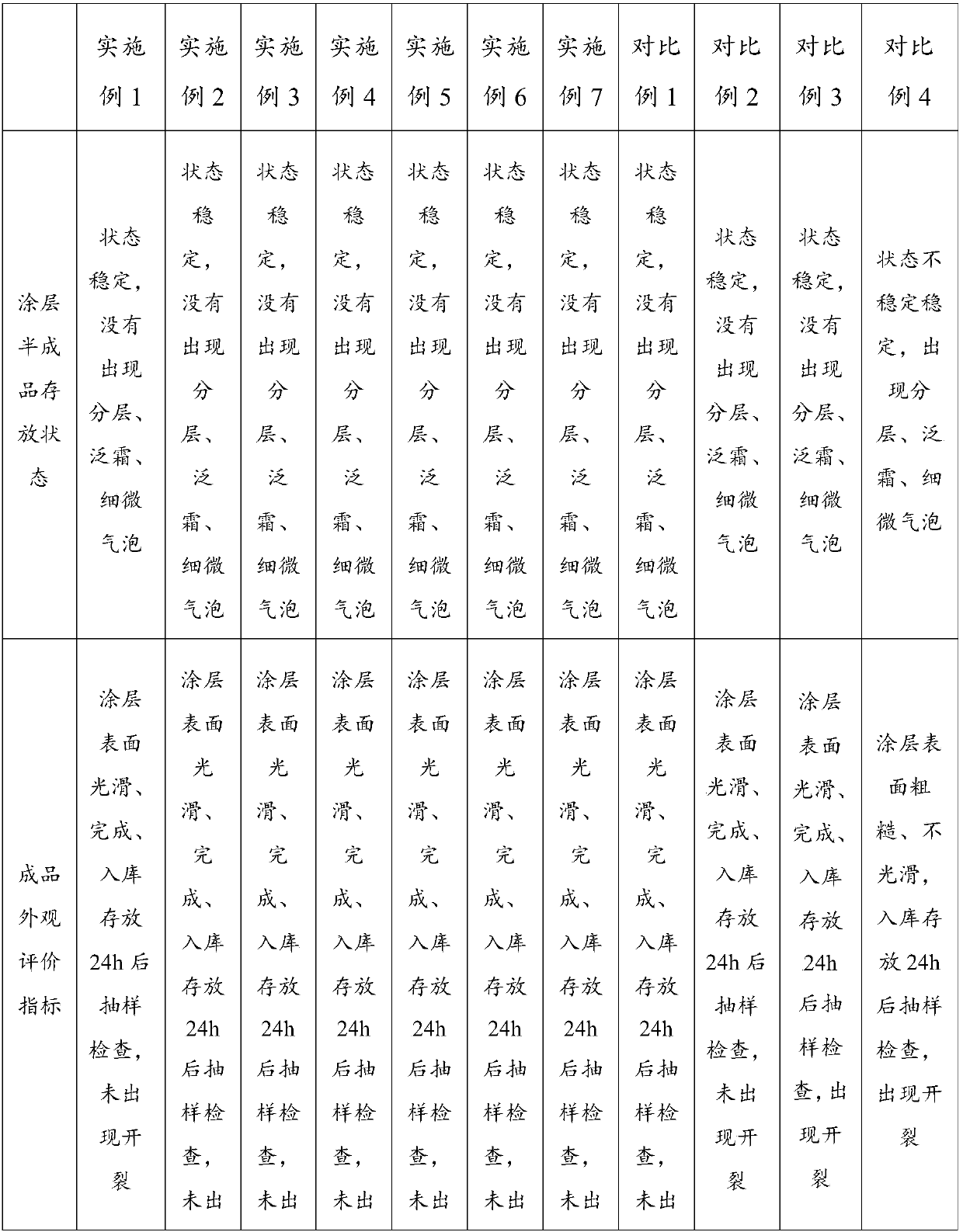

Examples

Embodiment 1

[0041] The present embodiment provides a yogurt taste chocolate coating composition, which consists of:

[0042] White sugar: 310kg; whole milk powder: 230kg; coconut oil: 325kg; palm oil: 45kg; yogurt powder: 30kg; cocoa butter substitute: 20kg; whey powder: 30kg; lecithin: 4kg; 5kg; emulsifier: 1kg.

[0043] The preparation method of the yogurt taste chocolate coating composition, its production process is:

[0044] Standardization of raw materials → add part of edible oil to mix all powdery raw materials → fine grinding with powder grinder → beating fine grinder → add the remaining ingredients and mix well.

[0045] Specific steps are as follows:

[0046] (1) Standardization of raw materials: The incoming raw materials are tested for indicators according to national standards and internal control standards;

[0047] (2) Add some edible oil and mix all the powdery ingredients: heat all the palm oil in the formula to 45°C, add all the white sugar, whole milk powder, yogurt...

Embodiment 2

[0052] The present embodiment provides a yogurt taste chocolate coating composition, which consists of:

[0053] White sugar: 310kg; whole milk powder: 230kg; coconut oil: 325kg; palm oil: 45kg; yogurt powder: 50kg; cocoa butter substitute: 20kg; whey powder: 10kg; lecithin: 4kg; 3kg; emulsifier: 3kg.

[0054] The preparation method of the yogurt taste chocolate coating composition, its production process is:

[0055] Standardization of raw materials → add part of edible oil to mix all powdery raw materials → fine grinding with powder grinder → beating fine grinder → add the remaining ingredients and mix well.

[0056] Specific steps are as follows:

[0057] (1) Standardization of raw materials: The incoming raw materials are tested for indicators according to national standards and internal control standards;

[0058] (2) Add some edible oil and mix all the powdery ingredients: heat all the palm oil in the formula to 46°C, add all the white sugar, whole milk powder, yogurt...

Embodiment 3

[0063] The present embodiment provides a yogurt taste chocolate coating composition, which consists of:

[0064] White sugar: 310kg; whole milk powder: 230kg; coconut oil: 325kg; palm oil: 45kg; yogurt powder: 45kg; cocoa butter substitute: 20kg; whey powder: 15kg; lecithin: 4kg; 4kg; emulsifier: 2kg.

[0065] The preparation method of the yogurt taste chocolate coating composition, its production process is:

[0066] Standardization of raw materials → add part of edible oil to mix all powdery raw materials → fine grinding with powder grinder → beating fine grinder → add the remaining ingredients and mix well.

[0067] Specific steps are as follows:

[0068] (1) Standardization of raw materials: The incoming raw materials are tested for indicators according to national standards and internal control standards;

[0069] (2) Add some edible oil and mix all the powdery ingredients: heat all the palm oil in the formula to 45°C, add all the white sugar, whole milk powder, yogurt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com