Method for preparing nanometer porous titanium oxide thick film

A nanoporous, titanium oxide technology, applied in the fields of semiconductor optoelectronics and semiconductor sensors, can solve problems such as difficulty in preparation and storage, and achieve the effects of short slurry grinding time, strong controllability, and improved preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

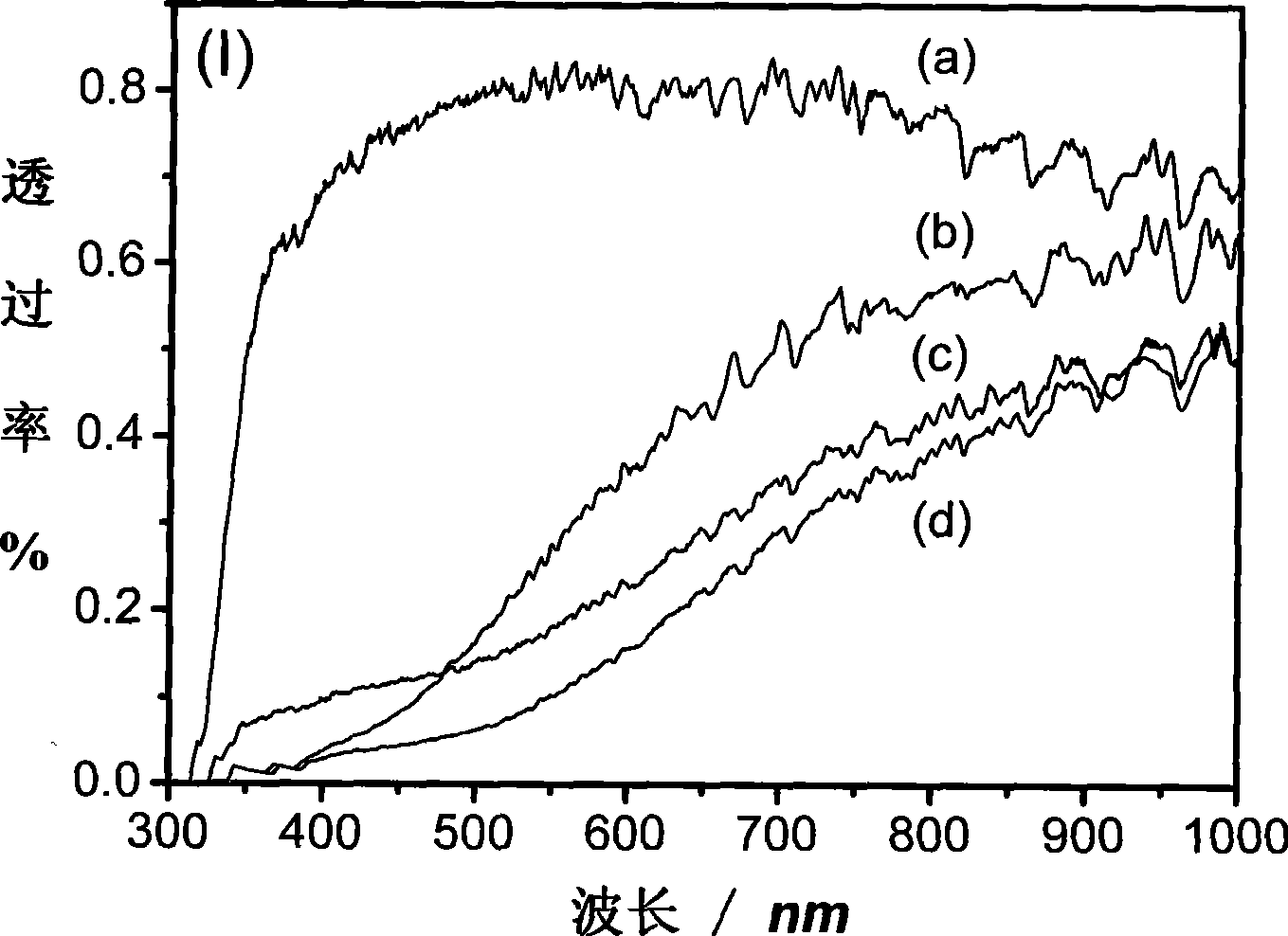

Embodiment 1

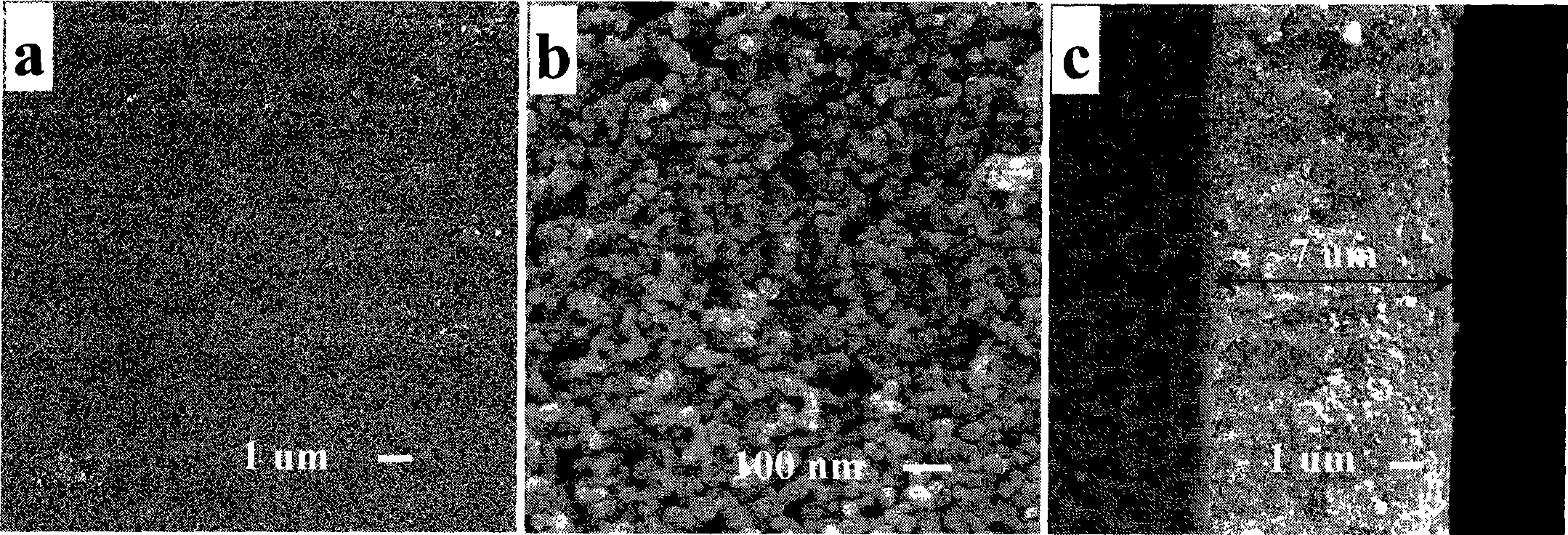

[0039] 1. TiO 2 Nano powder pretreatment and substrate preparation.

[0040] 1) TiO 2 Pretreatment of nanopowder

[0041] a. Preparation of nano-dispersion: Weigh P-25 TiO produced by Degussa Company 2 3.0 grams of nano powder, mixed with 60 milliliters of deionized water and 0.5 milliliters of concentrated nitric acid (mass concentration 65-68%), stirred to obtain milky white TiO 2 Suspension.

[0042] b. Water bath: the above TiO 2 The suspension was stirred in a water bath at 80°C for 8 hours.

[0043] c. Dehydration and drying: Remove water from the suspension after the water bath with a rotary evaporator to obtain TiO with nitrate groups adsorbed on the surface 2 Nano powder, denoted as TiO 2 -HNO 3 .

[0044] 2) Substrate preparation

[0045] Ordinary glass slides were used as substrates. First, soak the substrate in hot dilute sulfuric acid (about 60° C.) for 30 minutes, then rinse it thoroughly with acetone, ethanol and deionized water in turn, and place it ...

Embodiment 2

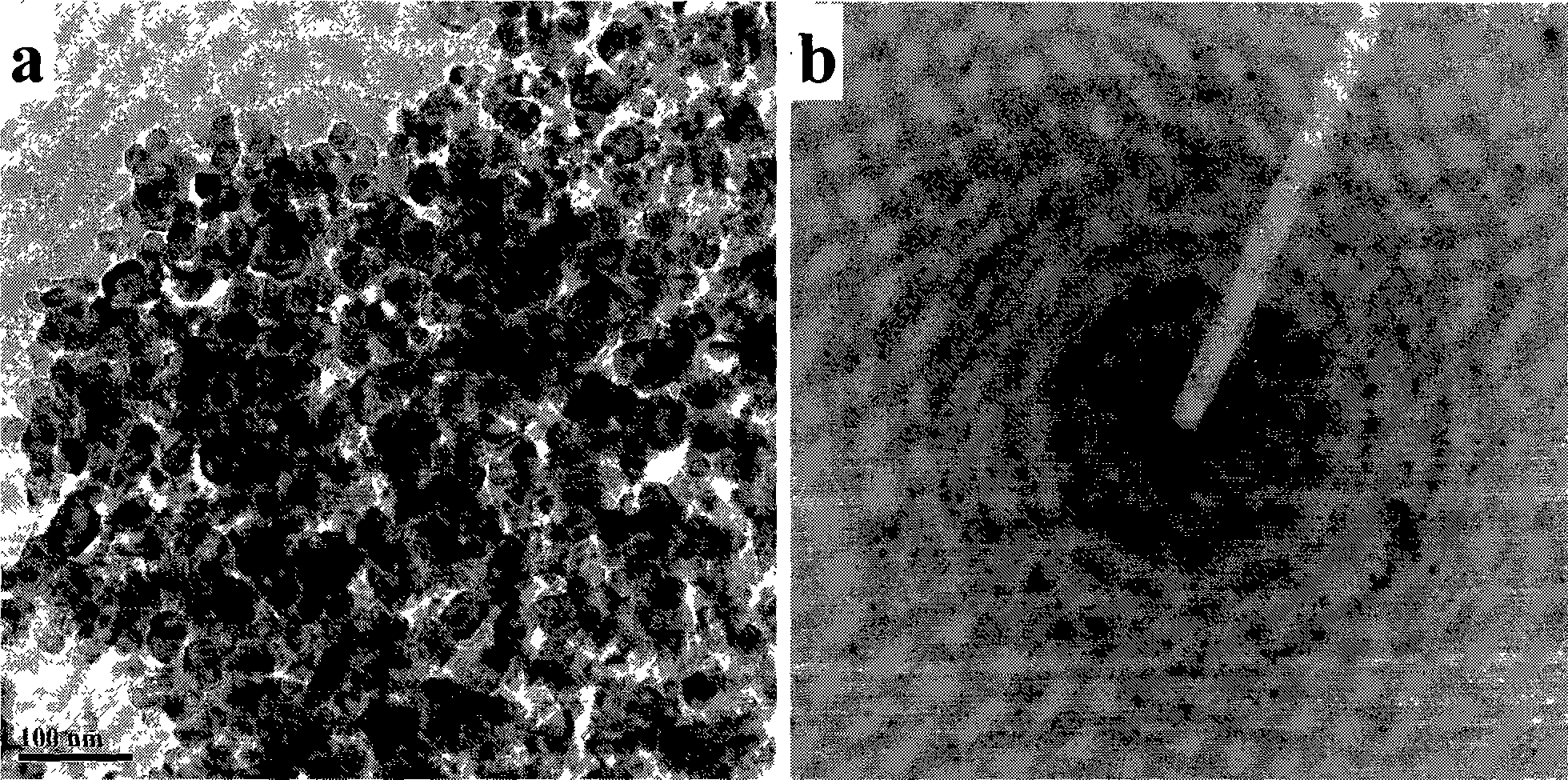

[0052] 1. TiO 2 Nano powder pretreatment and substrate preparation.

[0053] 1) TiO 2 Pretreatment of nanopowder

[0054] a. Preparation of nano-dispersion: Weigh P-25 TiO produced by Degussa Company 2 Mix 3.0 grams of nanometer powder with 60 milliliters of deionized water and 5 milliliters of concentrated nitric acid, and stir to obtain milky white TiO 2 Suspension.

[0055] 2) Substrate preparation

[0056] Select sapphire as the substrate. Its cleaning process is:

[0057] (1) Ultrasonic cleaning in trichloroethane at 50-60°C for 15 minutes; (2) Cleaning in acetone at 20-25°C for 2 minutes; (3) Washing with deionized water for 2 minutes; (4) Washing at 80- 90°C acidic hydrogen peroxide washing solution (composition: HCl: H 2 o 2 :H 2 O=1:4:20) ultrasonic cleaning for 10 minutes; (5) washing with deionized water for 2 minutes; (6) scrubbing the sapphire substrate with lens cleaning paper or a wiper; (7) cleaning at 90-95°C Alkaline hydrogen peroxide lotion (ingre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com